Abstract

This review gives an overview of current knowledge about 3-monochloropropane-1,2-diol (3-MCPD) formation and detection. Although 3-MCPD is often mentioned with regard to soy sauce and acid-hydrolysed vegetable protein (HVP), and much research has been done in that area, the emphasis here is placed on other foods. This contaminant can be found in a great variety of foodstuffs and is difficult to avoid in our daily nutrition. Despite its low concentration in most foods, its carcinogenic properties are of general concern. Its formation is a multivariate problem influenced by factors such as heat, moisture and sugar/lipid content, depending on the type of food and respective processing employed. Understanding the formation of this contaminant in food is fundamental to not only preventing or reducing it, but also developing efficient analytical methods of detecting it. Considering the differences between 3-MCPD-containing foods, and the need to test for the contaminant at different levels of food processing, one would expect a variety of analytical approaches. In this review, an attempt is made to provide an up-to-date list of available analytical methods and to highlight the differences among these techniques. Finally, the emergence of 3-MCPD esters and analytical techniques for them are also discussed here, although they are not the main focus of this review.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

3-Monochloropropane-1,2-diol (3-MCPD) is, together with 1,3-dichloro-2-propanol (1,3-DCP), the best-known component of a group of contaminants called chloropropanols (Fig. 1). 3-MCPD has probably existed in food since humans began to process food, but concerns have grown over the last few decades over the high levels of 3-MCPD in nontraditionally prepared soy sauce and its carcinogenic effects. The other two isomers, 2-MCPD and 2,3-DCP, are usually found at much lower concentrations, or not at all.

3-MCPD was first detected in acid-hydrolysed vegetable protein (HVP), which is a flavouring agent and is used in soy sauce production [1, 2]. Research has shown that the compound is formed during food processing [3–5]. It appears that it is possible to set safe levels of consumption, since the contaminant does not directly affect genetic material. However, this approach has only been considered useful for products known for their high 3-MCPD contents and regular consumption. In March 2001, the European Commission adopted a rule that fixed a limit on the level of 3-MCPD in soy sauce and HVP, which came into force in April 2002. Commission Regulation (EC) No 1881/2006 of 19 December 2006 [6] sets the tolerable daily intake (TDI) at 2 µg kg−1 bw (bodyweight). Maximum levels in foodstuffs (in particular HVP and soy sauce) are set at 20 µg kg−1. This limit is for a liquid product containing 40% dry matter, corresponding to a maximum level of 50 µg kg−1 in dry matter. The level needs to be adjusted according to the dry matter content of the product.

There is no EU regulation for the other chloropropanols. For 1,3-DCP, the general agreement is that its level should be kept as low as reasonably possible. Its mechanism of formation is less clear than that of 3-MCPD, which in some cases seems to be a precursor to it. However, it is likely that 1,3-DCP is also formed via other routes [7, 8].

3-MCPD also represents a challenge in the production of paper towels. The problem here was that the necessary wet-strength resin containing epichlorhydrin resulted in a high loading of 3-MCPD in the final paper towel, which is not in accordance with regulations. Research has enabled the content of 1,3-DCP and 3-MCPD to be reduced to almost zero [9, 10]. The key compound—epichlorhydrin—can also affect food, since it is often present in coating materials, and there is the possibility of 3-MCPD migrating into the food (such as sausage casings, tea bags, coffee filter, etc.) [11, 12]. Very low levels of 3-MCPD can also be found in drinking water from upland areas in the UK. This is due to its presence as a contaminant of epichlorhydrin-containing resins in flocculants used for water purification in a small number of treatment plants [13].

Surveys

Most surveys concentrate on soy sauce and related products, with much information coming from the Food Standards Agency (FSA) in the UK [13–20]. However, other surveys show that 3-MCPD can be found in a wide range of foods [21–24].

It seems that food groups other than soy sauce also have an important impact and contribute significantly to the estimated dietary 3-MCPD intake. These foods include those eaten in large quantities, such as bread, noodles, meat, cakes and biscuits, so that the high intake results from the quantity eaten rather than from a high level of 3-MCPD in the product. Furthermore, it should be noted that 3-MCPD is difficult to avoid considering the variety of foods containing the contaminant, even though it is present in them at only low levels.

According to some studies, the main contributors to dietary exposure to 1,3-DCP were minced meat, sausages, bread, and only then soy and similar sauces [7, 13, 21]. A survey performed by the Food Standards Australia New Zealand (FSANZ) in 2002 [7] found that 1,3-DCP was present in some samples without 3-MCPD, indicating that it may be formed independently of 3-MCPD.

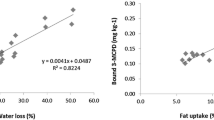

A survey presented by Divinova et al. [25] analysed 24 foods and determined the pH, the amount of water, chlorides, glycerol and fat, as well as the 3-MCPD content. They observed that 3-MCPD was positively correlated with fat and glycerol levels and negatively correlated with the pH. However, the authors were right to point out that 3-MCPD formation is a multivariate problem and that other variables (temperature of processing, length of storage, 3-MCPD ester content) must also be monitored to visualise the relationships between the various parameters more precisely.

In 2007, the FSA launched a survey that was instigated by the European Commission on process contaminants in retail foods. It will run for three years and it focusses on 3-MCPD, acrylamide, ethyl carbamate and furan [26].

Risks related to consumption

3-MCPD

3-MCPD was reported to affect male fertility, kidney functioning and body weight in rats when given regularly in high doses [27–29]. It has also been reported that the contaminant does not have significant genotoxic potential in vivo [13, 29–31]. Studies have shown that 3-MCPD is carcinogenic in rats when they were given this substance in high doses over a long period of time. However, a review of toxicological, metabolic, and mechanistic data on 3-MCPD by Lynch et al. [31] concluded that tumours reported in F344 rats developed as a result of nongenotoxic mechanisms and are not considered to be relevant to humans exposed to trace amounts of 3-MCPD. Thus, it is unlikely that 3-MCPD presents a carcinogenic risk to man, provided that normal exposure is 1000 times lower than the no observed effect level (NOEL) of 1.1 mg/kg bw/day for tumouricity [13, 27, 30, 32].

1,3-DCP

In contrast to 3-MCPD, 1,3-DCP can be considered a genotoxic carcinogen that causes cancer by directly damaging genetic material [13]. The committee of the WHO/FAO meeting concluded that 1,3-DCP was hepatotoxic (implies chemical-driven liver damage), induced a variety of tumours in various organs in the rat, and was genotoxic in vitro. Furthermore, it is reported that the Committee of Mutagenicity (COM) considers that the contaminant is not genotoxic in vivo [29, 33]. The establishment of a tolerable intake was considered to be inappropriate because of the nature of its toxicity. The dose that caused tumours in rats (19 mg kg−1 bw per day) was about 20,000 times the highest estimated intake of 1,3-dichloro-2-propanol by consumers of soy sauce (1 µg kg−1 bw per day) [32]. Nothing is known about the toxicity of the other chloropropanols.

Formation of 3-MCPD

In general, 3-MCPD can form via three pathways: acid hydrolysis, heat processing, and via 3-MCPD esters [33].

Acid hydrolysis

Commercially, hydrolysis is carried out using 4-6 M hydrochloric acid at 100 °C-130 °C for 4–24 hours, which is followed by neutralisation with sodium hydroxide. 3-MCPD is formed during this process from the reaction of the acid with residual vegetable oil. Hydrochloric acid and triacylglycerols and (to a smaller extent) phospholipids and glycerol, in the raw materials are the main precursors of chloropropanols [33]. The formation of chlorohydrins from glycerol and hydrochloric acid during HVP production was initially proposed and verified by Velíšek et al. and Davídek et al. [1, 2]. Collier et al. [34] and Hamlet et al. [35] later proposed a mechanism explaining the heat-induced formation of chloropropanols from triacylglycerols under acidic conditions. The key step involves the nucleophilic substitution of the acyl group by the chloride anion at positions activated by neighbouring ester groups. The resulting intermediate is a chloropropanediol diester that furnishes chloropropanol under hydrolytic conditions.

