Abstract

A ternary deep eutectic solvent (TDES) was used as both template and functional monomer in the synthesis of TDES-based molecularly imprinted polymers (TDES-MIPs). A meticulous miniaturized solid-phase microextraction (mini-SPME) method followed by high-performance liquid chromatography (HPLC) were used for the optimal speciation of 3,4-dihydroxybenzoic acid (3,4-DHBA) in the needle of a syringe system with response surface methodology (RSM). Under the optimal conditions for the determination of 3,4-DHBA (amount of adsorbent (2 mg), sample volume (1 mL), cycles for adsorption and desorption (6)), the actual extraction amount was 8.46 μg g−1. The limits of detection (LODs, S/N = 3) for 3,4-DHBA in Ilex chinensis Sims were 0.26–0.31 μg mL−1, and the intra-day and inter-day precision (relative standard deviations, n = 4) after spiking with 5 μg mL−1, 100 μg mL−1, and 200 μg mL−1 were both less than 4.21%. The meticulous method (TDES-MIP-mini-SPME) combined with RSM offers a significant advance over existing methods, because of the meticulous operation and excellent selectivity of 3,4-DHBA from complex samples.

ᅟ

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The leaves of Ilex chinensis Sims (I. chinensis) are used in traditional Chinese medicine, containing a large variety of chemical compounds such as triterpenoids [1], phenolic acids [2], and flavonoids [3]. 3,4-Dihydroxybenzoic acid (3,4-DHBA) is a type of phenolic acid found in I. chinensis. The compound is an anthocyanin metabolite with strong antioxidant activity, having potential anticancer and anti-inflammatory properties with diverse medicinal activities [4, 5]. Therefore, the analysis of 3,4-DHBA in I. chinensis is essential. High-performance liquid chromatography (HPLC) is the most commonly used technique for the analysis of 3,4-DHBA in different samples because of the simplicity, high sensitivity, and broad linear range [6]. In view of the low concentrations of 3,4-DHBA and the complexity of the matrix in real samples, an effective extraction and preconcentration step prior to chromatographic analysis is necessary. Thus far, several preconcentration methods, such as liquid-liquid extraction (LLE) [7], solid-phase extraction (SPE) [8], and solid-phase microextraction (SPME) [9], have been used to isolate and enrich phenolic acids in many types of samples. SPME is one of the most applicable sample preparation trends due to its unique properties and environmental perspectives, such as simple operation, reduced consumption of toxic organic chemicals, excellent sensitivity, and high preconcentration factor [10, 11].

In the SPME procedure, selective materials, including molecularly imprinted polymers (MIPs), can be used as adsorbents [12, 13]. MIPs are synthetic receptors possessing selective cavities designed for a target molecule. The intelligent polymers with molecular recognition sites specific to a target analyte can accommodate specific molecules or classes of molecules in preference to other closely related compounds. The combination of MIPs and SPME can be particularly useful when dealing with complex samples and can potentially bring huge benefits to sample preparation strategies [14]. Deep eutectic solvent (DES) is generally composed of two or three non-toxic, inexpensive, and safe components that produce an environment-friendly mixture with a much lower melting point than any of the individual components [15]. Owing to the excellent properties, DESs are widely spreading in analytical separation, organic synthesis, biocatalysis, and extractions [16,17,18]; in particular, recent breakthroughs in applications of DES on molecular imprinting techniques have been extremely relevant [19, 20]. Some studies applied DES as monomers in the preparation of MIPs, and this new type of functional monomer provided better performance for MIPs compared to traditional functional monomers, such as acrylic acid and acrylamide [21, 22].

In contrast to the typical one-variable-at-a-time methodology, multivariate statistic methodologies have been used to optimize the extraction efficiency. In particular, the response surface methodology (RSM) has become the most preferred approach for the optimization of analytical methods when a response is influenced by several variables [23]. RSM is a tool based on the fit of a polynomial equation to the experimental data via statistical analysis of a mathematical model [24]. Even though the process has been applied to the extraction of phenolic compounds in several matrices, such as Coriandrum sativum seeds [25] and blackberry leaves [26], few studies have examined multivariate optimization strategies, such as RSM for 3,4-DHBA.

