Abstract

Solid-phase extraction (SPE) is a widespread and powerful sample preparation technique in many analytical areas. Many of the used methods reduce residual water during sample preparation by drying the phase material. Despite the importance of this step, hardly any study deals specifically with the drying process, and if so, only few aspects are mentioned. The present study is the first systematic investigation of the drying process using SPE disks, including the influence of process parameters on the amount of residual water and its consequences for subsequent elution and gas chromatography–mass spectrometry (GC-MS) analysis. The following points were investigated in detail: (1) the change of pressure and volume flow during the drying process, (2) the remaining amount of water at different drying times for different SPE materials, (3) the influence of suspended particulate matter on the drying process and (4) the effects of the residual water on the elution step by using different organic solvents. The study shows that the volume of residual water in the SPE disk is affected by the fixation of the sorbent, the phase material, the amount of sorbent, the pumping settings and the duration of the drying process. Furthermore, systematic investigations demonstrate the influence of residual water on the GC-MS analysis and show analytical interferences only for a few of the investigated analytes. All results suggest that more problems in SPE GC-MS methods are caused by residual water than previously assumed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Solid-phase extraction (SPE) is a powerful and therefore widespread sample preparation technique in clinical, biochemical, pharmaceutical and environmental analysis [1–3]. It is used for matrix separation, rapid clean-up and enrichment of target compounds preceding chromatographic analysis [2–5]. The technical principle is based on the distribution of analytes between a solid and a liquid or a headspace vapour. In water analysis, the typical SPE process starts by sorbent cleaning, followed by the activation and the conditioning of the sorbent generally by an organic solvent and water (to remove the excess activation solvent) and the extraction of compounds from the water sample. The subsequent steps are the removal of interferences (clean-up) and water, and finally the elution of sorbed analytes (Fig. 1) [3, 4, 6]. Many of the reported methods reduce the remaining water volume on the phase material after the extraction step by actively drying the sorbent [4, 5, 7–12]. The reasons for this step are manifold [13, 14]. Residual water may hamper the elution of sorbed analytes by a non-polar solvent, e.g. n-hexane, and reduce the recovery of the analytes [9, 15–18] or can influence the elution strength of solvents by mixing [16]. Furthermore, residual water can disturb the subsequent solvent exchange to another solvent [5]. Reduction of the volume of residual water can also be a prerequisite for a derivatisation step after elution. For silylation, for example, it is necessary to eliminate water as completely as possible [19]. Finally, residual water on the phase material can induce interferences in the instrumental analysis step [4, 5, 10–12, 16, 20–22]. Van der Hoff et al. reports that small quantities of water can result in a rapid deterioration of the gas chromatography (GC) system. In the on-column introduction technique, this problem can be alleviated to some extent by using properly deactivated retention gaps [12]. Furthermore, the use of bonded and cross-linked stationary phases can prevent the damage of GC columns by water and organic solvents [23], which makes it even possible to carry out direct aqueous injection in GC analysis with comparable results to other techniques [24].

The points mentioned above demonstrate the importance of the drying process and the potential adverse effects of remaining water [9, 12, 18, 25]. It is well known that the amount of water after the drying step should be as small as possible or be precisely defined to prevent analytical problems and to achieve high recovery and reproducible results [15, 25]. Surprisingly, hardly any study deals specifically with this subject, and in the existing ones, only few aspects are covered [6, 11, 12, 18]. Pico et al. studied the use of several drying agents for the effective removal of water traces from the desorption solvent [20], Zorita et al. checked the effects on polychlorinated biphenyl (PCB) recoveries by drying the SPE disk under vacuum with and without additional drying in a desiccator [9], and van Hout et al. determined the remaining amount of water in the stationary phase of SPE disks at different drying times [21]. Finally, Senseman and co-workers investigated four desiccation methods for SPE disks after enrichment of pesticides in order to determine whether enhanced stability would result when residual water was removed from the disks before storage. They also added anhydrous sodium sulphate to the eluate to remove any excess water [13].

The study presented here was done in the framework of the method development for a multi-residue analysis of 54 non-polar organic compounds in surface water containing suspended particulate matter (SPM) by SPE disks and gas chromatography–mass spectrometry (GC-MS). It quickly became apparent that residual water after the drying step has a big influence on the results of the whole method. Therefore, the first extensive and systematic investigation of the vacuum-based drying of SPE disks was carried out in this study.

