Abstract

During the last few decades, increasing interest in biological surfactants led to an intensification of research for the cost-efficient production of biosurfactants compared with traditional petrochemical surface-active components. The quest for alternative production strains also is associated with new demands on biosurfactant analysis. The present paper gives an overview of existing analytical methods, based on the example of rhamnolipids. The methods reviewed range from simple colorimetric testing to sophisticated chromatographic separation coupled with detection systems like mass spectrometry, by means of which detailed structural information is obtained. High-performance liquid chromatography (HPLC) coupled with mass spectrometry currently presents the most precise method for rhamnolipid identification and quantification. Suitable approaches to accelerate rhamnolipid quantification for better control of biosurfactant production are HPLC analysis directly from culture broth by adding an internal standard or Fourier transform infrared attenuated total reflectance spectroscopy measurements of culture broth as a possible quasi-online quantification method in the future. The search for alternative rhamnolipid-producing strains makes a structure analysis and constant adaptation of the existing quantification methods necessary. Therefore, simple colorimetric tests based on whole rhamnolipid content can be useful for strain and medium screening. Furthermore, rhamnolipid purification from a fermentation broth will be considered depending on the following application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

During the last few decades, extensive research was performed in the field of biosurfactants [1–4]. These are surface-active metabolites produced by microorganisms. Biosurfactants have the potential to be applied in detergents, pharmaceuticals, cosmetics, and the food industry [5–10]. In contrast to traditionally produced surfactants based on petroleum feedstock, they are better biodegradable and do not permanently pollute the environment. Apart from good effectiveness they exhibit an antimicrobial activity against other microorganisms [5, 6].

Even though the biotechnological production of biosurfactants has already been established for several years, high production costs owing to intense foaming and expensive downstream processing have prevented their wide use up to now. Attempts are being made to overcome these difficulties by using cheaper substrates, optimising the process to improve yields, and integrating the process to reduce downstream processing steps [11–13]. Furthermore, mutant and recombinant rhamnolipid-producing strains have been developed to increase the yields by several factors. A better understanding of the natural role of biosurfactants in biofilms [14, 15] may also provide for new approaches to increasing production yields.

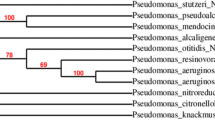

Some of the most extensively studied biosurfactants are the rhamnolipids, mostly produced by Pseudomonas aeruginosa [8]. Rhamnolipids are composed of one or two rhamnose molecules and up to three molecules of hydroxy fatty acids, whereas their chain length can vary from eight up to 14 carbon molecules [16–18]. In research related to these rhamnolipids, a large variety of analytical methods have been employed to identify and quantify the different rhamnolipid species. These methods range from simple colorimetric measurement of the rhamnose moiety after rhamnolipid hydrolysis [19] to a sophisticated analysis of sample composition by mass spectrometry (MS) [16, 20]. In order to compare the results of different research groups or to choose the appropriate method for a certain research activity (e.g. strain screening, process optimisation, etc.) and laboratory equipment some characteristics have to be considered. Among these are rapidity, the measuring range, accuracy, instrumentation, and costs of the method. The present review compares the different methods applied in the analysis of rhamnolipids so far and gives an overview of the existing purification methods. The advantages and disadvantages of these analytical methods are discussed. Recent developments made to accelerate rhamnolipid analysis for a better control of biosurfactant production are presented.

Rhamnolipid analysis techniques

Indirect methods

Indirect methods are based on physical properties of rhamnolipids, such as alteration of interfacial tension owing to the amphiphilic character of the biosurfactant or haemolysis, the breaking open of red blood cells with the release of haemoglobin into the surrounding medium. The influence of rhamnolipids on different bacteria, fungi, and algae [17, 21–24] is not considered here.

Surface tension

Amphiphilic molecules accumulate at the interface of different media and form micelles or vesicles above a certain concentration, called the critical micelle concentration. Below this value, surface or interfacial tension depends on the concentration of the active compound and can be used for an indirect quantification of the total rhamnolipid content using a calibration curve with pure rhamnolipid for comparison. Analysis is carried out with tensiometers [25] or with mercury electrodes [26], where the differential capacity potential is changed owing to adsorption of rhamnolipids on the electrodes. Samples have to be diluted to a concentration ranging from about 1 to 50 mg·L−1 prior to surface tension measurement [27]. Drawbacks of this method are the susceptibility to other surface-active compounds, the variable influence of every rhamnolipid species on surface tension, and the lack of information about sample composition. Tensiometric measurements were applied widely in the early days of rhamnolipid research [25, 28] owing to their simplicity. They are still used, especially for new rhamnolipid species [22, 23, 29].

Haemolytic activity

Haemolytic activity tests can be performed in two ways. Firstly, on blood agar plates which contain mammalian blood (usually sheep) in differential media. β-haemolytic activity indicates a complete lysis of the red blood cells surrounding the bacteria colonies, while α-haemolysis just partially lyses haemoglobin and appears green. These ready-made agar plates can only be used for screening new biosurfactant-producing strains and not for medium optimisation as medium composition cannot be altered. Moreover, the reaction is not specific for rhamnolipids, since lytic enzymes (e.g. protease, lysozyme) undergo the same reaction [30].

