Abstract

The effects of the non-amylolytic enzymes pentosanase (PP), glucose oxidase (GLZ) and laccase (LAC), singly and in binary and ternary combinations, and wheat flour—a pure cultivar F0, and low- grade F1 and high-grade F2 commercial blends—on the electrophoretic pattern of the glutenin macropolymer (GMP) were investigated by sodium dodecyl sulphate polyacrylamide gel electrophoresis (SDS–PAGE). GMP profiles of high (HMW), medium (MMW) and low (LMW) molecular weight glutenin subunits (GS) were correlated with dough and GMP characteristics and with bread quality and keepability.

The total relative percentages of separated HMW, MMW and LMW-GS of GMP in control and enzyme-supplemented samples were: 33–37, 11–16 and 46–54% (F0), 47–74, 0 and 26–57% (F1) and 30–47, 15–18 and 32–38% (F2), respectively. HMW-GS/LMW-GS ratios, a quality index of glutenin, were found to range from 0.63 to 0.80 for all flour GMP. Enzyme addition induced moderate effects in pure wheat cultivar F0. Combinations of PP and GLZ (PPGLZ) allowed glutenin repolymerization after resting, leading to an increase of the bands of 104–107 and 88–90 kDa in GMP by SDS–PAGE. Analogously, PP plus LAC (PPLAC) and LAC alone increased the amount of the subunit of 81–82 kDa. Subunits of LMW increased with PPLAC and LAC, the subunit of 37–38 kDa having a higher percentage in GMP probably due to the presence of α-, β- and γ-gliadins besides the LMW-GS. Only the subunit of 81–82 kDa was positively associated with the dynamic rheological moduli G′ and G* and the subunit of 88–90 kDa correlated with a lower delta angle and, consequently, with a more elastic gel. After fermentation, the total percentage of subunits of HMW, MMW and LMW changed mainly in low-grade flour F1 (36–37, 17–19 and 14–19%) compared with high-grade flour F2 (32–37, 14–17 and 47–51%). The subunit of HMW with MW of 120–125 kDa (F1) and 93–95 kDa (F2) was positively correlated with the specific volume of breads and negatively with firmness of fresh and stored bread. Subunits of MMW negatively influenced the quality of fresh and stored bread of F1. The ratio HMW/LMW was positively correlated with bread firmness during staling in breads prepared with F2.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The gluten protein network is considered mainly responsible for wheat flour dough viscoelasticity. The proportion of glutenins and gliadins determines the balance between elasticity and viscosity affecting gluten quality. High molecular weight (HMW-GS) and low molecular weight (LMW-GS) glutenin subunits have been shown to influence mixing time, dough strength and bread volume [1], the HMW-GS providing the major effects on dough functional properties [2, 3].

The sodium dodecyl sulphate (SDS) unextractable glutenin subfraction of flour, called glutenin macropolymer (GMP), has been highly related to quality parameters, such as loaf volume and physical dough properties [4, 5]. Glutenin subunits provide a structural backbone to the GMP through the formation of disulphide bonds highly resistant to rupture [6]. The ability of glutenin subunits to form these bonds supports their association within GMP, and their effects on gluten structure and functionality [7]. The functional properties of the polymeric protein have been associated with their subunit composition [5, 8], HMW-GS composition having been correlated with quality indicators in breadmaking [9]. A differentiation of wheat cultivars based on the HMW-GS content [10] and the HMW-GS/LMW-GS ratio [11] has been obtained. Wheat cultivars of good breadmaking performance showed higher levels of HMW-GS and a HMW-GS/LMW-GS ratio ranging from 0.18 to 0.74. The molecular weights (MW) of HMW-GS in SDS–PAGE were found to be between 80 and 120 kDa, although these subunits present a non-expected mobility in SDS–PAGE leading to an overestimation of their MW between 65 and 90 kDa by nucleotide sequentiation [12]. LMW-GS have been classified in B-, C- and D-subunits based on differences in mobility in SDS–PAGE. The MW of subunits B and C were 40–50 and 30–40 kDa, respectively [13], whereas subunit D of lower mobility than subunit B probably comes from a mutation of ω-gliadins [14].