Experimental

Reagents and materials

For investigation of the drying process, an SPE disk apparatus by Varian Inc. and a SPE manifold station by J. T. Baker were used.

Bakerbond Speedisk Extraction Disk C18 (diameter, 50 mm), Bakerbond Speedisk Extraction Disk H2O Phobic DVB (diameter; 50 mm) and Bakerbond Speedisk Extraction Disk H2O Phobic DVB—high capacity (hc) (diameter, 50 mm) are available at J. T. Baker and the Varian SPEC C18 SPE disk (diameter, 47 mm) was received from Varian Inc..

All organic solvents used for the solutions and experiments were picograde and obtained from LGC Standards GmbH. Tap water filtered through activated carbon was used as blank water, and nitrogen 5.0 and helium 5.0 were used at the concentration and analysis step.

The certified sediment standard PAH Loamy Clay 1 was purchased at LGC Standards GmbH.

The following standards and stock solutions were available at the Cambridge Isotope Laboratories, Dr. Ehrenstorfer, Fluka, LGC Standards GmbH, National Physical Laboratory (UK), PAH Research Institute, Riedel de Haën, SERVA and Ultra Scientific: alachlor, aldrin, atrazine, chlorfenvinphos, chlorpyrifos-ethyl, dieldrin, p,p′-(dichlorodiphenyl)-2,2-dichloroethylene (p,p′-DDE), 2,2-bis(o,p-chlorophenyl)-1,1,1-trichloroethane (o,p′-DDT), p,p′-dichlorodiphenyltrichloroethane (p,p′-DDT), p,p′-(dichlorodiphenyl)dichloroethane (p,p′-TDE), endrin, alpha-endosulfan, beta-endosulfan, hexachlorobenzene, hexachlorobutadiene, alpha-hexachlorocyclohexane (alpha-HCH), beta-hexachlorocyclohexane (beta-HCH), gamma-hexachlorocyclohexane (gamma-HCH, lindane), delta-hexachlorocyclohexane (delta-HCH), isodrin, pentachlorobenzene, 1,2,3-trichlorobenzene, 1,2,4-trichlorobenzene and 1,3,5-trichlorobenzene, trifluralin, simazine, polycyclic aromatic hydrocarbon (PAH)—mix by EPA (acenaphthene, acenaphthylene, anthracene, benzo[a]anthracene, benzo[a]pyrene, benzo[b]fluoranthene, benzo[g,h,i]perylene, benzo[k]fluoranthene, chrysene, dibenzo[a,h]anthracene, fluoranthene, fluorene, indeno[1,2,3-c,d]pyrene, naphthalene, phenanthrene, pyrene each 100 μg/mL in acetonitrile; LGC Standards GmbH), PCB Mix 1 (PCB 28, PCB 52, PCB 101, PCB 138, PCB 153, PCB 180 each 10 ng/μL in acetone; Dr. Ehrenstorfer), acenaphthene-d 10, anthracene-d 10, atrazine-d 5, chrysene-d 12, 4,4′-dibromoctafluorobiphenyl, 3,4-dichloronitrobenzene, fluoranthene-d 10 and 4-n-nonylphenol-d 8. The last eight substances were used as internal standards, whereby fluoranthene-d 10 was used as volumetric standard. Generally, the analytical standards were used to prepare fortification, standards and spike solutions. All stock solutions were prepared by weighing and dissolving in ethyl acetate or acetone and stored at 4 °C. After spiking, the concentrations of PAHs in the samples were 100 ng/L and of all other analytes, 50 ng/L. Concentrations of internal standards in 1 L sample varied from 0.1 to 1.12 μg/L depending on sensitivity.

Determination of the volume flow

The volume flow was determined by a self-made gas flow meter. This consists of a simple glass tube of a volume of 1.2 L. In the glass tube, soap bubbles move with different velocities depending on the volume flow during the drying process of the SPE disk. The gas flow meter is in-line with the SPE disk holder and the water jet pump and in the case of vacuum drying arranged also by this order.

For the experiments, the volume flow was determined for the original C18 SPE disks and during the drying process. Before determining the volume flow for the latter one, SPE disks were twice conditioned with 4 mL acetone and 4 mL water (contact time, 1 min), and 50 mL tap water was enriched to simulate the enrichment process.