Secondly, quantitative haemolytic activity tests are carried out using erythrocyte suspensions and by measuring the released haemoglobin absorbance at 540 nm [31]. The smallest amount of haemolysin causing a complete lysis of the blood cells is considered to be one haemolytic unit. The disadvantages are the same as those mentioned above.

Colorimetric methods

Colour reactions are generally performed by binding a dye to the rhamnolipid (e.g. cetyltrimethylammonium bromide, CTAB, agar test) or by reaction of the rhamnose moiety with a coloured chemical compound (e.g. anthrone method, orcinol test), which can be quantified afterwards by photometry. These assays were and still are applied most frequently in rhamnolipid analysis.

CTAB agar test

This semiquantitative agar plate cultivation test is based on the formation of an insoluble ion pair of anionic surfactants with the cationic surfactant CTAB and the basic dye methylene blue [30]. As the constitution of the agar medium, containing 0.2 g·L−1 CTAB and 0.005 g·L−1 methylene blue, can be altered, this quick and simple test is well suited for medium optimisation and screening new anionic biosurfactant production strains or mutants [32]. Rhamnolipids are detected as dark-blue halos around the colonies, with the spot diameter being dependent on rhamnolipid concentration. Nevertheless, care has to be taken in quantification, as the spot diameter is influenced by variable cell growths of the bacteria, cultivation times, migrations of the rhamnolipids, and filling levels of the agar plates.

Anthrone method

This colorimetric test is based on the reaction of rhamnose in the presence of a strong acid with anthrone (9,10-dihydro-9-oxoanthracene), forming a dye by heating, which can be measured at 625 nm by a photometer against a calibration curve with rhamnose or rhamnolipid [33, 34] (Fig. 1). As it is a quick and simple assay that does not require any expensive instrumentation, it is often used just for the detection of rhamnolipids or for quantification of the total rhamnolipid content down to 20 mg·L−1. For this purpose, the composition of the rhamnolipid mixture has to be known. However, it generally changes during rhamnolipid production (Fig. 2) or in adsorption experiments [35], which may render the method inexact. Additionally, interferences of several solvents, inorganic salts (e.g. NaCl), carbonyl or oxidising compounds, and proteins with the reaction have been reported [34]. An advantage consists in the possibility of treating larger quantities of samples on the micro titre plate scale [36].

Orcinol assay

In analogy to the anthrone method, this method modified by Chandrasekaran and BeMiller [19] is based on using a dye for the quantification of the rhamnolipid content in a sample by absorption measurements at 421 nm (Fig. 1). In this case, the rhamnose molecule of rhamnolipids reacts with sulphuric acid and orcinol (1,3-dihydroxy-5-methylbenzene) at high temperatures (30 min at 80 °C) to give a blue-green colour [37].

Chromatographic methods

One of the main disadvantages of the indirect and colorimetric methods described above is the ignorance of sample composition and, hence, the occurrence of various rhamnolipid species. Chromatographic separation of a rhamnolipid mixture, coupled with appropriate detection methods like MS, revealed that the hydroxy fatty acid moiety of the rhamnolipids may comprise various fatty acid chain lengths [16, 17, 38–40] (Table 1). Firstly, different chromatographic separation methods and, if necessary, derivation reactions of prepurified rhamnolipid samples will be discussed. Different extraction procedures for preliminary purification will be presented in “Rhamnolipid purification procedures”. Rhamnolipid detection methods for structure analysis or quantification will be outlined in more detail in “Composition and purity analysis”.

Thin-layer chromatography

Thin-layer chromatography (TLC) has been used extensively for determining the composition of culture broth extracts of rhamnolipids [40–42] and for their preliminary purification on a thicker chromatographic layer.

For the separation of different rhamnolipid species (the simplest separation is that into monorhamnolipids and dirhamnolipids), normal-phase or reversed-phase chromatography can be employed. Normal-phase chromatography on silica 60 plates with a solvent mixture of chloroform–methanol–water or 20% aqueous acetic acid (65:15:2) allows for the division into monosaccharide and disaccharide polar head groups. TLC with RP-8 plates using a mixture of methanol–water–trifluoroacetic acid (90:10:0.25) results in a good separation of a rhamnolipid mixture on the basis of the length of the fatty acid alkyl chain [42].

Separate rhamnolipid spots can be detected by staining and comparison with the retention times of standard substances. Suitable staining reagents for rhamnolipids are cerium ammonium molybdenum acid and diphenylamine or reagents specific for sugars (anthrone, 4-methoxy-benzaldehyde) and fatty acids (bromocresol green, bromothymol blue, 2′,7′-dichlorofluoresceine). Densiometric quantification by the spot diameter and intensity is also possible, if the sample is prepared automatically in advance. However, this method is not very accurate and larger quantities of rhamnolipids (more than 10 μg) are needed compared with other quantification methods (not suited for analysis of trace concentrations).

