Abstract

Pre-fermentation cold maceration of must by the direct addition of two cryogens was studied. The experiments were conducted on Sangiovese grape from a typical Chianti vineyard in the year 2001 with two cryogens (solid state carbon dioxide and liquid nitrogen) and at various temperatures (from −5 to +5 °C) in 500-L batches for 48 h. The wines obtained were characterized by chemical analyses and sensory evaluation, and higher quality resulted as seen from the analytical and sensory characteristics with higher extraction of polyphenolic compounds at lower cold maceration temperature. Liquid nitrogen was more effective than solid carbon dioxide at the same temperature. Proportional increase of wine quality with lower cold maceration temperature was observed for solid carbon dioxide. Further investigation is needed to establish the management protocol, a proper engineering of this technique, and to evaluate its economical advantages.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

One of the most challenging aspects of modern oenology is the use and tune-up of suitable technologies aiming at the exploitation of the characteristics of grapes and their preservation in the final wine. It is generally agreed that enhancing and preserving the intrinsic qualities of grapes results in a higher quality and characterization of the wine, with consequent possible increase in the commercial value of the final product.

In recent years the must cooling technique has been widely employed in the production of white wines, with results and protocols well established [1, 2, 3, 4]. As far as red wine making is concerned, pre-fermentative cold maceration was recently tested on a few vine cultivars (Pinot Noir, Merlot, Cabernet) and on specific wine productions [5, 6, 7, 8, 9]. Albeit generally positive effects of cold maceration were reported, no direct correlations between temperature and quality of the wines were established. In particular, the temperatures employed in the different experiments reported in literature were generally above 0 °C and only a narrow range (5–16 °C) was investigated [6, 7, 10]. In addition, cold maceration is generally achieved by the use of heat exchangers, and the experiences on the direct addiction of cryogens to the must are limited to liquid or solid state CO2 [9, 11, 12]. Therefore, exhaustive information on the effect of different refrigeration techniques and different temperature ranges (particularly in the range from −5 °C to +5 °C where the literature is scarce) would be of great interest for the exploitation and proper management of this technique. As regards the Sangiovese cultivar (i.e. the grape from which the most famous traditional Tuscan wines, such as Chianti, Brunello di Montalcino and Nobile di Montepulciano, are made), no experiences of cold maceration are reported. We present here the preliminary results of micro-vinification of Sangiovese grapes using pre-fermentative cold maceration conducted at different temperatures (from −5 °C to +5 °C) and with the use of two cryogens, i.e. solid state CO2 and liquid N2, added directly to the whole must.

Materials and methods

The grapes used in this experiment were obtained from a vineyard at “Casa Vinicola Luigi Cecchi & Figli” estate located in Castellina in Chianti near Siena, Italy, within the typical region of Chianti Classico. The vines, obtained by mass selection of Sangiovese, were grafted on 420 A rootstock (Vitis berlandieri x riparia) in 1965 and trained with the “guyot” system. The degree of grape ripeness was monitored by standard chemical analyses and phenolic ripeness indexes [13]. Grape harvesting was done manually in plastic cases (20 kg-capacity). Cold maceration experiments were set up in the experimental micro-vinification plant of “Casa Vinicola Luigi Cecchi & Figli”. The vinifications were conducted in 500-L stainless-steel jacketed fermentors with 15 cases of grapes (corresponding to 300 L of whole must). A random distribution of harvested grape cases among the different experiments was done to avoid any initial uncontrolled difference in grape composition. The set of experiments consisted of three batches subjected to cold maceration with solid-state CO2 (B, C, D) at three different temperatures (−5 °C, 0 °C, +5 °C, respectively), two batches brought to 0 °C and +5 °C with liquid N2 (E and F, respectively) and a control (A) not subjected to cold maceration. The experimental design is summarized in Table 1 (rows 1 and 2).