Water residue in SPE disks during the drying process

The water residue in extraction disks was determined for four kinds of SPE disks during the drying process. At the beginning, the extraction disks were conditioned twice with 6 mL acetone and 6 mL water (contact time, 1 min) followed by the enrichment of ca. 1 L tap water or blank water (50 mL/min). Afterwards, the SPE disks were dried by vacuum for max. 60 min. The water residue was determined by weighing the SPE disk during the drying process and subtracting the weight of the original SPE disk.

Influence of the drying time on the effectiveness of the elution step

The Bakerbond Speedisk Extraction Disk C18 was conditioned twice with 6 mL acetone and 6 mL water (contact time, 1 min) followed by the enrichment of ca. 1 L of a spiked blank water sample within 30 min. Afterwards, the SPE disk was dried for 7 or 60 min, respectively. Subsequently, the analytes were extracted three times with 3 mL acetone (contact time, 1, 5, 1 min). Finally, 100 μL of the volumetric standard (2.1 mg/L) were added to the combined eluates and analysed by GC-MS. Every variation of the drying time was investigated for three samples (n = 3).

Recoveries of different elution solvents (with and without sediment)

The Varian SPEC C18 SPE disk was conditioned analogously to the investigation of the influence of the drying time on the effectiveness of the elution step. Afterwards, ca. 1 L blank water spiked with analytes or 500 mg certified sediment was enriched on the SPE disk, followed by drying the extraction disk for 30 min. Then, the analytes were extracted four times with 4 mL of an organic solvent (acetone, ethyl acetate, dichloromethane, n-hexane or tetrahydrofuran; contact time, 5 min, each). After the addition of 100 μL volumetric standard (2.1 mg/L) to the combined eluates, the extract was concentrated to 1.5 mL at 40 °C (water bath) in a gentle stream of nitrogen. Finally, the eluates were analysed by GC-MS. Every elution solvent was investigated twice (n = 2), and additionally, a blank sample was investigated. The sediment spiked samples were investigated once (n = 1).

Influence of water on GC-MS analysis

A reference solution of all investigated analytes, internal standards and volumetric standard (1,120–100 μg/L) was spiked with 0% vol., 10% vol. and 20% vol. water and analysed by GC-MS.

GC-MS analysis

The eluates and solutions were analysed by a GC 6890/MSD 5973 of Agilent Technologies equipped with a cooled injection system (CIS 4) by Gerstel GmbH & Co. KG. The analytes were ionised in electron impact ionization mode (EI, 70 eV) and detected in selected ion monitoring. The compounds were identified by their retention times and up to four selected mass to charge ratios (m/z-ratio). One m/z-ratio was used for quantification. Separation was performed by a Zebron ZB5 ms (30 m × 0.25 mm × 0.25 μm) capillary column by Phenomenex Inc.. Helium was used as carrier gas at a constant flow of 1.0 mL/min. After the injection of 1 μL solution to be investigated, the CIS temperature was increased with 12 °C/s from 80 °C (0 min) to 300 °C and hold for 5 min. The injection was carried out in splitless mode by a splitless time of 0.5 min, a purge flow of 10 mL/min and a purge time of 2.00 min (gas: nitrogen). For the GC separation, the oven temperature was increased with 10 °C/min from 50 °C (0 min) to 300 °C, and the temperature was held for 5 min. The total runtime amounted to 30 min. The temperature for the transfer line and the ion source were set to 280 °C and 230 °C.