An alternative for rhamnolipid identification is to couple TLC analysis with a detection system based on, e.g., fast atom bombardment [40, 42]. This combination even allows one to distinguish different fatty acid chains and their sequences inside the rhamnolipid that cannot be dissociated by chromatography. However, no quantification is possible. For this reason, the method is not used frequently.

Nevertheless, large numbers of samples with small volumes can be treated by TLC and smaller amounts of organic solvents are consumed compared with column chromatography.

Gas chromatography

As whole rhamnolipids cannot be used for gas chromatography (GC), these are hydrolysed prior to analysis. Hydrolysis of rhamnolipids can be performed with acids (e.g. triflouroacetic acid) or bases (NaOH) which do not cleave the two fatty acid chains of the dirhamnolipid. Separation of rhamnose or fatty acids by GC, coupled with flame ionisation detectors or mass spectrometers, has been reported [41, 43–45].

Rhamnose is analysed quantitatively after conversion into trimethylsilyl esters, not giving any structural information about rhamnolipid composition [45].

In contrast to this, analysis of fatty acids or their methyl esters (after methylation with boron trifluoride, for example) with GC shows the whole spectrum of hydroxy fatty acids in rhamnolipids. In contrast to many cases of HPLC-MS analysis, the exact arrangement of the fatty acids in rhamnolipids cannot be obtained by GC.

High-performance liquid chromatography

In contrast to the methods described so far, high-performance liquid chromatography (HPLC) is not only appropriate for the complete separation of different rhamnolipid species [16, 44–47], but can also be coupled with various detection devices (UV, MS, evaporative light scattering detection, ELSD) for identification and quantification of rhamnolipids.

While normal-phase chromatography of rhamnolipids is quite popular in TLC, analytical column chromatography uses mostly reversed-phase silica columns with a gradient of acetonitrile and water (30–70% acetonitrile to 70–100% acetonitrile ) [16, 20, 44, 46, 48, 49]. For better rhamnolipid separation, acids or ammonium acetate is added to the solvent, depending on the detection system used (Table 2). Structural isomers of rhamnolipids (e.g. Rha-C10-C8 and Rha-C8-C10) cannot be separated by these HPLC methods. They are distinguished by tandem MS (MSMS) on the basis of their distinct fragmentation.

As rhamnolipids are only very faintly sensitive to UV light (detection limit 0.2 g), derivation to p-bromophenacyl esters for UV detection at 265 nm is recommended [46]. This derivation is achieved by a reaction of the crude rhamnolipid extract with p-bromoacetophenone and triethylamine at a molar ratio of 1:4:2 in acetonitrile at 60 °C for 1 h, the derivation rate being about 95%. By means of ELSD (measurement of the analyte droplet size after solvent evaporation) or MS, rhamnolipids can be detected without derivation [35, 45].

Their identification by comparison with retention times of standard substances is necessary for ELSD and UV detection. When coupled with MSMS, identification and quantification should be performed in the multiple reaction mode (MRM), which means that only defined analytes are recorded via several specific pseudomolecular ions (PI; quantifiers and qualifiers). This results in the advantage that even overlapping substances can be identified (by qualifier PI) and quantified (by quantifier PI) exactly, but only if they are included in the MRM method. Suitable instrument settings for MS detection are a source temperature of 450 °C (without split) and negative ionisation at −4,800 V to obtain negative [M-H]− ions. The negative ion mode is used, because identification and quantification in the positive mode are difficult owing to the formation of adducts by ammonium or sodium ions in the sample.

A suitable measuring range for rhamnolipid quantification with an ELSD detector lies between 0.015 and 1.5 g·L−1. Linear calibration for derived rhamnolipids and UV detection is possible between 0.01 and 0.25 g·L−1 rhamnolipid. Even lower concentrations (approximately 1 × 10−5 g·L−1) were detected by HPLC-MS, with a linear correlation of the peak area and rhamnolipid concentration over a range of almost two magnitudes.

Especially when HPLC-MS is used, samples should be prepurified, as salts and some other impurities influence rhamnolipid ionisation in the ion source of the mass spectrometer and, hence, affect the signal intensities measured. During these purification steps (e.g. centrifugation, extraction, solvent evaporation), losses of analyte may occur, which are evaluated by examining the recovery rates. For derivation including UV detection pursuant to the method of Schenk et al. [46], recovery rates of about 70% were estimated. If derivation is not needed (HPLC-MS), recovery rates higher than 90% have been achieved (Fig. 3). Generally, care has to be taken as regards analyte losses during the extraction of small quantities, as these may be very high owing to the amphiphilic character of the rhamnolipids (Fig. 4).

By adding an appropriate internal standard (e.g. hydroxyatrazine for phenacyl esters [46] for UV detection and 16-hydroxyhexadecanoic acid for rhamnolipid quantification by HPLC-MS [20]), measuring errors due to losses during sample preparation and changes of analyte ionisation may be compensated. The latter problem may also be overcome by standard addition experiments. If high sample dilution is possible (for matrix reduction) and optimised geometries are available for ionisation in mass spectrometers, purification steps prior to HPLC analysis may even be omitted by using an internal standard [20]. Our own work has shown that an internal standard must exhibit properties that are equivalent to those of rhamnolipids during chromatographic separation and ionisation for MS and can be applied in a certain measuring range only.

