Abstract

A method for the detection of iso-α-acid (IAA) type ingredient congeners that are derived from the hop plant (Humulus lupulus L.) was developed to detect recent consumption of beer in blood. Three structurally similar but chemically altered IAA, also used as beer-specific ingredients, are known as “reduced IAA”, consisting of the rho-, tetrahydro-, and hexahydro-IAA were also targeted. The use of a simple protein precipitation extraction and ultrahigh-performance liquid chromatography system coupled with a tandem mass spectrometer system enabled detection of these analytes in both antemortem and postmortem blood. Extracts were injected onto a C18 solid-core column under gradient elution to achieve separation of isobaric analogs and isomers within a 10-min run time. Electrospray ionization in negative multiple reaction monitoring mode was used to monitor three transitions for each of the analytes that were ultimately grouped together to form a calibration curve for quantification of each of the four IAA groups. The method was fully validated according to international guidelines that included extraction efficiency, matrix effects, process efficiency, ion suppression/enhancement of co-eluting analytes, selectivity, crosstalk, accuracy and precision, stabilities, and lower limits of quantification. Finally, applicability of the method described was demonstrated by the detection of IAA ingredient congeners in the blood of a volunteer following the consumption of a relatively small amount of beer in a pilot study.

Botanical illustration of Humulus lupulus (L). By permission of Puple Sage Botanicals

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Compounds other than ethanol and water that are present in alcoholic beverages are termed congeners and may be detected in blood and urine following alcoholic beverage consumption. The detection and interpretation of these congeners is termed alcohol congener analysis (ACA) and can provide information for after-drinking (or hip flask) defense cases regarding the feasibility of claimed alcohol consumption prior and/or subsequent to a motor vehicle incident [1–3]. Traditionally, ACA has been used to detect levels of fermentation by-product congeners (typically alcohols) that are found in nearly all alcoholic beverages [1, 4, 5]. However, the exact origin of the consumed ethanol cannot be determined and consequently, its use in a postmortem setting has been minimal [6–8].

Congeners may also exist in a beverage as a result of the ingredients used during beverage production, in the form of different classes of compound (i.e., not only alcohols) [9]. Ingredient congeners may often be beverage-specific and present as targets for detection in biological fluid to determine consumption of specific alcoholic beverages [8]. To date, the detection of ingredient congeners present in alcoholic beverage has only been explored in some herbal spirits (e.g., eugenol, anethole, and menthone) [10–12]. Furthermore, ACA that targets ingredient congeners may have fewer limitations to that of the fermentation by-products and can potentially be utilized in a broader range of medicolegal cases where determining the source of consumed alcohol is in dispute. There are no beer ingredient congeners thus far identified as targets for ingredient congener ACA, indicating the potential to identify targets in this common beverage.

Beer is the oldest and most widely consumed alcoholic beverage; just short of two billion hectoliters were produced in 2012 worldwide [13]. Beer traditionally utilizes the four ingredients—water, yeast, malt, and hops—and may contain other ingredients for preservation or specific flavoring [14, 15]. These ingredients provide up to 800 congeners consisting of not only alcohols but also aldehydes, esters, histamines, additives, tannins, phenols, and other organic and inorganic compounds [2, 14, 16, 17]. Of the range of congeners in beer, those identified as specific to beer and potential targets as ingredient congeners for ACA are those derived from the hop plant.

Traditionally in the boiling phase of beer brewing, the female cones (strobiles) from the hop plant (Humulus lupulus L.) are added to the wort (a liquid containing malt-derived sugars). Initially, hops were used to impart the desired bitterness and aromatic hoppy properties to the beer. It was later established that hops also stabilizes the beer, including the foam or head [14, 18, 19] and protects the beer principally against gram-positive bacteria and/or microbial damage [20, 21]. Dried hops contain approximately 2–17 % of alpha acids (AA), also known as α-acids or humulones, that consist of three major analogs (defined as n-, co-, and ad-AA) which are almost bitterless [16]. However, after the wort containing the hops is boiled for a prolonged time, the AA molecules are converted into the intensely bitter isomerised-α-acids (IAA) with cis and trans configurations (Fig. 1) [22–24]. The wort is then cooled and yeast is added; following fermentation, the beer is filtered and packaged into the final product.

Whole extract of the hop cone is also used as a natural herbal remedy commonly in combination with Valerian (Valeriana officinalis) for similar complementary properties as a mild sedative in humans for anxiety, insomnia, nervousness, memory, and mood disorders [25–27]. However, as this is a whole extract and does not undergo a boiling (isomerization) process, IAA are not present. Other than for beer, there are no other known uses for hops that undergo isomerisation and develop IAA, presenting a specific ingredient congener for beer.

Six stereoisomers of IAA are produced from the three predominant AA analogs that isomerise into diasterisomers [28]. The compounds are structurally very similar, only differing in the nature of the saturated acyl side chain and the absolute configuration of one of the chiral centers (Fig. 1). The IAA are water soluble, tensioactive, have low pK a values of ~3.5 and are responsible for the bitter character of beer and foam stabilization [16]. International bitterness units (IBU) are used by the alcohol industry as a measurement of the bitterness profile of beer with one unit being approximately equal to 1 mg/L of total IAA [29]. Beers historically ranged from 20 to 60 IBU; however, currently, they range from ~6 to 30 IBU with the exception of some craft beers [21]. It is known that the cis/trans ratios in beer are 68:32 [30]; however, the trans-IAA are present in the foam in greater proportion than the cis-IAA due to their lower water solubility. This hydrophobic property also explains the lower half-life of the trans-IAA (~1 year) compared to the cis-IAA (>5 years) [31] of which a variety of degradation products are formed [32]. Following the isomerization, minor analogs post-, pre-, and adpre-AA are also converted into their respective isomers; however, they are generally regarded as insignificant due to their relatively low concentrations [33]. Although co-elution may be problematic particularly with ultraviolet detection [34], the use of mass spectrometry potentially solves this issue due to the differences of selection based on molecular weights and detected ions.