Results and discussion

Drying

The drying step is an important and significant process step in SPE and follows the extraction of the water sample (Fig. 1). One important factor influencing the drying process is the volume flow. This was investigated with two setups that differed only in the SPE disk types and therefore in the fixation of the sorbent. The results show that the measured volume flow through the original, non-conditioned Bakerbond Speedisk Extraction Disk C18 was 2 L/min less than the volume flow through the Varian SPEC C18 SPE disk in spite of applying the same vacuum on the SPE systems. For the Varian SPEC C18 SPE disk, a volume flow of 5.8 ± 0.2 L/min (relative standard deviation (RSD) = 4%, n = 4) was determined leading to a vacuum pressure of −54 ± 10 mbar for the original extraction disk. For the Bakerbond Speedisk Extraction Disk C18, a volume flow of 3.8 ± 0.1 L/min (RSD = 3%, n = 4) was measured leading to a vacuum pressure of −173 ± 10 mbar. These differences were attributed to the SPE disk type and the fixation of the sorbent. In the Varian SPEC C18 SPE disk, the C18 phase material is bound to silica particles that are woven into fibreglass, and the disk is clamped like a filter in a filter apparatus in the SPE system by Varian Inc. [26, 27]. In contrast, loose C18 phase material is used for the Bakerbond Speedisk Extraction Disk C18. The SPE disk is constructed similar to a normal SPE cartridge but with a larger diameter [27, 28].

Pressure and volume flow also differ for both SPE systems during the drying process of wet extraction disks (Fig. 2). This is again due to the different SPE disk types and fixation of the sorbent. Furthermore, in spite of application of a constant working vacuum pressure system, the real pressure increases by 100 to 200 mbar and the volume flow increases on average by about 1.3 L/min during the drying process. These observations can be explained by the decreasing amount of water in the sorbents and therefore the decreasing resistance to the gas flow during the drying process. The different change of the volume flow of the SPE disks over time is also caused by the different SPE disk types. Theoretically, the volume flow should be constant, when the extraction disks are dry again. Figure 2 shows a nearly constant volume flow for the Varian SPEC C18 SPE disk after ca. 10 min drying. Despite being constant, the volume flow of the previously wet SPE disks did not nearly reach the volume flow for both SPE disk types of the original dry extraction disk within 45 min. This suggests that the phase material is irreversibly altered during the steps of conditioning and enrichment.

From these data, it is also possible to estimate the total gas volume for a definite drying time, by plotting the gas volume against the drying time considering the increasing volume flow for both investigated extraction disks. The dependencies of the gas volumes from the drying time can well be described by polynomial regression functions (coefficient of determination > 0.99) (Electronic supplementary material Fig. S1). The gradients of the functions correspond to the volume flows of the extraction disks. Therefore, it is not surprising that the needed gas volume for the drying process depends on the used SPE disk types in addition to the volume flow. For a drying time of 30 min, the total gas volume for the Varian SPEC C18 SPE disk amounts to 102 L and for Bakerbond Speedisk Extraction Disk C18 only to 56 L. In practice, the needed gas volumes are considerably smaller, because the drying time amounts only to a few minutes (3–7 min [17, 29–35]) in most published methods.

Nevertheless, in practice, it may be important to know which time period is necessary to totally dry the extraction disk. To find these out, the residual water in the extraction disk was determined by weighing the SPE disks at different drying times and for different SPE disk types (Fig. 3). For all examined SPE disks, the water contents decrease for increasing drying time similar to the investigation of van Hout et al. [21], but with different rates for the various disk types. This effect was also observed for SPE cartridges by Chee et al. and by Molina et al., but they did not further investigate it [16, 36]. Figure 3 shows that the Varian SPEC C18 SPE disk dries faster than the Bakerbond Speedisk Extraction Disk C18. After a drying time of 10 min, the water content in the Bakerbond Speedisk Extraction Disk C18 is nearly twice as high as in the Varian SPEC C18 SPE disk. Only after 50 min the values converge. As also mentioned above, this is due to the construction principle of the extraction disks. However, this is not the only reason for different drying rates. The water content in the Bakerbond Speedisk Extraction Disk H2O Phobic DVB is always smaller than in the Bakerbond Speedisk Extraction Disk C18, in spite of the same construction principle. This verifies that the type of sorbent plays a role in the drying process, too. Furthermore, the amount of phase material influences the drying process as evident from the different drying rates for the Bakerbond Speedisk Extraction Disk H2O Phobic DVB–hc and the Bakerbond Speedisk Extraction Disk H2O Phobic DVB. The amount of phase material for the hc extraction disk is twice as large as for the non-hc extraction disk. As demonstrated in Fig. 3, at any drying time, the residual water content is always higher in the DVB–hc SPE disk than in the DVB SPE disk. However, the water content cannot be correlated to the amount of phase material. Within the first 30 min, the water content of the DVB–hc SPE disk is only 1.3 times higher in relation to the DVB SPE disk. In Fig. 3, it is also shown that most water is evaporated after 30 min. Then, the water content is reduced further in very small steps. After a drying time of 30 min, ca. 100 μL water remained in the Varian SPEC C18 extraction disk. However, further tests demonstrated a strong fluctuation of the residual water despite constant drying conditions as mentioned for SPE cartridges by Kiss et al. and Gessner et al. [15, 25]. The average residue of water amounts to 280(±130) μL (n = 16, RSD = 50%) and varies between 13 and 460 μL after a drying time of 30 min for the Varian SPEC C18 extraction disk. The fluctuations cannot be correlated to the dry weight of the extraction disk (869 ± 9 mg, RSD = 1%, n = 16) for the Varian SPEC C18 SPE disk and therefore to the amount of phase material. This makes it very difficult to keep the content of water in the eluates constant or at a level near zero.

