Abstract

The fiber coating is the key part of the solid-phase microextraction (SPME) technique, and it determines the sensitivity, selectivity, and repeatability of the analytical method. In this work, amine (NH2)-functionalized material of Institute Lavoisier (MIL)-53(Al) nanoparticles were successfully synthesized, characterized, and applied as the SPME fiber coating for efficient sample pretreatment owing to their unique structures and excellent adsorption properties. Under optimized conditions, the NH2-MIL-53(Al)-coated fiber showed good precision, low limits of detection (LODs) [0.025–0.83 ng L-1 for synthetic musks (SMs) and 0.051–0.97 ng L-1 for organochlorine pesticides (OCPs)], and good linearity. Experimental results showed that the NH2-MIL-53(Al) SPME coating was solvent resistant and thermostable. In addition, the extraction efficiencies of the NH2-MIL-53(Al) coating for SMs and OCPs were higher than those of commercially available SPME fiber coatings such as polydimethylsiloxane, polydimethylsiloxane–divinylbenzene, and polyacrylate. The reasons may be that the analytes are adsorbed on NH2-MIL-53(Al) primarily through π–π interactions, electron donor–electron acceptor interactions, and hydrogen bonds between the analytes and organic linkers of the material. Direct immersion (DI) SPME–gas chromatography–mass spectrometry methods based on NH2-MIL-53(Al) were successfully applied for the analysis of tap and river water samples. The recoveries were 80.3–115% for SMs and 77.4–117% for OCPs. These results indicate that the NH2-MIL-53(Al) coating may be a promising alternative to SPME coatings for the enrichment of SMs and OCPs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Since its invention by Arthur and Pawliszyn [1] in the early 1990s, solid-phase microextraction (SPME) has been widely accepted and applied in different fields, such as food analysis [2], environmental analysis [3], forensic analysis [4], drug monitoring [5], and in vivo sampling [6]. The coating material of the SPME fiber is the key factor that affects the sensitivity, selectivity, and reproducibility of the technique. However, commercial fibers are expensive and are limited in the available types. Increasing research work has been focused on the development of coating materials [7, 8], including ionic liquids [9], carbonaceous materials [10], molecularly imprinted polymers and so on [11].

Metal–organic frameworks (MOFs), crystalline solids combining metal ions with organic linkers resulting in a highly porous framework, are emerging as a new family of molecular sieve materials [12]. They have versatile applications in gas separation and storage, drug delivery, and catalysis [13,14,15]. In addition, their unique properties, including uniform adjustable pore sizes, high surface areas, and specific adsorption affinities, make MOFs attractive for assembly as superior adsorbents for sample pretreatment and chromatographic separation [16, 17]. Moreover, a few MOF materials have been fabricated as SPME fiber coatings for versatile analyte analysis [18]. Among the various MOFs, material of Institute Lavoisier (MIL)-53(M) (M is Fe, Al, or Cr) is of special interest. MIL-53(Al) is built of infinite chains of octahedrons formed by coordination of Al(III) by terephthalate and OH groups with pore walls consisting mainly of aromatic rings [19]. The structure of MIL-53(Al) has remarkable flexibility, adjusting its cell volume in a reversible manner to optimize interactions between the guest molecules and the framework. On the basis of these merits, this MOF material and its derivates have been intensively investigated, including for use in liquid–liquid separation, gas sorption, thin film growth, and drug delivery [20, 21]. Besides, Chen et al. [22] have used MIL-53(Al, Cr, Fe) materials as the SPME fiber coating by an adhesive method and reported that the coating showed the highest extraction efficiency toward polycyclic aromatic hydrocarbons. Some research has demonstrated that functionalization of the MIL-53(Al) MOF with amino groups increases its selectivity in CO2/CH4 separations by orders of magnitude while a very high capacity for CO2 capture is maintained [23]. Very recently, a monolithic column based on amine (NH2)-functionalized MIL-53(Al) was prepared and efficiently applied to in-tube SPME for online coupling with high-performance liquid chromatography to the direct determination of five estrogens in human urine samples [24]. Thus, NH2-MIL-53(Al) may be a good choice for use as a coating material for the SPME fiber. To our knowledge, NH2-MIL-53(Al) has not been used as SPME fiber coating material.