For all the detection methods described, standard substances have to be used for calibration for proper quantification—simple comparison of intensities of several species with one standard curve generally is not sufficient. Suitable calibration methods (e.g. external standard, enriched media, internal standard) are selected depending on the recovery rates and changes of sample composition.

The high sensitivity of HPLC-MS allows for analysis down to trace concentrations. When coupled with HPLC and a proper sample preparation, it is the most precise method for rhamnolipid identification and quantification. Another advantage is the possibility to handle a high number of samples.

Composition and purity analysis

For a better understanding of the relationship among the chemical structures of rhamnolipids, the composition of mixtures, and their surface-active properties, detailed structural analysis is necessary. This is achieved by MS, infrared (IR) spectroscopy, and nuclear magnetic resonance (NMR) spectroscopy. MS also allows one to examine a rhamnolipid mixture composition. Compared with formerly applied methods like the hydrolysis of rhamnolipids and measurement of the fatty acid content by GC [41], the methods discussed below provide for a better insight into the structure composition of rhamnolipids, even for isomers [16, 17, 38].

Mass spectrometry

Nowadays, mixture composition and structure analysis can be performed by tandem quadrupole mass spectrometers (developed in the late 1970s). Good rhamnolipid ionisation is achieved by electrospray ionisation for direct infusion or HPLC-MS, as it represents a “soft” method with little fragmentation of primary molecules. Ionised molecules are selected by a mass analyser according to their mass-to-charge ratio (m/z) and are subsequently detected. Instrument settings are optimised by infusion experiments.

Scanning of the whole mass spectrum between 100 and 750 Da (Q1 scan) in the negative MS mode allows for the selection of the target ions (different rhamnolipids). A typical mass spectrum (Q1 scan) of a rhamnolipid mixture is presented in Fig. 2. Structural identification of the target ions can be accomplished by MSMS experiments (product ion scans), which means that a target ion is fractionated in the collision cell and the fragment ions (e.g. hydroxy fatty acids, rhamnose fragments) are detected. Potential sites of fracture for rhamnolipids are marked in Fig. 5, with Rha-Rha-C10-C10 being used as an example. Known rhamnolipid species typically produced by Pseudomonas aeruginosa, their pseudomolecular primary ions, and some corresponding fragment ions are listed in Table 1, demonstrating that even isomers (e.g. Rha-C10-C12 and Rha-C12-C10) can be discriminated [16, 17].

Fourier transform IR spectroscopy

A classic method for structure analysis is IR spectroscopy. Irradiation of molecules with IR light induces an oscillation of chemical bonds at characteristic frequencies and, thus, energy is absorbed. The resulting transmission of radiation is measured over a frequency spectrum from about 400–4,000 cm−1. The so-called fingerprint area between 400 and 1,500 cm−1 shows deformation bands which are characteristic of every molecule and allow for the chemical substances to be identified from spectrum files. Partial structures are analysed by dilation oscillations in the area from 1,500 to 4,000 cm−1, as chemical bonds generate distinct valency oscillation bands. A characteristic Fourier transform IR (FTIR) transmittance spectrum of Rha-Rha-C10-C10 is shown in Fig. 6. However, one of the most commonly used techniques for rhamnolipid analysis by IR spectroscopy is FTIR attenuated total reflectance (ATR) spectroscopy [23, 50].

Apart from structure analysis, it is being attempted to rapidly and simply quantify biosurfactants even in culture broth and mixtures with a view to obtain an online method for total rhamnolipid analysis [51]. Quantification in biosurfactant model solutions is based on the peak area due to the carbonyl bond in comparison with an internal standard (anthracene carbonitrile) in a concentration range suitable for fermentation monitoring (0.2–3 g·L−1). Depending on other medium compounds present, use of several characteristic peaks may be more accurate. Online measurements are especially useful for the process optimisation of rhamnolipid production during fermentations. ATR probes for direct introduction into bioreactors are commercially available (http://www.hitec-zang.de), but have not yet been used for the monitoring of rhamnolipid concentrations in bioreactors. Drawbacks of rhamnolipid quantification by FTIR spectroscopy may consist in a certain sensitivity to other medium components and influence of pH, resulting in measurement errors in excess of 50% [51]. However, analysis is much quicker than in case of HPLC as samples do not have to be treated before the measurements.

NMR spectroscopy

NMR spectroscopy allows for an even more accurate structure and purity analysis than IR spectroscopy and consists of solid-state and high-resolution techniques. NMR spectroscopy is based on transitions in atoms with a magnetic moment when an external magnetic field is applied. Structure information is obtained from three parameters: chemical shifts of the absorption frequency, coupling (mutual influence of adjacent nuclei), and integral height. Different techniques, such as correlation spectroscopy and heteronuclear multiple quantum coherence, can be applied for NMR spectroscopy [38]. One- and two-dimensional 1H and 13C NMR spectroscopy have already been performed for pure rhamnolipids [38, 52]. Measurements of deuterium-exchanged samples are generally carried out in chloroform-deuterated methanol (2:1 v/v) using tetramethylsilane as the internal standard. The chemical shifts and coupling constants obtained by the 1H NMR spectroscopy of rhamnolipids are listed in Tables 3 and 4; see Choe et al. [52]. In the last few years, NMR spectroscopic analysis [38, 53, 54] was performed in principle to confirm the structure of rhamnolipids produced by recently isolated or mutant bacteria strains compared with the structure of rhamnolipids mentioned in the literature [21, 41, 55].