Furthermore, the residual water volume in the extraction disk is also influenced by SPM. During the extraction of real water samples, SPM is collected on top of the extraction disk. Then, water can also be trapped within or between sediment particles. The amount of residual water depends on the kind and amount of SPM (data not shown). Therefore, it may be necessary to extend the drying time caused by possible stronger fluctuations in presence of a larger amount of SPM [37] compared with samples without SPM.

Certainly, the disadvantages of longer drying times are the high expenditure of time [5, 21] and the possible loss of volatile compounds. Volatile compounds could evaporate during the drying process and hence reduce recoveries. This was validated for the examined analytes by varying only the drying time. Indeed, for the most volatile compounds (here: substances with a partitioning coefficient log K acetone−air < 6.9 as calculated by a polyparametric linear free energy relationships based on Abraham’s linear solvation energy relationships theory [38]; personal communication with S. Endo (2011)), i.e. trichlorobenzenes, naphthalene and acenaphthylene, lower recoveries were obtained at a longer drying time, but for none of the other compounds evaporative losses were observed (Table 1 and Electronic supplementary material Table S1).

Thus, the drying process is influenced by the fixation of the sorbents or disk type, the pumping settings, the type of sorbent, the amount of sorbent, the SPM and, of course, the drying time (Fig. 1).

Elution und concentration

The subsequent elution step is influenced by residual water and takes place after the drying of the SPE disk (Fig. 1). Depending on the organic eluent used, residual water may not be fully miscible with it. This is the case, for example, for n-hexane, and can reduce recoveries and affect reproducibility [15, 16, 18]. In this study, five eluents, namely acetone, ethyl acetate, dichloromethane, n-hexane and tetrahydrofuran were tested. For these, no phase separation was observed in the absence of SPM. Tetrahydrofuran proved not suitable as eluent due to low recoveries (not shown) and many interfering peaks in subsequent gas chromatography. As shown in Fig. 4, lower recoveries were determined for n-hexane compared with acetone, ethyl acetate and dichloromethane. Some of the target compounds could not be detected with n-hexane as eluent, e.g. atrazine. In comparison with n-hexane, the differences among acetone, ethyl acetate and dichloromethane as eluents are small but noticeable. They show different elution strengths for the different substance groups except for PCBs. Ethyl acetate appears to be the best eluent for the highly volatile compounds (log K acetone−air < 6.9), e.g. hexachlorobutadiene, dichloromethane for the lower volatile analytes (log K acetone−air > 10.8) and acetone and ethyl acetate are comparable for all other target compounds (6.9 < log K acetone−air < 10.8). For example, the best of the five eluents for the two highest volatile PAHs (log K acetone−air < 6.9) is ethyl acetate, for the middle volatile PAHs (6.9 < log K acetone−air < 10.8) is acetone and for the lower volatile PAHs (log K acetone−air > 10.8) is dichloromethane (Fig. 4). The recoveries of acenaphthylene and acenaphthene with dichloromethane were only 35% of that with acetone. Therefore, dichloromethane is not suitable for the investigation of all PAHs.