In this study, ternary deep eutectic solvent-based molecular imprinted polymers (TDES-MIPs) were selected as adsorbents for the miniaturized SPME (mini-SPME) of 3,4-DHBA speciation in I. chinensis based in the needle of a syringe system. The RSM strategy was used to determine the appropriate parameters (amount of adsorbent, sample volume, cycles for adsorption and desorption) for the optimal extraction efficiency of 3,4-DHBA.

Experimental

Chemical and reagents

The leaves of I. chinensis were collected in Inha University (Incheon, Korea). 3,4-DHBA, 2-hydroxybenzoic acid (2-HBA), 4-hydroxybenzoic acid (4-HBA), 2,4-dihydroxybenzoic acid (2,4-DHBA), 3,4,5-trihydroxybenzoic acid (3,4,5-THBA), and dimethyl sulfoxide (DMSO) were bought from Sigma-Aldrich Co, Ltd. (Spruce, USA). 2-Methylpropionitrile (AIBN), hexane, acetone (CP), ethanol (EtOH), methanol (MeOH), acetic acid (HAc), methacrylic acid (MAA), and ethyl acetate (EAc) were acquired from Fisher Scientific Co., Ltd. (Seoul, Korea). Ethylene glycol dimethacrylate (EDMA), choline chloride (ChCl), and ethylene glycol (EG), and acetonitrile (ACN) were purchased from Daejung Chemicals & Metals Co., Ltd. (Gyeonggi-do, Korea). The other chemicals used were of HPLC grade.

Instrument

HPLC system was equipped with Waters 1515 liquid chromatography (Waters, MA, USA), a Waters 600 s Multi Solvent Delivery System, a 2489 UV dual-channel detector, and Empower™ 3 software (Waters, MA, USA) as the data acquisition system. Chromatographic separation was accomplished using a 250.0 × 4.6 mm (i.d. 5 μm) C18 column (RStech Corporation, Daejeon, Korea).

Fourier transform infrared (FT-IR) spectroscopy of the materials was performed in transmission mode on KBr pellet using Nexus 670 (Nicolet, USA) between 4000 and 400 cm−1. Scanning electron microscopy (SEM) images were collected on a Sigma VP Field Emission SEM (Oberkochen, Germany). Brunauer-Emmett-Teller (BET) surface area of the materials was recorded using a V-Sorb 2800TP-specific surface area and pore size analyzer (Norcross, USA). Thermogravimetric analysis (TGA) was carried out with TG 209 (Netzsch, Germany) under a nitrogen atmosphere with a heating rate of 10 °C/min up to 800 °C.

Preparation of the materials

Synthesis of TDES

The TDES employed in this study were combinations of ChCl, 3,4-DHBA, and EG with fixed molar ratios as the following: 1:1:1 (n/n/n, TDES-1), 1:1:2 (n/n/n, TDES-2), and 1:1:3 (n/n/n, TDES-3). The TDESs were prepared by stirring mixtures of their components at 80 °C until a homogeneous and clear liquid was formed, respectively.

Synthesis of TDES-MIP

One milliliter of TDES, both as the template and the functional monomer, was mixed in the presence of 24 mg of DMSO. Thirty minutes was allowed for TDES and DMSO to self-assemble. Subsequently, 36 mg of EDMA and 12 mg of AIBN were added to the solution, and the mixture was mixed ultrasonically to a homogenous solution. To remove air from the solution, the reactant solution was purged with nitrogen for 5 min. The resulting materials were placed in an oven and heated to 80 °C for 12 h. Subsequently, the TDES-MIP was washed with a mixture of methanol/acetic acid (90:10, v/v) and ACN until no residue of 3,4-DHBA and other reagents was found in the solvent. Non-deep eutectic solvent (using MAA as the normal functional monomers)-based MIP, ternary deep eutectic solvent-based molecularly imprinted polymers without the templates (TDES-NIP), and molecularly imprinted polymers without templates (NIP) were prepared using the same protocol. Figure 1 presents a preparation sketch of TDES-MIP.

Absorption capacity of the obtained materials

For the equilibrium adsorption experiment, the concentration of 3,4-DHBA was varied from 5.0 to 200.0 μg mL−1, and the materials were obtained under 25 °C with shaking for 6 h.