Rhamnolipid purification procedures

Batchwise separation of rhamnolipids from culture broth

After rhamnolipid production, a high expenditure is required for purification procedures to achieve a pure product. First, the production medium has to be separated from the microorganisms and the liquid volume has to be reduced. On the laboratory scale, microorganisms are generally removed by centrifugation prior to further purification steps. Preliminary purification can be performed in batches by precipitation, solvent extraction, or selective crystallisation.

Precipitation

Two different kinds of precipitation can be discriminated: acid [16, 27, 43] or aluminium sulphate precipitation [46]. Through acidification of the medium to a final pH between 2 and 3, rhamnolipids exist in their acid form and are therefore less soluble in an aqueous solution. The precipitate can be collected by centrifugation (after several hours at 4 °C) and resuspended in an appropriate buffer (e.g. bicarbonate). Aluminium sulphate also lowers the pH and precipitates rhamnolipids through salting-out.

Solvent extraction

Rhamnolipid extraction is often used for removing hydrophilic compounds prior to rhamnolipid analysis. Different solvents and solvent mixtures like ethyl acetate or chloroform–methanol (2:1) are applied [44, 46, 48]. In general, the extraction yield can be improved by an acidification of the sample prior to extraction, as rhamnolipids are present in their protonated form and, hence, are less soluble in water.

Selective crystallisation

Selective crystallisation may be applied after precipitation or extraction of rhamnolipid mixtures from culture broth and redissolution in an organic solvent (e.g. ethyl acetate). As rhamnolipids are concentrated in the solvent mixture, the addition of hexane or another comparable solvent, combined with a temperature reduction, results in the selective crystallisation of a rhamnolipid species owing to the reduced solubility of the rhamnolipid in the solvent. This has already been observed for Rha-Rha-C10-C10, which often is the most abundant rhamnolipid in mixtures [56].

Secondly, a crystallisation process is used to obtain pure crystals of Rha-Rha-C10-C10 after chromatographic purification steps. Lyophilisation in 0.05 M sodium bicarbonate solution causes the formation of crystals of monorhamnolipids, which cannot be obtained by solvent evaporation in the presence of water.

Continuous separation of rhamnolipids from culture broth

As product inhibition occurs at higher rhamnolipid concentrations, continuous separation of rhamnolipids from culture broth is desired in some cases for a continuous rhamnolipid production with a permanent product removal to achieve higher product yields. Several options are available for this purpose, including rhamnolipid adsorption on a resin or activated carbon, ion-exchange chromatography, membrane filtration, or foam fractionation after cell separation or immobilisation. Combination of several purification processes, as proposed by Reiling et al. [28] for adsorption and ion-exchange columns, improves the results of the downstream processing of larger culture broth quantities.

Adsorption

Most frequently, Amberlite XAD 2 or 16 polystyrene resin that absorb and release hydrophobic and amphiphilic substances (e.g. rhamnolipids) owing to basically hydrophobic interactions are used [17, 28, 57–59]. For primary enrichment, cell-free culture broth is directly applied to the adsorbent column and equilibrated with 0.1 M phosphate buffer at pH 6.1. Exhaustion of the adsorbent resin can be monitored by surface tension or UV absorption measurements for example [28, 57]. Washing of the resin with distilled water removes some pigments and free fatty acids [59]. Finally, rhamnolipids are eluted with methanol and the solvent is evaporated subsequently. Further purification of the crude rhamnolipid mixture can be performed by chromatographic methods after redissolving the rhamnolipids in an appropriate buffer. The adsorbent is regenerated with 1 M NaOH as described by Reiling et al. [28].

An adsorption material studied more recently is wood activated carbon [60]. Adsorption is possible at a pH ranging from 5 to 10 and a temperature of 40 °C, desorption (and regeneration) takes place with acetone at 30 °C to recover almost 90% of rhamnolipids. The wood activated carbon can be reused several times and in particular allows for the separation of water-soluble pigments from the rhamnolipids.

Adsorption chromatography represents a good alternative to solvent extraction, the advantages being a continuous process and smaller solvent consumption.

Ion exchange

Another purification step of the rhamnolipid mixture is anion-exchange chromatography [28, 46, 61]. Rhamnolipids are charged negatively at higher pH values, so they can be separated by a weak anion exchanger [e.g. (diethylamino)ethyl-Sepharose]. The anion exchanger is equilibrated with a tris(hydroxymethyl)aminomethane hydrochloride buffer (pH 8 or higher) containing 10% (v/v) ethanol. According to our own results, rhamnolipids are released from the resin by adding at least 0.6 M NaCl to the equilibration buffer. A second adsorption step or extraction removes the salt from the rhamnolipid fractions. Subsequent solvent evaporation and freeze-drying yield a solid and quite hygroscopic rhamnolipid mixture, still containing some fatty acids and pigments. The ion-exchange resin can be regenerated with a buffer containing 2 M NaCl and 20% ethanol (or methanol for pigment ejection) [28].