After the initial cooling at the chosen temperature, each batch was allowed to rise to 5 °C and kept at this temperature for a total pre-fermentative cold maceration time of 48 h. Then the temperature was rapidly brought to 28 °C by means of heat exchangers and a standard winemaking protocol was followed (see below). As for the control batch, the fermentation started immediately after crushing and destemming, i.e. 48 h before the batches subjected to cold maceration.

Vinification protocol

Each tank was supplemented with potassium metabisulfite (10 g/100 L), starter yeast culture (pied de cuve) prepared with 30 g/100 L of active dry yeast, inactivated yeast (15 g/100 L) and ammonium salts (20 g/100 L), added 48 h after the onset of fermentation.

The control batch (A) was supplemented with inactivated yeast just after sulfitation, whilst for the batches subjected to cold maceration (from B to F), with the aim of reducing unwanted microbial activities, the addition of inactivated yeasts was done twice, the first time at the beginning of the cold maceration procedure, and the second, with an equal dose of acclimated yeast, after the cold maceration, when the temperature reached 16 °C.

Two mixing of the must bodies were done daily during the first three days of turbulent fermentation followed by one daily mixing until the 12th day. The wines were drawn at 14th day from the beginning of fermentation. The wines from pomace pressing were discarded, and therefore their contribution was not considered either in the chemical analyses or in the sensory evaluation. Any other operation not described above was done likewise on all experiments to avoid possible biases.

Cold maceration procedures

The rationale of cold maceration by means of cryogens added directly to the must is to create a quick thermal shock to induce the formation of ice crystals within the berry skins. This results in a breaking of the cell walls and membranes, and in a leaking of the protoplasm from skin cells.

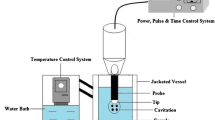

After the initial thermal shock at the different temperatures, all the batches were maintained at 5 °C for 48 h by adding suitable amounts of either solid CO2 or liquid N2. Solid CO2 was used for the batches B, C and D, while liquid N2 was used in the batches E and F. Both cryogens were added to the whole must during the tanks fill-up to enhance the homogenisation and to minimize the formation of thermal gradients among different zones of the must bodies. For the experiments with solid CO2, some aggregation of the little CO2 rods in large ice clusters was observed after the contact with must, resulting in a non-homogeneous distribution of cold and in thermal gradients of about 7 °C (Fig. 1), in spite of extensive hand-homogenisation with a wooden stick.

The following pieces of equipment were used for distribution of liquid N2:

-

Stainless-steel hand-lance with nozzle

-

“Dewar” tank for liquid nitrogen (400 L capacity)

-

Gas nitrogen tank (50 L)

After the tank fill-up, liquid nitrogen was distributed within the must bodies by a hand-lance connected to the “dewar” through a flexible hose. Thermal variations within the must body were smaller than in the experiments with CO2 and temperature gradients of about 2 °C were measured between the surface and the bottom of the tanks. In addition, no formation of ice blocks (which conversely occurred with CO2) was observed with liquid nitrogen, suggesting a quicker and more homogeneous distribution of cold. The must bodies were then kept at +5 °C with suitable addition of liquid N2. Temperature variations recorded during the pre-fermentation cold maceration experiments are reported in Fig. 1.

Chemical and sensory analyses

The chemical analyses aimed at evaluating the quality of grapes and wines in order to compare properly the different cold maceration techniques and temperature employed. In particular, some parameters related to the quality of red wines were considered, such as profile of phenolic components, colour hue, colour intensity, intensity of flavour, and taste with special reference to acidity, astringency and bitterness. Indexes of phenolic ripeness of grapes (“Glories’ indexes”, i.e. potential and extractable anthocyans, phenolic index, tannin contribute of grape stones, extractability of anthocyans, average weight of berries, juice/skin ratio) were determined on a sample of 400 berries randomly sampled from the vineyard [14]. The samples were divided in two parts: the first was weighted, crushed, and the juice was then separated for chemical analyses (such as sugar concentration, titratable acidity and pH). The grape skins were extensively washed, dried at 80 °C for 24 h, and weighed.

