Abstract

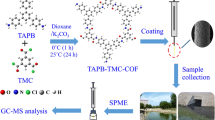

Direct head-space solid-phase microextraction (HS-SPME) of phenols in water is usually difficult due to its polarity and solubility in aqueous matrix. Herein we report the fabrication of metal–organic framework MOF-177 coated stainless steel fiber for the HS-SPME of phenols (2-methylolphenol, 4-methylolphenol, 2,4-dimethylolphenol, 2,4-dichlorphenol, and 3-methyl-4-chlorophenol) in environmental water samples prior to the gas chromatography-mass spectrometry detection. Several parameters affecting the extraction efficiency were optimized in the experiment, including extraction temperature and time, the pH value and salt addition. The results indicated that the coated fiber gave low detection limits (0.015–0.043 μg L−1) and good repeatability with the RSD ranging from 2.8% to 5.5% for phenols. The recoveries are between 84.5%–98.6% with the spiked level of 10 μg L−1 for the real water samples. The established method may afford a kind of potential enrichment material and a reference method for the analysis of methylphenols in water samples.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Solid-phase microextraction (SPME), a relatively new sample preparation technique introduced by Arthur and Pawliszyn, is a simple and effective technique which integrates sampling, extraction, and concentration (Arthur and Pawliszyn 1990; Zhang and Pawliszyn 1993; Pawliszyn 1997). Owing to the advantages of solvent-free nature, SPME has been widely used in the analysis of environment, food, biological forensic and so on (Vuckovic et al. 2011; Ouyang et al. 2011). The sorbent coated on the SPME fiber is the key factor affecting the sensitivity and selectivity of the analytes. However, the availability of commercial SPME fibers such as PDMS, PDMS/DVB, CAR/PDMS, PA are quite limited. And the silica-based fibers also have weak mechanical strength and relatively low thermal instability (usually 240–280°C) (Derouiche et al. 2007; Yang et al. 1998; Llompart et al. 1999; Landin et al. 2001). To overcome these problems, the exploitation of novel sorbents for SPME fibers is still challenging work.

Metal–organic frameworks (MOFs) are a novel class of porous materials built from metal ions and organic ligands which are extended infinitely into one, two or three dimensions mainly through the metal–ligand coordination, hydrogen bonding and π–π stacking. MOFs have various potential applications due to its large surfaces, modifiable pores and high thermal stability (Lin et al. 2002; Lee et al. 2009). MOFs have also been successfully explored as sorbents for solid-phase extraction (SPE) (Aquino et al. 2010; Barreto et al. 2010; Carvalho et al. 2009; Gu et al. 2010, 2012; Wang et al. 2012, 2014; Yang and Yan 2013; Zhou et al. 2006), solid-phase microextraction (SPME) (Chang et al. 2011; Cui et al. 2009; Gu et al. 2010; Wu et al. 2014; Yang et al. 2012), and as stationary phases of the chromatography column (Chang et al. 2010; Liu et al. 2012; Yang et al. 2011). To date, a few porous MOFs, such as MIL-101(Cr) (Xie et al. 2015; Zang et al. 2013), MOF-199 (Cui et al. 2009), ZIF-8 (Chang et al. 2011), MIL-53(Al) (Chen et al. 2012), MAF-X8 (He et al. 2013), ZIF-90 (Yu and Yan 2013), MIL-88B (Wu et al. 2014), UiO-66 (Shang et al. 2014), MOF-177 (Wang et al. 2015) have been all reported as SPME fibers.

Herein a porous MOF, MOF-177, possessing high surface area (4500 m2 g−1, BET) and large pore windows, was also explored as SPME adsorbent (Wang et al. 2015). Briefly, this work can be regarded as a continuation of developing the method for other classes of compounds. The environmental phenols were selected as analytic targets for their trace level, high toxicity, widespread environmental occurrence and resistance to biodegradation (Chae et al. 2004). Totally five kinds of phenols with different polarity (the log KOW ranges from 3.49 to 8.18) and molecular sizes (from 6.57 to 7.52 Å) were investigated as analytes from environmental water. The HS-SPME method was employed before the GC/MS analysis, and three kinds of real water samples (river water, lake water and waster water) were also determined.