Synthetic musks (SMs) are widely used as fragrances in a range of personal care products, and mainly comprise three categories: nitro musks, polycyclic musks, and macrocyclic musks [25, 26]. SMs have gained increasing interest in recent years because of their huge consumption, low rates of biological and chemical degradation, and potentially harmful concentrations in the air and aqueous environment [27, 28]. Organochlorine pesticides (OCPs) are a type of chlorinated hydrocarbons previously widely used to kill insects in the planting of farm crops [29]. Because of their high persistence, OCPs can still be found in the environment. Considering that SMs and OCPs are usually found in samples at very low concentrations, their direct determination is not feasible, and extraction steps, typically involving preconcentration of the analytes, are applied to achieve adequate sensitivity. Because of their inherent physicochemical properties, they can be easily analyzed by gas chromatography (GC), and methods based on GC coupled with mass spectrometry (MS) are the main approaches for the identification and quantification of these compounds [30, 31]. In this work, we applied NH2-MIL-53(Al) to fabricate an SPME fiber for the determination of five SMs and eight OCPs in environmental water samples by GC–MS.

Experimental

Chemicals and reagents

Aluminum nitrate nonahydrate (Aladdin Industrial, Shanghai, China) and 2-aminoterephthalic acid (Aladdin Industrial, Shanghai, China) were used to prepare NH2-MIL-53(Al). N,N-Dimethylformamide, methanol, anhydrous ethanol, acetone, sodium hydroxide, and concentrated hydrochloric acid of analytical grade were purchased from Guangzhou Chemical Reagent Company (Guangzhou, China). Methanol of high-performance liquid chromatography grade was purchased from Sigma-Aldrich (USA). Sikasil-C neutral multifunctional silicone sealant was purchased from Shanghai Cheng Shen Decoration Material Company (Shanghai, China). Ultrapure water was obtained from a water purification system (Millipore, Billerica, MA, USA).

Muscone, musk xylene, 6-acetyl-1,1,2,4,4,7-hexamethyltetralin (tonalide), and musk ketone were purchased from Dr. Ehrenstorfer (Augsburg, Germany). 1,3,4,6,7,8-Hexahydro-4,6,6,7,8,8,-hexamethylcyclopenta[g]benzopyran (galaxolide) was obtained from Toronto Research Chemicals (North York, ON, Canada). Hexachlorobenzene, heptachlor, aldrin, trans-chlordane, cis-chlordane, endrin, o,p′-DDT, and p,p′-DDT were purchased from Dr. Ehrenstorfer (Augsburg, Germany).

Instruments

Scanning electron microscopy (SEM) images were obtained with a Quanta 400 thermal field emission environmental scanning electron microscope (FEI, Eindhoven, Netherlands). The surface images of the NH2-MIL-53(Al) coating were obtained at 20 kV. Transmission electron microscopy images were obtained with a JEM-2010HR transmission electron microscope (JEOL, Tokyo, Japan). Powder X-ray diffraction peaks were obtained with a Bruker D8 ADVANCE X-ray powder diffractometer (Cu Kα). Thermal stability was evaluated with a thermogravimetric analyzer (model 209, Netzsch, Selb, Germany) from room temperature to 800 °C at a rate of 10 °C min-1 under N2.

A GC–MS system (6890 N gas chromatograph and 5975 mass spectrometer) from Agilent Technologies (Palo Alto, CA, USA) was used for all the experiments. The gas chromatograph was equipped with an Agilent Technologies HP-5 ms capillary column (30 m × 0.32-mm inner diameter, 0.25-μm film thickness). Helium (99.999%) was used as the carrier gas, and the gas flow rate was 1.2 mL min-1 in constant flow mode. The temperature of the transfer line was maintained at 300 °C, and the mass spectrometer ion source and quadrupole temperatures were 230 and 150 °C respectively. The mass spectrometer was operated with an electron ionization source (electron energy of 70 eV), and the mass-to-charge ratio scanned ranged from 50 to 500 to determine appropriate masses for selected-ion monitoring (Table S1). All SPME procedures were conducted with an MPS 2 multipurpose autosampler (Gerstel, Mülheim an der Ruhr, Germany).