Membrane filtration

Membrane filtration is another alternative for rhamnolipid enrichment and prepurification [11, 22, 58]. Generally, ultrafiltration with a membrane cutoff of 10 kDa leads to an almost complete retention of rhamnolipids even at neutral pH [58]. But also with bigger pores (e.g. 0.2 μm), high rhamnolipid retention rates are obtained under certain conditions. Low pH values, rhamnolipid concentrations above the critical micelle concentration, proteins, and other culture broth ingredients can promote rhamnolipid aggregation to micelles [58, 62]. By the direct filtration of culture broth, a gel layer forms on the membrane owing to fouling, which also acts like a membrane. Consequently, in situ product removal concepts for cell retention and continuous rhamnolipid removal failed owing to micelle formation [58]. In contrast to this, smaller medium components can be separated from rhamnolipids [63].

Foam fractionation

Foam fractionation by contrast uses the peculiarity of rhamnolipids of forming micelles and, thus, of foaming. When applied for the continuous removal of rhamnolipids during fermentations, foam is allowed to press out of the bioreactor through a fractionation column. Afterwards, it collapses in a separate recipient by acids or shear forces [57, 58]. Rhamnolipids adsorb on the interface of air bubbles and medium depending on the pH, the ionic strength, and the concentration of other surface-active compounds [64, 65]. With increasing residence time of the foam in the fractionation column, gravitational forces result in the drainage of the liquid in the foam lamellae, thus enriching rhamnolipids in the foam up to approximately 12 g.L−1 [58]. As recovery decreases at the same time, foam fractionation conditions have to be traded off depending on the prepurification desired. Factors influencing rhamnolipid enrichment, recovery, and the foam formation rate are given in Table 5. As regards rhamnolipid purification, adsorption of bacteria in foam is higher than that of rhamnolipids and proteins [58]; hence, immobilisation of the bacteria and retention of the immobilisates in the bioreactor are necessary for product enrichment.

Given that a higher enrichment of rhamnolipids is possible with low rhamnolipid concentrations in the culture medium (Fig. 7) and long residence times in the fractionation column only [58], this method is more effective in continuous rhamnolipid removal during fermentation (to achieve higher rhamnolipid production yields) than in purification.

Chromatographic separation of rhamnolipid mixtures

After rhamnolipid separation from bacterial cells and some water-soluble substances, chromatographic methods are applied to obtain pure rhamnolipids. For smaller volumes, preparative TLC may be applied, whereas larger quantities are separated by column chromatography (e.g. silica gel or reversed-phase material).

Preparative TLC

The process of preparative TLC is similar to that of analytical TLC. Generally, preparative silica gel plates are used with a solvent mixture of chloroform–methanol–water/acetic acid (e.g. 65:15:2) or mixtures of equivalent polarities. As one chromatographic run is not sufficient to achieve pure rhamnolipids, TLC often is performed several times with solvents of different polarities [16, 43] or after column chromatography for precision cleaning [38, 66]. Samples are applied onto TLC plates after extraction from culture broth and concentration. The separated rhamnolipids are eluted from silica by methanol or chloroform–methanol [38, 43, 66]. The advantages of TLC are its simple feasibility and the need for less equipment than for preparative column chromatography. On the other hand, only smaller quantities of samples can be treated. Consequently, it is suited in particular for analytical calibration standard purification and not for industrial downstream processing.

Normal phase

Normal-phase column chromatography using silica is a standard purification method for rhamnolipid separation if larger volumes have to be treated [21, 38, 46, 66]. The acidified rhamnolipid mixture, in a solvent like chloroform, is fed into the column after various prepurification steps (e.g. centrifugation and extraction or adsorption on a resin) to separate bacterial cells (generally Pseudomonas aeruginosa) and some water-soluble compounds. Flushing of silica with chloroform removes neutral lipids and some pigments [21, 66]. Rhamnolipids can be eluted with chloroform–methanol at a ratio of 50:3 for Rha-C10-C10 and 50:5 for the remaining Rha-C10-C10 to achieve a better separation, as was done in our group. Ultimate scrubbing at a ratio of 50:50 removes Rha-Rha-C10-C10. Thereafter, the solvent of the red-brown rhamnolipid fractions is evaporated. Dissolution of the residue in alkaline solution, followed by acidification and recrystallisation yields crystalline rhamnolipids according to their number of sugar and hydroxy fatty acid molecules [21]. Apart from recrystallisation, pure rhamnolipids can also be obtained by reapplication of column chromatography or TLC [21, 66].

