Abstract

Accurate detection of protein biomarkers in complex media remains a challenge due to severe nonspecific adsorption and biofouling, and sensing interfaces that combine the high sensitivity and antifouling ability are highly desirable. Herein, an antifouling sensing interface capable of sensitively assaying immunoglobulin E (IgE) in biological samples was constructed. The sensing interface was fabricated through the self-assembly of a zwitterionic peptide and the IgE aptamer onto a macroporous Au substrate, which was electrochemically fabricated with the aid of multilayer polystyrene nanospheres self-assembled on glassy carbon electrode. Due to the huge surface area arising from porous morphology and high specificity of aptamer, the developed electrochemical biosensor exhibits ultrahigh sensitivity and selectivity towards IgE, with the linear range of 0.1–10 pg mL−1, and a very low limit of detection down to 42 fg mL−1. Interestingly, owing to the presence of the zwitterionic peptide, the biosensing interface can satisfyingly reduce the nonspecific adsorption and fouling effect. Consequently, the biosensor was successfully applied to detect IgE in complex biological samples, indicating great promise of this peptide-based sensing interface for antifouling assays.

ᅟ

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Human immunoglobulin E (IgE), owning a short half-life and extremely low concentration in human serum (normally 50–500 ng mL−1), plays a very important role in allergic reactions and parasitic diseases [1, 2]. The elevated concentration of IgE has been demonstrated to be closely related to allergic reactions [3]. Therefore, the rapid and accurate detection of IgE via bioanalytical method is of great significance for the diagnosis of allergy [4, 5]. In principle, antibody-antigen complexes (enzyme-linked immunosorbent assay, ELISA) can be applied to the detection of IgE due to its specific binding to antigens [6]. However, conventional antibody (Ab)-based immunoassays are limited in complicated washing steps and employing reagents that are both temperature sensitive and expensive [7]. In contrast, aptamers are known to be chemically stable and easily synthesized, and aptamer-based sensors thus provide a number of advantages over Ab-based immunoassays including high stability against temperature and low cost [8, 9]. Consequently, extensive researches have been carried out using aptamer as recognition probes for the rational design of biosensors [10,11,12]. In the past few years, IgE aptamers have also been adopted to develop specific biosensors [13]. Nevertheless, the sensitivity of the sensors for IgE remains to be further improved, and the development of highly sensitive, specific, and facile sensing strategy for precise detection of IgE is still highly desirable.

Among various sensing strategies employed so far, the electrochemical sensing method is highly sensitive, simple to operate, and non-destructive with respect to the detection of target biomolecules [14,15,16]. Hence, electrochemical biosensors have been intensively investigated, and many efforts have been devoted into improving the sensitivity by employing advanced nanomaterials with superior physicochemical properties [17]. One of the most successful examples is that porous nanostructures were introduced onto the electrode surface to enlarge the specific surface area, thus to improve the sensitivity of the biosensors [18,19,20]. In fact, the three-dimensional (3D) nanoporous gold has become an attractive candidate for the construction of electrochemical biosensors, not only because of the efficiently increased surface area, but also due to the abundant sites for the immobilization of recognition probes, thus enhancing the capturing of the targets [21,22,23].

For real biological sample analysis, a considerable issue is that the nonspecific adsorption of serum proteins can severely influence the reliability and accuracy of the biosensor. Therefore, reducing the nonspecific adsorption on the sensing interface is essential for the practical application of biosensors, and numerous efforts have been devoted to solving this problem [24]. One efficient solution is to construct antifouling biosensing interfaces employing anti-nonspecific adsorption materials such as polyethylene glycol (PEG) [25,26,27], zwitterionic molecules [28], and peptide [29,30,31,32]. Due to its good biocompatibility and ease for design and synthesis, peptide has become a promising candidate material for anti-biofouling application [33, 34]. For example, it has been demonstrated that a designed peptide comprising alternating negatively charged glutamic acid (E) and positively charged lysine (K) residues shows satisfying performance in preventing nonspecific protein adsorptions [35]. Particularly, peptides with strong hydrophilicity and neutral charge behave well against biofouling [35, 36], as these properties help to prevent nonspecific protein adsorption through hydrophobic interaction and charge attraction, respectively.