Heat processing

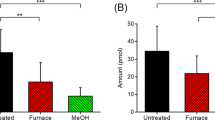

3-MCPD also occurs in the absence of acid-HVP. It appears to form from lipids and sodium chloride (present naturally or added) during normal manufacturing and cooking processes, such as baking and grilling [33]. Free glycerol released by the high-temperature hydrolysis of triglycerides can react with the chlorides present [26, 36]. 3-MCPD formation also depends on other factors, as studies on model systems based on water, sodium chloride and glycerol, phospholipid or triolein have shown [3, 37, 38]. With glycerol as a precursor, 3-MCPD production increases with water content up to 30% moisture, but decreases with higher moisture levels. Furthermore, in models presenting close to no water content, glycerol still appears to be able to produce 3-MCPD [37]. The kinetics of such models were studied and can be found in [39, 40]. Thus, glycerol seems to be the major precursor in foods with a low water content (<15%), and other precursors like lecithin in foods with high moisture contents [38]. The models also showed that 3-MCPD production increased with increasing temperature above 160 °C for all three precursors [37, 38, 41]. As well as temperature and moisture, 3-MCPD production is also greatly affected by the pH, and is unstable above a pH of 6 [33, 38, 41].

Esters

The contaminant may also be released in vivo from 3-MCPD esters by lipase-catalysed hydrolysis. Studies found that significant levels of 3-MCPD were released from bread when they were treated with bakery-grade lipase during the baking process [33, 42]. It also appears that hydrolytic enzymes may be directly involved in the formation of chloropropanols. In model studies comprising lipase, vegetable oil or fat, water and sodium chloride, the generation of 3-MCPD was found to be proportional to the lipase activity in the mixture. In dried savoury foods containing salt and fat, the residual lipase activities of certain ingredients should be monitored, as they may reflect the formation of unwanted contaminants over storage and processing time [43].

Occurrence of 3-MCPD

Cereal-derived products (bread, biscuits)

In leavened dough, the main precursors are chloride ions and glycerol, which do react with each other during the baking process to form 3-MCPD [38]. Glycerol accounts for 68% of the 3-MCPD formed upon baking proved commercial bread doughs. It is mainly generated by yeast during proving, but can also originate from flour or flour improvers [40].

3-MCPD is mainly found in the crust and can be present at very high levels (up to 400 µg kg−1) [44, 45]. This is because this part of the bread undegoes the greatest exposure to high temperatures during the baking process, thus boosting the reaction. No contaminant was detected in the breadcrumbs, thus moderating the 3-MCPD content throughout the whole loaf. This is even more critical for toast, since a much higher proportion of the bread is exposed to heat, resulting in more 3-MCPD and thus an enhanced 3-MCPD intake [45].

Breitling-Utzmann et al. [46] tested several bread ingredients for their influence on 3-MCPD formation. These included fat, baking agent, sour dough, emulsifiers, sugars, and leaven. The baking agent consisted of sugar, flour, soy flour, calcium sulfate, emulsifier (mono- and diacylglycerols of edible fatty acids, E471), enzymes and ascorbic acid. Among all these ingredients, the use of baking agent appeared to have the greatest effect, and high levels of 3-MCPD were detected. Considering the various components of the baking agent, this effect could not be explained by the emulsifiers (which were also tested separately), but the sugar content does seem to have a strong influence on the production of 3-MCPD. However, other ingredients must have synergetic effects.

The effect of sugar was also observed in a study realised in the UK. In preparations where sugar and yeast were added to dough, the sugar content did not influence glycerol generation in the yeast, but it did appear to increase the final level of 3-MCPD produced during baking [47]. Another observation was that storage of the simple model dough for one week prior to cooking produced twice the amount of 3-MCPD compared to the freshly prepared doughs, and this could not be explained. It was suggested that the storage period either increased the concentrations of the precursors or removed potential inhibitors of 3-MCPD production. It was also found that the addition of yeast to the model dough significantly increased the production of the contaminant, and that pre-incubating with yeast had even more of an effect [38].

According to the same researchers, phospholipids, which are minor components in flour, show better reactivity during the formation of 3-MCPD than glycerol. Finally, it was also found that commercial improvers used in bakery products, which typically contain ascorbic acid, soya flours and a source of monoacylglycerols (e.g. glycerolmonostearate or modified monoacylglycerols), could promote the formation of 3-MCPD in unleavened dough. More detail on formation reactions can be found in [48].

Malt-derived products

These can be food-grade malted grains, malt flours and malt extracts, products which are used for colouring and flavouring purposes. 3-MCPD results from the dry-kilning of malted and unmalted barley at temperatures above 170 °C. Although this presence seems to be inevitable, the consequences are not that important, as levels are low and when used for brewing they will be even more diluted. It has also been shown that the endogenous components of the grain are sufficient to promote 3-MCPD synthesis. No addition of fat, acid or chloride is necessary [38]. However, studies showed that only small amounts of 3-MCPD are detected in malt flours and pale brewing malt, whereas dark brewing malt sometimes contains very high levels (247 µg kg−1) [44, 45, 49]. Although strongly diluted in the resulting product [38], 3-MCPD may be bound to other components contained in the beer, such as acids, aldehydes or alcohol. It appears that the level of 3-MCPD esters is indeed much higher. The bound form has been shown to exceed the free form by factors of 0.4–36 [50].

Coffee

Coffee can contain 3-MCPD, but at low levels. It has been found in roasted coffee, but the highest levels were seen in instant coffee and in products with prolonged roasting. The final colour of the coffee beans is directly linked to 3-MCPD formation, with the darker beans having the greatest concentration. Chloride from salt and lipids naturally present in coffee beans are responsible for 3-MCPD formation during the roasting process. However, 3-MCPD is not detected in coffee beverages because of the dilution with water [33, 50, 51].

Cheese

3-MCPD only generally occurs at low levels in cheese, but it can be found in melted or grilled cheese. Crews et al. [22] found that grilling produced 3-MCPD in all studied cheese samples, whereas microwave heating significantly enhanced levels in Parmesan cheese only. The exact mechanism of formation is not yet known, but it can be assumed that chloride ions and glycerol (or substituted glycerol) are at the heart of it, since they are both abundant in cheese.

Smoked food

The contaminant was also detected at quite high levels in a study performed in Germany on smoked meat. The level of 3-MCPD appeared to be dependent on the duration and the type of wood used for the smoking [33]. Researchers from the same institute had the opportunity to analyse samples of one type of smoked sausage at different stages of the production process and also to analyse its ingredients. The smoking procedure took place at a low temperature (28 °C). The smoke itself and samples scraped from the walls showed very high levels of 3-MCPD. The pellets used to generate the smoke did not initially contain any 3-MCPD. Laboratory experiments showed that the addition of 20% calcium carbonate to the pellets prior to smoking significantly reduced the production of 3-MCPD in the smoke. Other experiments indicated that lipids are not involved in the generation of the contaminant. The authors proposed that 3-MCPD forms via 3-hydroxyacetone following the cracking of cellulose, but agreed that more research is needed [52].

A similar study in the UK focussing on cooked meat, prepared cheese, smoked food, etc., also found the contaminant, but not at levels as high as in the German study. This may be explained by different preparation/smoking procedures, which would have to be verified [33].

The 3-MCPD content in kippers seems to increase with the salt concentration in the brine used for the process and with the smoking time. The concentration of brine used in brine immersion curing had a significant effect on the salt content and a corresponding effect on the formation of 3-MCPD [38].

It should be pointed out that the smoking procedures associated with the occurrence of 3-MCPD were generally of the "cold smoking" type, meaning that they were performed at low temperatures. Nothing has been found concerning the occurrence of 3-MCPD after smoking at high temperatures.

Meat

3-MCPD can be present in cooked meats, such as salami, bacon, hamburgers, etc. However, the influence of the meat cooking process on the formation of the chloropropanediol is not understood, and there is no direct link to precursors like glycerol. It seems that the cooking sometimes encourages 3-MCPD formation and sometimes has no effect at all. In a study by Crews et al. [22], it was found that 3-MCPD is not formed in boiled or stewed meat, suggesting that temperatures of >100 °C might be necessary and that “wet” cooking may hinder its formation. Another explanation is that the contaminant may have originated from the epichlorhydrin in the coating from salami. Furthermore, salami can contain high levels of 3-MCPD esters (see “Esters”) [27].