Materials and Methods

The materials, chemical reagents (except the standard) and the equipment employed in this work were the same as in the previous work (Wang et al. 2015). The standard of 2-methylol-phenol (2-MP), 4-methylolphenol (4-MP), 2,4-dimethylphenol (2,4-DMP), 2,4-dichlorphenol (2,4-DCP), and 3-methyl-4-chlorophenol (3-M-4-CP) were purchased from Sigma-Aldrich (Saint Louis, USA). The stock solution of the mixed standard were prepared as 10 mg mL−1 in methanol, and stored at 4°C in darkness. The water samples were taken from different local areas, South of China. Before the SPME experiment, all samples were filtered with the 0.45 μm filter membranes and stored in precleaned brown glass bottles.

For the analysis, the column temperature of GC/MS was programmed as follows: 50°C for 2 min, then heated to 130°C at 5°C min−1, and finally to 280°C at 25°C min−1, with a hold time of 6 min. The injector port was maintained at 250°C and the SPME fiber was injected in splitless mode. After 5 min of desorption time, the data were acquired and processed using Agilent GC Solution software. The interface and ionization source temperature were 280 and 230°C, respectively. The analysis was performed in SIM mode, and the molecular ion (m/z 108, m/z 107, m/z 122, m/z 162, m/z 142) was used as the target ion for detection (ionization mode: electron ionization with 70 eV energy).

The fabrication of the SPME fiber was slightly modified on the basis of the reported work (Wang et al. 2015). Briefly, the stainless steel wire of a 5 μL GC micro-syringe was etched with hydrofluoric acid (38%, w/w) for 15 h. The MOF-177 powder was attached on the wire through silicone sealant diluted with n-hexane (w/v: 200 mg/1 mL). The coatings obtained after two coating cycles were around 30 μm thick and 1 cm long. Finally, the redundant coatings were removed and aged for 10 min at 250°C under the GC inlet. All HS-SPME extractions were carried out according to the publicated method (Wang et al. 2015).

Results and Discussion

The characterization of MOF-177 (X-ray powder diffraction and SEM, Fig. 1) were the same as our previous work (Wang et al. 2015). To obtain the optimization extraction efficiency, various experimental parameters influencing the extraction progress were investigated, including extraction temperature and time, ionic strength and pH value. To simplify the experimental step, the desorption time and temperature were set at 5 min and 250°C, which can assure the analytes be desorbed completely in this experiment. And the agitation speed was set at 700 rpm.

The effect of extraction temperature was studied from 30 to 70°C. As seen from Fig. 2a, the peak area increase steadily with the increase of temperature before 50°C. After 50°C, the extraction efficiency of 2,4-DCP and 3-M-4-CP still increase, however, for 2,4-DMP, 2-MP and 4-MP, the efficiency occur slight decline tendency. High extraction temperature is in favor of the release of analysts to the upper gaseous phase, however, too high extraction temperature is unfavorable for the exothermic adsorption of the analytes onto the SPME fiber (Wu et al. 2014). 60°C was chosen as the final extraction temperature.

The extraction time was also an important factor to influence the final result. The extraction efficiency always increases before the vapor–liquid phase reaches equilibrium. Thirty to seventy minutes were tested individually in the extraction process. As seen from Fig. 2b, the peak area increases with the extending of time. After 60 min, the peak area occur slight increase or decline tendency. The final extraction time was set at 60 min.

The effect of ionic strength on the peak area of the phenols was investigated in the NaCl addition range of 1–2.5 g with the sample volume of 10 mL. As presented in Fig. 2c, the peak area increase dramatically when the NaCl addition is lower than 1.5 g, and appear decrease with the further addition of NaCl. This may be ascribed that the salt-out effect plays the main role in the HS-SPME process, however, the excessive Na+ may also weaken the π–π interaction between the ligands and analytes. Therefore, further experiments were performed at the salt addition of 1.5 g.

The effect of pH value was also investigated from 3 to 9. The peak area increase when the pH value was improved from 3 to 5, and decrease with the further rise of pH value (Fig. 2d). When the solution was at lower pH, the release of HCl molecules may compete with the analytes adsorbed on the SPME fiber. If the solution appears basic, the solubility of phenols increase dramatically which cause the volatile amount of phenols decrease. For the next experiment, the pH value was adjusted to 5.