Oxidases and pentosanases induce changes in gluten protein structure and interactions [11] by direct and/or indirect action on the gluten network. Pentosans associated with wheat gluten can influence dough-handling properties, modifying gluten aggregation due to steric hindrance [15]. Thus, the use of pentosanases (PP) would improve gluten quality by counteracting chemical aggregation of gluten [16]. The use of oxidative enzymes such as glucose oxidase (GLZ) [17, 18, 19] and laccase (LAC) [19, 20] is increasing in breadmaking. GLZ catalyses the oxidation of α-d-glucose to d-gluconic acid and H2O2. Although the mechanism of bread improvement has not been fully established, the produced H2O2 has been hypothesized to be the responsible factor for this improvement [18, 21, 22]. A synergism between GLZ and PP has been proposed [23, 24, 25]. LAC catalyses the oxidative gelation of feruloylated arabinoxylans by dimerization to their ferulic esters [26] and exerts an oxidant effect on dough constituents, thus improving the resistance of the gluten network [20].

The aim of this study is to evaluate changes in composition of the subunits forming GMP induced by the addition of enzymes—PP, GLZ, LAC and their combinations—using SDS–PAGE. Doughs prepared in a farinograph and doughs from a breadmaking process were used. A profile of glutenin subunits was correlated with dough and GMP characteristics and with bread quality and shelf life.

Materials and Methods

Materials

Flour (F0) from a pure wheat cultivar (Farak) milled on a CD1 Chopin mill to an extraction rate of 68% and two commercial blending flours of low (F1) and good (F2) breadmaking quality were used (Table 1).

Three commercial enzymes, PP (endo-1,4-β-xylanase) (Pentopan Mono, BG) containing 2,500 fungal xylanase units/g, GLZ (Gluzyme) containing 500 glucose oxidase units/g and LAC containing 1,552 laccase units/mL, provided by Novozymes (Denmark), were added singly and combined (Table 2) at dosages (per 100 g flour) recommended by the supplier: 4 mg (PP), 2 mg (GLZ) and 50μL (LAC). Enzymes did not contain significant side activities, like amylase (Ceralpha method, Megazyme) [27] or protease (Universal protease substrate, Boehringer Mannheim). All chemicals used for analyses were of analytical grade or better.

Methods

Dough preparation

Flour F0 was used to prepare doughs in the Brabender farinograph using the 50-g mixing bowl. Dough formulation [28], based on 100 g flour, included 54.5 mL water, 2 g salt and the amount of enzyme indicated previously for each sample. Glucose (0.5 g) was added to samples containing glucose oxidase. Doughs were mixed for 10 min and rested for 60 min at 30 °C. Flours F1 and F2 were used in a straight breadmaking process following methodology previously described [19]. Samples of unfermented dough (UFD) and fermented dough (FD) were freeze-dried, ground and sieved, and then stored at 4 °C until use (Table 3).

Kieffer micro-extensibility test

The Kieffer dough extensibility test was carried out using a Texture Analyser TA-XT2i with the Kieffer dough and gluten extensibility rig (Stable Microsystems, UK) and a 25-kg load cell [29].

Gluten index

Determination of gluten index was performed in a Glutomatic system (Perten) following the ICC standard procedure [30].

GMP extraction

GMP was obtained according to Graveland et al. [31]. Suspensions of freeze-dried doughs (1:20 w/v) in 1.5% SDS were centrifuged for 30 min at 75,000 g and 20 °C in a Kontron ultracentrifuge. After decanting the supernatant the GMP was obtained as the gel-like layer on top of the starch. GMP was used for dynamic rheological experiments and pentosan determination.