In absence of SPM, ethyl acetate seemed to be a good compromise for all investigated target compounds (Fig. 4), including the examined pesticides. However, in presence of 500 mg certified sediment, a phase separation was observed when ethyl acetate was used and a higher vacuum was needed to suck the solvent through the SPE disk as described by Kiss et al. [15]. This is attributed to the additional trapped water in sediment, as mentioned above. To avoid the reduction of residual water by longer drying times, it is also possible to change the eluent. When using acetone instead of ethyl acetate, no problems appear due to the good miscibility of acetone and water [39]. Also, the recoveries when using acetone are similar or slightly higher than to those with ethyl acetate (Table 2). When processing surface water samples, the presence of SPM can not be avoided, therefore, the use of acetone instead of ethyl acetate is recommended.

Frequently, elution is followed by a solvent concentration step to achieve an even higher enrichment factor and subsequently lower detection limits. It quickly became apparent during the implementation of the procedure that the concentration step is heavily influenced by residual water. Basically, the concentration process is limited by the subsequent analytical method due to their respective limitation of residual water in the final concentrate. Although water can be further removed from the eluate, this often is associated with harsh conditions leading to evaporative losses or the destruction of individual analytes. This could be demonstrated when concentrating the eluate to a final volume smaller than 1 mL. The residual water may also limit any solvent exchange during the concentration step, if the residual water is not miscible with the replacing organic solvent. Furthermore, the content of residual water in the eluate may alter the viscosity of the final concentrate. It may influence further evaporation of solvent and often lead to low recovery of analytes.

This demonstrates that the elution as well as the following concentration step in SPE sample preparation is strongly influenced by the preceding drying step (Fig. 1).

Analysis

In this study, the eluates were analysed by GC-MS. As demonstrated above, the SPE method cannot fully prevent water from entering the GC column. However, the used Zebron ZB5 ms capillary column is a cross-linked and non-polar stationary phase, and therefore is suitable for injection of eluates containing water [23]. Carry-over is prevented due to high end temperatures of the cold injection system and the gas chromatograph (300 °C, 5 min, each). To exclude other effects caused by residual water, the same GC-MS reference solution was studied with different contents of water. The sensitivity of detection for the investigated analytes is hardly affected by the water content except for the less volatile PAH (Fig. 5). These are strongly influenced, and the peak areas considerably decrease with increasing amount of water. This trend was also observed for other analytes, for example, the trichlorobenzenes, but not as pronounced. On the other hand, the opposite was noticed as well, e.g. for triazines. For these substances, sensitivity slightly increases with an increasing amount of water. In the literature, no similar observation has been reported so far, and it cannot be explained till now. The effect could not be related to any molecular or physical parameter such as polarity, partitioning coefficient (for solvent-water or solvent-air) or vapour pressure.

It has been shown that it is difficult to prevent the fluctuation of the water content and therefore its influence on the peak area. By the used eight internal standards, deuterated PAHs and (deuterated and none deuterated) rare organic compounds, it is not possible to compensate the influence of water for the lower volatile PAHs (log K acetone−air > 10.8). Thus, further deuterated standards of lower volatile PAHs would be required. However, also for the other analytes, the influence of water can only partly be compensated.

Conclusion

This study shows that residual water from the drying step has a far-reaching influence on the development and the results of an analytical method. Therefore, residual water should be considered as one potential cause of failure, if a SPE-based method is poorly performing.

The presented study provides a basis for further investigations and the further understanding and control of the drying process. This is of high relevance for many analytical investigations utilizing a SPE step.

References

Walker V, Mills GA (2002) Solid-phase extraction in clinical biochemistry. Ann Clin Biochem 39:464–477

Li KM, Rivory LP, Clarke SJ (2006) Solid-phase extraction (SPE) techniques for sample preparation in clinical and pharmaceutical analysis: a brief overview. Curr Pharm Anal 2(2):95–102

Liska I (2000) Fifty years of solid-phase extraction in water analysis—historical development and overview. J Chromatogr A 885(1–2):3–16

Pichon V (2000) Solid-phase extraction for multiresidue analysis of organic contaminants in water. J Chromatogr A 885(1–2):195–215

Hankemeier T, Louter AJH, Dalluge J, Vreuls RJJ, Brinkman UAT (1998) Use of a drying cartridge in on-line solid-phase extraction gas chromatography mass spectrometry. Hrc-J High Res Chromatogr 21(8):450–456

Pico Y, Louter AJH, Vreuls JJ, Brinkman UAT (1994) Online trace-level enrichment gas-chromatography of triazine herbicides, organophosphorus pesticides, and organosulfur compounds from drinking and surface waters. Analyst 119(9):2025–2031

