Abstract

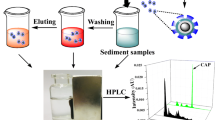

The synthesis and evaluation of a molecularly imprinted polymer (MIP) as a selective matrix solid-phase dispersion (MSPD) sorbent, coupled with high-performance liquid chromatography for the efficient determination of chloramphenicol (CAP) in fish tissues are studied. The polymer was prepared using CAP as the template molecule, vinylpyridine as the functional monomer and ethylene glycol dimethacrylate as the cross-linking monomer, and sodium dodecyl sulfate as the surfactant in the presence of water as a solvent by miniemulsion polymerization. The CAP-imprinted polymers and nonimprinted polymers (NIPs) were characterized by Fourier transform IR spectroscopy, scanning electron microscopy, and static adsorption experiments. The CAP-imprinted material prepared showed high adsorption capacity, significant selectivity, and good site accessibility. The maximum static adsorption capacity of the CAP-imprinted and the NIP material for CAP was 78.4 and 59.9 mg g-1, respectively. The relative selectivity factors of this CAP-imprinted material were larger than 1.9. Several parameters influencing the MSPD process were optimized. Finally, the CAP-imprinted polymers were used as the sorbent in MSPD to determine CAP in three kinds of fishes and resulted in satisfactory recovery in the range 89.8–101.43%. CAP-imprinted polymer as a sorbent in MSPD is better than C18 and attapulgite in terms of both recovery and percent relative standard deviation. The baseline noise was measured from a chromatogram of a blank fish sample which was treated after the MSPD procedure using CAP-imprinted polymer as a sorbent. Signal values of 3 times the noise (signal-to-noise ratio of 3) and 10 times the noise (signal-to-noise ratio of 10) were used to calculate the limit of detection and the limit of quantitation of the calibration curve. The limit of detection for CAP was 1.2 ng g-1 and the limit of quantitation was 3.9 ng g-1.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Molecularly imprinted polymers (MIPs) are an artificially synthesized macromolecular material, which is effective in encoding molecular information (shape, size, and functional group orientation) in bulk materials [1, 2]. In the last few years, MIPs were widely used for the selective enrichment and pretreatment of target compounds existing in a complex matrix. In addition, molecular imprinting technology has been expanded to the field of environmental analysis [3–7].

As early as 1973, suspension polymerization was used as a technique to obtain smaller droplet sizes by Ugelstad et al. [8], who scaled down the droplet size to several hundred nanometers by shearing the suspension. The idea of polymerization in microreactors can be realized by using suspension polymerization, where droplets in the micrometer range are created, and which can be polymerized [9]. Conventional approaches for the preparation of spherical MIP nanoparticles are based on precipitation [10] and emulsion polymerization [11] techniques. The polymerization processes in these systems are under kinetic control, resulting in nonideal MIP beads that have inhomogeneous binding sites and restricted particle size [12]. The components for obtaining MIP nanoparticles by miniemulsion polymerization consist of the template molecule, a functional monomer, a cross-linker, an initiator, a small amount of nonpolar solvent, water, and a surfactant to generate the miniemulsion. Miniemulsion polymerization is particularly suited for one-step preparation of molecularly imprinted nanospheres [13].

Matrix solid-phase dispersion (MSPD) is a sample-preparation technique with increasing acceptance in trace analysis of organic compounds using chromatographic techniques [14] and a one-step technique that simultaneously allows sample homogenization, analyte extraction, and cleanup [15]. This technique has been successfully applied to the determination of chloramphenicol (CAP) in muscle tissue [16] and many other applications in biological samples [17–20]. It is well known that C18 is used as a common sorbent in solid-phase extraction and MSPD. Attapulgite clay (ATP) has been studied for its sorbent properties and was used for one application [21–23]. However, owing to the fact that sorbents are nonselective, further purification of the extracts is often still required to remove coextractants before further analysis. In that case, using MIPs as selective MSPD sorbents for the simultaneous extraction and purification is a new trend and less work has to be done. Yan et al. [24] firstly used MIPs as selective MSPD sorbents for the simultaneous determination of five fluoroquinolones in chicken eggs and swine tissues.