The second portion was homogenized by means of an Ultra Turrax T 25 for 1 min and sequentially extracted with solutions at pH 3 and 1, respectively. After centrifugation, the anthocyan concentration and the phenol indexes were determined on the first fraction, whereas on the supernatant at pH 1 (second fraction) only anthocyans were measured, according to Glories et al. [15, 16]. Spectrophotometric measurements were done on an Agilent 8453 Diode-Array Spectrophotometer.

Sugar concentration in grapes, musts and wines was measured by the reduction of neocuproine in alkaline environment after dialyzing the sample. The reaction yields a yellow colour measured spectrophotometrically at 460 nm. The measurements were done automatically by a Systea continuous-flow analyser using a calibration curve constructed with glucose solutions of known weight/volume concentration. Titratable acidity and pH were determined potentiometrically; l-malic acid concentration was determined by an enzymatic reaction, employing the reduction of NAD+ by malate dehydrogenase (L-MDH), in presence of glutamate-oxalacetate-transaminase (GOT) and l-glutamate. The method was calibrated with a solution of l-malic acid of known concentration.

As for the wines, ethanol concentration was determined by integrating FT-IR spectra of wines in the near-IR, using ethanol/water solutions of known concentration as calibration standards. An Alfa Laval Bran-Lubbe InfraAnalyzer 260 was used. Volatile acidity was separated by micro-distillation in a N2 stream, and measured by redox titration with colorimetric detection at 410 nm (Systea continuous flow analyser) after desulfitation with H2O2 [17]. The methodology was calibrated with solutions of acetic acid of known concentration.

Chromatic characteristics of wines were established by the classical determinations of colour density and hue. Optical densities (O.D.) at 420, 520 and 620 nm were measured on an optical path of 1 cm with an Agilent 8453 Diode-Array Spectrophotometer. The colour density is given by the summation of the optical densities at the three wavelengths, whereas colour hue is given by the ratio of O.D.s at 420 nm and 520 nm [16, 18]. Phenolic composition was determined by some of the most commonly employed indexes as reported below. Total phenols by Folin-Ciocalteu reagent were determined (modification of the procedure described in Commission Regulation (EEC) No 2676/90, Method n° 41 [19]): after the reaction the pH was alkalinised with a fixed amount of Na2CO3 and the absorbance was recorded at 760 nm. A calibration curve was constructed with solutions of gallic acid of known concentration.

A wavelength scansion between 230 and 700 nm of wine diluted with an acidic ethanol solution (ethanol:water:HCl=70:30:1) allowed us to determine the composition of phenolic fractions such as total anthocyans (i.e. the main components accounting for the colour or red wines), total flavonoids and total flavanols. A solution containing malvidin chloride and (+)catechin of known concentration was used as calibration standard. As the total flavanols concentration gives only a quantitative evaluation of the catechins content, the pro-anthocyanidin index was calculated to establish the form in which these compounds exist in wine. The wines were diluted with ethanol solution (about 50%) at pH 1 in the presence of Fe2+ and placed on a boiling bath for 50 min. Then the solution was cooled in the dark, and the increase in anthocyans due to the acidic hydrolysis of pro-anthocyanidins was spectrophotometrically detected by means of the vis-spectrum between 400 and 650 nm. The pro-antocyanidins index calculated in this way is a function of initial concentration of condensed catechins as well as of their average degree of polymerisation, as it increases for the highly polymerised catechins [20].

The total anthocyans in wine are partly present as free molecules and partly associated with other phenolic compounds [12, 21]. The free fraction is by far the most prone to oxidation, whereas the associated fraction is generally more stable and has improved chromatic characteristics (density and hue). The free anthocyans were separated by adsorption on Polyclar AT ion-exchange resins, then eluted with an acidic ethanol solution (ethanol:water:HCl=70:30:1) and finally determined spectrophotometrically as described for the total anthocyans.