The extraction performance of MOF-177-coated fiber was compared with 100 μm PDMS, 65 μm PDMS/DVB, 85 μm PA, the etched stainless fiber and the adhesive-coated fiber, respectively. As shown in Fig. 3a, the MOF-177-coated fiber shows the best extraction efficiency towards the target analytes. For the analytes, the value of log KOW are followed an increasing order (4-MP < 2-MP < 2,4-DMP < 3-M-4-CP < 2,4-DCP). The minimum dynamic diameters of target molecules range from 3.9 Å (4-MP) to 5.4 Å (3-M-4-CP). The extraction performance gives an increasing order of 2-MP < 4-MP < 3-M-4-CP < 2,4-DMP < 2,4-DCP. The hydrophobicity, molecular size of phenols and the cavity characteristic of MOF-177 play the main roles towards the extraction efficiency. For MOF-177, the narrowest edge of pores is 10.8 Å, which allows all the analytes to enter into the pores. The H3BTB ligand contains four phenyl rings, which can afford abundant π–π and C–H…π interactions to phenols.

a Comparison of extraction efficiency of MOF-177-coated fiber, PDMS, PDMS/DVB and PA fiber; b the tic chromatogram of surface water sample (below) and the spiked surface water sample (up). Conditions: spike level, 10 μg L−1 for each analyte; sample volume, 10 mL; extraction temperature, 60°C; extraction time, 60 min; agitation speed, 700 rpm; NaCl addition, 1.5 g; pH value, 5

The limits of detection (LOD), correlation coefficients, repeatability were determined under the optimized conditions for phenols analysis (Table 1). The linearity range of the method was measured from 0.1 to 50 μg L−1. The correlation coefficients (R2) were found to be between 0.990 and 0.997. The LODs (S/N = 3) were in the range of 0.015–0.043 μg L−1. The LOQs (S/N = 10) were in the range of 0.05–0.144 μg L−1. The repeatability rates obtained from six replicate samples were from 2.8% to 5.5% and the reproducibility rates from the three fibers were from 4.2% to 7.4%. Among the direct HS-SPME or derivatization-HS-SPME method established for phenols, the LODs obtained in this work were lower or close to those reported results (Table 2) (Anbia et al. 2012; Regueiroa et al. 2009; Abolghasemi et al. 2016; Peñalver et al. 2002).

The established method was also applied to three kinds of real water samples (surface water, river water and waste water). The results were given in Table 3. For the surface water and river water samples, only 2,4-DCP was found in surface water2 and river water4 (Gao et al. 2008). Four kinds of analytes except 3-M-4-CP were found in waste water samples, ranging from 0.26 to 9.78 μg L−1, and the recoveries were between 84.5% and 98.6% for phenols (spiked at 10 μg L−1).

In this work, we have fabricated a thermal stable MOF-177-coated SPME fiber with an adhesive method, which offered good extraction efficiency for phenols than commercial fibers. The established method has good repeatability and relative LODs compared with the derivation method. The good stability and long lifetime of the prepared fiber suggest that the MOF-177-coated SPME fiber is promising in the analysis of real samples in separation field.

References

Abolghasemi MM, Parastari S, Yousefi V (2016) A nanoporous anodized alumina wire with a nanosized hydro-xyapatite coating for headspace solid-phase microextraction of phenol and chlorophenols. Microchim Acta 183:241–247

Anbia M, Haghia A, Shariati S (2012) Novel fiber coated with nanoporous carbons for headspace solid-phase microextraction of chlorophenols from aqueous media. Anal. Methods 4: 2555–2561

Aquino A, Wanderley KA, Paiva-Santos CDO, de Sá GF, Alexandre MDR, Júnior SA, Navickiene S (2010) Coordination polymer adsorbent for matrix solid-phase dispersion extraction of pesticides during analysis of dehydrated Hyptis pectinata medicinal plant by GC/MS. Talanta 83:631–636

Arthur CL, Pawliszyn J (1990) Solid-phase microextraction with thermal-desorption using fused-silica optical fibers. Anal Chem 62:2145–2148

Barreto AS, Silva RL, Santos Silva SCG, Rodrigues MO, Simone CA, De Sá GF, Júnior SA, Navickiene S, Mesquita ME (2010) Potential of a metal–organic framework as a new material for solid-phase extraction of pesticides from lettuce (Lactuca sativa), with analysis by gas chromatography-mass spectrometry. J Sep Sci 33:3811–3816

