Abstract

Polybrominated diphenyl ethers, polychlorinated biphenyls, polycyclic aromatic hydrocarbons and organochlorine pesticides in the low nanogram-per-litre range in water were enriched by solid-phase extraction (SPE) disks and their concentration determined by large-volume injection/gas chromatography–mass spectrometry (LVI/GC-MS). One advantage of using SPE disks in comparison with SPE cartridges is that suspended particulate matter (SPM) does not have to be separated prior to the enrichment step, which saves time and effort. To increase the sensitivity of the method, the SPE disk procedure was combined with LVI/GC-MS, which has not been reported so far for water analysis. The method was calibrated in ranges from 0.25 to 2.5 ng/L and from 2.5 to 25 ng/L. The average recovery was 76 % at an analyte concentration of 2.5 ng/L. The limits of quantification, defined at a signal-to-noise ratio of 6:1, reach from 0.1 to 24.0 ng/L and are up to 400 times lower than previously reported in water analysis. By the developed SPE/LVI/GC-MS method, it is possible to investigate the whole water sample without prior separation of the SPM within 2 h including GC-MS analysis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

One of the biggest advantages of solid-phase extraction (SPE) disks in water analysis is that no prior separation step is necessary for the investigation of surface water containing suspended particulate matter (SPM). Due to the higher cross-sectional area in contrast to SPE cartridges, SPE disks rarely tend to plug in the presence of SPM [1–3]. Therefore, no additional efforts are necessary to separate SPM, and time and work can be saved [4]. Other advantages of SPE disks compared with SPE cartridges mentioned in literature are mitigation of breakthrough and high flow rates [1, 2, 5], which allow the extraction of high sample volumes [5]. This is again linked with high enrichment factors and low limits of detection (LODs), without the risk of channelling [5].

Generally, after conditioning the SPE disk by an organic solvent and water, the whole water sample is enriched on the SPE disk, without prior separation of SPM. Thereby, the SPM remains on top of the extraction disk. Following a subsequent drying step, the analytes are eluted from the phase material and the SPM by an organic solvent in one step. After a potential volume reduction of the solvent, the extract can be analysed.

Due to the low concentration of organic compounds in the aqueous environment, sensitive methods are required for their determination. One possible way is to combine SPE disk enrichment with a large-volume injection (LVI)/gas chromatography–mass spectrometry (GC-MS) method. In contrast to the usual injection volume of a few microlitres, much larger volumes of extract are injected into the analytical device, and consequently, the sensitivity of the analytical method can be principally increased.

Despite the simplicity of this approach, in literature, only one method for water analysis is documented, which combines SPE disks (diameter, ≥47 mm) with LVI/GC. Steen et al. linked a LVI/GC–ion trap tandem MS method (injection volume, 40 μL) with a SPE disk sample preparation procedure by using styrene divinylbenzene extraction disks for the investigation of five pesticides, including atrazine. The study focused on increasing sensitivity by using MS/MS and different ionisation modes [6]. In contrast, with regard to sample preparation, the authors merely mentioned the used method without any validation. Thus, the study presented here is the first that details the validation of a SPE disk/LVI/GC-MS method.