Commercial polydimethylsiloxane (PDMS; 30 and 100 μm), polyacrylate (PA; 85 μm), and PDMS–divinylbenzene (DVB; 65 μm) SPME fibers were obtained from Supelco (Bellefonte, PA, USA), and stainless steel wire was bought from Small Parts (Miami, FL, USA).

Preparation of NH2-MIL-53(Al)-coated fiber

NH2-MIL-53(Al) was prepared following the synthesis procedure reported by Couck et al. [23]. Aluminum nitrate nonahydrate (0.878 g, 2.10 mmol) and 2-amino-1,4-benzenedicarboxylic acid (0.564 g, 3.12 mmol) were dissolved in 30 mL N,N-dimethylformamide, after which the solution was transferred in a Teflon insert and placed in an autoclave. The autoclave was heated in an oven at 130 °C for 3 days. The yellow gel product was filtered off and washed with acetone. After removal of the acetone under reduced pressure, the product was washed overnight with methanol under reflux and dried at 110 °C under a vacuum for 10 h.

The fabrication of the NH2-MIL-53(Al)-coated SPME fiber is similar to that in our previous work [32], just by a simple direct layer-by-layer coating method. The fiber coating is robust and stable, and has a thickness of approximately 30 μm, obtained by approximately three dipping cycles. Before use, 1 cm of coating is left and the other coating is scratched off. After that, the coated wire is inserted into the inside needle of the fiber assembly for use.

Preparation of sample solutions

The stock solutions for two types of analytes, SMs and OCPs, were individually prepared in methanol and a mixed solvent (100: 1 v/v n-hexane–isopropyl alcohol) at a concentration of 1 mg mL-1 for each of the analytes and stored in the dark at 4 °C for further use. The working standard solutions were prepared weekly by dilution of the standard solution with methanol, and more dilute working solutions were prepared daily by dilution of this standard solution with pure water.

SPME procedure and GC analysis

The SPME procedures were based on procedures presented in two articles [33, 34]. Before use, the prepared fiber was conditioned at 250 °C for 60 min in the gas chromatograph injection port under a N2 atmosphere to avoid any contamination or carryover. Sample solutions were prepared by dilution of working standard solutions with pure water. The extraction was conducted with an MPS 2 multipurpose autosampler with the use of 10-mL glass vials. DI-SPME parameters such as the extraction or desorption temperature and time were optimized with use of the MPS 2 autosampler. After a certain extraction time, the fiber was directly transferred into the gas chromatograph injector for desorption and analysis.

For the SMs, the column temperature program was as follows: the initial oven temperature of 100 °C (held for 1 min) was increased to 180 °C at a rate of 10 °C min-1 (held for 2 min), then raised to 190 °C at 2 °C min-1 (held for 2 min), and finally ramped to 250 °C at 30 °C min-1 (held for 3 min). The total run time was 23 min. The gas chromatograph injector port temperature was 280 °C in splitless mode. The gas chromatograph column temperature program for the OCPs was as follows: the initial oven temperature of 60 °C (held for 1 min) was increased to 180 °C (held for 1 min) at a rate of 10 °C min-1, then raised to 250 °C at 10 °C min-1 (held for 2 min), and finally ramped to 280 °C at 10 °C min-1 (held for 1 min). The total run time was 32 min. The gas chromatograph injector port temperature was 270 °C in splitless mode.

Real water samples

The water samples were freshly collected from the Pearl River and the tap water samples were from Sun Yat-sen University in Guangzhou, and they were stored at room temperature before use.

