Abstract

Cholesterol oxidation was studied in 12 samples of mass-produced egg pasta and in home-made egg pasta produced with fresh eggs obtained from hens bred in the open with organic methods (a), fresh eggs purchased in a local retail shop (b) and spray-dried eggs, which are not allowed by Italian law (c). The lipids of commercial egg pasta contained almost twice the concentration of cholesterol of hand-made egg pasta (2.6 vs. 1.4 mg/100 mg lipids). Mass-produced egg pasta contained 2.2±1.5 μg oxycholesterols (cholesterol oxidation products, or COPs)/g of pasta, αEpo being the most represented oxycholesterol. The oxycholesterol content in home-made pasta was 1.7, 3.5 and 3.6 μg/g pasta, for pasta obtained with samples a, b and c, respectively. 7β-Hydroxycholesterol and β-epoxy-cholesterol were not taken in account, because they co-eluted with campesterol and campestanol, respectively. The home-made procedure (eggs mixed with flour and water and dried for 48 h at 30 °C) led to the formation of 7 k and 7α, rather than αEpo. The use of eggs from hens bred in the open reduced the COPs content considerably. The home-made product should be consumed within a few days after manufacturing or should be immediately refrigerated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The daily intake of oxidized food lipids is one of the causes of some degenerative pathologies [1], such as arteriosclerosis [2, 3, 4, 5, 6] and diabetes [7]. The determination of cholesterol oxidation in egg products is an important issue for two reasons: (a) eggs are one of the most important natural sources of cholesterol, and (b) eggs are consumed by themselves or can be a very common “visible” or “invisible” ingredient of many food products (sweet or salty snacks, pasta, cookies, cakes, ice creams) which are widely consumed and are suspected to contain significant concentrations of oxycholesterols [8, 9].

The extent of cholesterol oxidation in egg products is affected by the physical status of the raw product (whole, liquid or powdered egg) and by the thermal treatments and the storage conditions of these ingredients. The production of oxycholesterols in egg products is increased during heat treatments, pre-cooking, irradiation, light and air exposure, spray-drying, freeze drying, dehydration and storage of thermally stressed food [10, 11] at room temperature.

In egg pasta, cholesterol can undergo oxidation depending on the raw material quality, the drying cycle or the storage of the finished product [12]. However, the drying cycle used for egg-containing pasta is milder with respect to those used for pasta without eggs, as shown by the determination of furosine in these products [13].

Unfortunately, the determination of cholesterol oxidation products (COPS) is not yet a routine analysis, due to the time-consuming purification of the analytes, the possibility of artefact formation during sample preparation, the interferences due to plant sterols, and plant sterol oxidation products [14], as happens when egg pasta is analyzed [15, 16]. For these reasons, high resolution techniques, such as high performance liquid chromatography [17] and gas chromatography [18] have been coupled with mass spectrometry [19, 20] in order to confirm the identification of oxycholesterols.

The aim of this work was the study of cholesterol oxidation in 12 samples of mass-produced egg pasta. The results are discussed and compared with those obtained from home-made egg pasta produced with three different types of egg products: (a) fresh eggs obtained from hens bred in the open with organic methods, (b) fresh eggs obtained in a local retail shop, and (c) spray-dried eggs. Although Italian law does not allow the use of spray-dried eggs for the production of egg pasta, we carried out this trial in order to verify the use of spray-dried eggs.

Materials and methods

Chemicals and materials

All the solvents were analytical grade. n-Hexane was from Merck (Darmstadt, Germany). Methanol and chloroform were from Carlo Erba (Milan, Italy), while propan-2-ol was purchased from Prolabo (Paris, France). The following standards used for the identification of oxycholesterols were purchased from Steraloids (Wilton, N.H., USA): 5-cholesten-3β,7α-diol (7α) and 5-cholesten-3β,7β-diol (7β). In addition, 5-cholesten-3β-ol-7-one (7 k), 5-cholestan-5α, 6α-epoxy-3β-ol (αEpo), 5-cholestan-5β,6β-epoxy-3β-ol (βEpo), 5-cholesten-3β,19-diol (19-OH) as the internal standard, 5-cholesten-3β,20α-diol (20-OH) and cholestane-3β,5α,6β-triol (Tr) were from Sigma (St. Louis, Mo., USA), as well as betulin (lup-20[29]-en-3β,28-diol).

Sample preparation

Twelve samples of commercial egg pasta of different size and producer were purchased in a local supermarket; the samples were analysed at least 8 months before their expiry dates.