Although attractive, there are also some limitations of LVI. The noise level and matrix-based interferences and therefore the LODs increase by increasing injection volume [7–9]. To suppress these effects, additional efforts during the sample preparation, such as pure solvents and cleanup procedures, are necessary [7, 8]. Furthermore, loss of analytes associated with low recoveries can occur because analytes are carried along during solvent elimination via the split vent, by strong adsorption onto the packing material or by degradation in the liner [8, 10–12]. These drawbacks can be overcome by closing the vent shortly before the solvent elimination is finished, by adding a solvent with higher boiling point (also called keeper or co-solvent) or by using empty liners, liners with suitable adsorption material or with smaller inner diameter [8]. Wei et al. suggested to set the programmable temperature vaporizer temperature at least to 10 °C below the boiling point of the solvent, to reduce the partial loss of polybrominated diphenyl ether (PBDE) congeners during solvent elimination, in particular of the lower PBDEs, and the thermal degradation at higher temperature [13]. A “dirty” liner may lead to degradation and discrimination of analytes, as described by Tollbäck et al. for heavy PBDEs. Correspondingly, they changed the liner after 100 to 200 injections [14]. Zhao et al. changed the liner already after 100 injections of sample extracts [9]. They determined halogenated persistent organic pollutants, such as PBDEs and polychlorinated biphenyls (PCBs), in soil, sediment and fish tissue [14] in contrast to Tollbäck et al., who investigated air samples [9]. Moisture in the sample extract may have negative influences on GC-MS analysis as well, e.g. on the ionisation process [15]. The occurrence of residual water and its effect on GC-MS measurement for the SPE disk method used in this study were already investigated previously [16].

Based on the experiences and results of a previous work, which investigated the determination of 54 xenobiotics in surface water without prior separation of up to 1,000 mg/L SPM by a SPE disk/GC-MS procedure [17], in the present study, a SPE disk/LVI/GC-MS method was developed to reduce further the limits of quantification (LOQs). The here described multiple compound method was validated for 24 analytes in water in the low nanogram-per-litre range and covered the substance groups of the PBDEs, PCBs, polycyclic aromatic hydrocarbons (PAHs) and organochlorine pesticides (OCPs).

Experimental

Materials

For the SPE procedure, the Varian SPEC C18 AR SPE disks (diameter, 47 mm) by Varian were used in combination with a SPE disk holder of Waters and a SPE vacuum manifold station by J.T. Baker. For GC-MS method development, empty, deactivated, single-baffled and multi-baffled glass liners and glass liners with silanized glass wool were tested in a cooled injection system (CIS) 4 from Gerstel.

Solvents, chemicals and standards

In this study, the following 24 target compounds were investigated: aldrin, dieldrin, 2,2-bis(o,p-chlorophenyl)-1,1,1-trichloroethane (o,p′-DDT), p,p′-(dichlorodiphenyl)dichloroethane (p,p′-TDE), endrin, alpha-endosulfan, beta-endosulfan, isodrin, BDE 28 (2,4,4′-tribromodiphenyl ether), BDE 47 (2,2′,4,4′-tetrabromodiphenyl ether), BDE 99 (2,2′,4,4′,5-pentabromodiphenyl ether), BDE 100 (2,2′,4,4′,6-pentabromodiphenyl ether), BDE 153 (2,2′,4,4′,5,5′-hexabromodiphenyl ether), BDE 154 (2,2′,4,4′,5,6′-hexabromodiphenyl ether), benzo[b]fluoranthene, benzo[g,h,i]perylene, benzo[k]fluoranthene, indeno[1,2,3-c,d]pyrene (PAH-mix by EPA, each 100 μg/mL in acetonitril), PCB 28, PCB 52, PCB 101, PCB 138, PCB 153 and PCB 180 (PCB Mix 1, each 100 ng/L in acetone; Dr. Ehrenstorfer). In addition, PCB 208 (Ultra Scientific) was used as volumetric standard (VS). The purity of all used substances was at least 97 %. They were purchased from Cambridge Isotope Laboratories, Dr. Ehrenstorfer, Fluka, LGC Promochem, National Physical Laboratory (UK), PAH Research Institute, Riedel de Haën, SERVA or Ultra Scientific.

The used stock solutions were prepared by weighing and solving the standards in a defined volume of solvent or were purchased from mentioned suppliers (electronic supplementary material Table S1). All other used solutions were made by diluting the stock solution or their dilutions in a defined volume of acetone (electronic supplementary material Tables S2–S5). The total method was validated in concentration ranges from 0.25 to 2.5 ng/L and from 2.5 to 25 ng/L. For every concentration range, seven spike solutions were used (electronic supplementary material Table S5). Up to their use, all solutions were stored in darkness at 4 °C.