CAP is an effective antibiotic against a wide range of Gram-positive and Gram-negative bacteria in both humans and animals [25]. Owing to this toxicity in humans, CAP is completely banned in food-producing animals within the EU [26]. A minimum required performance limit (MRPL) for CAP determination was recently set by the EU at 0.3 µg kg-1 in all food of animal origin [27]. Existing methods for the determination of CAP include immunoassays [28], microbiological methods [29], sensors [30], and chromatographic methods using gas chromatography–mass spectrometry (MS) [31] and liquid chromatography (LC)–MS/MS [32].

To our best knowledge, no detailed measurements have been reported for MIPs of CAP as a MSPD sorbent. The purpose of this work was to synthesize a MIP by miniemulsion polymerization and to evaluate it as a selective MSPD sorbent, coupled with high-performance LC (HPLC), for the efficient determination of CAP in several fish tissues. The proposed method had high selectivity and adsorption capacity for CAP.

Experimental

Materials and chemicals

CAP as the template molecule was purchased from Alfa Aesar (Karlsruhe, Germany; more than 98.5% purity) and thiamphenicol (TAP) was purchased from Chinese Veterinary Medicine Censorate (reference substance; 100%). Their structures are shown in Fig. 1.

Vinylpyridine (2-VP), used as the functional monomer, and ethylene glycol dimethacrylate (EGDMA), used as the cross-linking monomer, were also from Alfa Aesar. The initiator, azobis(isobutyronitrile) (AIBN), was from Tianjin Fuchen Chemistry Reagent (Tianjin, China). Sodium dodecyl sulfate (SDS), the surfactant, was purchased from Shanghai Shengzong Chemistry (Shanghai, China). n-Tetradecane, used as a hydrophobic agent, was from Beijing Chemical Plant (Beijing, China). Methanol (MeOH) and acetic acid (HAc) were from Tianjin Guangfu Chemical Engineering Graduate School (Tianjin, China). All these chemicals were of analytical grade.

HPLC-grade acetonitrile was from Dima Technology (Richmond Hill, ON, Canada). The ultrapure water was from a Milli-Q ultrapure water purification system (Millipore, Bedford, MA, USA). The mobile phase used for HPLC experiments was a mixture of acetonitrile and water (50:50), and was filtered through a 0.45-µm filter and ultrasonic treatment was used to degas it before use.

C18 (Tigerkin, 40 µm) was supplied by Dalian Institute of Chemical Physics, Chinese Academy of Sciences. ATP with an average diameter of 325 mesh was provided by Gansu ATP (Gansu, China).

Fishes including crucian, carp, and Wuchang fish were purchased from a local supermarket.

The stock solution of CAP with a concentration of 100 µg mL-1 was prepared in ultrapure water. All the working solutions were obtained by appropriate dilution.

Instrumentation

The MIP-MSPD study was developed in an off-line mode using a solid-phase extraction cartridge supplied by Dalian Institute of Chemical Physics, Chinese Academy of Sciences.

The HPLC-UV analyses were performed using a Varian 210 HPLC instrument (Varian, USA) equipped with a 325 UV–vis detector (Varian, USA) and a Varian Star chromatographic workstation (Varian, USA). The UV detector was operated at 278 nm. All separations were achieved on an analytical reversed-phase column (Hanbon Science & Technology, Jiangsu, China, C18 column, 4.6 mm × 150 mm) with a flow rate of 1.0 mL min-1 at room temperature.