Herein, we report an ultrasensitive and antifouling IgE aptasensor based on macroporous Au self-assembled with aptamer and zwitterionic peptide. The macroporous Au nanostructure was electrochemically deposited onto the electrode surface with the aid of multilayer polystyrene nanospheres self-assembled onto glassy carbon electrode. Then, the aptamer and peptide were self-assembled separately onto the surface via the Au–S bonding. Owing to the large surface area of the macroporous Au and the high bioaffinity of the aptamer, the electrochemical aptasensor is highly sensitive towards IgE. Moreover, the aptasensor is capable of sensing target in complex biological samples without significant fouling effect, thanks to the presence of zwitterionic peptide on the biosensing interface.

Materials and methods

Chemicals and apparatus

Chloroauric acid, chloroform, and monodisperse amine-modified polystyrene (PS, diameter ~ 0.25 μm, 2.5% w/v) nanospheres were purchased from Aladdin Reagents (Shanghai, China, http://www.aladdin-e.com/). Human serum albumin (HSA), immunoglobulin G (IgG), and lysozyme (Lyz) were purchased from Taitan Sci. Co. Ltd. (Shanghai, China, http://www.tansoole.com/). Fetal bovine serum (FBS) was purchased from Tianhang Biotechnology Co., Ltd. (Zhejiang, China, http://hzsjq.cnbio.net/). IgE aptamer (5′SH-GGGGCACGTTTATCCGTCCCTCCTAGTGGCGTGCCCC3′), DNA sequence 5′GAACAAAAGGAAGAAAATC3′, and the peptide with the sequence of EKEKEKE-PPPPC were synthesized and purified from Sangon Biotech Co., Ltd. (Shanghai, China, http://www.sangon.com/), with the confirmation report of HPLC, mass spectra, or PCR. Phosphate-buffered saline (PBS, 0.2 M, pH 7.4) was used to prepare stock solutions of oligonucleotides and peptide in all related experiments. All other reagents used were of analytical grade. All solutions used for experiments were prepared with ultrapure water produced from the Milli-Q purification system.

All electrochemical measurements were performed on a CHI660E electrochemical workstation (Shanghai CH Instruments Co., Ltd., China, http://www.chinstr.com/). A conventional three-electrode system was applied with a platinum wire as the counter electrode, a saturated calomel electrode (SCE) as the reference electrode, and a bare or modified glassy carbon electrode (GCE, diameter 3.0 mm) as the working electrode. Scanning electron microscopy (SEM) was performed to characterize the nanostructures and morphologies of the modified materials by a JEOL JSM-7500F SEM instrument (JEOL, Ltd., https://www.jeol.co.jp/en/). X-ray photoelectron spectroscopy (XPS) analysis was performed on glassy carbon piece using an AXIS Ultra spectrometer, with a high-performance Al monochromatic source operated at 15 kV. Static water contact angle tests were carried out with the JC2000 Instrument (Shanghai Zhongchen Instrument Co., Ltd., China, http://www.powereach.com/) to determine the hydrophilicity of various surfaces.

Cyclic voltammogram (CV) and differential pulse voltammetry (DPV) of the bare electrode and the modified electrodes were recorded in PBS (0.2 M, pH 7.4, if not otherwise stated) containing 5.0 mM redox probe [Fe(CN)6]3−/4− and 0.1 M KCl. CV conditions are scanning range from − 1.2 to 1.2 V with scan rate of 0.10 V/s. Electrochemical impedance spectroscopy (EIS) measurements were conducted in PBS (0.2 M, pH 7.4) with a frequency range of 1 to 100,000 Hz, a waveform magnitude of 5.0 mV, and the current potential of 0.20 V.