Carvalho PHV, Barreto AS, Rodrigues MO, Menezes Prata V, Alves PB, Mesquita ME, Jfflnior SA, Navickiene S (2009) Two-dimensional coordination polymer matrix for solid-phase extraction of pesticide residues from plant Cordia salicifolia. J Sep Sci 32:2132–2138

Chae HK, Siberio-Pérez DY, Kim J, Go YB, Eddaoudi M, Matzger AJ, ÓKeeffe M, Yaghi OM (2004) A route to high surface area, porosity and inclusion of large molecules in crystals. Nature 427:523–527

Chang N, Gu ZY, Yan XP (2010) Zeolitic imidazolate framework-8 nanocrystal coated capillary for molecular sieving of branched alkanes from linear alkanes along with high-resolution chromatographic separation of linear alkanes. J Am Chem Soc 132:13645–13647

Chang N, Gu ZY, Wang HF, Yan XP (2011) Metal-organic-framework-based tandem molecular sieves as a dual platform for selective microextraction and high-resolution gas chromatographic separation of n-alkanes in complex matrixes. Anal Chem 83:7094–7101

Chen XF, Zang H, Wang X, Cheng JG, Zhao RS, Cheng CG, Lu XQ (2012) Metal–organic framework MIL-53(Al) as a solid-phase microextraction adsorbent for the determination of 16 polycyclic aromatic hydrocarbons in water samples by gas chromatography–tandem mass spectrometry. Analyst 137:5411–5419

Cui XY, Gu ZY, Jiang DQ, Li Y, Wang HF, Yan XP (2009) In situ hydrothermal growth of metal-organic framework MOF-199 films on stainless steel fiber for solid-phase microextraction of gaseous benzene homologues. Anal Chem 81:9771–9777

Derouiche A, Driss MR, Morizur JP, Taphanel MH (2007) Simultaneous analysis of polychlorinated biphenyls and organochlorine pesticides in water by headspace solid-phase microextraction with gas chromatography-tandem mass spectrometry. J Chromatogr A 1138:231–243

Gao JJ, Liu LH, Liu XR, Zhou HD, Huang SB, Wang ZJ (2008) Levels and spatial distribution of chlorophenols-2,4-dichlorophenol, 2,4,6-trichlorophenol, and pentachlorophenol in surface water of China. Chemosphere 71:1181–1187

Gu ZY, Wang G, Yan XP (2010) MOF-5 metal-organic framework as sorbent for in-field sampling and preconcentration in combination with thermal desorption GC/MS for determination of atmospheric formaldehyde. Anal Chem 82: 1365–1370

Gu ZY, Yang CX, Chang N, Yan XP (2012) Metal-organic frameworks for analytical chemistry: from sample collection to chromatographic separation. Acc Chem Res 45:734–745

He CT, Tian JY, Liu SY, Ouyang GF, Zhang JP, Chen XM (2013) A porous coordination framework for highly sensitive and selective solid-phase microextraction of non-polar volatile organic compounds. Chem Sci 4:351–356

Landin P, Llompart M, Lourido M, Cela R (2001) Determination of tri-through heptachlorobiphenyls in water samples by SPME-GC-MS-MS: comparison of PDMS and PDMS-DVB coatings. J Microcolumn Sep 13: 275–284

Lee J, Farha OK, Roberts J, Scheidt KA, Nguyen ST, Hupp JT (2009) Metal–organic framework materials as catalysts. Chem Soc Rev 38:1450–1459

Lin CZJ, Chui SSY, Lo SMF, Shek FLY, Wu MM, Suwinska K, Lipkowski J, Williams ID (2002) Physical stability vs. chemical lability in microporous metal coordination polymers: a comparison of (Cu(OH) (INA))n and (Cu(INA)2)n:(INA = 1,4-(NC5H4CO2). Chem Commun 15:1642–1643

Liu SS, Yang CX, Wang SW, Yan XP (2012) High-performance liquid chromatographic separation of position isomers using metal-organic frame-work MIL-53(Al) as the stationary phase. Analyst 137:816–818

Llompart M, Li K, Fingas M (1999) Headspace solid-phase microextraction for the determination of polychlorinated biphenyls in soils and sediments. J Microcolumn Sep 11:397–402

Ouyang GF, Vuckovic D, Pawliszyn J (2011) Nondestructive sampling of living systems using in vivo solid-phase microextraction. Chem Rev 111:2784–2814