The equilibrium concentration, Q (μg g−1), of 3,4-DHBA on concentration was calculated using the following equation:

where Cfree (μg mL−1) is the free concentration of 3,4-DHBA, C0 (μg mL−1) is the initial concentration, V (mL) is the volume of the solution, and W (mg) is the mass of the polymer powder (1.0 mg).

For the kinetic adsorption experiment, the notional concentration of 3,4-DHBA was 150.0 μg mL−1 and the shaking time was varied from 30 to 360 min. The equilibrium concentration, Q (mg g−1), of 3,4-DHBA on time was calculated using the following equation:

where Qt and Qe (mg g−1) are the amounts of 3,4-DHBA adsorbed at a given time and equilibrium, respectively, and the constant k1 (min−1) is the rate constant of the adsorption.

1.0 mL (120.0 μg mL−1) of 2-HBA, 4-HBA, 2,4-DHBA, 3,4-DHBA, and 3,4,5-THBA was loaded onto the 1.0 mg of a TDES-MIP, MIP, and NIP cartridge to evaluate their selectivity. Recognition coefficient (α) calculated according to Eq. (3) was used to evaluate the adsorption abilities of the polymers.

where QTDES-MIP, QMIP, and QNIP represent the adsorption amounts of the template bound to TDES-MIP, MIP, and TDES-NIP, respectively.

Selectivity experiments were conducted using 2-HBA, 4-HBA, 2,4-DHBA, and 3,4,5-THBA as the structural analogues of 3,4-DHBA. The amount adsorbed on the TDES-2-MIPs was calculated by subtracting the residual amount of templates in solution from the total amount of 3,4-DHBA. The selectivity factor (β) was defined as follows:

where Qtemplate and Qanalogue are the adsorption amounts of the template and analogues on TDES-2-MIP and MIP, respectively.

Preconcentration procedure

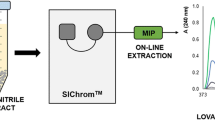

2.0 mg of TDES-MIP was placed into the needle of the syringe system (50 mm × 8 mm i.d.) using frits at both ends to avoid sorbent loss. The syringe system was preconditioned with 1 mL deionized water, MeOH, and acidic EtOH, respectively, to eliminate the impurities which might affect the extraction efficiency and results. All extracted samples were filtered through a 0.45-μm filter before being applied to the syringe system and each time the solution (1 mL) was sucked up into and out of micropipette type of the needle containing TDES-MIP by pulling and pushing the syringe. The extraction complex retained on the adsorbent was washed with EtOH, ACN, hexane, CP, and EAc (0.5 mL, 2 mol L−1), and a series of selected eluent solutions including MeOH, HAc, HAc/ACN, HAc/CP, and HAc/EAc (0.5 mL, 2 mol L−1) adjusted to pH = 3 were used, respectively, by several pulling and pushing cycles of the syringe system. The supernatant after the filter was concentrated to 2 mL and injected into the HPLC for further analysis.

The needle of the syringe system is suitable to be used as a meticulous mini-SPME cartridge because of its special mini-conical shape with different diameters in the two ends. With a tiny amount of adsorbent packed in the micropipette type of the needle, extraction can be carried out faster and more easily than conventional SPE cartridges, whereas the other end with a larger diameter facilitates the sample loading procedure. Based on this, a bigger pipette tip (100 μL) was inserted into the needle of the syringe system to assemble a new cartridge. Figure 2 presents the process of cartridge preparation and extraction of TDES-MIP-mini-SPME.

Optimization of the experimental variables with RSM

After determining the preliminary range of the analysis variables through a single-factor test, and considering the mini-SPME procedure with the needle of the syringe system for the measurement of 3,4-DHBA, three variables (amount of adsorbent, sample volume, and cycles for adsorption and desorption) were designed to optimize the extraction efficiency for a 3,4-DHBA determination. A 17-run Box-Behnken design (BBD) was chosen for the optimization of 3,4-DHBA extraction by evaluating the three significant variables.