Reversed phase

As already described for the analytical separation of rhamnolipids, mixtures are separated by reversed-phase chromatography according to the chain length of the hydroxy fatty acids [42]. Prepurified rhamnolipid mixtures are acidified and fed into an RP18 column. Our group separated the rhamnolipids isocratically using 70% acetonitrile and 30% distilled water. The resulting fractions of the main rhamnolipids (Rha-C10-C10, Rha-Rha-C10-C10) are free from fatty acids or pigments and give a white powder after crystallisation. Hence, a secondary treatment is not necessary. However, column material is more expensive than normal silica; therefore, it is used for semipreparative purposes only.

Conclusions

Rhamnolipid analysis is carried out by methods ranging from simple colorimetric tests to sophisticated chromatographic separation, coupled with detection systems like MS to provide detailed structural information. Most commonly, rhamnolipids are extracted from culture broth and then subjected to HPLC analysis. In this case, HPLC coupled with MS presents for the moment the most precise method for rhamnolipid identification and quantification. Recently, efforts were made to accelerate rhamnolipid quantification for better control of biosurfactant production. Suitable approaches are HPLC analysis directly from culture broth by adding an internal standard or FTIR-ATR spectroscopy measurements of culture broth as a quasi-online quantification method. Concerning FTIR-ATR spectroscopy, further efforts for application to complex rhamnolipid solutions have to be made. The search for alternative rhamnolipid-producing strains makes a structure analysis and constant adaptation of the existing quantification methods necessary. Therefore, simple colorimetric tests based on whole rhamnolipid content can provide a useful tool for strain and medium screening.

For downstream processing, the purification method chosen depends on the application desired. As costs of biosurfactant production have to be reduced for biosurfactants to be applied widely as detergents or emulsifiers, different approaches to process integration with a continuous removal of rhamnolipids from the bioreactor are being investigated, such as foam fractionation, membrane techniques, or adsorption. For high-purity products, chromatography followed by crystallisation is still the method of choice.

Abbreviations

- ATR:

-

attenuated total reflectance

- CTAB:

-

cetyltrimethylammonium bromide

- ELSD:

-

evaporative light scattering detection

- FTIR:

-

fourier transform infrared

- GC:

-

gas chromatography

- HPLC:

-

high-performance liquid chromatography

- IR:

-

infrared

- MRM:

-

multiple reaction monitoring

- MS:

-

mass spectrometry

- MSMS:

-

tandem mass spectrometry

- NMR:

-

nuclear magnetic resonance

- PI:

-

pseudomolecular ions

- TLC:

-

thin-layer chromatography

References

Lang S (2002) Curr Opin Colloid Interface Sci 7:12

Lin S-C (1996) J Chem Technol Biotechnol 66:109

Nitschke M, Costa SGVAO, Contiero J (2005) Biotechnol Prog 21:1593

Soberón-Chávez G, Lépine F, Déziel E (2005) Appl Microbiol Biotechnol 68:718

Desai JD, Banat IM (1997) Microbiol Mol Biol Rev 61:47

Banat IM, Makkar RS, Cameotra SS (2000) Appl Microbiol Biotechnol 53:495

Kitamoto D, Isoda H, Nakahara T (2002) J Biosci Bioeng 94:187

Lang S, Wullbrandt D (1999) Appl Microbiol Biotechnol 51:22

Fiechter A (1992) Trends Biotechnol 10:208

Maier RM, Soberon-Chavez G (2000) Appl Microbiol Biotechnol 54:625

Mulligan CN, Gibbs BF (1990) J Chem Technol Biotechnol 47:23

Van Hamme JD, Singh A, Ward OP (2006) Biotechnol Adv 24:604

Fiechter A (1992) Pure Appl Chem 64:1739

Davey ME, Caiazza NC, O’Toole GA (2003) J Bacteriol 185:1027

Caiazza NC, Shanks RMQ, O’Toole GA (2005) J Bacteriol 187:7351

Deziel E, Lepine F, Dennie D, Boismenu D, Mamer OA, Villemur R (1999) Biochim Biophys Acta 1440:244

Haba E, Pinazo P, Jauregui O, Espuny MJ, Infante MR, Manresa A (2003) Biotechnol Bioeng 81:316

Gunther NW, Nunez A, Fett W, Solaiman DKY (2005) Appl Environ Microbiol 71:2288

Chandrasekaran EV, BeMiller JN (1980) In: Whistler RL (ed) Methods in carbohydrate chemistry, vol 8. Academic., New York, p 89

Deziel E, Lepine F, Milot S, Villemur R (2000) Biochim Biophys Acta 1485:145

Itoh S, Honda H, Tomita F, Suzuki T (1971) J Antibiot 24:855

Haussler S, Nimtz M, Domke T, Wray V, Steinmetz I (1998) Infect Immun 66:1588

Tuleva BK, Ivanov GR, Christova NE (2002) Z Naturforsch C 57:356

Howe J, Bauer J, Andra J, Schromm AB, Ernst M, Rossle M, Zahringer U, Rademann J, Brandenburg K (2006) FEBS J 273:5101