Miliauskas G, van Beek TA, de Waard P, Venskutonis RP, Sudholter EJR (2006) Comparison of analytical and semi-preparative columns for high-performance liquid chromatography-solid-phase extraction-nuclear magnetic resonance. J Chromatogr A 1112(1–2):276–284

Quesada-Molina C, Garcia-Campana AM, del Olmo-Iruela L, del Olmo M (2007) Large volume sample stacking in capillary zone electrophoresis for the monitoring of the degradation products of metribuzin in environmental samples. J Chromatogr A 1164(1–2):320–328

Zorita S, Westbom R, Thorneby L, Bjorklund E, Mathiasson L (2006) Development of a combined solid-phase extraction-supercritical fluid extraction procedure for the determination of polychlorinated biphenyls in wastewater. Anal Sci 22(11):1455–1459

Sirvent G, Hidalgo M, Salvado V (2004) Evaluation of a new solid-phase cartridge for the preconcentration of phenolic compounds in water. J Sep Sci 27(7–8):613–618

Pittertschatscher K, Inreiter N, Schatzl A, Malissa H (1999) A multiresidue method with mobile on-site sampling based on SPE for ultratrace analysis of plant protectants in environmental waters. Fresenius’ J Anal Chem 365(4):338–350

van der Hoff GR, Pelusio F, Brinkman UAT, Baumann RA, van Zoonen P (1996) Automated solid-phase extraction coupled to gas chromatography with electron-capture detection: a combination of extraction and clean-up of pyrethroids in the analysis of surface water. J Chromatogr A 719(1):59–67

Senseman SA, Lavy TL, Mattice JD (1995) Desiccation effects on stability of pesticides stored on solid-phase extraction disks. Anal Chem 67(17):3064–3068

Stevens J, Crawford M, Robinson G, Roenneburg L (2007) Automated post-collection concentration for purified preparative fractions via solid phase extraction. J Chromatogr A 1142(1):81–83

Kiss G, VargaPuchony Z, Hlavay J (1996) Determination of polycyclic aromatic hydrocarbons in precipitation using solid-phase extraction and column liquid chromatography. J Chromatogr A 725(2):261–272

Chee KK, Wong MK, Lee HK (1995) Optimization by orthogonal array design of solid-phase extraction of organochlorine pesticides from water. Chromatographia 41(3–4):191–196

Messer DC, Taylor LT (1996) Recovery of fortified (2 ppb) EPA method 525.1 analytes from Chesapeake Bay water via solid phase deposition followed by supercritical fluid elution. Hrc-J High Res Chromatogr 19(7):397–402

Torreti L, Simonella A (1992) Determination of organochlorine pesticides residues by solid phase extraction and dual-column HRGC. J High Resolut Chromatogr 15(2):99–101

Hoai PM, Tsunoi S, Ike M, Kuratani Y, Kudou K, Viet PH, Fujita M, Tanaka M (2003) Simultanous determination of degradation products of nonylphenol polyethoxylates and their halogenated derivatives by solid-phase extraction and gas chromatography-tandem mass spectrometry after trimethylsilylation. J Chromatogr A 1020:161–171

Pico Y, Vreuls JJ, Ghijsen RT, Brinkman UAT (1994) Drying agents for water-free introduction of desorption solvent into a gc after online SPE of aqueous samples. Chromatographia 38(7–8):461–469

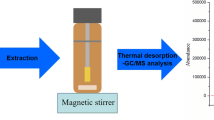

van Hout MWJ, de Zeeuw RA, Franke JP, de Jong GJ (2003) Solid-phase extraction–thermal desorption–gas chromatography with mass selective detection for the determination of drugs in urine. Chromatographia 57(3–4):221–225

van Hout MWJ, de Zeeuw RA, de Jong GJ (1999) Coupling device for desorption of drugs from solid-phase extraction-pipette tips and on-line gas chromatographic analysis. J Chromatogr A 858:117–122

Rood D (ed) (2007) The troubleshooting and maintenance guide for gas chromatography—fourth, revised and updated edition. Wiley-VCH Verlag CmbH & Co. KGaA, Weinheim