Preparation of the porous Au-modified electrode

The process of preparing the macroporous Au and the biosensor is shown in Scheme 1. Firstly, PS nanospheres were assembled onto the GCE surface by the vertical deposition technique according to our previous report [23]. The detailed procedure can be found in the Electronic Supplementary Material (ESM). Secondly, Au was deposited into the interstitial spaces of PS nanospheres by electrodeposition from a solution of 0.01 M chloroauric acid, using an amperometric i-t method with the applied potential of − 0.1 V for 200 s. The deposition time was optimized to achieve the best electrochemical response as shown in Fig. S1 (see ESM). Thirdly, the electrode modified with a nanocomposite film of Au and PS nanosphere was rinsed with alcohol, dried with a flow of nitrogen stream, and soaked in chloroform for 3 h to remove the PS templates. As a result, the electrode surface modified with macroporous Au film was obtained, and the macroporous Au/GCE was thoroughly rinsed with ethanol and water.

Preparation of the sensing interface

To immobilize the IgE-specific aptamer and peptide onto the electrode surface, the self-assembly strategy was used as shown in Scheme 1. Firstly, the fabricated porous Au/GCE was immersed into 0.2 μM of IgE aptamer solution and kept incubated for 12 h at room temperature to self-assemble the aptamer. The sequence of the aptamer for specific binding with IgE was adopted according to literature [5]. Secondly, the modified electrode was immersed into a 0.2 mg mL−1 of peptide solution and kept incubated for 12 h at room temperature to immobilize the peptide, serving as the antifouling layer on Au substrate. As a result, the antifouling aptasensor was obtained.

Characterization of the antifouling ability

To assess the antifouling performance of the peptide-based biosensing interface, different dilution ratios of FBS were used. FBS was diluted with PBS (10 mM, pH 7.4) to different dilution ratios (V/V) of 1, 2, and 5%. The EIS responses of modified electrodes before and after incubation in serum for 30 min (followed by washing with PBS and water) were recorded in PBS (0.2 M, pH 7.4) containing 5.0 mM redox probe [Fe(CN)6]3−/4− and 0.1 M KCl.

Detection of target protein IgE

The prepared aptasensor was incubated in PBS containing different concentrations of target protein IgE for 30 min at room temperature. The DPV signals of the sensor before and after target binding were measured in PBS (0.2 M, pH 7.4) containing 5.0 mM redox probe [Fe(CN)6]3−/4− and 0.1 M KCl. To investigate the specificity of the assay, other biomolecules such as DNA, HSA, IgG, and Lyz were used as possible interferents.

Results and discussion

Characterization of the modified electrode

Morphology of the porous Au/GCE

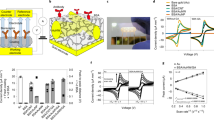

The morphologies of the PS template and porous Au-modified electrode surfaces were characterized by SEM. As shown in Fig. 1a, the PS nanospheres are rather monodisperse with an average diameter of around 250 nm and closely packed on the electrode surface. In addition, the PS nanospheres are multilayer as shown in Fig. 1b. The uniformly compact PS template is essential for the following preparation of a well-ordered porous Au film. The Au film was deposited into the interstitial spaces of PS spheres on the electrode surface by the electrochemical reduction of chloroauric acid, and then the PS nanospheres were removed by immersing the electrode in chloroform. Typical SEM image of the resulting porous Au film is shown in Fig. 1c. Clearly, the macroporous Au was formed on the electrode surface, with relatively uniform pores with diameters of 200–300 nm. Such a nanostructure can not only offer large specific surface area for the construction of a sensitive electrochemical biosensing interface, but also provide a reliable Au substrate for subsequent conjugation of biomolecules.