PCB 208 and fluoranthene-D10 were used as VSs and were combined in one solution (electronic supplementary material Table S2 and S4). The combination of the two VSs enables to connect a single sample preparation step with two subsequent analytical methods with different sensitivities and allows to cover a large concentration range. In this case, the SPE disk method can be combined with a GC-MS method with an injection volume of 1 [17] and 175 μL, whereby the latter method is described in the presented study and PCB 208 was used as VS.

All solvents used for the experiments were picograde and were purchased from LGC Promochem. The used nitrogen and helium gas had a purity of 5.0.

Blank water

For the experiments, tap water filtered through activated carbon (blank water, pH = 6.15) was used. This water was absolutely free of analytes and was used to prove the fitness of the developed method. The water was also used to rinse the sample bottles after the extraction step.

Solid-phase extraction

SPE was performed as described in the previous study [17] and is briefly described here. For method validation, the water sample was spiked with 200 μL of a spike solution 24 h before the sample preparation was implemented to enable equilibration. In the beginning, the SPEC C18 AR extraction disk was conditioned with acetone and blank water. Then, 1 L water sample was enriched within 20 min (50 mL/min) on the SPE disk. To transfer the whole sample on the SPE disk, the sample bottle was also rinsed with blank water. After drying the SPE disk for 30 min by vacuum, the analytes were extracted four times by 4 mL acetone (contact time, 2 min, 3 × 5 min). Subsequently, 100 μL of the volumetric standard (250 μg/L) was added to the combined eluates, and then the eluates were concentrated to 1.5 mL in a nitrogen stream at 40 °C (water bath). Finally, the extract was stored in darkness at 4 °C until it was analysed by GC-MS.

Gas chromatography–mass spectrometry

For the analysis of the extracts, a GC 6890/MSD 5973 of Agilent Technologies equipped with a CIS 4 and a multi-purpose-sampler (MPS)-2 by Gerstel was used. During method development, the injection volume, the injection speed, the injection temperature, including the holding time at the end of the CIS programme, the kind of liner and the splitless time were optimised.

In the final method, 175 μL of the extract was injected with an injection speed of 0.75 μL/s and at an injection temperature of 30 °C into an empty, deactivated, single-baffled glass liner (Fig. 1). The solvent was removed in solvent vent mode with a vent flow of 60 mL/min (gas, nitrogen). The split vent was closed 0.05 min after the MPS-2 had terminated the injection. At the same time, the CIS temperature was increased with 12 °C/s from 30 °C (0 min) to 300 °C, which was held for 5 min. When the CIS reached a temperature of 300 °C, the GC oven temperature was increased with 10 °C/min from 50 °C (0 min) to 300 °C and was then held for 10 min. To prevent carry-over, the split vent was opened again after a splitless time of 3 min with a gas flow of 20 mL/min nitrogen (Fig. 1). The separation was performed on an Optima®-5-ms capillary column (30 m × 0.25 mm × 0.25 μm) by Macherey-Nagel. Helium 5.0 was used as carrier gas at a constant flow of 1.0 mL/min. The analytes were ionised in electron impact ionisation mode (70 eV) and detected in selected ion monitoring (SIM). The identification was ensured by the retention times and maximal four characteristic mass-to-charge ratios (m/z ratio) of which one was used for quantification (Table 1). The temperature for the transfer line and the ion source was set constantly to 280 and 250 °C, respectively.