Salted fish

The contaminant was also detected in some samples of anchovy fillets in olive oil. However, a study revealed that it was not formed during maturation with salt, but later on, during packaging and storing [38]. The way in which 3-MCPD is formed in the anchovy fillets is not known, but it may result from enzyme action on fats. Such activity may release glycerol-related precursors which then react with chloride ions. On the other hand, chloroesters may be formed from the interaction of fats with chloride, which then create 3-MCPD upon hydrolysis. Whatever the exact mechanism of formation is, this type of fat/enzyme-related reaction may be quite widespread. However, there does not appear to be anything in the scientific literature on this topic so far.

Analytical determination of 3-MCPD

Although it has a relatively simple chemical structure, 3-MCPD has some characteristics that make it difficult to analyse sensitively. These are the absence of a suitable chromophore, a high boiling point, and a low molecular weight. The first of these affects its detection and makes the application of high-performance liquid chromatography (HPLC) with ultraviolet or fluorescence detection unfavourable. The other two affect analysis by gas chromatography (GC) and detection by mass spectrometry (MS). The low volatility and high polarity of 3-MCPD mean that it requires derivatisation, since direct GC analysis may give rise to unwanted interactions with components of the GC system or with other substances in the matrix, resulting in poor peak shape and low sensitivity. Detection by MS is affected by the low molecular weight of 3-MCPD, making it difficult to distinguish it from the background noise. Consequently, the analysis of 3-MCPD by GC requires matrix-adjusted sample preparation and derivatisation of the compound. Currently, methods based on solid-phase extraction, derivatisation and subsequent GC/MS analysis usually enable quantification of 3-MCPD at the µg kg−1 level [11, 35, 53, 54].

Another limitation arises when we consider the analysis of 1,3-DCP, which has a high volatility that complicates the concentration of solvent extracts, and so analyte losses are observed. Furthermore, detection using electron-capture detection (ECD) should be considered with care, since solvent extracts can contain other substances that coelute with 1,3-DCP during GC analysis and make it difficult to identify [54]. Van Rillaer and Beernaert proposed a procedure using steam distillation with extraction into codistilled petroleum ether/ethyl acetate and subsequent analysis by GC-ECD [55].

The European Commission doesn’t specify one standard method of analysis to apply, but rather defines performance criteria that a method must fulfil in order to provide officially acceptable results (under the condition that method validation should include—if possible—the use of a certified reference material). The criteria for 3-MCPD determination are given in Commission Regulation (EC) No. 333/2007 Annex 2, and are summarised in Table 1 [56].

In summary, methods that use underivatised analytes often lack sufficient sensitivity or selectivity for the determination of low concentrations in foods, as, it seems, do derivatisations using silylation [54]. Thus, the principal analytical approaches used to determine 3-MCPD in food involve derivatisation and will be described hereafter. Finally, some attention is afforded to other interesting methods of analysis. All of the methods are summarised in Table 2.

Heptafluorobutyryl (HFB) derivatives

The method of analysis recommended by the European Standard is described in EN 14573 [57]. It uses a method validated by Brereton et al. [58]. The method is based on published methods [59, 60], and was refined and validated in an interlaboratory study of malt extract, soup powder, bread crumbs, salami sausage, cheese alternative and hydrolysed vegetable protein. It has also been accepted as an official method by AOAC International (AOAC Official Method 2000.01) [11]. The principle is to blend an internal standard (in general 3-MCPD-d 5 ), a salt solution (NaCl 5 mol L−1), a solid support material (e.g. diatomaceous earth) and the sample into a homogeneous mixture, which is transferred to a glass chromatographic tube to wash the interfering material present in the food from the column using a hexane/ether mixture (9:1). The substance of interest, 3-MCPD, is then extracted with diethyl ether. The sample is concentrated by rotary evaporation at 35 °C. Derivatisation is carried out with heptafluorobutyrylimidazole (HFBI) in an organic solvent by rapidly vortexing and then heating it at 70 °C for 20 min. The derivative is formed through the esterification of the two hydroxyl groups of 3-MCPD with HFBI. After it has cooled down, water is added to deactivate the residual HFBI, and after recuperating the organic phase the sample is analysed on GC/MS. It should be noted that the sample preparation is relatively long and contains several more drying and cleaning steps that are not mentioned here. This may become a source of error, although the collaborative trial showed that the method gives acceptable levels of precision [58]. Heptafluorobutyric acid anhydride (HFBA) can be used instead of HFBI; HFBA has the advantage of being cheaper than HFBI [61] and of also creating the corresponding HFB diester [3, 61–63].

The method was originally designed for only 3-MCDP analysis, but can also be applied to DCP analysis; Collier et al. [34] have shown that 1,3-DCP is eluted in the hexane/ether extract. Nyman et al. [64] applied the method to 1,3-DCP analysis alone in soy and related sauces. Here, the principal steps of the sample preparation were identical but the sample was eluted from the column with diethyl ether/hexane (1:9), and only the first 50 ml of eluate were collected and transferred to a separatory funnel. 1,3-DCP was then extracted with acetonitrile and the extract was concentrated first by rotoevaporation and then under a stream of nitrogen, both at 70 °C. Derivatisation takes place with HFBI in an 80 °C heating block for 20 min. After cooling down and deactivating HFBI, the derivative was extracted into iso-octane and analysed by GC/MS. The first application of the method to analyse both types of chloropropanols can be found in the study of Collier et al. [34], and it was later used by Chung et al. [21], Chung et al. [62], Abu-El-Haj et al. [63], and Xu et al. [61]. All of these studies were based on the AOAC/EN method, but the latter three used HFBA instead of HFBI. In short, the extraction on the Extrelut® column is carried out in two steps, and the two separate extracts are then treated according to the procedures for 1,3-DCP and 3-MCPD. Only Chung et al. [21] and Abu-El-Haj et al. [63] have so far applied this method (or a similar one) to a wide range of foodstuffs, rather than just soy sauce. Characteristic ions of HFB derivatives are m/z 275, 110 and 277 for 1,3-DCP and m/z 253, 275, 289 and 453 for 3-MCPD (underlined values are quantifiers) [57, 63].

Limitiations of this derivatisation type have been discussed by Rétho and Blanchard [53] and by Meierhans et al. [65]. According to them, the derivatisation shows limited selectivity, as the derivatisation agents react with all nucleophilic molecules. Furthermore, they mention the low abundances of characteristic ions in the mass spectrum, the sensitivity of the derivatisation agents to moisture, the risks of incomplete derivatisation, and the inefficient partitioning and short-term stability of the derivatives [54].

A modified version of the abovedescribed method was proposed by Léon et al. [66]. Their approach to the analysis of 3-MCPD was to develop a sensitive method using programmable temperature vaporisation (PTV) with large volume injection (LVI) gas chromatography coupled to tandem mass spectrometry (MS-MS). The main idea behind this was to apply the sample preparation from the AOAC/EN method [57] but to increase the response of the analytical system by introducing a large volume (70 μl) of the final extract into the GC/MS-MS, which apparently succeeded (see LOD/LOQ values in Table 2). It also appears that 1,3-DCP can be detected using this method, although that was not the main focus of their study.

Boronic derivatives

Boronic acids react with 1,2- and 1,3-diols to give cyclic dioxaborolane/dioxaborinane derivatives. Rodman and Ross [67] carried out derivatisation under anhydrous conditions, while Pesselman and Feit [12] showed that a boronoic acid derivative of 3-MCPD could be prepared under aqueous conditions [3]. However, the former used phenylboronic acid (PBA) as the derivatisation agent, which was then adopted by all subsequently developed methods [54].