All of the variables were fixed at three levels: lower (− 1), higher (+ 1), and central point (0) for the optimal extraction efficiency of 3,4-DHBA (see the Electronic Supplementary Material (ESM) Table S1). The response variables were fitted to a second-order polynomial model equation (Eq. (5)) to correlate the relationship between the independent variables and the response (extraction recovery).

where Y is the dependent variable; A0 is a constant; Ai, Aii, and Aij are coefficients; and Xi and Xj are the levels of the independent variables that represent the linear and quadratic, respectively. The results were examined by ANOVA using Design-Expert software (v.7.1.6, Stat-Ease, Inc., Minneapolis, USA) to verify the validity of the statistical experimental strategies, and the coefficient of determination (R2) was used to estimate the fitness of the polynomial equation to the responses.

Determination of 3,4-DHBA in the real sample

The dried leaves of I. chinensis (20.0 g) were heated under reflux with 70:30 (v/v) EtOH (3 × 50 L, 1 h each). After removing EtOH under reduced pressure, the EtOH extract was suspended in H2O (3 L) and partitioned with ethyl acetate (3 × 3 L).

Under the optimal extraction conditions determined by the above experiments, the determination steps of 3,4-DHBA in the real sample were operated with the TDES-MIP-mini-SPME device. The eluate solution was collected for HPLC analysis.

Results and discussion

Meticulous purification of 3,4-DHBA with the obtained materials

The recoveries of 3,4-DHBA from I. chinensis with the resulting materials of TDES-MIPs, MIP, TDES-NIP, and NIP were determined using the meticulous method of mini-SPME. Among the materials, TDES-2-MIP showed the highest recoveries (89.95%) of 3,4-DHBA (Fig. 3). As the chemical structure of 3,4-DHBA includes an alkene double bond, TDES-2 can function as both a template and monomer during MIP preparation, fulfilling two roles. TDESs were used as template-functional monomer complexes to prepare the corresponding MIPs because compounds with strong intramolecular hydrogen bonds will not lead to the formation of sufficient stable template-functional monomer complexes in the imprinting process. Further experimental steps were operated to further examine the effects of TDES-2 as a functional monomer and to optimize the extraction efficiency of TDES-2-MIP in the mini-SPME procedure.

Adsorption properties

ESM Fig. S1 (a) shows the equilibrium absorption isotherms of 3,4-DHBA on MIP and TDES-2-MIP. The amounts of both MIP and TDES-2-MIP adsorbed increased with increasing initial concentration. On the other hand, the adsorption capacity of MIP for 3,4-DHBA was lower than that of TDES-2-MIP. The reason may be the specific adsorption produced by the imprinting effect, and TDES-2 plays an important role in the adsorption of 3,4-DHBA.

A kinetic study of adsorption was performed with an initial 3,4-DHBA concentration of 150.0 μg mL−1 for both MIP and TDE-2-MIP. As shown in ESM Fig. S1 (b), the adsorption capacity of 3,4-DHBA increased with increasing extraction time, and reached equilibrium adsorption for 3,4-DHBA at 300 min, whereas the adsorption capacity of TDES-2-MIP (47.01 mg g−1) was significantly higher than that of MIP (30.00 mg g−1). The adsorption equilibrium showed that the mass transfer rate of TDE-2-MIP was superior to that of MIP.

The results (ESM Table S2) showed that the recognition coefficient (α) of 3,4-DHBA on TDES-2-MIP (α1 = 2.73) was much higher than that of MIP (α2 = 1.82), as calculated by Eq. (4). The selectivity factor (β) of TDES-2-MIP on 3,4-DHBA (β3,4-DHBA = 0.29) is larger than that of the other analogues (β2-HBA = 0.14, β4-HBA = 0.13, β2,4-DHBA = 0.24, β3,4,5-THBA = 0.20), improving TDES-2-MIP having greater selectivity and higher binding capacities on 3,4-DHBA. The results were attributed to TDES-2-MIP recognizing the analytes to the interaction between recognition sites, and the cavities matched the template molecules in shape and size, because of stable template-functional monomer complexes.

Moreover, ESM Table S3 shows that compared to the ever-synthesized MIP using common functional monomer (4-vinylpyridine) on the adsorption of 3,4-DHBA [27, 28], TDES-2-MIP has much a higher adsorption capacity, imprinted factor, and selectivity.