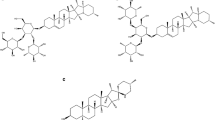

The IAA are prone to becoming light-struck in the presence of sunlight (near ultraviolet, blue light) and oxygen resulting in familiar and undesirable “skunky” aroma producing compounds, of which 3-methyl-2-butene-thiol (3-MBT) being the most offensive [30]. This historically led to beer being bottled in brown or green, lightproof glass. In recent years, a range of so-called light-stable “reduced IAA” were developed from the naturally available IAA, namely rho-IAA (RIAA), tetrahydro-IAA (TIAA), and, more recently, hexahydro-IAA (HIAA). By reducing the relatively weak double bonds or carbonyl group in the side chains of IAA to stronger single bonds as seen with the reduced IAA, photolytic cleavage is unable to occur on that side chain and the production of 3-MBT is prevented from developing (Fig. 2).

The synthesis of reduced-IAA and properties of increased hydrophobicity (i, iii) and photolytic cleavage prevention (ii, iii). The carbonyl group in the side chain of IAA is reduced with sodium borohydride to produce rho-IAA. Reduction by hydrogenation of both side chains double carbon bonds within the IAA produce the tetrahydro-IAA derivative. Execution of both the sodium borohydride and hydrogenation processes yields the hexahydro-IAA derivative of IAA

This reduction process provides altered intensities of bitterness [21]. Coincidently, due to increasing hydrophobicity of the compounds (in order of RIAA to HIAA to TIAA), enhanced beer foam stability, appearance, and “cling” are observed. As 2.4 and 4.2 ppm (for TIAA and HIAA, respectively) have been sufficient to show foam stabilization to that of the natural IAA; reduced IAA used for the purpose of foam improvement are added in lower concentrations [35].

The reduced IAA products are available as potassium salts preparations ready to be added directly to the finished beer (postfermentation) [21, 36]. Among other non-natural additives, the non-natural reduced forms of IAA are not allowed in beers for the German market due to the “Reinheitsgebot” law stating that only natural hop products, water, malt, and yeast may be used in the brewing process [37].

The aim of this study was to develop a fully validated method for the detection of IAA and reduced IAA in human blood as potential specific ingredient congeners for the confirmation of beer consumption using an ultrahigh-performance liquid chromatography system coupled with a tandem mass spectrometer (UHPLC-MS/MS). This may also alleviate some issues and limitations of current methodologies that detect only fermentation by-product congeners. The detection of reduced IAA in blood may also provide information on the type of beer consumed, for example, beer within a clear glass bottle.

Experimental

Chemicals and reagents

Reference standards for DCHA-Iso, ICS-I3 (containing 62.3 % w/w of trans-IAA); DCHA-Rho, ICS-R2 (containing 65.3 % w/w of cis-RIAA); Tetra, ICS-T2 (containing 99.4 % w/w of TIAA); DCHA-Hexa, ICS-H1 (containing 65.7 % w/w of cis-HIAA); and ICE-3 (containing 44.64 % w/w of AA) were obtained from Labor Veritas (Zurich, Switzerland). The isotope-labeled internal standard (IS) nimodipine-d7 was purchased from PM Separations (Brisbane, Australia). Acetonitrile (ACN), methanol, and formic acid were purchased from Merck (Melbourne, Australia). Ammonium formate was purchased from Sigma Aldrich (Sydney, Australia). All chemicals were of analytical grade or better and water was purified using a Milli-Q Ultrapure Water System from Waters (Sydney, Australia).

Specimens

Preserved blank blood 10 mL samples (containing 200 mg sodium fluoride and 30 mg potassium oxalate) for calibration purposes and validation experiments were obtained from a local blood bank (Melbourne, Australia). Blood of the volunteer in the application to authenticity study was collected in sterile 5 mL Venosafe blood tubes containing 9 mg sodium fluoride and 9 mg potassium oxalate purchased from Hazpak (Melbourne, Australia). Concentrations of the preservatives are therefore at least 2.25 % of each and blood samples were stored at −20 °C, sufficient to inhibit bacterial alteration of ethanol and congeners [38, 39].

Apparatus

The UHPLC-MS/MS system comprised of a Shimadzu MS 8030 quadrupole mass spectrometer (Melbourne, Australia) operated in the electrospray ionization (ESI) in negative mode and a Shimadzu Nexera UHPLC system (Melbourne, Australia) that consisted of a degasser, two eluent pumps, a column oven and a chilled autosampler. For MS data evaluation, Shimadzu Postrun and Shimadzu Browser Analysis (Melbourne, Australia) softwares were used. GraphPad Prism 5.04 from GraphPad Software (San Diego, USA) was used for statistical analysis.