To perform SDS polyacrylamide gel electrophoresis (SDS–PAGE) the extraction of GMP was modified as described by Weegels et al., [32]: suspensions of freeze-dried doughs (0.08 g) in 1.5% SDS (1:20 w/v) were centrifuged for 15 min at 15,000 g and 20 °C in an Eppendorf 5415 centrifuge. Supernatants were decanted and discarded. The resulting GMP plus starch was extracted again with 1.5% SDS, centrifuged and decanted. Over the GMP plus starch, 1.5% SDS and β-mercaptoethanol (5%) were added. The resulting suspension was stirred for 30 min in an Eppendorf compact thermomixer and centrifuged for 5 min at 20 °C under the same conditions. Supernatant containing the reduced GMP was boiled for 10 min. After cooling it was centrifuged again for 5 min at 15,000 g and the supernatant, the reduced GMP, was frozen and freeze-dried.

Protein content of GMP

The whole residue, gel layer plus starch, obtained from the GMP extraction was freeze-dried, and the protein content was determined with the ICC standard Kjeldahl method [33].

Total and water-soluble pentosans associated with GMP

Total pentosans (TP) and water-soluble pentosans (WSP) from GMP were measured with the orcinol–hydrochloric acid–ferric method [34, 35] with the modifications made by Jiménez and Martínez-Anaya [36, 37]. Freeze-dried GMP was used for TP and WSP quantification (125 and 100 mg, respectively).

Dynamic rheological properties of GMP

The dynamic rheological properties of GMP were characterized in a Bohlin VOR Rheometer (Germany) as described previously [38] and modified [28, 39]. A plate–plate geometry (Pt-Pt30) and a torsion bar of 1.7 g cm were used. Measurements were made with a gap of 1 mm at 20 °C and 1 g of GMP was scraped off from the top of the gel. An oscillatory test with a frequency sweep from 0.05 to 5 Hz with a fixed strain (2%), selected from the linear viscoelastic region obtained from a strain sweep [28], was performed. Dynamic rheological moduli, elastic modulus (G′), viscous modulus (G″), complex modulus (G*) and delta angle at 0.15 Hz and 2% strain, were obtained.

Sodium dodecyl sulphate polyacrylamide gel electrophoresis

Discontinuous vertical polyacrylamide (PAA) slab gel electrophoresis in the presence of sodium dodecyl sulphate (SDS–PAGE) was carried out following Laemmli’s methodology [40] in a Mini-Protean II cell (Bio-Rad) for characterizing protein subunits of GMP. Freeze-dried GMP was suspended in 0.5 mL of SDS sample buffer containing 0.5 M Tris–HCl of pH 6.8, 10% SDS, glycerol, 0.05% bromophenol blue and H2O. β-Mercaptoethanol was added for sample reduction, and the mixture boiled for 10 min. The subunit compositions of GMP were characterized using a 4% PAA stacking gel and a 7.5% PAA separating gel. Aliquots of 12, 25 or 18 μL (samples prepared with F0, F1 and F2) were loaded onto the gels. Two gels were simultaneously run at 200 V at room temperature until bromophenol blue ran out of the gel. After electrophoresis, the gels were stained with 0.1% Coomassie Blue R-250 in fixative containing 40% methanol and 10% acetic acid. Destaining was performed with fixative solution of the same composition. The apparent MW of the subunits was determined using standards (Bio-Rad, 161-0362) with MW of 10, 15, 25, 37, 50, 75, 100, 150 and 250 kDa. Stained gels were densitometered by applying the TDI Lane Manager program (Madrid, Spain) to the scanned gels (HP Scanjet IIcx).

Statistical analysis

The correlation matrix between technological and electrophoretic variables was obtained using the Bio-MeDical Statistical Package (BMDP, program 4 M).