Electrochemical characterization of the biosensor fabrication process

CV and DPV are effective methods to investigate the interface properties of modified electrodes. To characterize the stepwise fabrication of the biosensor, CV and DPV of the bare GCE and different modified electrodes were recorded and are shown in Fig. 2A, B, respectively. As shown in curve (a), the bare GCE shows a pair of well-defined redox peaks with the peak potentials centered at 0.15 and 0.25 V, respectively, because of the presence of electrochemical redox probe [Fe(CN)6]3−/4−. An obvious decrease (nearly 94%) of peak current was observed for PS/GCE (curve b) after PS nanospheres were modified onto the electrode surface, as the non-conductive PS nanospheres can block the electron transfer between the [Fe(CN)6]3−/4− probe and the electrode surface. As expected, the peak current of Au/PS/GCE (curve c) increases after Au was electrodeposited onto the interspace of the PS nanospheres. After the non-conductive PS nanospheres were removed, the porous Au/GCE (curve d) presents a six times larger peak current. Subsequently, the aptamer terminated with a thiol group was modified onto the Au surface via the Au–S bonding. The resulting aptamer/porous Au/GCE (curve e) shows a drastic decrease (about 27%) of the peak current, because the aptamer significantly prevents the electron transfer between the redox probe and the electrode surface. The zwitterionic peptide containing cysteine, which is rich in thiol group, was further assembled onto the macroporous Au surface via Au–S bonding, and the peptide/aptamer/porous Au/GCE (curve f) exhibits further decrease of the peak current as expected. The consistent CV and DPV results demonstrate that the peptide/aptamer/porous Au-modified electrode was successfully fabricated. Furthermore, XPS was used to characterize the surface modification process. As shown in Fig. S2 (see ESM), the existence of Au4f (84 and 88 eV) and Au4d (335 and 353 eV) demonstrates the successful deposition of Au film. After aptamer immobilization, two characteristic peaks appear, i.e., 134 and 169 eV, ascribed to phosphorus 2p (P2p) and sulfur 2p (S2p) from aptamer. Further assembly of the peptide enhances the signal intensity of S2p, demonstrating the successful modification of peptide onto the substrate. On the contrary, the P2p signal slightly reduces after covering the peptide because there is no P element in the peptide. Moreover, the Au signals gradually decrease as growing the modifiers, revealing the successive cover of aptamer and peptide. To verify the reproducibility of the preparation process, the electrochemical responses of five independently prepared biosensors were recorded and shown in Fig. S3 (see ESM). The small relative standard deviation (RSD) value of 2.9% strongly demonstrates the reliability of the preparation method.

Hydrophilic property of the modified interface

The water contact angle is commonly used to characterize the surface wettability. Figure 3 shows the change of water contact angle along with the electrode surface modification. The water contact angle of the porous Au electrode surface (about 82.0°, Fig. 3b) is larger than that of the bare GCE (about 63.5°, Fig. 3a), indicating poor wettability of the macroporous Au surface, because of many pores with the diameter not suitable for water filling [37]. As shown in Fig. 3c, the surface modified with aptamer shows a decreased contact angle of 60.2° due to the hydrophilicity of the aptamer chain backbone. Further assembly of peptide onto the electrode surface resulted in a contact angle of 35.8° (Fig. 3d), demonstrating a remarkably improved hydrophilicity due to the zwitterionic structure of the peptide carrying abundant amino (-NH2) and carboxyl (-COOH) groups. This high hydrophilicity meanwhile improves the antifouling ability of the biosensor, as the hydrophilic surface can prevent the nonspecific protein adsorption through the steric repulsion of hydration shell.

Antifouling property of the sensing interface

EIS has been proven to be one of the most powerful tools for interfacial investigation, and the electron transfer resistance (Rct) is a directive and sensitive parameter that responds to the change of the electrode interface, including the nonspecific adsorption on the electrode surface. The zwitterionic peptide with the sequence of EKEKEKE-PPPPC, possessing excellent hydrophilicity and nearly neutral charge, was selected as the antifouling material according to previous report in which the sequence has been demonstrated to show ultra-low fouling to protein adsorption with small variation compared with other sequences [35]. Particularly, the -PPPPC linker can provide a well-defined secondary structure needed to promote closely packed monolayers with ultra-low fouling property. In order to assess the antifouling ability of the biosensor, contrast experiments were conducted with electrodes modified with and without peptide. After incubation in 0, 1, 2, and 5% FBS, nearly no EIS change was observed for the peptide-modified electrode, as shown in Fig. 4b. While for the control experiments of the electrode without peptide, Rct shows a continuous increment along with the increase of FBS concentration (Fig. 4a), by 103.0, 131.1, and 181.6% compared with that of the sensor in absence of FBS. The noticeable resistance increment was caused by the nonspecific protein adsorption. This result indicates that the constructed biosensor with the zwitterionic peptide possesses satisfying antifouling ability.