Results and discussion

LVI/GC-MS optimisation

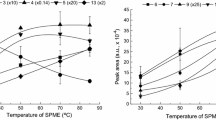

In order to investigate the maximal injection volume possible, the injection volume was systematically increased (electronic supplementary material Fig. S1) and was finally fixed to 175 μL, due to the maximum enrichment factor achieved over the whole method including the sample preparation procedure. In order to avoid loss of sensitivity at higher injection volumes, the splitless time was increased and was investigated from 3 to 7 min (electronic supplementary material Fig. S2). Finally, the splitless time was set to 3 min, caused by the small differences of peak areas between the different times. For the tested injection speeds (0.65 to 0.95 μL/min), the sensitivity showed also small differences and was set to 0.75 μL/s (electronic supplementary material Fig. S3). The injection temperature was varied from 20 to 50 °C and was set to the point of maximum sensitivity for most analytes at 30 °C (electronic supplementary material Fig. S4). Additionally, the holding time of the maximum temperature of the CIS was set to the point of maximum sensitivity at 5 min after it was tested between 3 and 7 min (electronic supplementary material Fig. S5). Moreover, the influence of different liner types on sensitivity was checked and was negligibly small in this case (electronic supplementary material Fig. S6). In the following, an empty, deactivated, single-baffled glass liner was used, although a multi-baffled glass liner and a glass liner with silanized glass wool are also suitable.

For all experiments of LVI/GC-MS optimisation, a solution corresponding to an analyte concentration of 25 ng/L in the water sample was used (electronic supplementary material Table S5, “Spike VII” solution).

Method validation

Limit of detection

Different definitions of LOD and LOQ used in literature complicate the comparison of different procedures and their performance. Therefore, in this study, the LOD and LOQ were calculated considering different definitions (Table 1 and electronic supplementary material Tables S6 and S7). The LODs were determined according to IUPAC with k = 3, whereby the noise level was determined at three blank samples. The LODs varied between 0.02 and 12 ng/L (Table 1). Additionally, in electronic supplementary material Table S6, the LOQs were calculated by the common signal-to-noise ratio (S/N) and the blank value method and the calibration method as described in DIN 32 645 [18] often used in Germany. The results of both methods mentioned in DIN 32 645 are not consistent. The LOQs determined by the blank method, which is recommended by DIN 32 645, are most comparable to the LOQs calculated by the S/N (electronic supplementary material Table S6) [18].

The definition of LOD and LOQ can also be important in association with legal standards. For example, the WFD (2000/60/EC) [19] and its German implementation, called Oberflächengewässerverordnung (OGewV) [20], demand that the LOQ is equal or below a value of 30 % of the relevant EQS (Table 1) [20, 21]. How to determine the LOQ is only further specified in the Guidance Document No. 19 of the common implementation strategy of the WFD [22]. This defines the LOQ as a multiple of the LOD at an analyte concentration that can reasonably be determined at an acceptable level of accuracy and precision, and the LOD is calculated by three times the standard deviation (SD) of the blank [22]. However, this document does neither specify the multiplier nor what an acceptable level of accuracy and precision is. For example, benzo[b]fluoranthene, benzo[k]fluoranthene and PCB 28 fulfilled the requirements of WFD in the presented study only depending on the factor of multiplication of the LOD (Table 1).

The aim to improve the LOQs by the use of LVI (electronic supplementary material Table S6) compared with previous injection of 1 μL [17] was achieved except for the PAHs. Direct comparison of the LOQs with literature shows that, especially for the volatile compounds (retention time, <23 min), the LOQs in this study are up to 400 times lower than previously reported in water analysis (electronic supplementary material Table S7) [23–25].