Plantinga et al. [68] adopted the method for the determination of 3-MCPD in liquid hydrolysed vegetable proteins. Their study indicated that n-hexane was an appropriate extraction solvent, since it gave a clean chromatogram of the extracts. They also observed that the salt concentration of the sample solution influences the extraction when n-hexane is used, due to a desalting effect. They found that a salt concentration of 12–20% was optimal. The method was fully validated and became an official Lebensmittel- und Bedarfständegesetz method (LMBG; the basis for German food legislation) [69]. The procedure can be summed up as follows. The sample is mixed and homogenised with a sodium chloride solution to give an end salt concentration of 20% (w/v). An aliquot is then derivatised with phenylboronic acid (PBA, 25% in acetone/water (19+1, w/v)) in a water bath at 90 °C for 20 min. After cooling it down, the substance is extracted with hexane, shaken and analysed by GC (MS or FID). When 3-MCPD-d 5 is used as the internal standard, it is added to the sample before derivatisation. Characteristic ions for 3-MCPD detection by MS were reported by Divinova et al. [70]; they used m/z 147 for quantitative analysis and m/z 91 and 196 as qualifiers (m/z 150 and m/z 93, 201, respectively, for 3-MCPD-d 5 ).

According to Divinova et al. [70], phenylboronic acid is the derivatisation agent of choice, as it is very selective and reacts specifically with diols to form nonpolar cyclic derivatives, and thus the product is extractable with nonpolar solvents. Only marginal contamination due to sample constituents occurs, and the tedious purification process on diatomaceous earth is not required (in contrast to the methods employing HFBI as a reagent).

Variations in the LOD and LOQ reported by Breitling-Utzmann et al. [45] were eliminated by performing a simple fat extraction for sample clean-up before the derivatisation [70]. However, dichloropropanols cannot be detected by this derivatisation method; they must be derivatised with HFBI, which is more complex and time-consuming.

Dioxolane derivatives

Another alternative to the AOAC/EN method can be found in an article by Meierhans et al. [65], who uses the ability of diols to form cyclic cetals with ketones, and employs acetone as both the reaction solvent and the derivatisation reagent. Although the method gives excellent results for 3-MCPD in soy sauce and seasonings, the proposed procedure cannot be applied as such to other foods because of too many unwanted substances in the extract. Modified procedures have been proposed by Rétho and Blanchard [53] and by Dayrit and Niñonuevo [71]. The former consists of four main steps. First there is an aqueous extraction, then a solid-phase extraction, which is followed by the derivatisation, and finally analysis by GC/MS. In the aqueous extraction, the sample is spiked with the IS solution (d 5 -3-MCPD in ethyl acetate) and mixed with water. The mixture is agitated for 3 h and left to stand overnight. The second step is similar to the Extrelut® extraction with the AOAC/EN method. Derivatisation is carried out by adding an aliquot of acidic acetone solution (1 mg ml−1 toluene 4-sulfonic acid monohydrate in dry acetone) and some sodium sulfate. The tube is tightly sealed and heated in a drying oven at 40 °C for 90 min, shaking it occasionally during the heating. After cooling, the sample is filtered through a basic aluminium oxide cartridge that was previously conditioned with dry acetone and then analysed. The ions monitored by Rétho and Blanchard are m/z 135 and 137 for 3-MCPD, and m/z 140 and 142 for d 5 -3-MCPD. The EI spectra of the cyclic ketal derivatives show intense and diagnostic isotope patterns [53, 54]. Apart from the derivatisation agent, their approach can be distinguished from the other methods by the use of pure water for sample dilution instead of NaCl solution, since they claim that it does not promote 3-MCPD extraction. However, they saturate the solution later in order to improve solid-phase extraction.

Dayrit and Niñonuevo’s procedure is similar in terms of its main steps to the AOAC/EN method, but derivatisation takes place on a dry extract with 4-heptanone and p-TsOH dissolved in ether. The ion fragments identified for 3-MCPD quantitation are at m/z 163 and 165 [71]. They proposed this derivatisation agent after having problems with the method described by Meierhans et al. The three following factors may be behind their erratic results. First, the derivatization step requires anhydrous conditions, which is difficult with acetone. Second, the dioxolane formed by acetone may still be relatively water soluble, and losses may occur when the reaction mixture is partitioned between water and hexane. Third, the use of acetone limits the reaction temperature to the boiling point of acetone, which is 56 °C [71].

Other methods

The only nonchromatographic method for the analysis of 3-MCPD found so far was proposed by Xing et al. [72, 73], and it uses capillary electrophoresis with electrochemical detection (CE/ED). The sample is diluted with the running buffer (borate buffer) and filtered through a 0.22 μm nylon filter. A small aliquot is further diluted with 30 mmol L−1 borate (pH 9.24) and the sample is injected electrokinetically. Operated in a wall-jet configuration, a 0.45 mm copper disk electrode that is used as the working electrode exhibits a good response at 0.65 V.

The advantages of this method are obvious in that it needs only very little sample preparation, minor amounts of consumables, and is very fast, but unfortunately this is only the case for the analysis of 3-MCPD in soy sauce. No attempts have been made so far to apply this technique to other food stuffs, which would certainly require more extensive sample preparation. It also appears that its sensitivity is not comparable to current GC methods. However, for soy sauce, the detection limit (S/N = 3) of 0.13 μg ml−1 for 3-MCPD coincides with the food safety criterion and is thus sufficient.

It was reported by Breitling-Utzmann [44] that tests to analyse 3-MCPD without prior derivatisation directly from the aqueous sample extract by LC/MS did not show much success. The contaminant was difficult to ionise and the sensitivity was too low. This was however only the second report found with any mention of the use of liquid chromatography for 3-MCPD analysis, and not much was said about it. In their review, Wenzl et al. [54] report the application of HPLC with refractive index (RI) detection to study the kinetics of 3-MCPD formation in model systems [74]. However, the method appears to be unfit for determining the contaminant at trace levels in food matrices [54].

The earliest method used specifically for the analysis of both types of chloropropanols (DCP and MCPD) comes from Wittmann [75], and it determines the contaminant levels in seasonings and foodstuffs containing seasonings. It has detection limits of less than 0.05 mg kg−1 for DCP and 0.1 mg kg−1 for MCPD. Sample preparation is done by extraction and concentration followed by analysis on GC/MS. Solid samples are blended with water, and the aqueous sample is then gradually mixed with a sodium hydroxide solution (1.25 mol L−1) to get a pH of 8.5. The solution is then transferred to an Extrelut® column for extraction. Next, the substances of interest are eluated with ethyl acetate and internal standard solution is added (1,3-dichloracetone in ethyl acetate 5 mg L−1). The sample is then concentrated in a water bath at 65 °C, readjusted to a fixed volume and analysed by GC/MS. The ions of interest in SIM mode were m/z 79 and 81 for 1,3-DCP and m/z 61, 79 and 81 for 3-MCPD. Trimethylsilyl (TMS) derivatives were only produced and analysed to confirm the identification of 2-MDCP and other less frequent chloropropanols. An interesting observation was that the content of 2-MCPD was higher than that of 3-MCPD in a few seasonings. This does not appear to be unusual, because although 3-MCPD is the major chloropropanol formed, it degraded faster in the processes used to remove chloropropanols in seasonings based on HVP, whereas 2-MCPD is more stable and can still be found in the product even when 3-MCPD has completely degraded [4, 38, 41]. This raises the question of the toxicity of 2-MCPD.

Crews et al. present an alternative method focussing on the analysis of 1,3-DCP [76]. They propose analysis by headspace GC/MS (HS/GC/MS), requiring almost no sample preparation and presenting a good limit of detection (LOD 3 μg kg−1). However, it has only been applied to the analysis of 1,3-DCP, the most volatile compound in the chloropropanol group, so far. The method has been validated by a collaborative trial in which participants used both static headspace and SPME, and the method was shown to be rapid, accurate and fit for purpose [3, 77]. However, it was only applied to soy sauce or similar products, so it might not work with other foodstuffs containing 1,3-DCP too, or when it is present at even higher levels than 3-MCPD, as in sausages.