A further speciation of the anthocyans on the basis of their combination degree was done by monitoring the changes in absorbance at 520 nm after bleaching with SO2. In fact, both the free anthocyans (dAl) and the poorly combined anthocyans (dTA) are bleached by SO2 addition, whereas the steadily combined ones are not sensitive to SO2. Hence, by knowing the amount of free SO2, pH, amount of monomeric anthocyans, and absorbance at 520 nm of wines, it is possible to calculate the Glories indexes [15, 16, 22].

Ochratoxin A was determined by HPLC with fluorimetric detection after liquid/liquid extraction with chloroform [23].

As for the sensory characteristic of wines, an evaluation protocol was established, composed of seven sensory descriptors that were most likely affected by the cold maceration technique. They were: colour intensity and hue, intensity and complexity of flavour, acidity, tannins and bitterness, brightness, and a general evaluation of balance.

All wines were randomly tasted in the same session in a well-lighted testing room as ‘blind’ samples by a panel of 15 experts. No preliminary preparation of tasters was necessary as they were professional Chianti experts. The wines were served at 18 °C in Riedel Vinum Bordeaux 21-oz glasses filled to one-third. To each descriptor a score between 1 and 5 was given depending on the intensity perceived by the panellists. The data were reported as the mean value±standard error of means.

Results

The degree of grape ripeness as detected by chemical analyses is reported in Table 2. The high concentration of sugars and polyphenolic compounds indicated a satisfactory degree of ripeness albeit a delayed harvesting would have reduced the astringent taste due to the tannins. Unfortunately, there was a widespread infection by Botritis cinerea on about 20% of grapes and an early harvesting was done on October 12th.

The fermentation proceeded regularly for all batches, without sudden thermal rise, with temperature always below 31 °C. Periodical determination of sugar showed similar fermentation profile for all experiment. Residual sugar at the end of turbulent fermentation was from 1.3 to 1.7 g/L, confirming the regular ongoing of the fermentation process (Table 1).

Chemical parameters of drawn wines

The results of chemical analyses on drawn wines are reported in Table 1. The colour density of wines from different experiments (Fig. 2) increased from batches B to F with the highest values found in batches E and F, i.e. where liquid N2 was applied. In contrast, colour hue was higher in the control and in the batches B and C. This indicated that oxidized components, which are primarily responsible for the O.D. at 420 nm where mostly formed at higher temperature for the batches treated with solid state CO2. Colour hue values lower than control were measured for the two batches with N2 (E, F).

The batch B had the least colour intensity, lower than the control (batch A), indicating the poor quality of this wine, as also confirmed by the other analytical parameters. This probably resulted from the negative effects of oxidative enzymes (e.g. tyrosinases and laccases) produced by the mouldy grapes (Botritis cinerea), which might have increased in batch B because the must remained at a higher effective temperature than in the other cold maceration experiments (due to non-homogeneous temperature, as discussed in material and methods). Hence, in batch B the inhibition of enzymatic activity by the low temperature would not have occurred, resulting in lower intensity and different hue in comparison to batches C–F. These negative factors due to mouldy grapes were presumably less effective on the control because, due to the yeast inoculum, the fermentation started immediately, and the activity of Botritis cinerea was reduced by competition of fermenting yeasts. This hypothesis seems to be confirmed by the presences of some ochratoxin only in the batch B (Table 1).

The comparison of total polyphenolic content of wines, reported in Fig. 3, shows two main effects: a) the polyphenol extraction increased with the decrease of temperature in batches with solid state CO2 (B, C, D); b) a higher efficiency of liquid N2 in comparison with solid CO2, temperature being equal (B vs E, C vs F). Besides, no relationships between temperature and polyphenols extraction were observed with N2, as the data at 5 °C and 0 °C were similar.

The analysis of the phenolic fraction (Fig. 4) revealed that flavonoids and anthocyanidins trend was similar to the total polyphenolic compounds. In contrast, the pro-anthocyanidin index was largely influenced by the type of cryogen used. Solid state CO2 yielded a lower and temperature-independent extraction of these products in comparison with liquid N2 where the extraction increased at lower temperature. The pro-anthocyanidin index, which is bound to the degree of polymerization of tannins, is extremely interesting in view of a qualitative improvement of the resulting wines.