Guerra-Santos L, Käppeli O, Fiechter A (1984) Appl Environ Microbiol 48:301

Emons H, Werner G, Haferburg D, Kleber H-P (1989) Electroanalysis 1:555

Zhang YM, Miller RM (1992) Appl Environ Microbiol 58:3276

Reiling HE, Thanei-Wyss U, Guerra-Santos LH, Hirt R, Käppeli O, Fiechter A (1986) Appl Environ Microbiol 51:985–989

Ochoa-Loza FJ, Noordman WH, Jannsen DB, Brusseau ML, Maier RM (2007) Chemosphere 66:1634

Siegmund I, Wagner F (1991) Biotechnol Tech 5:265

Johnson MK, Boese-Marrazzo D (1980) Infect Immun 29:1028

Perfumo A, Banat I, Canganella F, Marchant R (2006) Appl Microbiol Biotechnol 72:132

Helbert JR, Brown KD (1957) Anal Chem 29:1464

Hodge JE, Hofreiter BT (1962) In: Whistler RL, Wolfrom ML (eds) Methods in carbohydrate chemistry, vol 1. Academic., New York, p 380

Noordman WH, Brusseau ML, Janssen DB (2000) Environ Sci Technol 34:832

Fox JD, Robyt JF (1991) Anal Biochem 195:93

Koch AK, Käppeli O, Fiechter A, Reiser J (1991) J Bacteriol 173:4212

Monteiro SA, Sassaki GL, de Souza LM, Meira JA, de Araujo JM, Mitchell DA, Ramos LP, Krieger N (2007) Chem Phys Lipids 147:1

Bosch M-P, Parra JL, Manresa M-A, Ventura F, Rivera J (1989) Biol Mass Spectrom 18:1046

Rendell NB, Taylor GW, Somerville M, Todd H, Wilson R, Cole PJ (1990) Biochim Biophys Acta 1045:189

Syldatk C (1984) Mikrobielle Bildung und Charakterisierung grenzflächenaktiver Rhamnolipide aus Pseudomonas spec. DSM 2874. TU Braunschweig, Braunschweig

de Koster CG, Vos B, Versluis C, Heerma W, Haverkamp J (1994) Biol Mass Spectrom 23:179

Van Dyke MI, Couture P, Brauer M, Lee H, Trevors JT (1993) Can J Microbiol 39:1071

Mata-Sandoval JC, Karns J, Torrents A (1999) J Chromatogr A 864:211

Arino S, Marchal R, Vandecasteele J-P (1996) Appl Microbiol Biotechnol 45:162

Schenk T, Schuphan I, Schmidt B (1995) J Chromatogr A 693:7

Lépine F, Déziel E, Milot S, Villemur R (2002) J Mass Spectrom 37:41

Trummler K, Effenberger F, Syldatk C (2003) Eur J Lipid Sci Technol 105:563

Benincasa M, Abalos A, Oliveira I, Manresa A (2004) Antonie Van Leeuwenhoek 85:1

Borgund AE, Erstad K, Barth T (2007) J Chromatogr A 1149:189

Gartshore J, Lim YC, Cooper DG (2000) Biotechnol Lett 22:169

Choe B-Y, Krishna NR, Pritchard DG (1992) Magn Reson Chem 30:1025

Tahzibi A, Kamal F, Assadi MM (2004) Iran Biomed J 8:25

Wei Y-H, Chou C-L, Chang J-S (2005) Biochem Eng J 27:146

Jarvis FG, Johnson MJ (1949) J Am Chem Soc 71:4124

Manso Pajarron A, Koster CG, Heerma W, Schmidt M, Haverkamp J (1993) Glycoconj J 10:219

Matulovic U (1987) Verfahrensentwicklung zur Herstellung grenzflächenaktiver Rhamnolipide mit immobilisierten Zellen von Pseudomonas spec. DSM 2874. TU Braunschweig, Braunschweig

Gruber T (1991) Verfahrenstechnische Aspekte der kontinuierlichen Produktion von Biotensiden am Beispiel der Rhamnolipide. PhD thesis, University of Stuttgart

Abalos A, Pinazo A, Infante MR, Casals M, Garcia F, Manresa A (2001) Langmuir 17:1367

Dubey KV, Juwarkar AA (2005) Biotechnol Prog 21:860

Matsufuji M, Nakata K, Yoshimoto A (1997) Biotechnol Lett 19:1213

Sanchez M, Aranda F, Espuny MJ, Marques A, Teruel JA, Manresa A, Ortiz A (2007) J Colloid Interface Sci 307:246

Mulligan CN, Mahmourides G, Gibbs BF (1989) J Biotechnol 12:37

Helvaci SS, Peker S, Ozdemir G (2004) Colloids Surf B 35:225

Ozdemir G, Peker S, Helvaci SS (2004) Colloids Surf A 234:135

Sim L, Ward OP, Li Z-Y (1997) J Ind Microbiol Biotechnol 19:232

Brown AK, Kaul A, Varley J (1999) Biotechnol Bioeng 62:278

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Heyd, M., Kohnert, A., Tan, TH. et al. Development and trends of biosurfactant analysis and purification using rhamnolipids as an example. Anal Bioanal Chem 391, 1579–1590 (2008). https://doi.org/10.1007/s00216-007-1828-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-007-1828-4