Three samples of egg pasta were prepared using a home-made procedure. Soft wheat flour (500 g) was mixed with five whole organic eggs (sample a), five whole commercial eggs (sample b) or reconstituted spray-dried eggs (sample c). In order to reconstitute the spray-dried eggs, 50 g whole egg powder were thoroughly mixed with 200 g tap water. The pastry was rolled out and dried for 1 h at room temperature before it was cut. Afterwards, the drying process was carried out at 30 °C for 48 h. Subsequently, egg pasta was stored in open vessels in a dry, dark place at room temperature for 18 days before analysis.

Each sample was analyzed in two replications and the average value of the determinations was reported.

Lipid extraction

Prior to extraction, all the samples were powdered with a Braun Multipractic food processor (Kronberg, Germany). The lipid fraction of the samples was extracted from the powdered sample (25 g) using the procedure of Folch et al. [21] with slight modifications as reported elsewhere [22].

Determination of oxycholesterols

Oxycholesterols were purified with a procedure described elsewhere [22], involving addition of the internal standard (12.5 μg of 19-OH) to 250 mg lipids, cold saponification [23] and NH2 solid phase extraction (SPE) of the analytes [24]. The dried eluate was silylated [25] and dried again under nitrogen flow. An aliquot of the silylated extract was analyzed by capillary gas chromatography using a HRGC 5300 by Carlo Erba (Rodano, Italy) equipped with a flame ionization detector (FID). The GC separation column was a DB-1 (30 m×0.32 mm i.d.) from J&W (Folsom, Calif., USA) coated with a 0.25 μm film of 100% dimethyl-polysiloxane. The samples were split injected with a temperature program rising from 250 to 325 °C at 3 °C/min; the injector and detector were set to 325 °C. The carrier gas was helium at a flow of 2 mL/min and the split ratio was 1/15. The identification of oxycholesterols was confirmed by gas chromatography-mass spectrometric (GC-MS) analysis. A Varian 3400 (Palo Alto, Calif., USA) gas chromatograph coupled with an ion trap ITS40 mass spectrometer by Finnigan (Manchester, UK) was used. The GC separation column was a ZB-5 (30 m×0.25 mm i.d.) from Phenomenex (Torrance, Calif., USA) coated with a 0.25 μm film of 5% phenylpolysiloxane. The split ratio and the temperature program were the same as in the GC-FID analysis; however, the helium flow was 1.4 mL/min and the injector and detector were set to 250 °C and 300 °C, respectively. The ion trap was used in the electronic impact mode (70 eV) and a mass range of 40–650 m/z was monitored. The GC retention time and fragmentation pattern of the identified peaks was compared with those of pure standard substances.

Determination of total cholesterol

An aliquot of the lipid fraction (250 mg) was spiked with betulin (3 mg) as the internal standard, and saponified, as reported in the previous section. After saponification, the ether fraction was extracted, dried, silylated and injected into the GC under the same conditions as reported above.

Results and discussion

Lipid content of egg pasta

The lipid content of commercial egg pasta was 4.4±1.2 g/100 g product (average±standard deviation, n=12). This is a low value, compatible with the low caloric requirements of modern alimentation; however, the fat content was highly variable among 12 different samples, showing that both the raw material and the processing technology are heterogeneous.

The home-made egg pasta was fattier, 5.6±0.4 g/100 g product. In ancient times, egg pasta was an important caloric food and source of carbohydrates and proteins for Mediterranean populations [26].

Cholesterol oxidation in samples of mass-produced egg pasta

The repeatability of the quantification was evaluated by analysing one sample of commercial egg pasta (sample no. 11) in three replications: the average oxycholesterol content (±standard deviation, n=3, expressed as micrograms per gram of lipids) was 6.6±2 for 7α, 30.5±3 for αEpo, 2.1±0.3 for Tr, 7.8±1.6 for 7 k, 47.0±6.6 for total oxycholesterols; thus the repeatability was acceptable. However, the plant sterols derived from the lipidic fraction of flour can interfere with the determination of oxycholesterols. With GC-MS analysis it was observed that 7β-hydroxycholesterol and β-epoxy-cholesterol co-eluted with campesterol and campestanol, respectively; thus, these oxycholesterols were not determined. The oxycholesterol content in the 12 egg pasta samples purchased in a local supermarket is reported in Table 1. Our data agree with previous literature [12, 27], which, however, reports the concentration of 7 k only. It should be noted that the fat percentage of this type of noodle is low, thus the dietary intake is low, ranging between 0.9 and 6.5 μg oxycholesterols/g of pasta. There were no remarkable differences in the total oxycholesterol content among samples of different size, nor differences due to the photo-oxidation caused by the type of packaging (transparent or opaque bag or box) or the expiration date, as already found by other authors [12]. Moreover, there was no correlation between the fat content and the oxycholesterol content. The rate of oxidized cholesterol was not related to the cholesterol content of pasta. The most represented oxycholesterol (8–35 μg/g lipids) was αEpo. The second most represented oxycholesterol was 7 k (6.9–55 μg/g lipids). The β-isomers were present, but not quantified because they overlapped with plant sterols.