Results and discussion

Effect of enzyme addition on the protein subunit composition of GMP of a pure wheat cultivar

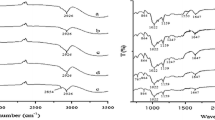

Previous assessment of GMP protein composition by RP-HPLC had proved the macropolymer contained major glutenins and about 1–3% minor ω-gliadins, whereas capillary electrophoresis showed that 0.5–2.5% of GMP proteins were different to glutenins of low MW [32]. The electrophoretic pattern of GMP obtained from flour F0, a pure wheat cultivar, mixed in the farinograph differentiated three main groups of proteins (Fig. 1). The first group containing HMW-GS showed three bands with apparent MW of 104–107, 88–90 and 81–82 kDa, respectively. Wheat variety Farak (F0) has been previously [41] separated into five HMW-GS, in locus A1 glutenin 1, in locus B1 the pair 7+8 and in locus C1 the pair 5+10 [42] grouped into three double bands. The second group of medium MW (MMW), containing a mixture of D subunits of LMW-GS and ω-gliadins, separated into two subunits of apparent MW 64–67 and 60–61 kDa. The third group of LMW-GS, B and C, showed three different electrophoretic bands: two B subunits with MW 55–57 and 49 kDa and one C subunit of 37–38 kDa. The relative percentage of each GS (%) and the content (g subunit/100 g of freeze-dried dough) of separated subunits in GMP is shown in Table 4. The total relative percentage of HMW-, MMW- and LMW-GS was 33–37, 11–16 and 46–54%, respectively. Enzyme addition induced moderate effects. The amount of HMW-GS was slightly modified by the combinations of PP with GLZ and LAC. PPGLZ induced repolymerization of glutenin after resting, leading to an increase of the bands of 104–107 and 88–90 kDa in GMP; analogously, PPLAC and LAC increased the fraction of 81–82 kDa. LMW-GS increased with PPLAC and LAC, the fraction of 37–38 kDa exhibiting a higher percentage in GMP probably due to the presence of α-, β- and γ-gliadins besides the LMW-GS.

SDS–PAGE of HMW-, MMW and LMW-GS of GMP from wheat cultivar Farak. See Table 2 for enzyme codes. PS, protein standards

Enzyme addition and, in particular, the PPGLZ combination decreased the extractability of HMW-GS (Fig. 2), increasing its content in the GMP. MMW-GS increased with PPGLZ. The unextractability of LMW-GS was higher when enzymes were added, mainly with PPLAC and LAC. The HMW-GS/LMW-GS ratio, a quality index of glutenin, was found to be between 0.63 and 0.79.

Effect of enzyme addition on total content (g/100 g freeze-dried dough) of HMW-, MMW- and LMW-GS and on the HMW/LMW-GS ratio of GMP from wheat cultivar Farak. See Table 2 for enzyme codes

Relationships between protein subunits and functional characteristics of GMP and dough

Correlations between variables of functional characteristics of GMP and dough from F0 [25, 28] and the relative percentage of subunits of GMP were studied. The correlation matrix compiled the higher correlations (Table 5). There was a lack of significant correlation between HMW-GS and dynamic rheological moduli. Exceptions were the subunit of 81–82 kDa that was positively associated with G′ and G* and the subunit of 88–90 kDa which correlated with a lower delta angle and, consequently, with a more elastic gel. Thus, the elasticity of GMP depends not only on the presence of certain glutenin subunits but also on their aggregation in the GMP. Subunits of higher MW negatively correlated with the content of WSP associated to GMP and with dough extensibility and, accordingly, determined a higher gluten quality. The subunit of 81–82 kDa was directly related to the content of TP and to resistance to extension of the dough. This is in agreement with earlier findings concerning the relationship between HMW-GS and maximum resistance to extension of dough and gluten samples [43]. MMW-GS of 64–67 kDa negatively influenced delta angle and resistance to extension of dough. LMW bands of 55–57 kDA were, on the other hand, negatively related with dynamic rheological moduli and delta angle and positively with dough extensibility.