UHPLC conditions

Gradient elution was performed on a Kinetex C18 (3.0 × 150 mm, 2.6 μm) column coupled with a SecureGuard C18 Ultra guard column (3.0 × 10 mm, 2.6 μm), both purchased from Phenomenex (Melbourne, Australia). The mobile phases consisted of 50 mmol/L aqueous/ACN (90:10) ammonium formate pH 2.8 (eluent A) and ACN containing 0.1 % formic acid (eluent B). The flow rate of the mobile phase was 0.5 mL/min and was degassed by the integrated Shimadzu Nexera degasser during use. The gradient was programmed as follows: 0–0.5 min hold at 50 % eluent B; 0.5–6.0 min eluent B increasing to 60 %; 6.0–9.5 min eluent B increasing to 75 %; and 9.5–10 min eluent B hold at 75 %. Before the start of batch analysis and before each injection, the UHPLC system was flushed for 2 min (90 % eluent B) and equilibrated at starting conditions (50 % eluent B) for 3 min. The column oven was maintained at 30 °C, the autosampler was operated at 4 °C and the autosampler needle was rinsed before and after aspiration of the sample using methanol.

MS/MS conditions

The MS data were acquired with the following ESI inlet conditions: nebulizing gas and drying gas were nitrogen at a flow rate of 3.0 and 12.5 L/min, respectively; the interface voltage was set to 4.8 kV, desolvation line temperature was 190 °C, and the heat block temperature was 500 °C. The mass spectrometer was operated in negative multiple reaction monitoring mode (MRM) with argon as the collision-induced dissociation gas at a pressure of 230 kPa; the detector voltage was set to 1.72 kV.

Specific MRM conditions for nimodipine-d7 were auto-optimized by direct flow injection of 1 μL of a 1 mg/mL solution in acidic methanol. However, as the IAA and reduced IAA compounds are only available as a combined mixture of analogs, each analyte was manually optimized by injecting 10 μL of a 1 mg/mL solution of the respective IAA group in acidic methanol onto the column. With the system in Q1 scan mode, the retention time and a precursor mass (Q1 mass) were obtained for each analytes. Using product ion scan mode in a series of repeated injections over a range collision energies (CE) from 10 to 50 V at increments of 2 V, the three most abundant product ions and optimal CE for each individual analyte were obtained. The most abundant product ion was selected as the quantifier ion and subsequent two ions as suitable qualifiers. The results of the auto and manual optimizations are summarized in Table 1. All analyte dwell times were set at 25 ms.

Preparation of stock solutions, control samples and calibration standards

Individual stock solutions of each IAA group and nimodipine-d7 were prepared at a concentration of 1 mg/mL using acidic methanol (0.05 % formic acid) and methanol, respectively. The working solutions of IAA were prepared by pooling IAA stock solutions to make a single 0.1 mg/mL working solution with subsequent dilutions at the following concentrations: 0.01, 0.001, and 0.0001 mg/mL; using acidic methanol. Stock and working solutions were stored at −20 °C for a maximum time frame of 6 and 1 months, respectively.

The calibration standards were prepared using pooled blank blood spiked with the working solutions to obtain the final concentrations of 0.001, 0.01, 0.05, 0.15, 0.06, 2, 5, and 10 mg/L. These calibrations provided the levels required for varying calibration models for each IAA group (Table 2).

The quality control (QC) samples were prepared using pooled blank blood spiked with the working solutions to obtain the final concentrations of 0.1 mg/L (low), 0.8 mg/L (med), and 6 mg/L (high; Table 2), and were stored at −60 °C before analysis.

Sample preparation

Briefly, 100 μL of blood underwent protein precipitation in a 2 mL Eppendorf tube from Eppendorf (Sydney, Australia) using 200 μL of cold (−20 °C) ACN containing the IS nimodipine-d7 (0.5 mg/L) for 5 min on a shaker at 2,500 rpm. After a 10-min rest and subsequent centrifugation at 15,000 rpm for 10 min, the supernatant was transferred to an autosampler vial and evaporated to dryness under nitrogen using a Ratek dry block heater DBH10 (Melbourne, Australia) operated at room temperature. The residue was reconstituted in 50 μL of a mixture of eluent A and eluent B (60:40, v/v). Twenty microliters of the final extract was injected into the UHPLC-MS/MS system.

Validation

Full validation was performed as per international guidelines [40, 41]. Although results are reported as the concentration of the groups (rather than individual analytes), individual analytes were validated for such parameters as selectivity, the stabilities and matrix effects, as they each have their own chemical properties. Accuracy and precision was based on the calibration model of total area of the analytes consisting in that group.

Selectivity and crosstalk

Selectivity experiments were carried out using 10 antemortem and 10 postmortem blood samples obtained by the authors' laboratory for routine toxicological requirements. In total, the 20 different blood samples were analyzed to demonstrate no interference with endogenous peaks and targeted ions, including potential crosstalk of ions within the MS. An additional two zero samples (blank sample + IS) were analyzed to check for the absence of analyte ions in the respective peaks of the IS. Furthermore, pooled blank blood was spiked with either trans-IAA, cis-RIAA, TIAA, cis-HIAA, or AA in duplicates at concentrations of the upper limit of calibration curve 10 mg/L using individual stock solutions to check for the absence of interference with IS ions. This also ensured there was no interference between IAA groups as the IAA/AA family of compounds are structurally similar and include similar fragmented product ions. Pooled blank blood was also spiked with a mix of ~350 common therapeutic drugs ranging from levels 1–10 mg/L to determine any interference with individuals taking medications concurrent to beer consumption.