Other HS methods were proposed in combination with solid-phase microextraction (SPME) and a derivatisation step for the analysis of 3-MCPD and 1,3-DCP in HVP and soy sauce, and they give rather good results as well. However, again, no other foodstuff was tested [78, 79]. The three methods differ in their procedures, so only the main characteristics of the sample preparation are highlighted here. Crews et al. [76] mixed ammonium sulfate and the sample in a headspace vial. Internal standard (d 5 -1,3-DCP in methanol) was added, the vial was sealed, and it was incubated in the headspace sampler oven for 20 min at 80 °C before injection. Huang et al. [78] first derivatised the sample containing 3-MCPD with PBA in an aqueous solution at 90 °C for 10 min, and then extracted with HS-SPME using a polydimethylsiloxane (PDMS, 10 μm) fiber for 30 min at room temperature, and finally detected with GC/MS. Finally, Lee et al. [79] first extracted 1,3-DCP and 3-MCPD in an aqueous solution (NaCl 0.36 g mL−1, pH 6) using a 85 μm polyacrylate-coated fiber at 50 °C for 15 min. Analytes were then desorbed at 260 °C for 3 min and HS derivatization was conducted in a laboratory-made design with N-methyl-N-(trimethylsilyl)-trifluoroacetamide (MSTFA) vapour at an oil bath temperature of 230 °C for 40 s.

Esters

Recent studies have reported the presence of mono- and diesters of fatty acids with 3-MCPD in a range of processed and unprocessed foods, especially vegetable oils [23, 30, 31, 37, 38, 80–85]. This has been the subject of a very recent workshop organised by ILSI Europe (International Life Science Institute) in Brussels (March 2009), involving (among other organisations) the Health and Consumer Protection Directorate General of the European Commission (DG SANCO), the European Food Safety Authority (EFSA), and the US Food and Drug Administration (FDA). One of the key issues highlighted was the lack of exposure data and information about bioavailability in vivo, which makes risk assessment impossible at the moment [84].

It is generally reported that the amount of esterified 3-MCPD exceeds the amount of nonesterified contaminant in many samples. This tendency is notably highlighted in a study realised by Davidek et al. [2] on the generation of chlorohydrins and their esters from a number of specific lipids. After the hydrolysis of tripalmitin, tristearin and triolein, they mainly found chloropropanol esters, with the main reaction product being esters of 3-chloropropane-1,2-diol.

Based on this knowledge, it was also reported at the ILSI workshop [84] that the German risk assessment body (BfR) performed an evaluation of dietary 3-MCPD esters in December 2007 in which exposures of up to 20-fold the tolerable daily intake (TDI) of 3-MCPD were anticipated in infants fed formulas. For adult men, consuming 100 g vegetable fat per day would exceed the TDI for 3-MCPD by up to five times. More recently, EFSA confirmed the BfR’s approach and calculations. Thus, 3-MCPD esters have become an extremely important issue.

As with 3-MCPD, the esters occur in foods processed at high temperatures, with low water contents, high levels of sodium chloride, and that are stored for long periods. In bread, for example, the levels of 3-MCPD and its esters are similar, and they both increase with heating.

Some foods are known to contain high levels of chloroesters, such as vegetable oils. Research has shown that preliminary heat treatment and the refining process have a huge impact on the ester content. The esters are probably formed during deodorisation, a high-temperature process. 3-MCPD esters in refined seed and olive oil exceed levels of 3-MCPD by hundreds or even thousands of times. On the other hand, no esters were detected in virgin seed and olive oil. It should be mentioned here that many refined oils are used in tinned fish, antipasti, pesto sauces, etc., which therefore also contain these esters. No esters were detected in animal fats. However, highly refined vegetable oils and fats (as well as some hardened and transesterified fats) are base products for chip fat and margarines, and it appears that this group shows some of the highest ester contents observed so far. Similar observations were made with cake icings and some biscuit fillings. The probable reason for this is that these fats undergo the refining process twice. For palm oil, there is the additional factor of high levels of mono- and diglycerides, which are important precursors in the formation of 3-MCPD esters.

Oil extracted from savoury crackers was shown to contain high levels of esterified 3-MCPD (>100 times the amount of free 3-MCPD), which is a potential source of free 3-MCPD during cracker production/storage [38]. Finally, coffee has been shown to contain a high level of esters, and 3-MCPD may be released through the action of enzymes in the human body. The level of 3-MCPD esters was observed to vary between 6 µg kg−1 (soluble coffees) and 390 µg kg−1 (decaffeinated coffee), and it exceeded the free 3-MCPD level by factors of 8–33. Similar results were found in coffee surrogates, where ester contents were 32–81 times higher [50, 51]

The esters include fatty acid monoesters and diesters of chloropropanols, and are thus structurally related to the contaminant. However, there is not yet enough data to make any definitive statements about their intake and eventual toxicity. Even if they are not toxic, we must still determine whether they act as a reservoir for 3-MCPD. It appears that they can release 3-MCPD in the presence of hydrolysing enzymes. The extent to which these enzymes can be found in food or the digestive system is still to be determined. According to a study organised by the FSA [38], 3-MCPD was released from the esters identified in bread crust and toasted bread following treatment with a commercial lipase from Aspergillus oryzae.

Appropriate manufacturing can control the levels of 3-MCPD esters in edible oils, but not much is known about other foods. Identifying the primary routes of 3-MCPD ester exposure, reducing their levels in food products, and mitigating their biological effects are still subjects for research.

Very recently a laboratory in Germany identified an emerging issue relating to 3-MCPD esters. There are strong indications that a significant amount of measured bound 3-MCPD results from fatty acid esters of glycidol [85]. However, little is currently known about the toxicity, formation, etc., of glycidolesters, and thus further information cannot be given here.

Analytical aspects

Ester-linked 3-MCPD usually is determined as free 3-MCPD by GC-MS after acidic hydrolysis with sulfuric acid/methanol followed by derivatization. The main methods presented so far appear in Hamlet and Sadd [86], Divinova et al. [70] and Weisshaar [87], with the latter using alkaline hydrolysis instead of acidic hydrolysis.

Hamlet and Sadd [86] apply two procedures. In the first one, air-dried samples are extracted with ethyl acetate and the esters are isolated by preparative TLC according to the procedure of Davidek et al. [2]. Sample extracts are analysed by GC/MS, and all esters are quantified as 3-MCPD dipalmitate using 5α-cholestane as an internal standard. The other procedure is carried out by enzyme hydrolysis, where the samples are dispersed in phosphate buffer (pH 7.0). A commercial lipase from Aspergillus oryzae (LIPOPAN 50 BG) is added and the sample is incubated at 23 ± 1 °C for 24 h. The esters are determined from the MCPD released by the lipase: MCPDs were analysed as their HFB esters by GC/MS according the procedure of Hamlet [59].

Divinova et al. [70] optimised an analytical method for the determination of 3-MCPD which was described earlier (see “Boronic derivatives”), and included an additional preparative step for the extraction of 3-MCPD esters, which were then transformed into free 3-MCPD and determined by the optimised method. The sample is extracted with diethyl ether and then filtered. After washing with diethyl ether, the filtrate is extracted in a separatory funnel with water and centrifuged if necessary. The solvent is dried over anhydrous sodium sulfate and evaporated using a vacuum rotary evaporator. The obtained residue is dissolved in tetrahydrofurane and aliquots are then interesterified by methanolysis using sulfuric acid in methanol and analysed using the optimised method.

Since 3-MCPD can be formed from glycerol, acylglycerols and chloride ions in hot acidic solution, it may be possible that the contaminant also forms under the conditions of acidic hydrolysis used in the standard procedure for determining 3-MCPD esters if any chloride ions are present. As well as acidic cleavage, free alcohols can also be obtained from fatty acid esters by transesterification with sodium methoxide, which is the method applied by Weisshaar [87]. The 3-MCPD esters are transesterified with NaOCH3/methanol and analysed by GC-MS after derivatization with phenylboronic acid in NaCl solution. The concentrations of 3-MCPD esters obtained are calculated as the free 3-MCPD. However, methoxide ions are strong nucleophilic agents that affect the 3-MCPD molecule and can cause a measurable decomposition of 3-MCPD by nucleophilic substitution, even under these mild reaction conditions. For this reason, an isotope-labeled 3-MCPD must be used as an internal standard.