Procedures for the preparation of the CAP-imprinted polymer

The following procedures, modified versions of those procedures described in the literature [12, 13], were used in this study. Polymers were prepared by mixing the functional monomer (2-VP, 4.0 mmol, 0.42 g), the cross-linking monomer (EGDMA, 20.0 mmol, 3.95 mL), the initiator (AIBN, 0.56 mmol, 91.0 mg), the hydrophobic agent (n-tetradecane, 0.8 mmol, 182 mg), and the surfactant (SDS, 0.25 mmol, 72 mg) with 50 mL water. In the CAP-imprinted polymer, 0.32 g (1.0 mmol) CAP was added to the monomer phase and no CAP was added in the nonimprinted polymer (NIP). The polymerization mixture was sonicated for 5 min. Then it was degassed with N2 for 5 min and sonicated for 5 min more for formation of a miniemulsion prior to the polymerization. After that, the polymerization was carried out at 80 °C for 14.5 h by stirring vigorously. Finally, the polymers were ground and sieved, and the particle size fraction of 75 µm or less was taken. Then the polymers were washed in 100 mL ultrapure water and recovered by centrifugation five times and then washed in 100 mL MeOH–HAc (9:1) and recovered by centrifugation five times to remove the template molecule, SDS, residual 2-VP, and AIBN completely. Finally, the polymers were dried in an oven at 60 °C for 24 h.

Static adsorption test

Various working solutions of CAP were prepared at 200, 300, 400, 500, 600, 700, and 800 mg L-1. To 10 mL of each of these solutions was added 10 mg CAP-imprinted polymer. The mixture was shaken for 1 h at room temperature to facilitate adsorption of the CAP onto the CAP-imprinted sorbent. After the solution had been filtrated, the concentration of CAP in the solution was determined by HPLC. The same procedure was performed for the NIP.

Selectivity experiment

Adsorption and competitive recognition studies were performed with CAP and the structurally similar compound TAP.

The mixtures of CAP and TAP, each of 300 or 600 mg L-1, were prepared separately. To 10 mL of the solutions was added 10 mg CAP-imprinted polymer. The mixture was shaken for 1 h at room temperature. After the solutions had been centrifuged, the concentrations of CAP and TAP in the supernatants were determined by HPLC.

The same procedure was performed for the NIP.

MSPD procedure for determination of CAP in fish tissues

The eatable parts of the fish were stripped away and a meat chopper was used to grind them. The blank fish samples and the samples with CAP added in various concentrations (50–5,000 ng g-1) were treated by freeze-drying and then they were stored at -20 °C.

A 100-mg amount of dried fish was weighed and blended with 70 mg MIP sorbent in an agate mortar. Intimate contact between the sorbent and the sample was obtained by pounding with the pestle for some minutes to produce a homogenous packing material for MSPD in a 6-mL solid-phase extraction (SPE) cartridge. The blend was tamped to form a compact extraction layer (1 mL). The next procedures were the same as for the common SPE.

The crucian samples with CAP added in various concentrations (50–5,000 ng g-1) were treated using the same procedure as described above to create a calibration curve.

For the comparison of sorbents, the fish samples with CAP added at 100, 1,000, and 5,000 ng g-1 were treated by freeze-drying and were then stored at -20 °C. A 100-mg amount of each sample was weighed and blended separately with 70 mg MIP, C18, and ATP sorbent in an agate mortar. The following procedures were the same as described above. From the HPLC result and the calibration curve, the recoveries and percent relative standard deviation (RSD%) were compared for three sorbents in three concentrations.

Results and discussion

Preparation of the CAP-imprinted polymer sorbent

For molecular imprinting, weak interactions such as electrostatic interaction and hydrophobic interaction may contribute to the interaction between the template molecule and the monomer. Hydrogen bonding is the dominant driving force for the molecular recognition between the template and the monomers, and has been hypothesized by Priego-Capote et al. [12]. Figure 2 shows a possible preparation protocol for CAP-imprinted polymer. It illustrates that the monomer–template interaction in this MIP is considered to be a hydrogen-bonding interaction on the particle surface. After the residue of 2-VP and CAP had been removed, the imprinted functionalized polymer sorbent containing a cavity tailor-made for CAP was formed.

Characteristics of the Fourier transform IR spectra

The Fourier transform (FT) IR spectra (obtained with a Thermo Mattson FT-IR spectrometer; Madison, WI, USA) of MIP and NIP were obtained. For both materials, an IR peak was observed near 1,590 cm-1, which indicated the existence of pyridyl. No peak near 1,648 cm-1 demonstrated no vinyl was present in the polymers and that the polymerization of 2-VP was complete. This result demonstrated that the characteristic groups of 2-VP were present in the polymers and that the polymerization was successful. When the intensities of peaks near 3,430 cm-1 (C = N in pyridyl) were compared for MIP and NIP, obvious decreases in intensity and sharpness were observed for the MIP. This indicates that the nitrogen in the pyridyl of the MIP can form hydrogen bonds with CAP. Therefore, the FT-IR analysis confirmed the occurrence of hydrogen bonding between CAP and the polymer.