Cholesterol oxidation in samples of home-made egg pasta

A chromatographic trace of oxycholesterols in pasta is reported in Fig. 1: the trace describes the unsaponifiable matter after SPE clean-up of oxycholesterols, not the total unsaponifiable extract.

Gas chromatographic trace of egg pasta sterolic fraction after SPE clean-up of oxycholesterols. Chol Cholesterol, 7α 5-cholesten-3β7α-diol, 19-OH 5-cholesten-3β19-diol (internal standard), αEpo 5-cholestan-5α6α-epoxy-3β-ol, Tr cholestane-3β5α6β-triol, 7 k 5-cholesten-3β-ol-7-one, βster β−sitosterol, βstan β-sitostanol. 7β-hydroxycholesterol (7β) and β-epoxy-cholesterol (βEpo) co-eluted with campesterol and campestanol respectively

The data on cholesterol oxidation in home-made pasta are shown in Table 2. The total oxycholesterol content is high, especially considering the pasta obtained with commercial eggs (65.7 μg/g lipids) and spray-dried eggs (68 μg/g lipids), as expected. However, these values are comparable with those detected in mass-produced pasta (49.3±21, as an average value). At the same time, pasta obtained with organic eggs showed a smaller amount of COPs (27.5 μg/g lipids). This could be due to the nutrition of the hens, which was probably rich in vegetable antioxidants; moreover, the breeding conditions were less “stressing” for the animals with respect to the industrial plants. The storage period tested here was about 18 days, which is considered an extremely long time interval before consuming this home-made product; usually, home-made pasta is consumed within 3–4 days of manufacture.

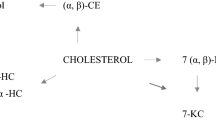

The oxycholesterol profile of home-made egg pasta was different with respect to commercial samples: the most represented was 7 k or 7α, not αEpo, showing that the drying cycle has an influence on the formation of oxycholesterols. Moreover, the most represented oxycholesterol in egg pasta obtained with spray-dried eggs was 7α; the formation of hydroxy derivatives of cholesterol during the spray-drying process has been already reported elsewhere [28].

Total cholesterol content

It is remarkable that the cholesterol content of the lipids in mass-produced pasta was on average almost twofold (2.6 mg/100 mg lipids) that of home-made pasta (1.4 mg/100 mg). This indicates that the food industry makes a strong use of high-cholesterol eggs for pasta production, thus reducing the number of eggs to be mixed to the flour (the Italian official method for determining the egg content of pasta is based on the determination of cholesterol) due to the use of semolina. Although this practice reduces the protein content of egg pasta, it seems to be a good approach in order to decrease the concentration of COPs. In fact, the fraction of oxidized cholesterol in the mass-produced pasta (0.19%) was similar to that of home-made pasta containing eggs from hens bred in the open (0.20%).

Nevertheless, the rate of oxidized cholesterol was remarkably high and similar in home-made pasta obtained from both spray-dried and commercial eggs.

In conclusion, 7 k has been reported as the main marker for cholesterol oxidation in food. However, in thermally stressed pasta (due to drying cycles or spray-drying of the eggs) 7k represented not more than one-third of the measured oxycholesterols. 7α and αEpo represented the main oxycholesterols in spray-dried egg pasta, and in products submitted to a drying cycle (mass-produced pasta), respectively.

Eggs used for industrial production of pasta show high concentrations of cholesterol (about twofold), with respect to the eggs purchased in the retail shop. However, this difference does not affect the quality of the lipid fraction from the point of view of cholesterol oxidation; conversely, the small amount of lipids in mass-produced pasta limits the dietary assumption of COPs. It is evident that the industrial processing technology of pasta has evolved in recent times, thus preserving the nutritional quality of the raw product during the processing steps. Although the characteristics of mass-produced pasta were remarkably heterogeneous, the quality of the products was usually good.

A significant quality improvement could be obtained by using eggs from hens bred in the open, in which cholesterol oxidation was low, at least in the home-made production of pasta. Considering spray-dried eggs, currently this technology allows the manufacture of pasta which is not significantly different from the home-made pasta produced with commercial eggs. However, the home-made procedure leads to the formation of 7 k and 7α, rather than αEpo, which is the precursor of Tr. It should be pointed out that the quality of eggs affects the pasta quality. The home-made products should be consumed within a few days after manufacture or should be refrigerated in order to decrease the rate of formation of oxycholesterols.