Results and discussion

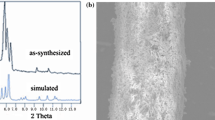

Characterization of NH2-MIL-53(Al)

A Bruker D8 ADVANCE X-ray powder diffractometer (Cu Kα) was used to confirm the structure of synthesized NH2-MIL-53(Al). The powder X-ray diffraction patterns in the 2θ range from 5° to 40° are shown in Fig. S1. The peaks of NH2-MIL-53(Al) totally corresponded with those reported by Couck et al. [23], which indicated that NH2-MIL-53(Al) had been successfully synthesized. Elemental analysis of NH2-MIL-53(Al) powder (Table S2) revealed the presence of nitrogen. NH2-MIL-53(Al) particles are small crystals with sizes on the nanoscale (see Fig. S2). Figure S3 shows the N2 adsorption–desorption isotherms of NH2-MIL-53(Al), indicating a pore volume of 1.36 mL g-1 and a specific Brunauer–Emmett–Teller surface area of 1025.8 m2 g-1.

Morphological structure of NH2-MIL-53(Al) coating

The NH2-MIL-53(Al)-coated fiber was fabricated by our sequentially coating the stainless steel wire with silicone sealant film and mesoporous NH2-MIL-53(Al) powder. Different numbers of coating layers may affect the extraction efficiencies for the target analytes, and we finally chose three coating layers for the proposed fiber. Figure 1 shows the SEM images of the NH2-MIL-53(Al) coating. Figure 1a shows that the fiber possessed a homogeneous surface and a coating thickness of nearly 30 μm, whereas the high-magnification SEM images in Fig. 1b–d show that the fiber’s surface was covered with well-distributed particles, which was beneficial for the extraction performance. Besides, according to Fig. 1, the coating tightly adhered to the stainless steel wire and the NH2-MIL-53(Al) particles had been linked together layer-by-layer, strongly avoiding peeling off.

Thermal and chemical stability of NH2-MIL-53(Al)-coated fiber

The thermogravimetric analysis profile is shown in Fig. 2. The results indicated that NH2-MIL-53(Al) powder is stable up to 450 °C, with weight loss of less than 10%. The high thermostability makes NH2-MIL-53(Al) a favorable material for preparing an SPME fiber coating. Besides, the thermal stability of the NH2-MIL-53(Al) coating was tested by aging at high temperature. The fiber was inserted into the gas chromatograph injector port and kept there for 1 h; the injector temperature was set at 250, 270, 290, and 300 °C in turn. Comparison of the extraction efficiencies of treated SPME fibers for OCPs (see Fig. S4) indicated that the extraction efficiencies of the NH2-MIL-53(Al) coating remained constant after treatment at high temperature, which demonstrates the good thermal stability of the NH2-MIL-53(Al) coating.

The pH of the solution and that of the solvent used affect the coating stability and adsorption process, possibly leading to decreased extraction efficiency and fiber life span. The chemical stability of the NH2-MIL-53(Al)-coated fiber was tested by sequential immersion of the fiber in 0.1 M hydrochloric acid, 0.01 M sodium hydroxide, hexane, and methanol for 1 h, before it was subjected to further experiments. The extraction efficiencies of treated and untreated fibers are compared in Fig. 3. There were no significant effects through these treatments. The results indicate that the fiber was stable within the pH range from 2 to 12 and tolerated some polar and nonpolar solvents. In addition, Fig. S5 shows that the fiber can be reused more than 200 times without significant changes, which illustrates the long life span of the NH2-MIL-53(Al)-coated fiber.

Extraction efficiencies of organochlorine pesticides in pure water for NH2-MIL-53(Al)-coated fiber as originally made (untreated) and after each sequential immersion in 0.1 M hydrochloric acid, 0.01 M sodium hydroxide, hexane, and methanol. Sample volume 10 mL, concentration of the analytes 10 μg L−1. Error bars show the standard deviation for triplicate determinations with one fiber. HCB hexachlorobenzene