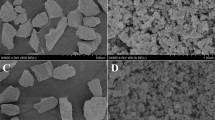

Morphological features

As shown in Fig. 3, the scanning electron microscope (Hitachi S-4800) images revealed that spherical particles with a rather broad size distribution were formed. There were no significant morphological differences between the MIP and the NIP. (Fig. 3). In both cases, particles with a diameter from 100 up to 550 nm were formed with an average particle diameter of approximately 250 nm.

Adsorption capacity of CAP-imprinted sorbent for CAP

The adsorption capacity was an important factor when evaluating MIPs. A range of CAP solutions with concentrations of 200–800 mg L-1 were studied. As can be seen in Fig. 4, the amount of CAP adsorbed increased as the initial concentration of the CAP solution increased. The static adsorption capacities of the CAP-imprinted polymer and the NIP for CAP were calculated as 78.4 and 59.9 mg g-1.

In the MIP, there were specific and nonspecific binding sites, but in the NIP, there only were nonspecific binding sites. From the experimental results, it seems that CAP adsorbed to the nonspecific sites before it adsorbed to the specific sites. After most nonspecific sites had been occupied, specific sites began to be occupied. This is the reason why at low concentrations the adsorption capacities for the MIP and the NIP are similar. But at high concentration of CAP, when the nonspecific sites were almost all occupied in the MIP, the specific sites containing a cavity tailor-made for CAP could interact with CAP efficiently; and the adsorption of the MIP was more than that that of the NIP.

Selectivity of the imprinted sorbent

The structurally similar compound TAP was used as a species that competed with CAP in a competitive recognition study. The distribution coefficient (K d), the selectivity coefficient of the sorbent (k), and the relative selectivity coefficient (k′) were obtained in these competitive experiments (Table 1). K d indicates the affinity of the sorbent for a particular substance, k indicates how selective the sorbent is for one of the substances when it is exposed to two substances, and k′ indicates how selective a sorbent is for a particular substance when compared with the selectivity of a different sorbent. These factors were calculated using Eqs. 1, 2, and 3 [33].

where C i and C f represent the initial and final concentrations of the species adsorbed.

The CAP-imprinted polymer adsorbed twice as much CAP as TAP. The k(CAP/TAP) value of the CAP-imprinted polymer sorbent (2.0 in 300 mg L-1 and 1.9 in 600 mg L-1) was larger than that of the NIP sorbent (1.0), which shows that the CAP-imprinted polymer sorbent has a higher selectivity for CAP than for TAP, which is structurally very similar to CAP. k′ was greater than 1 and showed that the CAP-imprinted polymer sorbent had a higher selectivity than the NIP sorbent.

As expected, TAP was retained to some extent in the MIP’s active centers, but not in a quantitative way and the repeatability was poor. There were specific and nonspecific binding sites in the MIP, but in the NIP there were only nonspecific binding sites. So the NIP allows the interaction with CAP and TAP; at the same time, the MIP shows a higher affinity for CAP owing to the specific sites. It is also evident that the specific recognition sites are mainly complementary to the template in terms of size and shape. We compared the retention characteristics on the basis of their molecular structures. When the results for CAP and TAP are compared, it is clear that only one-substituent difference in the phenyl ring gives rise to a dramatic decrease of the retention efficiency. Consequently, the cavities formed during MIP synthesis have a three-dimensional shape for which CAP molecules definitely exhibit excellent complementarity.

Application of the CAP-imprinted polymer sorbent to the selective off-line MSPD -HPLC determination of CAP in fishes

Optimization of the washing solutions at different concentrations

The MSPD procedure was optimized as described in “Experimental.”

The mixture of the sample spiked with CAP and MIP sorbent was loaded onto the cartridge as described earlier. After the cartridge had been washed with 0.5 mL MeOH (20, 40, 60, and 80%), the contents were eluted with 0.50 mL of the MeOH–HAc (9:1) mixture. Different concentrations of MeOH can wash away different polar impurities, but MeOH may wash away the CAP to a certain extent. On the basis of the eluent recoveries obtained, 20% MeOH was chosen as the washing solution.