Biosensing performance

To assess the sensing performance of the prepared biosensor, DPV was employed to record the signal responses in 5.0 mM [Fe(CN)6]3−/4−. As shown in Fig. 5a, the peak current of the biosensor decreases along with the increased concentration of IgE, owing to the specific binding of the aptamer and the target protein IgE. The DPV response change (-ΔIp/Ip0) behaves as a good linear correlation (R2 = 0.997) with the logarithmic value of IgE concentration, as shown in Fig. 5b, and the linear range lies between 0.1 and 10 pg mL−1. The limit of detection (LOD) was calculated to be 42 fg mL−1 (S/N = 3), which is much lower than that of previous reports, as summarized in Table S1 (see ESM). The ultrasensitive performance of the fabricated biosensor is mainly attributed to the large surface area of the macroporous Au and the excellent antifouling property of the peptide, as well as the high bioaffinity of the aptamer to IgE. For clarifying the advantage of the macroporous structure of the Au substrate, the sensing performances of the electrode without modification of macroporous Au were investigated as contrast. As shown in Fig. S4 (see ESM), the biosensor without porous Au film always shows less DPV response changes towards IgE in a concentration range of 0.5–5.0 pg/mL compared with the sensor with porous Au, manifesting the macroporous structure indeed enhances the sensing performance.

a DPV curves of the aptasensor after incubation in different concentrations of IgE in PBS (0.2 M, pH 7.4). b The DPV response changes [-△Ip/Ip0 (%)] of the aptasensor as a function of IgE concentration. The inset shows the corresponding calibration curve. Error bars represent the standard deviations across three repeated measurements

To assess the reproducibility of the aptasensor, the same sensor was employed to detect 5.0 pg/mL IgE for three reduplicate measurements, and the resulting electrochemical responses are shown in Fig. S5 (see ESM). The small RSD value of 1.1% indicates the excellent reproducibility of the aptasensor.

To evaluate the selectivity of the developed biosensor towards IgE, the response of the biosensor was tested in different solutions containing HSA, DNA, and Lyz separately. IgG, structurally similar to IgE, was also selected as a possible interfering protein to test the specificity of the biosensor. As shown in Fig. 6, the relative responses of the biosensor to other biomolecules with 100 times higher concentration are negligible, in comparison to those of the biosensor response to IgE. The low aptamer cross-reactivity towards HSA, DNA, Lyz, and even structurally similar IgG assures the excellent selectivity of the biosensor towards IgE. This can be ascribed to the high specificity of the aptamer and the antifouling ability of the peptide which can effectively prevent the nonspecific adsorption onto the sensing interface. This result demonstrates that the current biosensor is favorable for the accurate detection of IgE in complicated biological samples.

In order to investigate the accuracy of the biosensor in real samples, different concentrations of IgE were added into 5% (V/V) bovine serum solutions and then measured with the prepared biosensor. The results are listed in Table S2 (see ESM), and the results show satisfying recoveries of IgE (vary from 97.83 to 101.18%), with the RSD between 1.2 and 5.2%. This further reveals the low cross-reactivity of the aptasensor for IgE even in FBS, indicating that the antifouling aptasensor has a promising potential for practical applications.

Conclusion

An ultrasensitive and specific electrochemical biosensor based on macroporous Au and zwitterionic peptide for IgE detection was developed. The macroporous Au film can greatly increase the specific surface area and thus improve the sensitivity of the biosensor. The selected aptamer well ensures the high selectivity of the biosensor towards IgE. Furthermore, the presence of the zwitterionic peptide on the biosensing interface exhibits satisfying antifouling ability, which enables the designed biosensor to achieve accurate detection of targets within complex biological samples. Notably, the fabricated biosensor shows ultrahigh sensitivity for the detection of IgE with the LOD of 42 fg mL−1, and it is capable of sensing target in 5% serum without significant biofouling. The current investigation has provided an effective and reliable approach to construct sensitive and specific antifouling biosensors, especially for the detection of biomarkers in complex biological samples.

References

Chen H-X, Busnel J-M, Peltre G, Zhang X-X, Girault HH. Magnetic beads based immunoaffinity capillary electrophoresis of total serum IgE with laser-induced fluorescence detection. Anal Chem. 2008;80:9583–8.