Future research should be carried out on the study of a larger sample amount (if available), the determination of natural antioxidants of eggs and pasta (e.g. isoflavones, carotenoid pigments) and the study of their influence on processing and storage of egg pasta of different origin.

References

Kullisaar T, Songisepp E, Mikelsaar M, Zilmer K, Vihalemm T, Zilmer M (2003) Br J Nutr 90:449–456

Brown AJ, Jessup W (1999) Atherosclerosis 142:1–28

Leonarduzzi G, Sottero B, Poli G (2002) J Nutr Biochem 13:700–710

Leitinger N (2003) Mol Aspects Med 24:239–250

De Nigris F, Lerman A, Ignarro LJ, Williams-Ignarro S, Sica V, Baker AH, Lerman LO, Geng YJ, Napoli C (2003) Trends Mol Med 9:351–359

Cabre A, Girona J, Vallve JC, Heras M, Masana L (2003) Atherosclerosis 169:245–250

Miwa S, Inouye M, Ohmura C, Mitsuhashi N, Onuma T, Kawamori R (2003) Diabetes Res Clin Pract 61:81–88

Lercker G, Rodriguez-Estrada MT (2003) J Food Composition Anal 13:625–631

Appelqvist LÅ (1996) Bull Int Diary Fed 315:52–58

Guardiola F, Codony R, Miskin D, Rafecas M, Boatella J (1995) J Agric Food Chem 43:1903–1907

Savage GP, Dutta PC, Rodriguez-Estrada MT (2002) Asia Pacific J Clin Nutr 11:72–78

Zunin P, Evangelisti F, Calcagno C, Tiscornia E (1996) Cereal Chem 73:691–694

Acquistucci R, Panfili G, Marconi E (1996) J Agric Food Chem 44:3855–3857

Bortolomeazzi R, Cordaro F, Pizzale L, Conte LS (2003) J Agric Food Chem 51:2394–2401

Ahn DU, Lee JI, Jo C, Sell JL (1999) Poult Sci 78:1060–4

Guardiola F, Codony R, Rafecas M, Boatella J (1995) J Chromatogr A, 705:289–304

Rodríguez-Estrada MT, Caboni MF (2002) Determination of cholesterol oxidation products by high-performance liquid chromatography In: F Guardiola, PC Dutta, R Codony, G P Savage (eds) Cholesterol and phytosterol oxidation products: analysis, occurrence, and biological effects, chap. 4. AOCS, Champaign, Illinois, pp 66–100

Guardiola F, Boatella J, Codony R (2002) Determination of cholesterol oxidation products by gas chromatography. In: F Guardiola, PC Dutta, R Codony, G P Savage (eds) Cholesterol and phytosterol oxidation products: analysis, occurrence, and biological effects, chap.3. AOCS, Champaign, Illinois, pp 50–65

Toschi TG, Caboni MF (1992) Ital J Food Sci 4:223–228

Razzazi-Fazeli E, Kleineisen S, Luf W (2000) J Chromatogr A 896:321–34

Folch J, Lees M, Sloane Stanley GH (1957) J Biol Chem 226:497–509

Boselli E, Velazco V, Caboni MF, Lercker G (2001) J Chromatography A, 917:239–244

Sander BD, Addis PB, Park SW, Smith DE (1989) J Food Prot 52:109–114

Rose-Sallin C, Huggett AC, Bosset JO, Tabacchi R, Fay LB (1995) J Agric Food Chem, 43:935–941

Sweeley CC, Bentley R, Makita M, Wells WW (1963) J Am Oil Chem Soc 85:2497–2507

Barbagallo CM, Cavera G, Sapienza M, Noto D, Cefalu AB, Polizzi F, Onorato F, Rini G, Di Fede G, Pagano M, Montalto G, Rizzo M, Descovich G, Notarbartolo A, Averna MR (2002) J Am Coll Nutr 21:523–529

Caboni MF, Chiorboli V, Lercker G (1998) Tec Molitoria 1297–1303

Messia MC, Fratianni A, Marconi E, Panfili G, Falasca L, Caboni MF (2001) Tec Molitoria 52:756-759

Acknowledgements

This study was carried out with financial support from CNR-Agenzia 2000 (CNRG001BE9).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boselli, E., Caboni, M.F., Frega, N.G. et al. Cholesterol oxidation in pasta produced with eggs of different origin. Eur Food Res Technol 218, 410–414 (2004). https://doi.org/10.1007/s00217-004-0894-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-004-0894-5