Effect of quality of commercial wheat blends and enzyme addition on the protein subunit composition of GMP

With the aim to gain insight into the consequence of the combined effect of enzyme addition, flour quality and breadmaking process on GMP, the subunit composition of GMP from doughs made with two commercial flours, F1 and F2, in a straight breadmaking process before (UFD) and after fermentation (FD) was studied. The subunit composition of GMP of UFD and FD from both flours is presented in Fig. 3. GMP from flour of lower breadmaking quality (F1) separated four HMW-GS with apparent MW 124–127, 105–110, 98–100 and 92–96 kDa. GMP from flour of higher breadmaking quality (F2) showed four HMW-GS with apparent MW 121–124, 107–109, 94–97 and 90–93 kDa, one MMW-GS of 62–64 kDa and two LMW-GS of 43–44 (B-LMW) and 36–37 kDa (C-LMW).

SDS–PAGE of HMW-, MMW- and LMW-GS of GMP from unfermented (left) and fermented (right) doughs made of wheat flours F1 and F2. See Table 2 for enzyme codes. PS, protein standards

The resting time produced repolymerization [10, 44, 45, 46], increasing qualitatively and quantitatively the protein subunits in GMP (Fig. 3). GMP from FD of F1 separated four HMW-GS with apparent MW of 120–125, 102–105, 93–95 and 88–90 kDa, respectively, corresponding with the HMW-GS found in UFD. Three new MMW-GS of 65–68, 61–63 and 58–60 kDa and two bands of LMW-GS of 50–51 (B-LMW) and 34–35 kDa (C-LMW) appeared in the unextractable fraction after fermentation. In F2, GMP of FD presented four HMW-GS corresponding with the subunits found in the UFD; MMW-GS presented three bands of 68–72, 64–66 and 60–63 kDa and LMW-GS presented four bands, three B-LMW of 49–52, 43–44 and 40–42 kDa and one band of C-LMW-GS of 35–36 kDa.

The quantity and percentage of subunits was modified, after enzyme addition, mainly in F1, resulting in GMP depolymerization during mixing (Table 6). The amount of HMW-GS increased, except for LAC and for the subunit 105–110 kDa, although the percentage decreased generally with the enzymes. LMW-GS in dough containing enzymes increased after mixing. The effect of enzymes was lower in flour of higher breadmaking quality, F2, where GLZ and LAC increased the amount of HMW-GS and PPLAC decreased it.

Fermentation time allowed repolymerization of proteins and more subunits becoming unextractable in SDS (Table 7). In F1, differences between samples were reduced and single and combined GLZ increased the quantity of HMW-GS. The quantity of HMW-GS was higher in F2 in accordance with its better breadmaking quality [41, 47, 48] and the effect of enzymes was lower. Changes in LMW-GS of 40–42 and 35–36 kDa were probably due to the presence of α-, β- and γ-gliadins, as stated before.

The total percentage of subunits in UFD accounted for 47–74, 0 and 26–57% in F1 and 30–47, 15–18 and 32–38% in F2, for HMW-, MMW- and LMW-GS, respectively. After fermentation the total percentage of subunits changed to a higher degree in F1 (36–37, 17–19 and 14–19%) than in F2 (32–37, 14–17 and 47–51%) for HMW-, MMW- and LMW-GS, respectively. The amount of subunits of GMP was lower in F1, but the ratio HMW/LMW-GS was similar for both flours (0.63–0.80) (Fig. 4).