Recoveries, repeatability and linearity

The recoveries as well as the repeatability were determined for the whole method, including the SPE procedure, for an analyte concentration of 2.5 ng/L (n = 3). Due to higher LOQs than 2.5 ng/L (S/N = 6:1, electronic supplementary material Table S6), the values could not be calculated for the late eluted analytes (retention time, >23.85 min) and therefore are not shown in Table 2. The recoveries vary from 42 to 114 % and are higher than 70 % for 80 % of the regarded analytes. With the exception of o,p′-DDT, all analytes in Table 2 fulfilled the minimum performance criteria of the WFD that the uncertainty of measurement should be smaller or equal 50 % (k = 2) estimated at the level of the relevant EQS values [21, 26]. Compared with the injection of 1 μL extract [17], for 73 % of the investigated substances, the uncertainty is higher in the presented study, which is due to the ca. ten times lower analyte concentration used. Matrix effects, sorption or partial thermal degradation of the analyte during the injection catalysed by residues in the liner may all contribute to the higher uncertainty at low concentrations using LVI. Additionally, the comparison of the peak values with and without consideration of the SPE showed a substantial influence of the sample preparation on the results despite the use of a volumetric standard (chromatograms are shown in electronic supplementary material Fig. S7), due to partial plugging of the autosampler syringe caused by eventual not totally separated phase material. Sensitivity loss over a series of GC-MS measurements was observed after significantly less than 100 injections in contrast to Tollbäck et al. and Zhao et al. [9, 14]. Degradation during the sample preparation process can be excluded based on the results of a previous study [17].

For all analytes, reasonable working ranges could be established from LOQ (S/N = 6:1, electronic supplementary material Table S6) to a maximum of 25 ng/L (electronic supplementary material Table S8), with the exception of BDE 154 due to its high LOQ.

Comparison with alternative methods

The performance of the method was also checked by comparison with methods from literature (Table 3). In general, the comparison is difficult due to different experimental conditions and definitions, for example for the LOD as mentioned above. Consequently, the values in Table 3 are hardly comparable.

The only method mentioned in literature, which combined SPE disk with LVI/GC-MS, investigated none of the target compounds in this study [6]. All methods dealing with one substance group listed in Table 3 have higher or similar LODs [23, 27–30] than in the developed multi-compound procedure. Only Labadie et al. demonstrate equal or lower LODs for PBDEs by separate analysis of water phase and SPM [31] connected with several more sample preparation steps than in the method described here. Other procedures mentioned in Table 3 also cover several substance groups similar to the developed method. LODs of these LVI-based methods are in a similar range [24, 25, 32–35].

However, none of these other methods specifically addressed those priority pollutants of the WFD.

Conclusions

This study is one of the first investigations that combines SPE disk extraction with LVI/GC-MS and was designed to minimize the expenditure of time and work and to make the investigation of surface water containing SPM possible in one step. It is possible to achieve LOQs at the low nanogram-per-litre level by the described SPE disk/LVI/GC-MS method. The aim to improve the LOQs for all 24 analytes by the use of LVI could be achieved, with the exception of the PAHs. It could be also shown that the LOQs of the developed method are lower compared with numerous methods described in literature. Further reduction of the LOQs could be reached in the future by an increase of the sample volume. Additionally, in the following studies, the influence of the sample preparation should be investigated in more detail.

References

Pichon V, Charpak M, Hennion MC (1998) Multiresidue analysis of pesticides using new laminar extraction disks and liquid chromatography and application to the French priority list. J Chromatogr A 795(1):83–92

Bao ML, Pantani F, Barbieri K, Burrini D, Griffini O (1996) Multi-residue pesticide analysis in soil by solid-phase disk extraction and gas chromatography ion-trap mass spectrometry. Int J Environ Anal Chem 64(4):233–245

Sun L, Liu Y, Chu XG, Lin JM (2010) Trace analysis of fifteen androgens in environmental waters by LC-ESI-MS-MS combined with solid-phase disk extraction cleanup. Chromatographia 71(9–10):867–873

Werres F, Balsaa P, Schmidt TC (2009) Total concentration analysis of polycylic aromatic hydrocarbons in aqueous samples with high suspended particulate matter content. J Chromatogr A 1216(12):2235–2240

Domingues V, Cabral M, Alves A, Delerue-Matos C (2009) Use and reuse of SPE disks for the determination of pyrethroids in water by GC-ECD. Anal Lett 42:706–726

Steen RJCA, Freriks IL, Cofino WP, Brinkman UAT (1997) Large-volume injection in gas chromatography-ion trap tandem mass spectrometry for the determination of pesticides in the marine environment at the low ng/l level. Anal Chim Acta 353:153–163