Proczek G, Gassner A-L, Busnel J-M, Girault HH. Total serum IgE quantification by microfluidic ELISA using magnetic beads. Anal Bioanal Chem. 2012;402:2645–53.

Mansouri M, Pourpak Z, Mozafari H, Gorji FA, Shoormasti RS. Follow-up of the wheat allergy in children; consequences and outgrowing the allergy. Iran J Allergy Asthma Immunol. 2012;11:157–63.

Gould HJ, Sutton BJ. IgE in allergy and asthma today. Nat Rev Immunol. 2008;8:205–17.

Jiang B, Li F, Yang C, Xie J, Xiang Y, Yuan R. Aptamer pseudoknot-functionalized electronic sensor for reagentless and single-step detection of immunoglobulin E in human serum. Anal Chem. 2015;87:3094–8.

Kirsch S, Fourdrilis S, Dobson R, Scippo M-L, Maghuin-Rogister G, De Pauw E. Quantitative methods for food allergens: a review. Anal Bioanal Chem. 2009;395:57–67.

Vojdani A. Detection of IgE, IgG, IgA and IgM antibodies against raw and processed food antigens. Nutr Metab. 2009;6:22.

Ellington AD, Szostak JW. In vitro selection of RNA molecules that bind specific ligands. Nature. 1990;346:818–22.

Hasanzadeh M, Shadjou N, de la Guardia M. Aptamer-based assay of biomolecules: recent advances in electro-analytical approach. TrAC Trends in Anal Chem. 2017;89:119–32.

Liu Y, Tuleouva N, Ramanculov E, Revzin A. Aptamer-based electrochemical biosensor for interferon gamma detection. Anal Chem. 2010;82:8131–6.

Willner I, Zayats M. Electronic aptamer-based sensors. Angew Chem Int Edit. 2007;46:6408–18.

Zhao W, Chiuman W, Lam JCF, McManus SA, Chen W, Cui Y, et al. DNA aptamer folding on gold nanoparticles: from colloid chemistry to biosensors. J Am Chem Soc. 2008;130:3610–8.

Alonso MC, Trapiella-Alfonso L, Fernández JMC, Pereiro R, Sanz-Medel A. Functionalized gold nanoclusters as fluorescent labels for immunoassays: application to human serum immunoglobulin E determination. Biosens Bioelectron. 2016;77:1055–61.

Labib M, Sargent EH, Kelley SO. Electrochemical methods for the analysis of clinically relevant biomolecules. Chem Rev. 2016;116:9001–90.

Meng F, Liang W, Sun H, Wu L, Gong X, Miao P. A peptide-based electrochemical biosensor for facile measurement of whole-blood heparin. Chem Electro Chem. 2017;4:472–5.

Liu T, Yin J, Wang Y, Miao P. Construction of a specific binding peptide based electrochemical approach for sensitive detection of Zn2+. J Electroanal Chem. 2016;783:304–7.

Hu P, Chen L, Kang X, Chen S. Surface functionalization of metal nanoparticles by conjugated metal–ligand interfacial bonds: impacts on intraparticle charge transfer. Accounts Chem Res. 2016;49:2251–60.

Sun D, Lu J, Zhong Y, Yu Y, Wang Y, Zhang B, et al. Sensitive electrochemical aptamer cytosensor for highly specific detection of cancer cells based on the hybrid nanoelectrocatalysts and enzyme for signal amplification. Biosens Bioelectron. 2016;75:301–7.

Zhao F, Xie Q, Xu M, Wang S, Zhou J, Liu F. RNA aptamer based electrochemical biosensor for sensitive and selective detection of cAMP. Biosens Bioelectron. 2015;66:238–43.

Sun X, Hui N, Luo X. Reagentless and label-free voltammetric immunosensor for carcinoembryonic antigen based on polyaniline nanowires grown on porous conducting polymer composite. Microchim Acta. 2017;184:889–96.

Zhang Q-L, Wang A-J, Meng Z-Y, Lu Y-H, Lin H-J, Feng J-J. A study on the direct electrochemistry and electrocatalysis of microperoxidase-11 immobilized on a porous network-like gold film: sensing of hydrogen peroxide. Microchim Acta. 2013;180:581–7.