Effect of enzyme addition on total protein content (g/100 g freeze-dried dough) of HMW-, MMW- and LMW-GS and on the HMW/LMW-GS ratio of GMP from fermented doughs (FD) of wheat flours F1 and F2. See Table 2 for enzyme codes

Relationship between protein subunits and quality and shelf life of bread

The relationship between quality and shelf life of bread made with F1 and F2 [19, 49] and percentage of subunits of GMP isolated from FD were studied. This will allow us to know the significance of correlation between parameters in explaining differences in the breadmaking quality of flour. The correlation matrix (Table 8) shows the most relevant correlations. The shape of the breads (width/height ratio) was improved in the presence of a certain HMW-GS depending on the flour quality. This HMW-GS with MW of 120–125 and 93–95 for F1 and F2, respectively, was positively correlated with the specific volume of breads and negatively with firmness of fresh and stored bread. MMW-GS negatively influenced the quality of fresh and stored bread of F1. LMW-GS led to different effects depending on their MW; in F1 the subunit of 34–35 kDa, in F2 the subunit of 40–42 kDa and the total LMW in both flours negatively determined the quality and shelf life of bread. Nevertheless, the subunit of 43–44 kDa in F2 positively influenced the shape of bread and determined a softer crumb during staling. The ratio HMW/LMW-GS correlated positively with bread firmness during staling in breads prepared with F2.

Conclusion

Flours from different wheat varieties differ in the type and amount of glutenin subunits separated from their GMP by SDS–PAGE. Their characteristics point out the structural differences on the protein matrix of flours and their influence on baking quality. Some correlations between specific GMP protein subunits and fresh and stored bread properties indicate their role in determining baking flour quality. The effect of enzymes on the GS of GMP was discrete, showing that other factors in addition to the nature and proportion of the GS, such as their association and the presence of other components (non-starch polysaccharides), may influence GMP properties.

References

Khelifi D, Branlard G (1992) J Cereal Sci 16:195–209

Gupta RB, Paul JG, Cornish GB, Palmer GA, Békés F, Rathjen AJ (1994) J Cereal Sci 19:9–17

Wieser H, Kieffer P (2001) J Cereal Sci 34:19–27

Schofield JD (1994) Wheat proteins: structure and functionality in milling and breadmaking. In: Bushuk W, Rasper V (eds) Wheat: production, composition and utilization. Blackie, Glasgow, pp 73–100

Weegels PL, Hamer RJ, Schofield JD (1996) J Cereal Sci 23:1–17

Lindsay MP, Skerritt JH (1998) J Agric Food Chem 46:3447–3457

Lindsay MP, Skerritt JH (1999) Trends Food Sci Technol 10:247–253

Gupta RB, Kahn K, McRitchie F (1993) J Cereal Sci 18:23–41

Payne PI, Nightingale MA, Krattiger AF, Holt LM (1987) J Sci Food Agric 440:51–65

Weegels PL, Hamer RJ, Schofield JD (1997) J Cereal Sci 25:155–163

Veraverkebe WS, Delcour JA (2002) Crit Rev Food Sci Nutr 42:179–208

Shewry PR, Halford NG, Tatham AS (1992) J Cereal Sci 15:105–120

Payne PI, Corfield KG, Blackman JA (1979) Theor Appl Genet 55:153–159

Masci S, Lafiandra D, Procedi E, Lew EJL, Tao HP, Kasarda DD (1993) Cereal Chem 70:581–585

van Oort MG, van Straaten F, Laane C (1995) Int Food Ingred 2:23–27

Weegels PL, Hamer RJ (1992) Cereal Foods World 37:379–385

Martínez-Anaya MA, Jiménez T (1998) Z Lebensm Unters Forsch A 206:134–142

Vemulapalli V, Miller KA, Hoseney RC (1998) Cereal Chem 75:439–442

Primo-Martín C, Martínez-Anaya MA (2003) J Food Sci 68:31–41

Si QS (1994) International Patent Application PCT/DK94/00232

Vemulapalli V, Hoseney RC (1998) Cereal Chem 75:859–862

Hilhorst R, Dunnewind B, Orsel R, Stegeman P, Van Vliet T, Gruppen H, Schols HA (1999) J Food Sci 64:808–813

Souppe J (1997) VII Encuentro para la aplicación industrial de enzimas. Jornadas IQS, Barcelona