No agreement on a standardised method has been reached so far. In general, many research projects are currently trying to shed light on the various items of missing information relating to 3-MCPD esters, as mentioned above.

Methods of reducing and/or avoiding 3-MCPD generation

Modifying food processing in order to reduce or avoid 3-MCPD formation is not an easy task, since the formation mechanism is not known precisely for all products and does also vary. In general, 3-MCPD is not very stable in foods, and any net amount is the result of the mass balance between formation and decomposition. The contaminant often results from some of the required ingredients of a recipe. Hence, a satisfactory compromisemust be found between the sensory characteristics of the final product and the levels of the contaminant-producing ingredients. Furthermore, the microbiological stability and nutritional properties of the food need to remain optimal, and the inadvertent addition of new contaminants must be avoided.

Mechanisms that can be used to limit the amount of 3-MCPD can be summarised as follows [38, 42]:

-

Raising the pH of high moisture content food

-

Lowering the maximum processing temperature and salt content of the food

-

Avoiding low-water/high-temperature treatments

-

Limiting the amount of glycerol produced in the food during preparation and storage

-

Avoiding the use of partial glycerides as additives

-

Using spice extract instead of native spices, or reducing the microbial load via thermal treatment

-

Confirming the purity of food additives

-

Inactivation of lipases/esterases

-

Screening food contact materials for 3-MCPD precursors.

Generally speaking, kinetic models that take into account the different process parameters (pH, moisture, time, temperature) could be useful for devising potential reduction strategies (i.e. by driving the reaction to favour rapid "decay" and avoid the formation of 3-MCPD) [41, 42].

Another option for reducing 3-MCPD could be to use micro-organisms, cell extracts or purified enzymes with dehalogenating properties. Although model studies have shown some success, this approach does have limitations, as the studies are often conducted with non-food-grade microorganisms or enzymes derived from them. An additional constraint is that certain models are oversimplified and cannot be extrapolated to a food system [42].

Concerning HVP, the member companies of the International Hydrolysed Protein Council stated that the organoleptic properties of the products would be adversely affected due to the occurrence of other reactions during the hydrolysis process that reduces the concentration of 3-MCPD to below 0.1 mg/kg. This was confirmed by German producers, who admitted that they were unable to produce an acceptable product for use containing less than 0.1 mg/kg [11]. However, a procedure for the production of acid-hydrolysed winged bean and soybean proteins (aHWBP and aHSBP), where an additional alkaline thermal treatment at pH 8.5 for 2 h at 100 °C effectively reduced the 3-MCPD content to undetectable levels, was proposed by Sim et al. [88].

A general approach reported by the FSA [38] and by Velišek et al. [89] used the fact that 3-MCPD is unstable under neutral and alkaline conditions. They evaluated the potential of some common food additives to lower the level of 3-MCPD. Comparing the inhibitory effects of sodium carbonate and bicarbonate and the reducing agents glutathione and cysteine under similar conditions indicated that the most active inhibitor was sodium bicarbonate, followed by sodium carbonate, cysteine and glutathione. The reaction of 3-MCPD with either sodium carbonate or sodium bicarbonate gives glycerol as the final degradation product [38, 89]. It would be interesting to study their effects and their application to real food production.

Conclusion

Chloropropanols are a result of food processing and have probably been present in foods since food was first processed or cooked. However, it is only recently that scientists have been able to detect them reliably. They were observed in the late 1970s for the first time in HVP, and have received much attention due to the high levels of 3-MCPD in soy sauce. This has triggered research activities aimed at finding out how the contaminant is formed in soy sauce, how to analyse it, and finally how to reduce it. Since then, 3-MCPD has been detected in a wide range of other foodstuffs.

3-MCPD is almost exclusively analysed by gas chromatography (mostly coupled to mass spectrometry), and there are three main approaches to sample preparation, plus some other alternatives. There appear to be many methods for the determination of 3-MCPD in final food products, but not many that can be applied to industrial food production. One would expect more techniques that can screen for the contaminant during the actual steps of food production, such as those applied in pharmaceutical technology.

Finally, there is growing concern over the potential of 3-MCPD esters to release 3-MCPD in the body and the possibility that they are toxic themselves. Especially worrying is the fact that when these esters are present in food ingredients, they are often present at very high levels. An overview of the current situation and knowledge relating to it, including available analytical approaches, has been provided in this review. However, much research is still needed in this area.

References

Velisek J, Davidek J, Hajslova J, Kubelka V, Janicek G, Mankova B (1978) Chlorohydrins in protein hydrolysates. Z Lebensm Unters Forsch 167(4):241–244

Davidek J, Velisek J, Kubelka V, Janicek G, Simicova Z (1980) Glycerol chlorohydrins and their esters as products of the hydrolysis of tripalmitin, tristearin and triolein with hydrochloric acid. Z Lebensm Unters Forsch 171(1):14–17

Hamlet C, Sadd PA (2009) In: Stadler RH,Lineback DR (ed) Process induced food toxicants: occurrence, formation, mitigation, and health risks. Wiley, Hoboken, NJ

Velisek J (2009) In: Stadler RH,Lineback DR (ed) Process induced food toxicants: occurrence, formation, mitigation, and health risks. Wiley, Hoboken, NJ

Kuballa T, Ruge W (2004) Analysis and detection of 3-monochloropropane-1,2-diol (3-MCPD) in food by GC/MS/MS. Varian GC/MS Appl Note 73(1):1–2

EC (2006) Commission Regulation (EC) No. 1881/2006 of 19 December 2006 setting maximum levels for certain contaminants in foodstuffs. Off J Eur Union L364:5–24

FSANZ (2003) Chloropropanols in food—an analysis of the public health risk (technical report series 15:62). Food Standards Australia New Zealand, Canberra

Matthew BM, Anastasio C (2000) Determination of halogenated mono-alcohols and diols in water by gas chromatography with electron-capture detection. J Chromatogr A 866(1):65–77

Crisp M, Padley I (2007) European wet-strength resin drivers. Tissue World Apr/May

Boden L, Lundgren M, Stensio KE, Gorzynski M (1997) Determination of 1, 3-dichloro-2-propanol and 3-chloro-1, 2-propanediol in papers treated with polyamido amine-epichlorohydrin wet-strength resins by gas chromatography-mass spectrometry using selective ion monitoring. J Chromatogr A 788(1–2):195–203

Schlatter J, Baars AJ, DiNovi M, Lawrie S, Lorentzen R (2002) Safety evaluation of certain food additives and contaminants: 3-chloro-1, 2-propanediol. WHO Food Addit Ser 48:1–30

Pesselman RL, Feit MJ (1988) Determination of residual epichlorohydrin and 3-chloropropanediol in water by gas chromatography with electron-capture detection. J Chromatogr A 439(2):448–452

EC (2004) Collection and collation of data on levels of 3-monochloropropanediol (3-MCPD) and related substances in food (scientific co-operation report). EC Directorate-General of Health and Consumer Protection, Brussels

Cheng WC, Chen HC, Lin YP, Lee HF, Chang PC, Chou SS (2004) Survey on 3-monochloro-1, 2-propandiol (3-MCPD) contents of soy sauce products during fiscal year 2002 in Taiwan. J Food Drug Anal 12(4):336–341

Crews C, Hasnip S, Chapman S, Hough P, Potter N, Todd J, Brereton P, Matthews W (2003) Survey of chloropropanols in soy sauces and related products purchased in the UK in 2000 and 2002. Food Addit Contam 20(10):916–922

FSA (2001) Survey of 3-monochloropropane-1,2-diol (3-MCPD) in soy sauce and related products. Food Standards Agency, London

Macarthur R, Crews C, Davies A, Brereton P, Hough P, Harvey D (2000) 3-Monochloropropane-1,2-diol (3-MCPD) in soy sauces and similar products available from retail outlets in the UK. Food Addit Contam 17(11):903–906