Teske J, Engewald W (2002) Methods for, and applications of, large-volume injection in capillary gas chromatography. Trends Anal Chem 21(9–10):584–593

Mol HGJ, Janssen H-G, Cramers CA, Brinkman UAT (1996) Large-volume injection in gas chromatographic trace analysis using temperature-programmable (PTV) injectors. Trends Anal Chem 15(4):206–214

Zhao Y, Yang L, Wang Q (2007) Pulsed large volume injection gas chromatography coupled with electron-capture negative ionization quadrupole mass spectrometry for simultaneous determination of typical halogenated persistent organic pollutants. J Am Soc Mass Spectrom 18:1375–1386

Mol HGJ, Janssen H-G, Cramers CA, Brinkman UAT (1995) Large volume sample introduction using temperature programmable injectors: implications of liner diameter. J High Resolut Chromatogr 18:18–26

Hoh E, Mastovska K (2008) Large volume injection techniques in capillary gas chromatography. J Chromatogr A 1186:2–15

van Leeuwen SPJ, de Boer J (2008) Advances in the gas chromatographic determination of persistent organic pollutants in the aquatic environment. J Chromatogr A 1186:161–182

Wei H, Dassanayake PS, Li A (2010) Parametric evaluation for programmable temperature vaporisation large volume injection in gas chromatographic determination of polybrominated diphenyl ethers. Int J Environ Anal Chem 90(7):535–547

Tollbäck P, Bjroklund J, Östman C (2003) Large-volume programmed-temperature vaporiser injection for fast gas chromatography with electron capture and mass spectrometric detection of polybrominated diphenyl ethers. J Chromatogr A 991(2):241–253

Li YT, Whitaker J, McCarty C (2009) New advances in large-volume injection gas chromatography–mass spectrometry. J Liq Chromatogr R T 32(11–12):1644–1671

Erger C, Balsaa P, Werres F, Schmidt TC (2012) Occurrence of residual water within disk-based solid-phase extraction and its effect on GC-MS measurement of organic extracts of environmental samples. Anal Bioanal Chem 403:2541–2552

Erger C, Balsaa P, Werres F, Schmidt TC (2012) Multi-component trace analysis of organic xenobiotics in surface water containing suspended particular matter by solid phase extraction/gas chromatography–mass spectrometry. J Chromatogr A 1249:181–189

DIN 32 645 “Nachweis-, Erfassungs- und Bestimmungsgrenze-Ermittlung unter Wiederholbedingungen-Begriffe, Verfahren, Auswertung” (Mai 1994)

European Commission (2000) Directive 2000/60/EC of the European Parliament and of the Council of 23 October 2000 establishing a framework for community action in the field of water policy

Verordnung zum Schutz der Oberflächengewässer (Oberflächengewässerverordnung-OGewV), Bundesgesetzblatt Teil 1, Nr. 37 (25 July 2011)

European Commission (2009) Directive 2009/90/EC of 31 July 2009 laying down, pursuant to Directive 2000/60/EC of the European Parliament and of the Council, technical specifications for chemical analysis and monitoring of water status

European Commission (2009) Common implementation strategy for the Water Framework Directive (2000/60/EC)—guidance document no. 19—guidance on surface water chemical monitoring under the Water Framework Directive

Brondi SHG, Spoljaric FC, Lancas FM (2005) Ultratraces analysis of organochlorine pesticides in drinking water by solid phase extraction coupled with large volume injection/gas chromatography/mass spectrometry. J Sep Sci 28:2243–2246

Prieto A, Schrader S, Moeder M (2010) Determination of organic priority pollutants and emerging compounds in wastewater and snow samples using multiresidue protocols on the basis of microextraction by packed sorbents coupled to large volume injection gas chromatography—mass spectrometry analysis. J Chromatogr A 1217(38):6002–6011