Comparison of NH2-MIL-53(Al)-coated fiber with commercial fibers

To evaluate the adsorption ability of the 30-μm NH2-MIL-53(Al)-coated fiber toward target analytes, three commercial fibers (30 or 100-μm PDMS, 65-μm PDMS–DVB, and 85-μm PA) were selected for comparison. Extraction of the 10 μg L-1 SM and 10 μg L-1 OCP solutions was conducted under optimized conditions. The results illustrated in Fig. 4 show that the extraction abilities of the NH2-MIL-53(Al)-coated fiber for the SMs and OCPs were much better than those of commercial fibers. According to some articles [22, 24], three main reasons could account for the superior performance: (1) π–π interactions between the analytes and the organic linker of the coating material; (2) hydrogen bonding between the NO2 and COR groups of SMs and –OH, –NH2, and –COOH groups of the NH2-MIL-53(Al) coating, and (3) electron donor–electron acceptor interactions between electron-withdrawing regions of SMs (NO2 and COR) or OCPs (Cl and C = C) and the electron donor of the NH2-MIL-53(Al) coating, which has abundant π–π conjugated structures.

Comparisons of the extraction performance of NH2-MIL-53(Al)-coated fiber with commercial fibers. AHTN 6-acetyl-1,1,2,4,4,7-hexamethyltetralin (tonalide), DVB divinylbenzene, HHCB 1,3,4,6,7,8-hexahydro-4,6,6,7,8,8,-hexamethylcyclopenta[g]benzopyran (galaxolide), MK musk ketone, MX musk xylene, PA polyacrylate, PDMS polydimethylsiloxane

Optimization of the extraction conditions

SMs and OCPs were chosen as the target analytes to evaluate the extraction performance of the NH2-MIL-53(Al)-coated fiber. Various factors affect the extraction performance of the coated fiber, such as the extraction time and temperature and the desorption time and temperature. To achieve greater extraction efficiency, these factors were investigated and optimized.

The effects of extraction time on the extraction efficiency for SMs and OCPs were investigated from 20 to 120 min (Fig. 5a) and from 20 to 90 min (Fig. 5b). Extraction time selection is always a compromise between the time, cost, sensitivity, and repeatability of the analytical method. For the SMs, the peak areas of five analytes were all increased with increasing extraction time. Considering good extraction efficiencies could be obtained in 60 min, to save time, 60 min was chosen as the optimal extraction time. For OCPs, the extraction equilibrium occurred at 60 min for most of the analytes; thus, 60 min was chosen as the extraction time.

The extraction temperature has a twofold effect on the experimental results. Increasing temperature could accelerate the diffusion rate in the liquid sample matrix, whereas high temperature would lower the partition coefficients of analytes between the coating and the water sample. The effects of extraction temperature in the same range from 30 to 70 °C on the extraction efficiencies were investigated. From the results illustrated in Fig. 5c and d, the optimal extraction temperature was chosen to be 50 °C for the SMs and 60 °C for the OCPs.

Proper desorption time and temperature are both important parameters, which can not only eliminate the carryover but at the same time can also increase the sensitivity of the fiber. In this work, the desorption time and temperature were investigated from 3 to 7 min (Fig. S6a, b) and from 250 to 290 °C (Fig. S6c, d). On the basis of the effects mentioned above and the results reflected in Fig. S6, 4 min for the SMs and 5 min for the OCPs were selected as optimal desorption times, whereas the optimized desorption temperature was 280 °C for the SMs and 270 °C for the OCPs.

As mentioned already, the final extraction conditions were as follows: for SMs, extraction time 60 min, extraction temperature 50 °C, desorption time 4 min, and desorption temperature 280 °C; for OCPs, extraction time 60 min, extraction temperature 60 °C; desorption time 5 min, and desorption temperature 270 °C. Considering the commercial PDMS, PA, and PDMS–DVB fibers had good extraction efficiencies under the final extraction conditions, to save time and cost, all the fibers were used and compared under the optimized conditions.

Method evaluation and real sample analysis

The analytical performances of proposed methods for determination of SMs and OCPs, including linear ranges, coefficient of determination (R 2), LODs, limits of quantification (LOQs), repeatability, and reproducibility, were investigated under the optimal conditions. Table 1 summarizes the figures of merit of the optimized DI-SPME–GC–MS analysis method using the NH2-MIL-53(Al)-coated fiber. The enhancement factor was defined as the ratio of the sensitivity of an analyte after extraction to that before extraction (i.e., by direct injection of 1 μL of standard solution) with use of the chromatographic peak area for quantification [35]. The NH2-MIL-53(Al)-coated fiber offered large enhancement factors from 8108 (musk ketone) to 24,912 (tonalide) for the SMs and from 5427 (endrin) to 26,149 (trans-chlordane) for the OCPs.