Fu WS, Zhao Y, Zhang G, Zhang L, Li JG, Tang CD, Miao H, Bo J, Zhang Q, Wu YN (2007) Occurrence of chloropropanols in soy sauce and other foods in China between 2002 and 2004. Food Addit Contam 24(8):812–819

Nyman PJ, Diachenko GW, Perfetti GA (2003) Survey of chloropropanols in soy sauces and related products. Food Addit Contam 20(10):909–915

Wong KO, Cheong YH, Seah HL (2006) 3-Monochloropropane-1,2-diol (3-MCPD) in soy and oyster sauces: occurrence and dietary intake assessment. Food Contr 17(5):408–413

Chung SWC, Kwong KP, Yau JCW, Wong AMC, Xiao Y (2008) Chloropropanols levels in foodstuffs marketed in Hong Kong. J Food Compos Anal 21(7):569–573

Crews C, Brereton P, Davies A (2001) The effects of domestic cooking on the levels of 3-monochloropropanediol in foods. Food Addit Contam 18(4):271–280

Crews C, Hough P, Brereton P, Harvey D, Macarthur R, Matthews W (2002) Survey of 3-monochloropropane-1,2-diol (3-MCPD) in selected food groups, 1999–2000. Food Addit Contam 19(1):22–27

FSA (2001) Survey of 3-monochloropropane-1,2-diol (3-MCPD) in selected food groups. Food Standards Agency, London

Divinova V, Svejkovska B, Novotny O, Velisek J (2004) Survey of 3-chloropropane-1,2-diol and its precursors in foods in the Czech Republic. Czech J Food Sci 22:267–271

Massey R (2007) Fight against 3-MCPD. Food Manufact 82:35–36

FAO/WHO (2006) Discussion paper on acid HVP containing products and other products containing chloropropanols. In: Proc Session 38 of Codex Committee on Food Additives and Contaminants, The Hague, The Netherlands, 24–28 Apr 2006

Cho WS, Han BS, Nam KT, Park K, Choi M, Kim SH, Jeong J, Jang DD (2008) Carcinogenicity study of 3-monochloropropane-1,2-diol in Sprague-Dawley rats. Food Chem Toxicol 46(9):3172–3177

Olsen P (1993) Chloropropanols (WHO Food Additives Series 32). http://www.inchem.org/documents/jecfa/jecmono/v32je17.htm. Accessed 05 Nov 2008

SCF (2001) Opinion of the Scientific Committee on Food on 3-monochloro-propane-1,2-diol (3-MCPD): updating the SCF opinion of 1994 (SCF/CS/CNTM/OTH/17, final version). EC, Brussels

Lynch BS, Bryant DW, Hook GJ, Nestmann ER, Munro IC (1998) Carcinogenicity of monochloro-1,2-propanediol (α-chlorohydrin, 3-MCPD). Int J Toxicol 17(1):47–76

JECFA (2001) Summary of the fifty-seventh meeting of the Joint FAO/WHO Expert Committee on Food Additives (JECFA). FAO/WHO, Rome

FAO, WHO (2007) Discussion paper on chloropropanols derived from the manufacture of acid-HVP and the heat processing of food. In: Proc 1st Session of Codex Committee on Contaminants in Foods, Beijing, China, 16–20 April 2007

Collier PD, Cromie DDO, Davies AP (1991) Mechanism of formation of chloropropanols present in protein hydrolysates. J Am Oil Chem Soc 68(10):785–790

Hamlet CG, Sadd PA, Crews C, Velisek J, Baxter DE (2002) Occurrence of 3-chloro-propane-1, 2-diol (3-MCPD) and related compounds in foods: a review. Food Addit Contam 19(7):619–631

Massey R, Hamlet C (2007) Chloropropanol contaminants in food: the story continues. Food Sci Tech 21(4):32–34

Calta P, Velisek J, Dolezal M, Hasnip S, Crews C, Reblova Z (2004) Formation of 3-chloropropane-1,2-diol in systems simulating processed foods. Eur Food Res Tech 218(6):501–506

Reece P (2005) The origin and formation of 3-MCPD in foods and food ingredients (final project report). Food Standards Agency, London

Dolezal M, Calta P, Velisek J (2004) Formation and decomposition of 3-chloropropane-1,2-diol in model systems. Czech J Food Sci 22:263–266

Hamlet CG, Sadd PA, Gray DA (2004) Generation of monochloropropanediols (MCPDs) in model dough systems. 1. Leavened doughs. J Agr Food Chem 52(7):2059–2066

Hamlet CG, Sadd PA, Gray DA (2003) Influence of composition, moisture, pH and temperature on the formation and decay kinetics of monochloropropanediols in wheat flour dough. Eur Food Res Tech 216(2):122–128

Stadler RH, Theurillat V, Studer A, Scanlan F, Seefelder W (2007) In: SKLM SCoFS (ed) Thermal processing of food: potential health benefits and risks (Forschungsberichte (DFG)), 1st edn. Wiley-VCH, Weinheim

Robert MC, Oberson JM, Stadler RH (2004) Model studies on the formation of monochloropropanediols in the presence of lipase. J Agr Food Chem 52(16):5102–5108

Breitling-Utzmann CM (2002) 3-MCPD: Untersuchungen in Lebensmitteln. Bundesverband der Lebensmittelchemiker/-innen im öffentlichen Dienst e.V. (BLC). http://www.lebensmittel.org/lebensm/mcpd.htm. Accessed Nov 2008

Breitling-Utzmann CM, Kobler H, Harbolzheimer D, Maier A (2003) 3-MCPD: occurrence in bread crust and various food groups as well as formation in toast. Dtsch Lebensm Rundsch 99(7):280–285

Breitling-Utzmann CM, Hrenn H, Haase NU, Unbehend GM (2005) Influence of dough ingredients on 3-chloropropane-1,2-diol (3-MCPD) formation in toast. Food Addit Contam 22(2):97–103

Hamlet CG, Sadd PA (2004) Effects of yeast stress and organic acids on chloropropanols formation in cereal products. Czech J Food Sci 22:255–258

Hamlet CG, Sadd PA, Gray DA (2004) Generation of monochloropropanediols (MCPDs) in model dough systems. 2. Unleavened doughs. J Agr Food Chem 52(7):2067–2072

Hamlet CG, Jayaratne SM, Matthews W (2002) 3-Monochloropropane-1,2-diol (3-MCPD) in food ingredients from UK food producers and ingredient suppliers. Food Addit Contam 19(1):15–21

Divinova V, Dolezal M, Velisek J (2007) Free and bound 3-chloropropane-1,2-diol in coffee surrogates and malts. Czech J Food Sci 25(1):39–47

Dolezal M, Chaloupska M, Divinova V, Svejkovska B, Velisek J (2005) Occurrence of 3-chloropropane-1,2-diol and its esters in coffee. Eur Food Res Tech 221(3–4):221–225

Kuntzer J, Weißhaar R (2006) The smoking process: a potent source of 3-chloropropane-1,2-diol (3-MCPD) in meat products. Dtsch Lebensm Rundsch 102(9):397–400

Retho C, Blanchard F (2005) Determination of 3-chloropropane-1,2-diol as its 1,3-dioxolane derivative at the μg kg−1 level: application to a wide range of foods. Food Addit Contam 22(12):1189–1197

Wenzl T, Lachenmeier DW, Gokmen V (2007) Analysis of heat-induced contaminants (acrylamide, chloropropanols and furan) in carbohydrate-rich food. Anal Bioanal Chem 389(1):119–137

Van Rillaer W, Beernaert H (1989) Determination of residual 1, 3-dichloro-2-propanol in protein hydrolysates by capillary gas chromatography. Z Lebensm Untersuch Forsch 188(4):343–345

EC (2007) Commission Regulation (EC) No 333/2007 of 28 March 2007 laying down the methods of sampling and analysis for the official control of the levels of lead, cadmium, mercury, inorganic tin, 3-MCPD and benzo(a)pyrene in foodstuffs. Off J Eur Union L88:29–38

CEN (2004) Foodstuffs: determination of 3-monochloropropane-1,2-diol by GC/MS (EN 14573). European Committee for Standardization, Brussels