Prieto A, Telleria O, Etxebarria N, Fernandez LA, Usobiaga A, Zuloaga O (2008) Simultaneous preconcentration of a wide variety of organic pollutants in water samples. Comparison of stir bar sorptive extraction and membrane-assisted solvent extraction. J Chromatogr A 1214(1–2):1–10

European Commission (2010) Common implementation strategy for the Water Framework Directive (2000/60/EC)—guidance document no. 25—guidance on chemical monitoring of sediment and biota under the Water Framework Directive

Nakamura S, Yamagami T, Daishima S (2001) Determination of organochlorine pesticides in river water by gas chromatography-negative-ion chemical-ionization mass spectrometry using large volume injection. Analyst 126(10):1658–1662

Lüthje K, Hyötyläinen T, Riekkola M-L (2004) On-line coupling of microporous membrane liquid–liquid extraction and gas chromatography in the analysis of organic pollutants in water. Anal Bioanal Chem 378:1991–1998

Schellin M, Popp P (2003) Membrane-assisted solvent extraction of polychlorinated biphenyls in river water and other matrices combined with large volume injection-gas chromatography–mass spectrometric detection. J Chromatogr A 1020(2):153–160

Serôdio P, Salomé CM, Nogueira JMF (2007) Use of experimental design in the optimization of stir bar sorptive extraction for the determination of polybrominated diphenyl ethers in environmental matrices. J Chromatogr A 1141:259–270

Labadie P, Tlili K, Alliot F, Bourges C, Desportes A, Chevreuil M (2010) Development of analytical procedures for trace-level determination of polybrominated diphenyl ethers and tetrabromobisphenol A in river water and sediment. Anal Bioanal Chem 396:865–875

Li Y, George JE, McCarty CL (2007) Online in situ analysis of selected semi-volatile organic compounds in water by automated microscale solid-phase extraction with large-volume injection/gas chromatography/mass spectrometry. J Chromatogr A 1176(1–2):223–230

Li YT, McCarty CL, George EJ (2011) Determination of selected semi-volatile organic compounds in water using automated online solid-phase extraction with large-volume injection/gas chromatography/mass spectrometry. Front Environ Sci En 5(3):417–425

Schellin M, Popp P (2007) Application of a poly siloxane-based extraction method combined with large volume injection-gas chromatography–mass spectrometry of organic compounds in water samples. J Chromatogr A 1152(1–2):175–183

Bizkarguenaga E, Ros O, Iparraguirre A, Navarro P, Vallejo A, Usobiaga A, Zuloaga O (2012) Solid-phase extraction combined with large volume injection-programmable temperature vaporization-gas chromatography–mass spectrometry for the multiresidue determination of priority and emerging organic pollutants in wastewater. J Chromatogr A 1247:104–117

European Commission (2008) Directive 2008/105/EC of the European Parliament and of the Council of 16 December 2008 on environmental quality standards in the field of water policy, amending and subsequently repealing Council Directives 82/176/EEC, 83/513/EEC, 84/156/EEC, 84/491/EEC, 86/280/EEC and amending Directive 2000/60/EC of the European Parliament and of the Council

López FJ, Beltran J, Hernández MFF (1998) Comparison of simplified methods for pesticide residue analysis. Use of large-volume injection in capillary gas chromatography. J Chromatogr A 823:25–33

Acknowledgements

The work was supported by the Federal Ministry for Economy and Technology based on a resolution of the German Parliament, ZIM—Zentrales Innovationsprogramm Mittelstand and AiF—Arbeitsgemeinschaft industrieller Forschungsvereinigungen “Otto von Guericke” e.V.. Furthermore, we thank Varian Inc. for donation of materials.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 726 kb)

Rights and permissions

About this article

Cite this article

Erger, C., Balsaa, P., Werres, F. et al. Determination of organic priority pollutants in the low nanogram-per-litre range in water by solid-phase extraction disk combined with large-volume injection/gas chromatography–mass spectrometry. Anal Bioanal Chem 405, 5215–5223 (2013). https://doi.org/10.1007/s00216-013-6918-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-013-6918-x