For the analysis of SMs using the NH2-MIL-53(Al) coating, two analytes exhibited good linearity in the concentration range from 1 to 1000 ng L−1, and R 2 ranged from 0.9979 to 0.9997. The LODs calculated on the basis of a signal-to-noise ratio of 3 were between 0.025 and 0.83 ng L−1. The LOQs (signal-to-noise ratio of 10) of the method were in the 0.083–2.77 ng L−1 range. Under the optimized conditions, the relative standard deviations (RSDs) for six replicate extractions using one NH2-MIL-53(Al)-coated fiber ranged from 1.5% to 8.8%, and the fiber-to-fiber reproducibility, which was determined with three different fibers with three replicates for each fiber, ranged from 3.8% to 11%.

For the analysis of OCPs using the NH2-MIL-53(Al) coating, eight OCPs exhibited good linearity in the concentration range from 1 to 500 ng L−1, and R 2 ranged from 0.9961 to 0.9995. The LODs and LOQs of the method were 0.051–0.97 ng L−1 and 0.17–3.23 ng L−1 respectively. In addition, the RSDs of one fiber toward the OCPs ranged from 4.6% to 9.7%, and the fiber-to-fiber reproducibility ranged from 3.0% to 12%. In summary, both of the proposed methods possessed wide linear ranges, low LODs, and good repeatability. Besides, the LODs for the SMs and OCPs obtained by the DI-SPME–GC–MS method using NH2-MIL-53(Al)-coated fiber were lower than or close to those recently reported (Tables 2 and 3)

A DI-SPME–GC–MS method based on NH2-MIL-53(Al) was successfully applied for the analysis of tap and river water samples. As shown in Table S3, two SMs were detected in lake water and river water, whereas no OCPs were found in tap water and four OCPs were found in river water. To estimate the accuracy of the results, the water samples were spiked with different concentrations of the analytes. The recoveries were 80.3–115% with RSDs of 2.5–7.7% for the SMs and 77.4–117% with RSDs of 2.5–7.4% for the OCPs, indicating the accuracy and precision of the proposed method.

Conclusion

NH2-MIL-53(Al) nanoparticles were successfully synthesized, characterized, and applied as the SPME fiber coating for efficient sample pretreatment owing to their unique structure and excellent adsorption properties. Compared with commercial SPME coatings, the NH2-MIL-53(Al)-coated fiber exhibited excellent characteristics, such as good thermal stability and solvent resistance, long lifetime, large enhancement factors, and good reproducibility for the SPME of SMs and OCPs in environmental water samples. In addition, the proposed autosampler-assisted DI-SPME–GC–MS method was successfully used to determine trace SMs and OCPs in water samples with low LODs and a wide linear range and satisfactory recoveries. It is suggested that the NH2-MIL-53(Al)-coated fiber might be a promising alternative to commercial fibers for the determination of SMs and OCPs in water samples.

References

Arthur CL, Pawliszyn J. Solid phase microextraction with thermal desorption using fused silica optical fibers. Anal Chem. 1990;62(19):2145–8.

Kataoka H, Lord HL, Pawliszyn J. Applications of solid-phase microextraction in food analysis. J Chromatogr A. 2000;880(1-2):35–62.

Lambropoulou DA, Konstantinou IK, Albanis TA. Recent developments in headspace microextraction techniques for the analysis of environmental contaminants in different matrices. J Chromatogr A. 2007;1152(1-2):70–96.

Bermejo AM, Lopez P, Alvarez I, Tabernero MJ, Fernandez P. Solid-phase microextraction for the determination of cocaine and cocaethylene inhuman hair by gas chromatography-mass spectrometry. Forensic Sci Int. 2006;156(1):2–8.

Vogliardi S, Tucci M, Stocchero G, Ferrara SD, Favretto D. Sample preparation methods for determination of drugs of abuse in hair samples: a review. Anal Chim Acta. 2015;857:1–27.