Brereton P, Kelly J, Crews C, Honour S, Wood R, Davies A (2001) Determination of 3-chloro-1,2-propanediol in foods and food ingredients by gas chromatography with mass spectrometric detection: collaborative study. JAOAC Int 84(2):455–465

Hamlet CG (1998) Analytical methods for the determination of 3-chloro-1,2-propandiol and 2-chloro-1,3-propandiol in hydrolysed vegetable protein, seasonings and food products using gas chromatography/ion trap tandem mass spectrometry. Food Addit Contam 15(4):451–465

Van Bergen CA, Collier PD, Cromie DDO, Lucas RA, Preston HD, Sissons DJ (1992) Determination of chloropropanols in protein hydrolysates. J Chromatogr 589(1–2):109–119

Xu X, Ren Y, Wu P, Han J, Shen X (2006) The simultaneous separation and determination of chloropropanols in soy sauce and other flavoring with gas chromatography-mass spectrometry in negative chemical and electron impact ionization modes. Food Addit Contam 23(2):110–119

Chung WC, Hui KY, Cheng SC (2002) Sensitive method for the determination of 1,3-dichloropropan-2-ol and 3-chloropropane-1,2-diol in soy sauce by capillary gas chromatography with mass spectrometric detection. J Chromatogr A 952(1–2):185–192

Abu-El-Haj S, Bogusz MJ, Ibrahim Z, Hassan H, Al Tufail M (2007) Rapid and simple determination of chloropropanols (3-MCPD and 1,3-DCP) in food products using isotope dilution GC-MS. Food Contr 18(1):81–90

Nyman PJ, Diachenko GW, Perfetti GA (2003) Determination of 1,3-dichloropropanol in soy and related sauces by using gas chromatography/mass spectrometry. Food Addit Contam 20(10):903–908

Meierhans DC, Bruehlmann S, Meili J, Taeschler C (1998) Sensitive method for the determination of 3-chloropropane-1,2-diol and 2-chloropropane-1,3-diol by capillary gas chromatography with mass spectrometric detection. J Chromatogr A 802(2):325–333

Leon N, Yusa V, Pardo O, Pastor A (2008) Determination of 3-MCPD by GC-MS/MS with PTV-LV injector used for a survey of Spanish foodstuffs. Talanta 75(3):824–831

Rodman LE, Ross RD (1986) Gas-liquid chromatography of 3-chloropropanediol. J Chromatogr A 369(C):97–103

Plantinga WJ, Van Toorn WG, Van der Stegen GHD (1991) Determination of 3-chloropropane-1,2-diol in liquid hydrolysed vegetable proteins by capillary gas chromatography with flame ionization detection. J Chromatogr 555(1–2):311–314

Bundesinstitut für Gesundheitlichen Verbraucherschutz und Veterinärmedizin (1995) Bestimmung von 3-Chlor-1,2-Propandiol (3-MDCP) in Speisewürzen (Eiweisshydrolysate) (No 52.02 1). Beuth Verlag, Berlin

Divinova V, Svejkovska B, Dolezal M, Velisek J (2004) Determination of free and bound 3-chloropropane-1,2-diol by gas chromatography with mass spectrometric detection using deuterated 3-chloropropane-1,2-diol as internal standard. Czech J Food Sci 22(5):182–189

Dayrit FM, Ninonuevo MR (2004) Development of an analytical method for 3-monochloropropane-1,2-diol in soy sauce using 4-heptanone as derivatizing agent. Food Addit Contam 21(3):204–209

Xing X, Cao Y, Wang L (2005) Determination of rate constants and activation energy of 3-chloro-1,2-propanediol hydrolysis by capillary electrophoresis with electrochemical detection. J Chromatogr A 1072(2):267–272

Xing X, Cao Y (2007) Determination of 3-chloro-1,2-propanediol in soy sauces by capillary electrophoresis with electrochemical detection. Food Contr 18(2):167–172

Hamlet CG, Sadd PA (2002) Kinetics of 3-chloropropane-1,2-diol (3-MCPD) degradation in high temperature model systems. Eur Food Res Tech 215(1):46–50

Wittmann R (1991) Bestimmung von Dichlorpropanolen und Monochlorpropandiolen in Wurzen und wurzehaltigen Lebensmitteln (Determination of dichloropropanols and monochloropropandiols in seasonings and in foodstuffs containing seasonings). Z Lebensm Unters Forsch 193(3):224–229

Crews C, LeBrun G, Brereton PA (2002) Determination of 1,3-dichloropropanol in soy sauces by automated headspace gas chromatography-mass spectrometry. Food Addit Contam 19(4):343–349

Hasnip S, Crews C, Potter N, Brereton P, Diserens H, Oberson JM, Baigrie B, Byrd N, Campbell DJ, Diserens H, Hageman L, Hollywood F, Noro Y, Nyman P, Wehage H (2005) Determination of 1,3-dichloropropanol in soy sauce and related products by headspace gas chromatography with mass spectrometric detection: interlaboratory study. J AOAC Int 88(5):1404–1412

Huang M, Jiang G, He B, Liu J, Zhou Q, Fu W, Wu Y (2005) Determination of 3-chloropropane-1,2-diol in liquid hydrolyzed vegetable proteins and soy sauce by solid-phase microextraction and gas chromatography/mass spectrometry. Anal Sci 21(11):1343–1347

Lee MR, Chiu TC, Dou J (2007) Determination of 1,3-dichloro-2-propanol and 3-chloro-1,2-propandiol in soy sauce by headspace derivatization solid-phase microextraction combined with gas chromatography-mass spectrometry. Anal Chim Acta 591(2):167–172

Hamlet CG, Sutton PG (1997) Determination of the chloropropanols, 3-chloro-1,2-propandiol and 2-chloro-1,3-propandiol, in hydrolysed vegetable proteins and seasonings by gas chromatography/ion trap tandem mass spectrometry. Rapid Comm Mass Spectrom 11(13):1417–1424

Kuballa T, Ruge W (2003) Nachweis und Bestimmung von 3-Monochlorpropan-1,2-diol (3-MCPD) mit GC-MS/MS. Lebensmittelchem 57(3):57–58

Kissa E (1992) Determination of 3-chloropropanediol and related dioxolanes by gas chromatography. J Chromatogr 605(1):134–138

Spyres G (1993) Determination of 3-chloropropane-1,2-diol in hydrolyzed vegetable proteins by capillary gas chromatography with electrolytic conductivity detection. J Chromatogr 638(1):71–74

ILSI (2009) Workshop on 3-MCPD Esters in Food Products. http://europe.ilsi.org/events/past/Workshop3MCPDesters.htm. Accessed May 2009

Weißhaar R (2009) Fatty acid esters of 3-MCPD: overview of occurrence in different types of foodstuffs. In: Proc Workshop on 3-MCPD Esters in Food Products, Brussels, Belgium, 5–6 Feb 2009

Hamlet CG, Sadd PA (2004) Chloropropanols and their esters in cereal products. Czech J Food Sci 22:259–262

Weißhaar R (2008) Determination of total 3-chloropropane-1,2-diol (3-MCPD) in edible oils by cleavage of MCPD esters with sodium methoxide. Eur J Lipid Sci Technol 110(2):183–186

Sim CW, Muhammad K, Yusof S, Bakar J, Hashim DM (2004) The optimization of conditions for the production of acidhydrolysed winged bean and soybean proteins with reduction of 3-monochloropropane-1,2-diol (3-MCPD). Int J Food Sci Tech 39(9):947–958

Velisek J, Calta P, Crews C, Hasnip S, Dolezal M (2003) 3-Chloropropane-1,2-diol in models simulating processed foods: precursors and agents causing its decomposition. Czech J Food Sci 21(5):153–161

Acknowledgements

The referees of this review are kindly acknowledged for their constructive advice and helpful comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baer, I., de la Calle, B. & Taylor, P. 3-MCPD in food other than soy sauce or hydrolysed vegetable protein (HVP). Anal Bioanal Chem 396, 443–456 (2010). https://doi.org/10.1007/s00216-009-3177-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-009-3177-y