Characterization

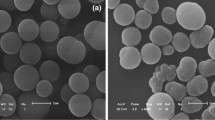

Figure 4(I) presents the difference of FT-IR spectra between TDES-2-MIP and MIP. After immobilization of TDES-2, the resulting TDES-2-MIP showed strong broad peaks at 3500–3100 cm−1, 1350–1000 cm−1, and 1300–1000 cm−1, which were corresponded to the VN-H, VC-N, and VC-O vibration peaks, respectively. It was shown that TDES-2-MIP using TDES-2 as the functional monomer had been polymerized successfully. Figure 4(II) shows SEM images of MIP (Fig. 4(a)) and TDES-2-MIP (Fig. 4(b)) at × 10,000 and × 50,000 magnifications, respectively. The TDES-2-MIP had a soft texture and a smooth surface. Moreover, the TDES-2-MIP particles were smaller and more dispersed (Fig. 4(II)), increasing the surface area and absorption efficiency of the target molecules.

As observed in ESM Fig. S2 (I), different from MIP, the N2 adsorption-desorption isotherms of TDES-2-MIP was observed with small change under a relative pressure (P/P0) of 0.6, while increased rapidly above that. The specific surface area of TDES-2-MIP was 40.69 m2 g−1, higher than that of the corresponding MIP (3.60 m2 g−1), implying the mesoporous structure of TDES-2-MIP was favorable to application in the mini-SPME process. Mesoporous structure was contributed to the hydrothermal stability and imprinted cavities, which could enhance significantly the adsorption capability of adsorbents. According to TGA (ESM Fig. S2 (II)), the weight loss was MIP (4.6%, below 180 °C) and TDES-2-MIP (8.9%, below 300 °C) in the initial step, which may be caused by volatilization of the absorbed water in the samples. Compared to MIP, the weight loss (5%) of TDES-2-MIP in the range of 180–300 °C was very smaller, indicating the higher thermal stability of TDES-2-MIP compared to MIP below 300 °C. The weight loss of MIP (89%) in the range of 180–420 °C and that of TDES-2-MIP (85%) in the range of 300–420 °C were significant, which resulted from the decomposition and vaporization of polymers.

Optimization of the TDES-MIP-mini-SPME condition

Without fracturing the interaction between analytes and TDES-MIP, the selection of type and volume of washing solvents is critical to remove various interfering impurities in mini-SPME process. Different types of washing solvents, including EtOH, ACN, hexane, CP, and EAc, were tested (1 mL extracted solution). When hexane was used as the washing solvent, the recovery of 3,4-DHBA was superior to that of the other solvents and there was a better purification effect (Fig. 5(a)). For further optimization of the washing solvent, various volumes (0.2–2.0 mL) were tested in the TDES-MIP-mini-SPME process. 1.5 mL of hexane was selected as the washing solvent for it gave the highest recovery (92.02%) of 3,4-DHBA and was relatively constant in the range of 1.5–2.0 mL.

To recover the retained analyte from the syringe system, the effective elution procedure is very important to ensure the determination of the analytes by subsequent HPLC analysis. Acidic elution solvents can reduce the ionization of the analyte and reduce polarity, allowing for a clear detection of the analytes under the HPLC conditions. Therefore, several acidic solvents (MeOH, HAc/MeOH, HAc/ACN, HAc/CP, and HAc/EAc) were assessed to optimize the elution solvent. HAc was added to control the pH because TDES-MIP possesses multiple adsorption mechanisms that not only interact with the analytes through ion-exchange, electrostatic, and π-π interactions but also adsorb through hydrogen bonding. Therefore, with the addition of HAc in MeOH, the polarity of the analyte and the affinity with the elution solvent became stronger. The elution performance of the HAc/MeOH solution was better than that of the others (Fig. 5(b)). In particular, its elution efficiency was much higher than that of MeOH. For further optimization of the elution solvent, various volumes (0.2–2.0 mL) were tested in the TDES-MIP-mini-SPME process. The highest and relatively constant recovery of 3,4-DHBA (94.60%) was obtained in the range of 1.2–2.0 mL, so 1.2 mL of HAc/MeOH as the elution solvent was selected for further experiments.