Ouyang GF, Vuckovic D, Pawliszyn J. Nondestructive sampling of living systems using in vivo solid-phase microextraction. Chem Rev. 2011;111(4):2784–814.

Mehdinia A, Aziz-Zanjani MO. Recent advances in nanomaterials utilized in fiber coatings for solid-phase microextraction. Trends Anal Chem. 2013;42:205–15.

Xu JQ, Zheng J, Tian JY, Zhu F, Zeng F, Su CY, et al. New materials in solid-phase microextraction. Trends Anal Chem. 2013;47:68–83.

Liu JF, Li N, Jiang GB, Liu JM, Jönsson JÅ, Wen MJ. Disposable ionic liquid coating for headspace solid-phase microextraction of benzene, toluene, ethylbenzene, and xylenes in paints followed by gas chromatography-flame ionization detection. J Chromatogr A. 2005;1066:27–32.

Herrera-Herrera AV, Angel Gonzalez-Curbelo M, Hernandez-Borges J, Angel R-DM. Carbon nanotubes applications in separation science: a review. Anal Chim Acta. 2012;734:1–30.

Turiel E, Tadeo JL, Martin-Esteban A. Molecularly imprinted polymeric fibers for solid-phase microextraction. Anal Chem. 2007;79(8):3099–104.

Ferey G. Hybrid porous solids: past, present, future. Chem Soc Rev. 2008;37(1):191–214.

Betard A, Fischer RA. Metal-organic framework thin films: from fundamentals to applications. Chem Rev. 2012;112(2):1055–83.

Li JR, Sculley J, Zhou HC. Metal-organic frameworks for separations. Chem Rev. 2011;112(2):869–932.

Lee JY, Farha OK, Roberts J, Scheidt KA, Nguyen ST, Hupp JT. Metal-organic framework materials as catalysts. Chem Soc Rev. 2009;38(5):1450–9.

Yang CX, Yan XP. Application of metal-organic frameworks in sample pretreatment. Chin J Anal Chem. 2013;41(9):1297–300.

Gu ZY, Yang CX, Chang N, Yan XP. Metal-organic frameworks for analytical chemistry: from sample collection to chromatographic separation. Acc Chem Res. 2012;45(5):734–45.

Pocio-Bautista P, Pacheco-Fernandez I, Pasan J, Pino V. Are metal-organic frameworks able to provide a new generation of solid-phase microextraction coatings? - a review. Anal Chim Acta. 2016;939:26–41.

Serre C, Millange F, Thouvenot C, Nogues M, Marsolier G, Louer D, et al. Very large breathing effect in the first nanoporous chromium(III)-based solids: MIL-53 or Cr-III(OH)·{O2C-C6H4-CO2}·{HO2C-C6H4-CO2H}x·H2Oy. J Am Chem Soc. 2002;124(45):13519–26.

Yang CX, Liu SS, Wang HF, Wang SW, Yan XP. High-performance liquid chromatographic separation of position isomers using metal-organic framework MIL-53(Al) as the stationary phase. Analyst. 2012;137(1):133–9.

Llewellyn PL, Bourrelly S, Serre C, Filinchuk Y, Férey G. How hydration drastically improves adsorption selectivity for CO2 over CH4 in the flexible chromium terephthalate MIL-53. Angew Chem Int Ed. 2006;45(46):7751–4.

Chen XF, Zang H, Wang X, Cheng JG, Zhao RS, Cheng CG, et al. Metal-organic framework MIL-53(Al) as a solid-phase microextraction adsorbent for the determination of 16 polycyclic aromatic hydrocarbons in water samples by gas chromatography-tandem mass spectrometry. Analyst. 2012;137(22):5411–9.

Couck S, Denayer JFM, Baron GV, Rémy T, Gascon J, Kapteijn F. An amine-functionalized MIL-53 metal-organic framework with large separation power for CO2 and CH4. J Am Chem Soc. 2009;131(18):6326–7.