Pawliszyn J (1997) Solid-phase microextraction: theory and practice. Wiley, New York

Peñalver A, Pocurull E, Borrull F, Marcé RM (2002) Solid-phase microextraction coupled to high-performance liquid chromatography to determine phenolic compounds in water samples. J Chromatogr A 953:79–87

Regueiroa J, Becerril E, Garcia-Jaresa C, Llomparta M (2009) Trace analysis of parabens, triclosan and related chlorophenols in water by headspace solid-phase microextraction with in situ derivatization and gas chromatography–tandem mass spectrometry. J Chromatogr A 1216:4693–4702

Shang HB, Yang CX, Yan XP (2014) Metal-organic framework UiO-66 coated stainless steel fiber for solid-phase micro-extraction of phenols in water samples. J Chromatogr A 1357:165–171

Vuckovic D, Risticevic S, Pawliszyn J (2011) In vivo solid-phase microextraction in metabolomics: opportunities for the direct investigation of biological systems. Angew Chem Int Ed Engl 50:5618–5628

Wang GH, Lei YQ, Song HC (2012) Exploration of a coordination polymer as a novel sorbent for the solid-phase extraction of benzo(a)pyrene in edible oils. Anal Methods 4:647–651

Wang GH, Lei YQ, Song HC (2014) Evaluation of Fe3O4@SiO2–MOF-177 as an advantageous adsorbent for magnetic solid-phase extraction of phenols in environmental water samples. Anal Methods 6:7842–7847

Wang GH, Lei YQ, Song HC (2015) Exploration of metal-organic framework MOF-177 coated fibers for headspace solid-phase microextraction of polychlorinated biphenyls and polycyclic aromatic hydrocarbons. Talanta 144:369–374

Wu YY, Yang CX, Yan XP (2014) Fabrication of metal-organic framework MIL-88B films on stainless steel fibers for solid-phase microextraction of polychlorinated biphenyls. J Chromatogr A 1334:1–8

Xie LJ, Liu SQ, Han ZB, Jiang RF, Liu H, Zhu F, Zeng F, Su CY, Ouyang GF (2015) Preparation and characterization of metal-organic framework MIL-101(Cr)-coated solid-phase microextraction fiber. Anal Chim Acta 853:303–310

Yang CX, Yan XP (2013) Application of metal-organic frameworks in sample pretreatment. Chin J Anal Chem 41:1297–1301

Yang Y, Miller DJ, Hawthorne SB (1998) Solid-phase microextraction of polychlorinated biphenyls. J Chromatogr A 800:257–266

Yang CX, Chen YJ, Wang HF, Yan XP (2011) High performance separation organic framework MIL-101(Cr). Chem Eur J 17:11734–11737

Yang CX, Liu SS, Wang HF, Wang SW, Yan XP (2012) High-performance liquid chromatographic separation of position isomers using metal-organic framework MIL-53(Al) as the stationary phase. Analyst 137:133–139

Yu LQ, Yan XP (2013) Incorporation of metal-organic framework UiO-66 into porous polymer monoliths to enhance the liquid chromatographic separation of small molecules. Chem Commun 49:2142–2144

Zang H, Yuan JP, Chen XF, Liu CA, Cheng CG, Zhao RS (2013) Hollow fiber-protected metal–organic framework materials as micro-solid-phase extraction adsorbents for the determination of polychlorinated biphenyls in water samples by gas chromatography-tandem mass spectrometry. Anal Methods 5:4875–4882

Zhang Z, Pawliszyn J (1993) Headspace solid-phase micro extraction. Anal Chem 65:1843–1852

Zhou YY, Yan XP, Kim KN, Wang SW Liu MG (2006) Exploration of coordination polymer as sorbent for flow injection solid-phase extraction on-line coupled with high-performance liquid chromatography for determination of polycyclic aromatic hydrocarbons in environmental materials. J Chromatogr A 1116: 172–178

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant 21207121) and the Science and Technology Projects of Guangdong Province (Nos. 2016B020211004 and 2014B010108016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, GH., Lei, YQ. Fabrication of Metal–Organic Framework MOF-177 Coatings on Stainless Steel Fibers for Head-Space Solid-Phase Microextraction of Phenols. Bull Environ Contam Toxicol 99, 270–275 (2017). https://doi.org/10.1007/s00128-017-2101-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00128-017-2101-y