RSM model fitting and statistical analysis

ESM Table S4 lists the matrix of the design including the investigated factors and responses (extraction recovery of 3,4-DHBA). Each run was performed in duplicate, and the extraction efficiency of 3,4-DHBA was an average of two sets of experiments. The predicted values of the responses were obtained from a quadratic model fit using the abovementioned software.

Based on RSM results, a polynomial equation in terms of the response variables and the corresponding coded values was obtained by fitting the BBD model, as follows:

The significance of each coefficient was checked using a F-test and p value (ESM Table S5). The p value was used to check the significance of each coefficient, and its p value is less than 0.0500, indicating the model was remarkably significant in predicting the extraction efficiency of 3,4-DHBA. The model F-value of 16.49 suggested that the model was not significant relative to the noise, and the “lack of fit F-value” of 1.88 validated the suitability of the predicted model. In ESM Table S6, the high value of coefficient of determination (R2 = 0.9550) and adjusted coefficient of determination (R2Adj = 0.8971) is clearly illustrated, and only a 1.64% variation could not be explained by the model. The “Adeq. precision” of 10.746 was a measure of the signal-to-noise ratio, which was significantly greater than 4, indicating that the model was adequate to navigate through the design space and predict 3,4-DHBA extraction efficiency.

From the 3D response surface plots (ESM Fig. S3), it was found out that the extraction recovery decreased as both the amount of adsorbent increased in the range of 2–8 mg and the sample volume increased from 1 to 10 mL. But, the extraction recovery initially increased and then decreased with cycles for adsorption and desorption, increasing from 2 to 10. The highest extraction recovery of 3,4-DHBA was obtained when the amount of adsorbent of 2 mg, sample volume of 1 mL, and cycles for adsorption and desorption of 6 were achieved. The theoretical extraction recovery of 3,4-DHBA, which was predicted under the optimal conditions was 96.02%, and the actual extraction efficiency under the optimal condition was 97.11%.

Meticulous purification of Ilex chinensis Sims with TDES-MIP-mini SPME

To evaluate the practical applicability of the developed TDES-MIP-SPME-HPLC method, real I. chinensis was extracted and analyzed selectively. The actual amount of 3,4-DHBA from fruit juice using the TDES-2-MIP with the SPME method was 8.46 μg g−1. Figure 6 presents different chromatograms of the sample extracts using TDES-2-MIP and MIP. The chromatogram of TDES-2-MIP had fewer interfering peaks, a larger peak height, and a better chromatogram shape than the MIP, and the peak of the target was easier to distinguish. ESM Fig. S4 shows the reusability of TDES-2-MIPs. No decrease in the amount of 3,4-DHBA adsorbed was observed after five consecutive adsorption-desorption cycles. This indicated that the damage of the imprinting sites was not obvious in the TDES-2-MIPs during the desorption process.

To examine the effects of the sample matrix on the analytical performance of the TDES-MIP-mini-SPME method, increasing spiking concentrations in the range of 0.50–500.00 μg mL−1 for 3,4-DHBA were pretreated with the presented TDES-MIP, and a recovery study was performed by spiking 5 μg mL−1, 100 μg mL−1, and 200 μg mL−1 individual 3,4-DHBA in the samples (Table 1). The method recoveries ranged from 87.57–102.62% for 3,4-DHBA, and the relative standard deviations (RSDs) (n = 4) of the intra-day and inter-day determinations were less than 4.21%. ESM Table S7 presents a comparison of the previous methods reported for the determination of 3,4-DHBA [29,30,31]. The proposed method clearly provided a meticulous mini-SPME method using novel TDES-based MIPs, satisfactory linearity, and recoveries under simple steps.

Conclusions

The actual amount of 3,4-DHBA extracted using the TDES-2-MIP-mini-SPME method was 8.46 μg g−1 under the optimal conditions (amount of adsorbent (2 mg), sample volume (1 mL), and cycles for adsorption and desorption (6)). The meticulous mini-SPME method using novel TDES-based MIPs may open up a new avenue of MIP-SPME with excellent recognition and high adsorption capacity.