Patel J, Radhakrishnan L, Zhao B, Uppalapati B, Daniels RC, Ward KR, et al. Electrochemical properties of nanostructured porous gold electrodes in biofouling solutions. Anal Chem. 2013;85:11610–8.

Liu S, Ma Y, Zhang R, Luo X. Three-dimensional nanoporous conducting polymer poly(3,4-ethylenedioxythiophene) (PEDOT) decorated with copper nanoparticles: electrochemical preparation and enhanced nonenzymatic glucose sensing. ChemElectroChem. 2016;3:1799–804.

Blaszykowski C, Sheikh S, Thompson M. Surface chemistry to minimize fouling from blood-based fluids. Chem Soc Rev. 2012;41:5599–612.

Hui N, Sun X, Niu S, Luo X. PEGylated polyaniline nanofibers: antifouling and conducting biomaterial for electrochemical DNA sensing. ACS Appl Mater Inter. 2017;9:2914–23.

Luo X, Xu Q, James T, Davis JJ. Redox and label-free array detection of protein markers in human serum. Anal Chem. 2014;86:5553–8.

Vaisocherová H, Brynda E, Homola J. Functionalizable low-fouling coatings for label-free biosensing in complex biological media: advances and applications. Anal Bioanal Chem. 2015;407:3927–53.

Luo X, Xu M, Freeman C, James T, Davis JJ. Ultrasensitive label free electrical detection of insulin in neat blood serum. Anal Chem. 2013;85:4129–34.

Cui M, Wang Y, Jiao M, Jayachandran S, Wu Y, Fan X, et al. Mixed self-assembled aptamer and newly designed zwitterionic peptide as antifouling biosensing interface for electrochemical detection of alpha-fetoprotein. ACS Sensors. 2017;2:490–4.

Ladd J, Zhang Z, Chen S, Hower JC, Jiang S. Zwitterionic polymers exhibiting high resistance to nonspecific protein adsorption from human serum and plasma. Biomacromolecules. 2008;9:1357–61.

Rana D, Matsuura T. Surface modifications for antifouling membranes. Chem Rev. 2010;110:2448–71.

Wang G, Han R, Su X, Li Y, Xu G, Luo X. Zwitterionic peptide anchored to conducting polymer PEDOT for the development of antifouling and ultrasensitive electrochemical DNA sensor. Biosens Bioelectron. 2017;92:396–401.

Feyzizarnagh H, Yoon D-Y, Goltz M, Kim D-S. Peptide nanostructures in biomedical technology. WIREs Nanomed Nanobiotechnol. 2016;8:730–43.

Goda T, Tabata M, Sanjoh M, Uchimura M, Iwasaki Y, Miyahara Y. Thiolated 2-methacryloyloxyethyl phosphorylcholine for an antifouling biosensor platform. Chem Commun. 2013;49:8683–5.

Nowinski AK, Sun F, White AD, Keefe AJ, Jiang S. Sequence, structure, and function of peptide self-assembled monolayers. J Am Chem Soc. 2012;134:6000–5.

Chelmowski R, Köster SD, Kerstan A, Prekelt A, Grunwald C, Winkler T, et al. Peptide-based SAMs that resist the adsorption of proteins. J Am Chem Soc. 2008;130:14952–3.

Adamson K, Spain E, Prendergast U, Moran N, Forster RJ, Keyes TE. Peptide-mediated platelet capture at gold micropore arrays. ACS Appl Mater Inter. 2016;8:32189–201.

Funding

This research was supported by the Natural Science Foundation of Shandong Province of China (ZR2017BB009), the National Natural Science Foundation of China (21422504, 21675093), and the Taishan Scholar Program of Shandong Province of China (ts20110829).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Electronic supplementary material

ESM 1

(PDF 873 kb)

Rights and permissions

About this article

Cite this article

Wang, Y., Cui, M., Jiao, M. et al. Antifouling and ultrasensitive biosensing interface based on self-assembled peptide and aptamer on macroporous gold for electrochemical detection of immunoglobulin E in serum. Anal Bioanal Chem 410, 5871–5878 (2018). https://doi.org/10.1007/s00216-018-1201-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-018-1201-9