Zwank L, Schmidt TC, Haderlein SB, Berg M (2002) Simultaneous determination of fuel oxgenates and BTEX using direct aqueous injection gas chromatography mass spectrometry (DAI-GC/MS). Environ Sci Technol 36:2054–2059

Gessner MO, Schmitt AL (1996) Use of solid-phase extraction to determine ergosterol concentrations in plant tissue colonized by fungi. Appl Environ Microbiol 62(2):415–419

Booklet ‘SPEC’ of Varian Inc.; 7716-190 Int’l 12/02 printed in the USA (2002)

Thurman EM, Snavely K (2000) Advances in solid-phase extraction disks for environmental chemistry. Trends Anal Chem 19(1):18–26

Good TJ, Madre S, Redmond AF (1997) United States Patent of ‘Microcolumn for extraction of analytes from liquids’; Pantent Number: 5,595,653

Valsamaki VI, Sakkas VA, Albanis TA (2007) Determination of the pesticides considered as endocrine-disrupting compounds (EDCs) by solid-phase extraction followed by gas chromatography with electron capture and mass spectrometric detection. J Sep Sci 30:1936–1946

Werres F, Balsaa P, Schmidt TC (2009) Total concentration analysis of polycylic aromatic hydrocarbons in aqueous samples with high suspended matter content. J Chromatogr A 1216:2235–2240

Kayali-Sayadi MN, Rubio-Barroso S, Cuesta-Jimenez MP, Polo-Díez LM (1998) Rapid determination of polycyclic aromatic hydrocarbons in tea infusion samples by high-performance liquid chromatography and fluorimetric detection based on solid-phase extraction. Analyst 123:2145–2148

Chee KK, Wong MK, Lee HK (1996) Determination of organochlorine pesticides in water by membranous solid-phase extraction, and in sediment by microwave-assisted solvent extraction with gas chromatography and electron-capture and mass spectrometric detection. J Chromatogr A 736:211–218

Niu HY, Cai YQ, Shi YL, Wei FS, Liu JM, Jiang GB (2008) A new solid-phase extraction disk based on a sheet of single-walled carbon nanotubes. Anal Bioanal Chem 392:927–935

Romanik G, Gilgenast E, Przyjazny A, Kaminski M (2007) Techniques of preparing plant material for chromatographic separation and analysis. J Biochem Biophys Methods 70(2):253–261

Westbom R, Thörneby L, Zorita S, Mathiasson L, Björklund E (2004) Development of a solid-phase extraction method for the determination of polychlorinated biphenyls in water. J Chromatogr A 1033:1–8

Molina C, Grasso P, Benfenati E, Barcelo D (1996) Automated sample preparation with extraction columns followed by liquid chromatography ionspray mass spectrometry—interferences, determination and degradation of polar organophosphorus pesticides in water samples. J Chromatogr A 737(1):47–58

Bao ML, Pantani F, Barbieri K, Burrini D, Griffini O (1996) Multi-residue pesticide analysis in soil by solid-phase disk extraction and gas chromatography ion-trap mass spectrometry. Int J Environ Anal Chem 64(4):233–245

Abraham MH, Ibrahim A, Zissimos AM (2004) Determination of sets of solute descriptors from chromatographic measurements. J Chromatogr A 1037:29–47

Leandro CC, Bishop DA, Fussell RJ, Smith FD, Keely BJ (2006) Semiautomated determination of pesticides in water using solid phase extraction disks and gas chromatography-mass spectrometry. J Agric Food Chem 54(3):645–649

Acknowledgement

The work was supported by the Federal Ministry for Economy and Technology based on a resolution of the German Parliament; ZIM—Zentrales Innovationsprogramm Mittelstand and AiF—Arbeitsgemeinschaft industrieller Forschungsvereinigungen “Otto von Guericke” e.V.. We also thank Varian Inc. and J. T. Baker for donation of materials.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in the topical collection Analytical Challenges in Environmental and Geosciences with guest editor Christian Zwiener.

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 9.73 MB)

Rights and permissions

About this article

Cite this article

Erger, C., Balsaa, P., Werres, F. et al. Occurrence of residual water within disk-based solid-phase extraction and its effect on GC-MS measurement of organic extracts of environmental samples. Anal Bioanal Chem 403, 2541–2552 (2012). https://doi.org/10.1007/s00216-011-5659-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-011-5659-y