As it concerns the condensation of anthocyans with tannins, measured by the parameter dTA (which is related to the stability of anthocyans with aging and, therefore, to the lasting of red colour), a trend similar to the total polyphenolic compound was observed (Fig. 5).

When the TA values were reported as percentage (TA%) of the total anthocyans (free anthocyans+TA+TAT), only small variation among batches were observed. This indicated that increase of dTA was due to an actual increased extraction rather than to a different distribution of the several combined forms.

A large variability in final ethanol concentration was observed in the batches with the lowest value for batches B probably due to the activity of Botritis cinerea as previously discussed. For the other batches, higher ethanol concentrations than the control seem to be related to cold maceration as also reported by Girard et al. [5]. However, further investigation with a suitable experimental design are needed to confirm this trend.

Sensory evaluation

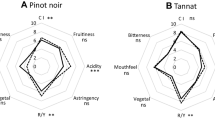

Sensory evaluation, performed two months after wine drawing, when the malolactic fermentation was concluded, confirmed the differences among the batches already pointed out by chemical analyses. The mean values ±standard error of means of the parameters considered for the characterization of sensory profiles were reported in detail in Table 3 and overviewed in the spider plot in Fig. 6. Two groups of wines are differentiated: the first (corresponding to batches A, B, and C) shows a lower intensity of all the descriptors (especially for batch B); the second group, consisting of batches D, E and F, differed mainly in structure, flavour and balance, i.e. the most representative descriptors. The results of a panel test, with special reference to the chromatic characteristics (density and hue) and astringency, are in good agreement with the analytical parameters on phenol composition and confirm the quality increase of wines obtained with pre fermentative cold maceration of Sangiovese grapes.

Discussion

In this preliminary work, the wines from batches subjected to cold maceration generally showed a large improvement in quality as indicated by both chemical analysis and sensory evaluation. In spite of the lack of replicates the differences among the treatments and the control were so huge (especially for some parameters) to deserve attention and give significant contribution to the understanding of the effectiveness of this technique.

Discordant results are reported in literature on the effect of cold maceration on red wine quality.

A large improvement in tannins and anthocyan extraction (about 50%) is reported by Couasnon [9] on Merlot and Cabernet grapes using solid state CO2 at cold maceration temperature of 4 °C and for prolonged soaking (ten days).

Girard et al. [5] in a study of vinification of Pinot Noir obtained a large improvement in all sensory characteristics of wine when the cold maceration procedure was modified by freezing the marc at −20 °C after separating the free run juice; conversely, the cold maceration at about 15 °C had little effect on the quality, resulting in wines comparable to the controls.

For other cold maceration experiments conducted on Pinot Noire in the range 10–15 °C, only positive results to sensory evaluation are reported by Feuillat [8] whereas no significant increase in extraction and chemical parameters was found.

Cuénat [24] obtained large increase in the extraction of tannins, whereas the extraction of anthocyans was not affected. However, better sensory characteristics were obtained even if largely influenced by vintage.

In experiments of pre-fermentation maceration on Cabernet Sauvignon grapes, Mc Mahon et al. [10] found that a cold soak at 10 °C (pre-fermentation skin contact) for three days increased the total glycoside extraction by 103% whereas 177% increase was obtained in batches at 20 °C (ambient soak). However, neither glycoside nor colour differences caused by soak temperature were evident at the end of fermentation.

Albeit all these findings are difficult to compare, the experiments being conducted in different experimental condition and with different aims, it generally emerges that:

-

The improvement in quality resulting from cold maceration varies with different grapes and vintages

-

The choice of cold maceration temperature and soaking time is very important to sensory and chemical characteristics of the resulting wine and may lead to completely different qualitative results

Our results showed that the temperature of cold maceration batches, generally supposed to be constant, is subjected to a large variability that may account for differences in the resulting wine. In addition, the cooling technique and the type of cryogen used influence the quality of wines. Hence it is possible to hypothesize that, for every cooling technique, different extraction efficiencies exist as a function of temperature. On the whole, a decrease of cold maceration temperature lead to an increase in extraction and wine quality, up to a plateau beyond which any further decrease in temperature has no effect.