Luo X, Li GK, Hu YF. In-tube solid-phase microextraction based on NH2-MIL-53(Al)-polymer monolithic column for online coupling with high-performance liquid chromatography for directly sensitive analysis of estrogens in human urine. Talanta. 2017;165:377–83.

Kallenborn R, Gatermann R, Planting S, Rimkus GG, Lund M, Schlabach M, et al. Gas chromatographic determination of synthetic musk compounds in Norwegian air samples. J Chromatogr A. 1999;846(1-2):295–306.

Vallecillos L, Borrull F, Pocurull E. An automated headspace solid-phase microextraction followed by gas chromatography-mass spectrometry method to determine macrocyclic musk fragrances in wastewater samples. Anal Bioanal Chem. 2013;405(29):9547–54.

Rimkus GG. Polycyclic musk fragrances in the aquatic environment. Toxicol Lett. 1999;111(1-2):37–56.

Jjemba PK. Excretion and ecotoxicity of pharmaceutical and personal care products in the environment. Ecotox Environ Safe. 2006;63(1):113–30.

Liu HT, Liu L, Xion YQ, Yang XM, Luan TG. Simultaneous determination of UV filters and polycyclic musks in aqueous samples by solid-phase microextraction and gas chromatography-mass spectrometry. J Chromatogr A. 2010;1217:6747–53.

Huang Z, Lee HK. Micro-solid-phase extraction of organochlorine pesticides using porous metal-organic framework MIL-101 as sorbent. J Chromatogr A. 2015;1401:9–16.

Ke YY, Zhu F, Zeng F, Luan TG, Su CY, Ouyang GF. Preparation of graphene-coated solid-phase microextraction fiber and its application on organochlorine pesticides determination. J Chromatogr A. 2013;1300:187–92.

Xie LJ, Liu SQ, Han ZB, Jiang RF, Liu H, Zhu F, et al. Preparation and characterization of metal-organic framework MIL-101(Cr)-coated solid-phase microextraction fiber. Anal Chim Acta. 2015;853:303–10.

Liu SQ, Xie LJ, Zheng J, Jiang RF, Zhu F, Luan TG, et al. Mesoporous TiO2 nanoparticles for highly sensitive solid-phase microextraction of organochlorine pesticides. Anal Chim Acta. 2015;878:109–17.

Li SY, Zhu F, Jiang RF, Ouyang GF. Preparation and evaluation of amino modified graphene solid-phase microextraction fiber and its application to the determination of synthetic musks in water samples. J Chromatogr A. 2016;1429:1–7.

Cui XY, Gu ZY, Jiang DQ, Li Y, Wang HF, Yan XP. In situ hydrothermal growth of metal − organic framework 199 films on stainless steel fibers for solid-phase microextraction of gaseous benzene homologues. Anal Chem. 2009;81(23):9771–7.

Polo M, Garcia Jares C, Llompart M, Cela R. Optimization of a sensitive method for the determination of nitro musk fragrances in waters by solid-phase microextraction and gas chromatography with micro electron capture detection using factorial experimental design. Anal Bioanal Chem. 2007;388(8):1789–98.

Zhang SL, Du Z, Li G. Metal-organic framework-199/graphite oxide hybrid composites coated solid-phase microextraction fibers coupled with gas chromatography for determination of organochlorine pesticides from complicated samples. Talanta. 2013;115:32–9.

Li SY, Lu CW, Zhu F, Jiang RF, Ouyang GF. Preparation of C18 composite solid-phase microextraction fiber and its application to the determination of organochlorine pesticides in water samples. Anal Chim Acta. 2015;873:57–62.

Acknowledgments

We acknowledge financial support from the 973 Project (2012CB821701), NNSFC (21225731, 20477166), and the NSF of Guangdong Province (S2013030013474).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 750 kb)

Rights and permissions

About this article

Cite this article

Xie, L., Liu, S., Han, Z. et al. Amine-functionalized MIL-53(Al)-coated stainless steel fiber for efficient solid-phase microextraction of synthetic musks and organochlorine pesticides in water samples. Anal Bioanal Chem 409, 5239–5247 (2017). https://doi.org/10.1007/s00216-017-0472-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-017-0472-x