Extraction efficiencies, matrix effects, and process efficiencies

The extraction efficiencies, matrix effects, and process efficiencies were estimated with a set of three different samples at two concentrations (low and high QC levels) with five samples each according to the simplified approach described by Matuszewski et al. [42]. The IS was estimated concurrently at a concentration used in the described method. Sample set 1 represented the neat standard, sample set 2 represented blank matrix spiked after extraction, and sample set 3 consisted of blank matrix spiked before extraction. Extraction efficiencies were estimated by comparison of the peak area of the samples of set 2 to those of set 3. For the matrix effects, the peak area of the samples of set 2 was compared to those of set 1. For process efficiencies, the peak area of the samples of set 3 was compared to set 1. All values are reported in percentage. General acceptability levels of 50 % extraction efficiency or more were applied. Values over 100 % for matrix effects indicate ion enhancement, while values below 100 % indicate ion suppression.

Linearity

The calibration model was based on the total area of the analytes consisting in that group as ratio to the IS area. Blank blood aliquots were spiked at concentrations given in Table 2 and extracted as described previously to obtain calibration standards. Replicates (n = 6) at each of the eight concentration levels were analyzed. As the expected concentrations of IAA in blood are unknown, the calibration model was tiered into two calibration levels based on the QC to be analyzed. Quality controls low and medium were analyzed using calibration standards 1–6 while the high QC was analyzed using the full (1–8) calibration curve. All groups were visually checked for a linear or quadratic fit and weighting (none, 1/x or 1/x 2). Daily calibration curves using the same concentrations (single measurements per level) were prepared with each batch of validation and authentic samples.

Lower limit of quantification

The lower limit of quantification (LLOQ) was defined as the lowest point of the calibration curve of the method (Table 2) and fulfilled the requirement of LLOQ, signal-to-noise ratio ≥10:1 for quantifier and qualifier of the lowest abundant peak in the respective group. Furthermore, it was tested whether the quantifier/qualifier ratio of the MRM signals was within the acceptable limits and if there were at least 12 data points available at this concentration for each analyte of the group. Limit of detection values were not systematically evaluated due to the multiple analytes present in each group, a signal-to-noise ratio ≥3:1 of at least one analyte is sufficient to confirm detection of the respected group [40, 41].

Processed sample stability

The stability of the processed samples during batch analysis under the conditions of the described method were estimated. Quality control samples at low and high concentrations (n = 9 of each) were extracted as described previously and resulting extracts pooled. Aliquots of these pooled extracts at each concentration level were transferred to autosampler vials and injected into the UHPLC-MS/MS system and analyzed under the described method. The time intervals between the analyses of the QC samples were extended to 3.1 h by the injection of 11 blank samples repeated over a 24.8 h period. Stability of the extracted analytes was tested by regression analysis plotting absolute peak areas of each analyte at each concentration versus injection time. The instability of the processed samples was indicated by a negative slope, significantly different from zero (P ≤ 0.05) [41, 43].

Freeze/thaw and bench-top stability

Combined freeze/thaw and bench-top stability were evaluated by analysis of low and high QC samples (n = 6 of each) before (control samples) and after four and eight freeze/thaw cycles (stability samples) for evaluation of freeze/thaw stability. Samples completed in total eight freeze/thaw cycles by undergoing 22 h freezing period (−60 °C) and a thawing period of 2 h at room temperature to incorporate bench-top stability. The experiments were carried out together with the accuracy and precision experiments and the concentrations of the control and stability samples were calculated via daily calibration curves. For stability, there are two criteria which have to be fulfilled: the ratio of means (stability/control) has to be within 90–110 % and the 90 % confidence interval has to be within 80–120 % from the control sample [40].

Accuracy and precision

Low-, medium-, and high-quality control samples were prepared at the previously described concentrations and in duplicate each QC concentration was analyzed over a period of eight consecutive days using the described method using daily calibration curves. Accuracy was calculated for each analyte and bias determined by calculating the percent deviation of the mean of all calculated concentration values at a specific level from the respective nominal concentration. Repeatability (within-day precision) and time-different intermediate precision were calculated as relative standard deviation (RSD) [44] using one-way analysis of variance (ANOVA) with the grouping variable “day”. For low and medium concentrations, the acceptance limit was set to 20 % CV and RSD, respectively, and 15 % CV and RSD, respectively, for high concentrations.

Application to authentic samples

A normal healthy male volunteer was administered ~570 mL of West Coast IPA from Green Flash Brewery (San Diego, USA) described as 95 IBU and therefore assumed that ~55 mg of total IAA was consumed. The volunteer consumed this quantity of beer at 7.3 % alcohol by volume in order to obtain ~0.05 blood alcohol concentration, the legal limit in Australia and many other countries. Blood was sampled prior (zero), 0.5, 2, and 6 h postconsumption where the zero sample acted as the control and blank blood of the participant.

Results and discussion

Separation and detection

Sample preparation and methods of detection

Historically, the bitter content of beer was estimated by a broad photometric analysis to provide an IBU rating [45] and has shown to suffice for the brewing industry to attribute a general bitterness profile for beers. Currently, the technique predominately used in routine beer and hop product analysis ensures consistent testing using a standardized HPLC-UV method by the European Brewery Convention (EBC method 7.8) [46]. Other analytical techniques utilizing capillary electrophoresis [47] and HPLC-UV [23, 34] showed improvement; however, accurate and specific determination of IAA and reduced IAA content was not possible until the emergence of LC-MS(MS) [33, 34, 48]. These LC-MS(MS) methods are highly selective and sufficiently sensitive for the analysis of beer that contain a relatively high concentration of IAA. Our method describes an extraction with sufficient recovery to allow for the analysis of IAA compounds in human blood after consumption of beer. A typical sample chromatogram acquired in ESI-negative mode shows the separation of the analytes (Fig. 3). Liquid–liquid extraction was found to be inappropriate when in combination with the highly acidic buffers required to improve extraction of the acidic IAA compounds. The combination would lyse the red blood cells and cause intracellular matrix to fall into the extracted sample and interfere with analysis. Protein precipitation was demonstrated as a sufficient clean-up step that did not degrade the biological matrix or result in a loss of recovery of the analytes. The extraction was found to be further optimized with the use of cold (−20 °C) ACN and the supernatant allowed to rest for 10 min after centrifugation.