Conclusions

Pre-fermentative cold maceration of Sangiovese grape by means of cryogens showed significant increase in the quality of the wines. The qualitative improvement was detectable either by chemical analyses or directly by tasting. The kind of cryogen used affected the quality of the resulting wine, temperature being equal; in particular, the increase in quality with solid state CO2 was directly proportional to the decrease in cold maceration temperature, whereas for liquid nitrogen no significant differences were found between experiments at +5 °C and 0 °C. The wines obtained with cold maceration at −5 °C with solid CO2 and at +5 °C with liquid nitrogen were similar, with some additional good characteristic for the latter. Even if it is clear from these experiments that the differences in wines obtained with the two cryogens depend upon the characteristics of solid CO2 and liquid N2, further studies are necessary to understand fully the relationship between cooling off dynamics and extraction of red grapes as well as the thermodynamic and economic implications of this technique. This information is necessary for the optimisation and the related engineering of the process.

References

Sapis JC, Caboulet D, Samson A, Chauvet S (1995) Rev Franc Oenol 153:55–56

Ramey D, Bertrand A, Ough CS, Singleton VL, Sanders E (1986) Am J Enol Vitic 37:99–106

Amati A, Pallotta U, Potentini G, Zironi R (1990) VigneVini 12:59–65

Arfarelli G (1990) VigneVini 9:15–18

Girard B, Yuksel D, Cliff MA, Delaquis P, Reynolds AG (2001) Food Res Int 34:483–499

Cuénat P, Lorenzini F, Brègy C-A, Zufferey E (1996) Rev Suisse Vitic Arbo Ortic 4:259–265

Gerbaux V, Naudin R, Meurgues O, Monamy C (1997) Rev Fr Oenol 166:10–14

Feuillat M (1997) Rev Fr Oenol 82:29–31

Couasnon MB (1999) Rev Fr Oenol 92:26–30

McMahon HM, Zoecklein BW, Jasinski YW (1999) Am J Enol Vitic 50:385–389

Couasnon MB (1999) Rev Fr Oenol 93:28–30

Boulton RB, Singleton VL, Bisson LF, Kunkee RE (1996) Chapman & Hall, New York

Saint-Cricq De Gaulejac N, Vivas N, Glories Y (1998) Rev Fr Oenol 169:19–25

Romani A, Mancini P, Tatti S, Vinceri FF (1996) Ital J Food Sci 1:503–505

Glories Y (1984) Conn Vigne Vin 18:195–217

Glories Y (1984) Conn Vigne Vin 18:253–271

Kaffka KJ, Norris KH (1976) Acta Alimentaria 5:267–279

Sudraud P (1958) Ann Technol Agric 7:203–208

Commission Regulation (EEC), No 2676/90 of 17 September 1990 Official Journal L 272, 03/10/1990, 1-192 Method no 41

Di Stefano R, Cravero MC, Gentilini N (1989) L’Enotecnico 5:83–90

Iland P, Ewart A, Sitters J, Markides A, Bruer N (2000) Patrick Ilend Wine Promotion, Campbelltown, Australia

Di Stefano R, Cravero MC (1989) L’Enotecnico 10:81–88

Tateo F (1999) Ind Bevande 164:592–596

Cuénat P (1998) Rev Fr Oenol170:53–57

Acknowledgements

We gratefully acknowledge Casa Vinicola Luigi Cecchi & Figli for hosting the experiments and supplying the grapes, and SOL s.p.a. industries for providing the cryogens. We also thank the oenologist Alessandro Fusi, whose committed and dedicated work made this research possible.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Parenti, A., Spugnoli, P., Calamai, L. et al. Effects of cold maceration on red wine quality from Tuscan Sangiovese grape. Eur Food Res Technol 218, 360–366 (2004). https://doi.org/10.1007/s00217-003-0866-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-003-0866-1