Primo-Martín C, Lichtendonk W, Plitjer J, Wang M, Hamer RJ (2003) In: Courtin CM, Veraverbeke WS, Delcour JA (eds) Recent advances in enzymes in grain processing. ACCO, Leuven, pp 261–267

Primo-Martín C, Lichtendonk W, Plitjer J, Hamer RJ (2003) J Cereal Sci (submitted)

Figueroa-Espinoza MC, Rouau X (1998) Cereal Chem 75:259–265

Mccleary BV, Sheenan H (1987) J Cereal Sci 6:237–251

Primo-Martín C, Valera R, Martínez-Anaya MA (2003) J Agric Food Chem 51:4673–4679

Kieffer R, Wieser H, Henderson MJ, Graveland A (1998) J Cereal Sci 27:53–60

ICC Standard Methods (1994) International Association for Cereal Chemistry. Gluten Index No 155

Graveland A, Bongers P, Bosveld P (1979) J Sci Food Agric 30:71–84

Weegels PL, Orsel R, van de Pijpekamp AM, Lichtendonk WJ, Hamer RJ, Schofiels JD (1995) J Cereal Sci 21:117–126

ICC Standard Methods (1995) International Association for Cereal Chemistry. Protein No 105/2

Hashimoto S, Shogren MD, Pomeranz Y (1987) Cereal Chem 64:30–64

Delcour JA, Vanhamel S, De Geest C (1989) Cereal Chem 66:107–111

Jiménez T, Martínez-Anaya MA (2000) Food Sci Technol Int 6:197–205

Jiménez T, Martínez-Anaya MA (2001) Food Sci Technol Int 7:5–14

Bekkers ACAPA, Lichtendonk WJ, Graveland A, Plitjer JJ (2000) Wheat gluten. In: Shewry PR, Tatham AS (eds) Proceedings of the 7th international workshop Gluten 2000. Royal Society of Chemistry, Cambridge

Don JAC, Lichtendonk WL, Plitjer JJ, Hamer RJ (2003) J Cereal Sci 37:1–7

Laemmli UK (1970) Nature 227:680–685

Jood SJ, Schofield D, Tsiami AA, Bollecker S (2001) Int J Food Sci Technol 36:573–584

Rodríguez Quijano M, Vázquez F, Carrillo JM (2002) XIV Jornadas técnicas sobre la calidad de los trigos de España. Asociación Española de Técnicos Cerealistas, Valencia, pp II.5.1–II.5.20

Wieser H, Seilmeier W, Kieffer R (1994) Gluten proteins 1993. Assoc Cereal Res, Detmold, pp 141–150

Graveland A, Bosveld P, Lichtendonk WJ, Moonen JHE (1980) Biochem Biophys Res Commun 93:1189–1195

Hamer RJ, Lichtendonk WJ (1987) In: Lasztity R, Békés F (eds) Proceedings of the third international workshop on gluten proteins. World Scientific, Singapore, pp 227–237

Weegels PL, Hamer RJ, Schofiels JD (1997) J Cereal Sci 25:165–173

Luckow OM, Dyck PL, Bushuk W (1989) Cereal Chem 66:531–532

Singh NK, Donovan R, MacRitchie F (1990) Cereal Chem 67:161–170

Primo-Martín C, Martínez-Anaya MA (2003) Molinería Panadería 1114:30–38

Acknowledgements

The authors thank the Spanish Institutions Comisión Interministerial de Ciencia y Tecnología (Project CICYT. ALI98-1039) and Ministerio de Ciencia y Tecnología (Project AGL2001-1273) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Primo-Martín, C., Martínez-Anaya, M.A. & Collar, C. Composition of the glutenin macropolymer: effects of flour quality and nonamylolytic enzyme addition. Eur Food Res Technol 218, 428–436 (2004). https://doi.org/10.1007/s00217-003-0849-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-003-0849-2