Chromatograph of individual analytes at spiked blood concentrations of 1 mg/L for the trans-IAA, cis-RIAA, TIAA, and cis-HIAA groups (0.1 mg/L for IS) using the validated LC-MS/MS method presented. Residual cis-IAA (mainly analyte I2, but also I4 and I6 in higher concentrations) remain in the trans-IAA reference standard and as carry-over during production

Only in recent years have methods (using typically C18 columns) shown near complete separation and selectivity of individual IAA [33, 34] and reduced IAA analytes [29], requiring a run time of 20–50 min. After extraction from blood, our method separated the analytes using a gradient elution on a core–shell C18 column within 10 min. Preliminary experiments showed increased chromatographic selectivity and sensitivity using this column with considerably lower flow rates under high pressure (data not shown). The decrease of flow rate over the run improved the separation and peak shape of late eluting compounds. This chromatographic system was further optimized by applying a lower pH to eluent A (preferably at least 1 pH unit below the ~3.5 pKa of IAA) in order to obtain improved ionization of acidic compounds. However, phosphate buffers are not compatible with MS detection and ammonium acetate buffer systems allowing for relatively low pH ranges were tested with poor chromatography results. Although the lowest capacity of the chosen ammonium formate buffer system is pH 2.8, this pH demonstrated the best separation of nearly all analytes. The class of IAA compounds contains two analogs (n- and ad-IAA) with the same molecular weight and there are structural isomers within these analogs (cis and trans; see Figs. 1 and 2). It is therefore expected that separation difficulties with compounds of related chemistries and selectivity issues may be encountered with isobaric compounds with similar fragmentation. To avoid misidentifications, chromatographic separation of these isobaric compounds needed to be achieved. The determination of retention times within a batch of analysis compared to the IS in positive samples was necessary to avoid misidentifications of isobaric compounds. Some isobaric structural isomers (T5 and T6, as well as H5 and H6) were not baseline separated. However, as they are present in their respective standards and in the reduced hop products used, the total area of the combined peaks was sufficient to achieve reasonably accurate quantification under the described conditions.

Stability

Information from the IAA manufacture Labor Veritas and EBC indicate that IAA standards are unstable after a day in methanol but the use of phosphoric acid in methanol for stock and working solutions was sufficient to stabilize most of the compounds. However, degradation of trans-IAA in the DCHA-Iso, ICS-I1 standard has still been demonstrated [34]. Due to the known deterioration with MS metallic parts following the continual use of the nonvolatile phosphoric acid, formic acid was substituted. A 0.05 % concentration of formic acid in methanol was found to stabilize the IAA sufficient for stock and working solutions to be stored at −20 °C over a 6- and 1-month period, respectively. As reduced on-column stability of the analytes was observed with increases in temperatures (data not shown), the column oven was maintained at a minimal temperature above ambient (30 °C).

Grouped standards

Due to the unavailability of individual analyte standards and as each analyte has variable abundance within the respective group, the LLOQ of the group was restricted to the analyte with the lowest abundance with a signal-to-noise ratio of 10:1. However, detection of individual analytes with a signal-to-noise ratio of 3:1 [40] was sufficient to report beer consumption as detected. This also proves problematic for the determination of MRM transitions which resulted in the precursor and product ions meticulously selected manually by repeated injections of standards at different conditions described in Table 1. This review process ensured that all fragment ions were explainable as possible fragments of the respective chemical structure. To improve overall sensitivity of IAA compounds, a thorough source optimization was undertaken improving all groups of analytes with the IAA group recording the greatest gains. This reflects the relatively lower LLOQ for this group specifically and results in better sensitivity for the majority of beer consumption. The dwell times were optimized depending on the signal response of each individual analyte by repeated injection; all analytes obtained >30 points across the peaks. Although there are more theoretical reduced IAA isomers present in brewing products and reference standards (i.e., the trans isomers of the RIAA and HIAA groups), the extremely low relative abundance of these analytes did not provide sufficient detection limits. These analytes were also unable to be detected at high (10 mg/L) concentrations and would therefore not interfere with quantification even with large beer consumption. Although the manufacturer of the IAA standards claim that residual pre-, post-, and adpost-IAA may be present from the production process [46], the difference in precursor ions to that of the scheduled MRMs allows for accurate selectively of targeted IAA using MS.