References

Xia WQ, Li RF, Liu JB, Cui BS, Hou Q, Sun H, et al. Triterpenoids from the leaves of Ilex chinensis. Phytochemistry. 2018;148:113–21.

Zhang AL, Ye Q, Li BG, Qi HY, Zhnag GL. Phenolic and triterpene glycosides from the stems of Ilex litseaefolia. J Nat Prod. 2005;68(1):1531–5.

Li LJ, Zhang Y, Zhang P, Pi HF, Ruan HL, Wu JZ. Flavans from the leaf of Ilex centrochinensis. J Asian Nat Prod Res. 2011;13(04):367–72.

Son JH, Kim SY, Jang HH, Lee SN, Ahn KJ. Protective effect of protocatechuic acid against inflammatory stress induced in human dermal fibroblasts. Biomed Dermatol. 2018;2(1):9–14.

Musa M, Ibrahim WAW, Marsin FM, Keyon ASA, Nodeh HR. Graphene-magnetite as adsorbent for magnetic solid phase extraction of 4-hydroxybenzoic acid and 3,4-dihydroxybenzoic acid in stingless bee honey. Food Chem. 2018;265:165–72.

Mateos R, Espartero JL, Trujillo M, Ríos JJ, León-Camacho M, Alcudia F, et al. Determination of phenols, flavones, and lignans in virgin olive oils by solid-phase extraction and high-performance liquid chromatography with diode array ultraviolet detection. J Agric Food Chem. 2001;49(5):2185–92.

Shalash M, Makahleh A, Salhimi SM, Saad B. Vortex-assisted liquid-liquid-liquid microextraction followed by high performance liquid chromatography for the simultaneous determination of fourteen phenolic acids in honey, iced tea and canned coffee drinks. Talanta. 2017;174:428–35.

Hou X, Lu X, Tang S, Wang L, Guo Y. Graphene oxide reinforced ionic liquid-functionalized adsorbent for solid-phase extraction of phenolic acids. J Chromatogr B. 2018;1072:123–9.

Tafazoli Z, Azar PA, Tehrani MS, Husain SW. Facile preparation of multifunctional carbon nanotube/magnetite/polyaniline nanocomposite offering a strong option for efficient solid-phase microextraction coupled with GC-MS for the analysis of phenolic compounds. J Sep Sci. 2018;41(13):2736–42.

De GS, Gionfriddo E, Pawliszyn J. A new and efficient solid phase microextraction approach for analysis of high fat content food samples using a matrix-compatible coating. Talanta. 2017;167:754–60.

Trabalón L, Nadal M, Borrull F, Pocurull E. Determination of benzothiazoles in seafood species by subcritical water extraction followed by solid-phase microextraction-gas chromatography-tandem mass spectrometry: estimating the dietary intake. Anal Bioanal Chem. 2017;409(23):5513–22.

Chen L, Huang X. Preparation and application of a poly (ionic liquid)-based molecularly imprinted polymer for multiple monolithic fiber solid-phase microextraction of phenolic acids in fruit juice and beer samples. Analyst. 2017;142(21):4039–47.

Liu YC, Liu YJ, Liu ZM, Hu XZ, Xu ZG. β-Cyclodextrin molecularly imprinted solid-phase microextraction coatings for selective recognition of polychlorophenols in water samples. Anal Bioanal Chem. 2018;410(2):509–19.

Li G, Row KH. Recent applications of molecularly imprinted polymers (MIPs) on micro-extraction techniques. Sep Purif Rev. 2018;47(1):1–18.

Shishov A, Bulatov A, Locatelli M, Carradori S, Andruch V. Application of deep eutectic solvents in analytical chemistry: a review. Microchem J. 2017;135:33–8.

Panhwar AH, Tuzen M, Kazi TG. Deep eutectic solvent based advance microextraction method for determination of aluminum in water and food samples: multivariate study. Talanta. 2018;178:588–93.

Sutton AT, Fraige K, Leme GM, Bolzani VS, Hilder EF, Cavalheiro AJ. Natural deep eutectic solvents as the major mobile phase components in high-performance liquid chromatography—searching for alternatives to organic solvents. Anal Bioanal Chem. 2018;410(16):3705–13.