Effect of different eluent volumes

As previously mentioned, the MeOH–HAc (9:1) mixture was used to elute CAP from the MSPD cartridges. Different volumes of the eluent between 0.10 and 0.70 mL were tested. Eluent volumes of 0.50 mL or larger permitted extraction efficiencies of around 100% to be achieved. Eluent volumes of 0.10–0.40 mL did not result in complete extraction. An eluent volume of 0.50 mL was therefore employed in subsequent work.

Determination of CAP in fish samples

The proposed method was applied to the analysis of CAP in three fish tissue samples. CAP was detected in all three fish tissues. The CAP standard was added at levels of 50–5,000 ng g-1 to the crucian to create a calibration curve. Good linearity was obtained over the concentration range studied, with a correlation coefficient (r) higher than 0.9981.

The limit of detection (LOD) was obtained from the signal-to-noise ratio (S/N) and the calibration curve. In this work, the baseline noise was measured from a chromatogram of a blank fish sample. A signal value of 3 times the noise (S/N = 3) was used to calculate the LOD of the calibration curve. The LOD obtained was 1.2 ng g-1 and the limit of quantitation (S/N = 10) was 3.9 ng g-1. The LOD for CAP of around 1.2 ng g-1 of the MIP-MSPD/reversed-phase HPLC detection system used in this study is lower than that of the MIP-HPLC/optical detection system [34] and MIP-SPE/voltammetry [35]. Nevertheless, the MRPL of 0.3 ng g-1 cannot be reached by these systems. In regard to the complexity of the sample matrix, an efficient cleanup method in combination with a sensitive detection method will have to be applied. Therefore, the combination of MIP-MSPD with LC-MS/MS or other electrochemistry methods will be a task for further studies to achieve the MRPL.

The CAP concentrations in crucian, carp, and Wuchang fish (Fig. 5b) were 27.8, 15.7, and 35.2 ng g-1.

C18 and ATP were used as sorbents for comparison with MIP sorbent in MSPD. The recovery and RSD% data are given in Table 2. Obviously, MIP as a sorbent in MSPD is better than C18 and ATP in terms of both recovery and RSD%.

Conclusion

This study described the synthesis of a CAP-imprinted polymer, its characterization, and its chromatographic evaluation. The synthesis of MIP is brief. The results presented demonstrate that the use of well-designed MIPs for CAP allows the selective and effective preparation of the target analyte. The MIP showed better retention of CAP than did the NIP. This CAP-imprinted polymer, first used as an MSPD sorbent and coupled with sensitive HPLC detection, allows the quantification of CAP in complex samples such as fish. The pretreatment of the fish samples used was much simpler than performing normal liquid–liquid extraction several times. CAP-imprinted polymer as a sorbent in MSPD is better than C18 and ATP in terms of both recovery and RSD%. The LOD obtained was 1.2 ng g-1 and the limit of quantitation was 3.9 ng g-1 but the MRPL of 0.3 ng g-1 cannot be reached. The combination of MIP-MSPD with LC-MS/MS or other electrochemistry methods will be a task for further studies to achieve the MRPL.

References

Wulff G, Sarhan A (1972) Angew Chem Int Ed Engl 11:341–346

Vlatakis G, Andersson LI, Muller R, Mosbach K (1993) Nature 361:645–647

Watabe Y, Hosoya K, Tanaka N, Kubo T, Kondo T, Morita M (2005) J Chromatogr A 1073:363–370

Lakshmi D, Prasad BB, Sharma PS (2006) Talanta 70:272–280

Nie F, Lu J, He Y, Du JX (2005) Talanta 66:728–733

Yang GL, Liu HY, Wang MM, Liu SB, Chen Y (2006) React Funct Polym 66:579–583

Jiang XM, Tian W, Zhao CD, Zhang HX, Liu MC (2007) Talanta 72:119–125

Ugelstad J, El-Aasser MS, Vanderhoff JW (1973) Polym Lett Ed 11:503–508

Dawkins JV (1989) In: Allen G, Bevington JC (eds) Comprehensive polymer science. Pergamon, Oxford, pp 231–251