Calibration model

As a deuterated derivative of IAA is currently unavailable, the chemical and structural similarities of various compounds were examined. Nimodipine-d7 was selected as a suitable IS for the calibration model. Other techniques have used an ECHO technique consisting of a shortly followed second injection containing the IAA group as the IS [33]. However, a closely followed injection of IS does not compensate for injection volume variability and is not wholly appropriate when gradient elution chromatography is undertaken. The relatively low abundance of R5 only produced a signal-to-noise ratio of 10:1 at total cis-RAA concentrations of 2 mg/L. Therefore, the R5 analyte does not contain a peak in Fig. 3 and validation data using QCs at lower concentrations were also unable to be performed. For this reason, it was not used for calculation of the concentration curve or for any samples. As mentioned earlier, the calibration models involved two curves for analysis. The same calibrations standards were used for quantification, the two curves only differed on whether points 7 and 8 were included when quantifying high-quality controls. All IAA groups were spiked into all standards, irrespective of whether the particular group would be included in the calibration level (i.e., groups cis-RIAA, TIAA, and cis-HIAA were not examined at calibration level 1 due to their LLOQ, see Table 2; however, the groups were still present in the extracted samples). Antemortem blood was chosen as the matrix for the calibration standards, matrix effects and quality controls rather than postmortem blood. Excess blank postmortem blood from deceased persons is difficult to obtain ethically for assay calibration purposes and matrix effects studies, whereas antemortem blood was readily available through blood donor banks.

Validation

The described procedure was validated according to internationally accepted recommendations [40, 41]. For the detection of the IAA and reduced IAA, three MRM transitions were used for each analyte; their use and their respective peak area ratios enabled unambiguous identification of all IAA and reduced IAA compounds included in the assay. The selectivity studies showed no interference or crosstalk in 20 different clinical and postmortem samples.

Table 3 shows mean values of extraction efficiencies and matrix effects of the corresponding variation over five different blood samples. Datasets in which the variation (minimum and maximum values in percentage) is greater than 20 % difference of the mean value are marked in bold type. Overall, the method showed satisfactory extraction efficiencies for most analytes; however, variation occurred for many analytes at low concentrations. Table 3 also shows the mean values of matrix effects and the corresponding variation over five different blood samples with strong ion enhancement demonstrated. The described extraction procedure showed no significant matrix effects over five different blank blood samples in high concentrations. However, nearly half of the analytes demonstrated variation in matrix effects at low concentrations. Matrix effect studies of IS nimodipine-d7 were also performed at the target concentration with no significant matrix effects observed over five different blank blood samples with satisfactory results. The described method demonstrated satisfactory process efficiency of 50 % or more for all analytes.

Linear regression was applied to all studied groups and no weighting applied when using the full calibration curve for high QC analysis. As a result of heteroscedasticity that is commonly encountered for calibrations ranges spanning more than 1 order of magnitude [40], a weighted model (1/x for IAA and cis-RIAA, 1/x 2 for TIAA, and cis-HIAA; Table 2) was used for the calibration curve using standards 1–6 for lower and medium QC analysis. The calibration fit showed a coefficient of determination of r 2 > 0.95 for all groups and calibration ranges.

In the freeze/thaw and long-term stability experiments, the ratio of means (stability versus control samples) was within 90–110 %, whereas the 90 % CIs for stability samples were within 80–120 % of the respective control means. Stability issues have demonstrated degradation of the trans-IAA standard when stored at 20 °C for 24 h without light exposure [34], potentially problematic for processed sample stability. However, in the processed sample extracts, the acidic eluent conditions that the samples were reconstituted with assisted in sufficiently stabilizing the analytes for over 24 h analytes at low and high concentrations. Stability was potentially assisted as the described method utilizes a chilled autosampler for storage of processed samples at 4 °C.

Accuracy data was within the acceptance interval of ±15 % (±20 % for low and medium) of the nominal values for all IAA groups excluding TIAA at low QC concentrations. Within-day (repeatability) and intermediate precision required limits of ±15 % RSD (±20 % for low and medium) of which all repeatability data was within. However, the results summarized in Table 4 demonstrate variability in intermediate precision for low and high concentrations in most groups when criteria above are applied. The calibration model incorporating total peak areas as a single group may induce greater variation in accuracy and precession results. The synthesis of a deuterated IAA may help alleviate some of the problems. Overall, the grouped calibration using the described IS provides an approximate quantification for trans-IAA, cis-RIAA, TIAA, and cis-HIAA and is a good representative value for the amount of IAA, RIAA, TIAA, and HIAA, respectively, in blood postconsumption of beer.

Application to authentic samples

Detection of all IAA analytes were present in the 0.5 and 2.0 h duplicate bloods at trans-IAA concentrations of ~0.2 (Fig. 4) and ~0.02 mg/L, respectively, of the volunteer. Blood taken 6 h postconsumption detected the I1 analyte only and therefore accurate quantification was not possible. This is most probably due to the increased sensitivity of this presented method for that particular analyte, compared to analogs I3 and I5 at the similar concentrations. However, detection of solely I1 at 6 h demonstrates how detection of individual analytes is sufficient to show beer consumption. Similarly, detection of the I2, I4, and I6 analytes of the cis-IAA group that were not quantified due to unavailability of a reference standard was also able to confirm beer consumption. Furthermore, should trans isomers undergo a more rapid metabolism and/or have since degraded at the time of sampling, the cis isomers have a much longer half-life and may still be used to indicate beer consumption over a greater detection window. The detection of beer ingredient congeners in the participant of the pilot study at a relatively low amount of beer consumption than what might be typical, demonstrates high sensitivity and consequently, applicability of the method.