Alhassan Y, Pali HS, Kumar N, Bugaje IM. Co-liquefaction of whole Jatropha curcas seed and glycerol using deep eutectic solvents as catalysts. Energy. 2017;138:48–59.

Liang S, Yan H, Cao J, Han Y, Shen S, Bai L. Molecularly imprinted phloroglucinol-formaldehyde-melamine resin prepared in a deep eutectic solvent for selective recognition of clorprenaline and bambuterol in urine. Anal Chim Acta. 2017;95:68–77.

Fu N, Li L, Liu X, Fu N, Zhang C, Hu L, et al. Specific recognition of polyphenols by molecularly imprinted polymers based on a ternary deep eutectic solvent. J Chromatogr A. 2017;1530:23–34.

Liu Y, Wang Y, Dai Q, Zhou Y. Magnetic deep eutectic solvents molecularly imprinted polymers for the selective recognition and separation of protein. Anal Chim Acta. 2016;936:168–78.

Xu K, Wang Y, Wei X, Chen J, Xu P, Zhou Y. Preparation of magnetic molecularly imprinted polymers based on a deep eutectic solvent as the functional monomer for specific recognition of lysozyme. Microchim Acta. 2018;185(2):146–53.

Díaz-de-Cerio E, Arráez-Román D, Segura-Carretero A, Ferranti P, Nicoletti R, Perrotta GM, et al. Establishment of pressurized-liquid extraction by response surface methodology approach coupled to HPLC-DAD-TOF-MS for the determination of phenolic compounds of myrtle leaves. Anal Bioanal Chem. 2018;410(15):3547–57.

Li G, Zhu T, Lei Y. Choline chloride-based deep eutectic solvents as additives for optimizing chromatographic behavior of caffeic acid. Korean J Chem Eng. 2015;32(10):2103–8.

Zeković Z, Vidović S, Vladić J, Radosavljević R, Cvejin A, Elgndi M, et al. Optimization of subcritical water extraction of antioxidants from Coriandrum sativum seeds by response surface methodology. J Supercrit Fluid. 2014;95:560–6.

Aybastıer Ö, Işık E, Şahin S, Demir C. Optimization of ultrasonic-assisted extraction of antioxidant compounds from blackberry leaves using response surface methodology. Ind Crop Prod. 2013;44:558–65.

Dmitrienko SG, Irkha VV, Duisebaeva TB, Mikhailik YV, Zolotov YA. Synthesis and study of the sorption properties of 4-hydroxybenzoic acid-imprinted polymers. J Anal Chem. 2006;61(1):14–9.

You QP, Peng MJ, Zhang YP, Guo JF, Shi SY. Preparation of magnetic dummy molecularly imprinted polymers for selective extraction and analysis of salicylic acid in Actinidia chinensis. Anal Bioanal Chem. 2014;406(3):831–9.

Klejdus B, Plaza M, Šnóblová M, LeaLojková L. Development of new efficient method for isolation of phenolics from sea algae prior to their rapid resolution liquid chromatographic–tandem mass spectrometric determination. J Pharmaceut Biomed. 2017;135:87–96.

Du Y, Wang Z, Wang L, Gao M, Wang L, Gan C, et al. Simultaneous determination of seven phenolic acids in rat plasma using UHPLC-ESI-MS/MS after oral administration of Echinacea purpurea extract. Molecules. 2017;22(9):1494–509.

Mattonai M, Parri E, Querci D, Degano L, Ribechini E. Development and validation of an HPLC-DAD and HPLC/ESI-MS2 method for the determination of polyphenols in monofloral honeys from Tuscany (Italy). Microchem J. 2016;126:220–9.

Funding

This study was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2015R1A4A1042434).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Electronic supplementary material

ESM 1

(PDF 967 kb)

Rights and permissions

About this article

Cite this article

Li, G., Row, K.H. Selective extraction of 3,4-dihydroxybenzoic acid in Ilex chinensis Sims by meticulous mini-solid-phase microextraction using ternary deep eutectic solvent-based molecularly imprinted polymers. Anal Bioanal Chem 410, 7849–7858 (2018). https://doi.org/10.1007/s00216-018-1406-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-018-1406-y