Ye L, Weiss R, Mosbach K (2000) Macromolecules 33:8239–8245

Perez N, Whitcombe MJJ (2000) J Appl Polym Sci 77:1851–1859

Priego-Capote F, Ye L, Shakil S, Shamsi AS, Nilsson S (2008) Anal Chem 80:2881–2887

Vaihinger D, Landfester K, Krauter I, Brunner H, Gunter EMT (2002) Macromol Chem Phys 203:1965–1973

Garcia-Lopez M, Canosa P, Rodriguez I (2008) Anal Bioanal Chem 391:963–974

Crescenzi C, Bayoudh S, Cormack PAG, Klein T, Ensing K (2001) Anal Chem 73:2171–2177

Kubala-Drincic H, Bazulic D, Sapunar-Postruznik J, Grubelic M, Stuhne G (2003) J Agric Food Chem 51:871–875

Xiao HB, Krucker M, Albert K, Liang XM (2004) J Chromatogr A 1032:117–124

Zhao M, Van der Wielen F, De Voogt P (1999) J Chromatogr A 873:129–138

Pensado L, Casais MC, Mejuto MC, Cela R (2005) J Chromatogr A 1077:103–109

Tolls J, Haller M, Sijm DT (1999) Anal Chem 71:5242–5247

Ahmed AF, Ahmad J, Amer AR, Saif AH (2007) Environ Geol 51:1317–1327

Dai RL, Zhang GY, Gu XZ, Wang MK (2008) Environ Geochem Health. doi:10.1007/s10653–007–9130–0

Keito B, Naomitsu S, Kazuo M (2001) J Am Oil Chem Soc 78(7):733–736

Yan HY, Qiao FX, Row KH (2007) Anal Chem 79:8242–8248

Vivekanandan K, Swanmy MG, Prasad S, Mukherjee R (2005) Rapid Commun Mass Spectrom 19:3025–3030

Bogusz MJ, Hassan H, Al-Enzai E, Ibrahim Z, Al-Tufail M (2004) J Chromatogr B 807:343–356

European Council (1994) Council Regulation (EEC) no. 2377/90 laying down a Community procedure for the establishment of maximum residue limits of veterinary medicinal products in foodstuffs of animal origin, amending regulation no. 1430/94 of 22 June 1994. Off J Eur Community L15623:6

Delahaut P, Levaux C, Eloy P, Dubois M (2003) Anal Chim Acta 483:335–340

Singer CJ, Katz SE (1985) J Assoc Off Anal Chem 68:1037–1041

Ferguson J, Baxter A, Young P, Kennedy G, Elliott C, Weigel S, Gatermann R, Ashwin H, Stead S, Sharman M (2005) Anal Chim Acta 529:109–113

Posyniak A, Zmudzki J, Niedzielska J (2003) Anal Chim Acta 483:307–311

Mottier P, Parisod V, Gremaud E, Guy P, Stadler R (2003) J Chromatogr A 994:75–84

Han DM, Fang GZ, Yan XP (2005) J Chromatogr A 1100:131–136

Raphael L, Scott M, Sergey AP, Soo-Hwan C, Kazuyoshi Y, Isao K (1997) Anal Chem 69:2017–2021

Mena ML, Agui L, Martinez-Ruiz P, Yanez-Sedeno P, Reviejo AJ, Pingarron JM (2003) Anal Bioanal Chem 376:18–25

Acknowledgements

This work was supported by the National Natural Science Foundation of China Fund (no. 20775029), the Huo Ying Dong Science Fund of China (no. 104038), the Program for New Century Excellent Talents in University (NCET-07–0400), and the Central Teacher Plan of Lanzhou University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, L., Guan, M., Zhao, C. et al. Molecularly imprinted matrix solid-phase dispersion for extraction of chloramphenicol in fish tissues coupled with high-performance liquid chromatography determination. Anal Bioanal Chem 392, 1431–1438 (2008). https://doi.org/10.1007/s00216-008-2454-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-008-2454-5