Chromatograph of blood taken 30 min after consumption of ~570 mL beer containing ~55 g of IAA (trans and cis) from a volunteer. The concentration of the trans-IAA (analytes I1, I3, and I5) was ~0.2 mg/L. The cis-IAA group (analytes I2, I4, and I6) are unable to be quantified due to the unavailability of a reference standard; however, they do provide evidence for the consumption of beer. All IAA analytes demonstrate baseline separation as not to interfere with quantification results. Colored lines demonstrate quantification ions; black full and dashed lines indicate the two other MRMs

Conclusion

The UHPLC-MS/MS assay presented is a suitable procedure for the separation, detection, and quantification of IAA, RIAA, TIAA, and HIAA compounds as beer-specific ingredient congeners in blood samples to confirm beer consumption. Validation has proven to be selective, linear, accurate, and precise for the range of beer ingredient congeners at concentrations expected to be found in blood. The trans-IAA were quantified in a volunteer postconsumption of beer and demonstrates possible applicability for clinical and forensic toxicological casework.

References

Bonte W (2000) Congener analysis. In: Encylopedia of forensic sciences, vol 1. Academic, Duesseldorf, pp 93–102

Iffland R, Jones AW (2003) Evaluating alleged drinking after driving—the hip-flask defence. Part 2. Congener analysis. Med Sci Law 43(1):39–68

Krause D, Wehner HD (2004) Blood alcohol/congeners of alcoholic beverages. Forensic Sci Int 144(2–3):177–183

Greizerstein HB (1981) Congener contents of alcoholic beverages. J Stud Alcohol 42(11):1030–1037

Murphree HB, Price LM, Greenberg LA (1966) Effect of congeners in alcoholic beverages on the incidence of nystagmus. Q J Stud Alcohol 27(2):201–213

Urban R, Liebhardt E, Spann W (1983) Vergleichende Untersuchungen der Konzentrationen an Begleitstoffen alkoholischer Getranke im Magen, Blut und Urin. (Comparative studies on the concentrations of congeners of alcoholic beverages in stomach, blood and urine). Beitr Gerichtl Med 41:223–227

Jungmann L, Grosse Perdekamp M, Bohnert M, Auwarter V, Pollak S (2011) Complex suicide by ethanol intoxication and inhalation of fire fumes in an old lady: interdisciplinary elucidation including post-mortem analysis of congener alcohols. Forensic Sci Int. doi:10.1016/j.forsciint.2011.03.024

Rodda LN, Beyer J, Gerostamoulos D, Drummer OH (2013) Alcohol congener analysis and the source of alcohol: a review. Forensic Sci Med Pathol 9(2):194–207

McAnalley BH, Aguayo EH (2008) The chemistry of alcoholic beverages. In: Garriott JC (ed) Medicolegal aspects alcohol, 5th edn. Lawyers and Judges, Tuscan, pp 1–23

Schulz K, Schlenz K, Malt S, Metasch R, Romhild W, Dressler J, Lachenmeier DW (2008) Headspace solid-phase microextraction-gas chromatography–mass spectrometry for the quantitative determination of the characteristic flavouring agent eugenol in serum samples after enzymatic cleavage to validate post-offence alcohol drinking claims. J Chromatogr A 1211(1–2):113–119

Schulz K, Schlenz K, Metasch R, Malt S, Römhild W, Dreßler J (2008) Determination of anethole in serum samples by headspace solid-phase microextraction-gas chromatography–mass spectrometry for congener analysis. J Chromatogr A 1200(2):235–241

Schulz K, Bertau M, Schlenz K, Malt S, Dreßler J, Lachenmeier DW (2009) Headspace solid-phase microextraction-gas chromatography–mass spectrometry determination of the characteristic flavourings menthone, isomenthone, neomenthol and menthol in serum samples with and without enzymatic cleavage to validate post-offence alcohol drinking claims. Anal Chim Acta 646(1–2):128–140

Barth-Haas Group (2013) Hops 2012/2013. Nuremberg, Germany

Buiatti S (2009) Beer composition: an overview. In: Preedy VR (ed) Beer in health and disease prevention. Elsevier, San Diego, USA, pp 212–225

Trevor R, Richard W (2006) Hops. Food science and technology, second ed. CRC Press, New York, pp 177–279

Cortacero-Ramirez S, Hernainz-Bermúdez de Castro M, Segura-Carretero A, Cruces-Blanco C, Fernández-Gutiérrez A (2003) Analysis of beer components by capillary electrophoretic methods. Trends Anal Chem 22(7):440–455

Gerhäuser C (2005) Beer constituents as potential cancer chemopreventive agents. Eur J Cancer 41(13):1941–1954

Kovačevič M, Kač M (2002) Determination and verification of hop varieties by analysis of essential oils. Food Chem 77(4):489–494

Kovačevič M, Kač M (2001) Solid-phase microextraction of hop volatiles: potential use for determination and verification of hop varieties. J Chromatogr A 918(1):159–167

Schmalreck AF, Teuber M (1975) Structural features determining the antibiotic potencies of natural and synthetic hop bitter resins, their precursors and derivatives. Can J Microbiol 21(2):205–212

Schönberger C, Kostelecky T (2011) 125th Anniversary review: the role of hops in brewing. J Inst Brew 117(3):259–267

Kappler S, Krahl M, Geissinger C, Becker T, Krottenthaler M (2010) Degradation of iso-α-acids during wort boiling. J Inst Brew 116(4):332–338

Raumschuh J, Ackermann R, Burkhardt R, Gant C, Hamilton B, Kawasaki M, Pruneda T, Smith R, Thompson D, Van Der Merwe W, Vincent M, Wong S, Murphey J (1999) Determination of iso-alpha-, alpha-, and beta-acids in hop extracts and isomerized hop extracts by high-performance liquid chromatography. J Am Soc Brew Chem 57(4):162–165

Ting PL, Kay S, Ryder D (2007) Separation and identification of stereoisomers of isomerized α-acid derivatives by HPLC/DAD and electrospray HPLC/MS. J Am Soc Brew Chem 65(1):9–14

Salter S, Brownie S (2010) Treating primary insomnia—the efficacy of valerian and hops. Aust Fam Physician 39(6):433–437

Brattström A (2009) Humulus lupulus (hops), is there any evidence for central nervous effects related to sleep? Acta Hort 848:173–178

Weeks BS (2009) Formulations of dietary supplements and herbal extracts for relaxation and anxiolytic action: Relarian™. Med Sci Monit 15(11):RA256–RA262

Kappler S, Schönberger C, Krottenthaler M, Becker T (2010) Isohumulones—a review. Brew Sci 63:105–111

Vanhoenacker G, Sandra P (2009) Methods for the assay of iso-α-acids and reduced iso-α-acids in beer. In: Preedy VR (ed) Beer in health and disease prevention. Academic, San Diego, pp 1015–1029

De Keukeleirc D (2000) Fundamentals of beer and hop chemistry. Quim Nova 23(1):108–112

Hughes P (2000) The significance of iso-a-acids for beer quality. J Inst Brew 106(5):271–276

Intelmann D, Haseleu G, Dunkel A, Lagemann A, Stephan A, Hofmann T (2011) Comprehensive sensomics analysis of hop-derived bitter compounds during storage of beer. J Agric Food Chem 59(5):1939–1953

Intelmann D, Haseleu G, Hofmann T (2009) LC-MS/MS quantitation of hop-derived bitter compounds in beer using the ECHO technique. J Agr Food Chem 57(4):1172–1182

Hofta P, Dostálek P, Sýkora D (2007) Liquid chromatography-diode array and electrospray high-accuracy mass spectrometry of iso-α-acids in DCHA-Iso standard and beer. J Inst Brew 113(1):48–54

Kunimune T, Shellhammer TH (2008) Foam-stabilizing effects and cling formation patterns of iso-alpha-acids and reduced iso-alpha-acids in lager beer. J Agric Food Chem 56(18):8629–8634

O'Rourke T (2003) Hops and hop products. Brew Int 3(1):21–25

Vanhoenacker G, De Keukeleire D, Sandra P (2004) Analysis of iso-α-acids and reduced iso-α-acids in beer by direct injection and liquid chromatography with ultraviolet absorbance detection or with mass spectrometry. J Chromatogr A 1035(1):53–61

Dick GL, Stone HM (1987) Alcohol loss arising from microbial contamination of drivers' blood specimens. Forensic Sci Int 34(1–2):17–27

Lewis RJ, Johnson RD, Angier MK, Vu NT (2004) Ethanol formation in unadulterated postmortem tissues. Forensic Sci Int 146(1):17–24

Peters FT, Drummer OH, Musshoff F (2007) Validation of new methods. Forensic Sci Int 165(2–3):216–224

Peters FT, Maurer HH (2002) Bioanalytical method validation and its implications for forensic and clinical toxicology—a review. Accred Qual Assur 7(11):441–449

Matuszewski BK, Constanzer ML, Chavez-Eng CM (2003) Strategies for the assessment of matrix effect in quantitative bioanalytical methods based on HPLC-MS/MS. Anal Chem 75(13):3019–3030

Shah VP, Midha KK, Findlay JW, Hill HM, Hulse JD, McGilveray IJ, McKay G, Miller KJ, Patnaik RN, Powell ML, Tonelli A, Viswanathan CT, Yacobi A (2000) Bioanalytical method validation: a revisit with a decade of progress. Pharm Res 17(12):1551–1557

Beyer J, Peters FT, Kraemer T, Maurer HH (2007) Detection and validated quantification of nine herbal phenalkylamines and methcathinone in human blood plasma by LC-MS/MS with electrospray ionization. J Mass Spectrom 42(2):150–160

De Keukeleire D, Vindevogel J, Szücs R, Sandra P (1992) The history and analytical chemistry of beer bitter acids. Trends Anal Chem 11(8):275–280

Purple Sage Botanicals (2011) Humulus lupulus (L). North Yorkshire, UK

Royle L, Ames JM, Hill CA, Gardner DSJ (2001) Analysis of hop acids by capillary electrophoresis. Food Chem 74(2):225–231

Hofte AJP, Van Der Hoeven RAM, Fung SY, Verpoorte R, Tjaden UR, Van Der Greef J (1998) Characterization of hop acids by liquid chromatography with negative electrospray ionization mass spectrometry. J Am Soc Brew Chem 56(3):118–122

Acknowledgments

The authors would like to acknowledge Dr. Jochen Beyer for his contribution in the initial phase of the project. The authors would also like to acknowledge Dr. Morris Odell, Dr. Angela Sungaila, and Ms. Adele O'Hehir in providing the resources, medical supervision, and phlebotomy of the volunteer in the drinking study.

Conflict of interest

The authors declare that there is no conflict of interest.

Ethics

Approval for the human consumption of beer and subsequent specimen retrieval and analysis was obtained from the Human Research Ethics Committee at the Victorian institute of Forensic Medicine.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rodda, L.N., Gerostamoulos, D. & Drummer, O.H. The rapid identification and quantification of iso-α-acids and reduced iso-α-acids in blood using UHPLC-MS/MS: validation of a novel marker for beer consumption. Anal Bioanal Chem 405, 9755–9767 (2013). https://doi.org/10.1007/s00216-013-7413-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-013-7413-0