Abstract

An online UV photolysis and UV/TiO2 photocatalysis reduction device (UV–UV/TiO2 PCRD) and an electrochemical vapor generation (ECVG) cell have been used for the first time as an interface between high-performance liquid chromatography (HPLC) and atomic fluorescence spectrometry (AFS) for selenium speciation. The newly designed ECVG cell of approximately 115 μL dead volume consists of a carbon fiber cathode and a platinum loop anode; the atomic hydrogen generated on the cathode was used to reduce selenium to vapor species for AFS determination. The noise was greatly reduced compared with that obtained by use of the UV–UV/TiO2 PCRD–KBH4–acid interface. The detection limits obtained for seleno-DL-cystine (SeCys), selenite (SeIV), seleno-DL-methionine (SeMet), and selenate (SeVI) were 2.1, 2.9, 4.3, and 3.5 ng mL−1, respectively. The proposed method was successfully applied to the speciation of selenium in water-soluble extracts of garlic shoots cultured with different selenium species. The results obtained suggested that UV–UV/TiO2 PCRD–ECVG should be an effective interface between HPLC and AFS for the speciation of elements amenable to vapor generation, and is superior to methods involving KBH4.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It is well recognized that the species in which an element occurs determines its toxicity and bioavailability in a biological system and in the environment [1, 2]. To meet the need of studies in biological and environmental sciences increasing concern has been focused on speciation of the different chemical forms of selenium and not the determination of total selenium concentration [3, 4]. Highly efficient separation techniques, such as high-performance liquid chromatography (HPLC) [5] and capillary electrophoresis (CE) [6], coupled with highly sensitive detectors such as inductively coupled plasma mass spectrometry (ICP–MS) [7–11], atomic absorption spectrometry (AAS) [12] and atomic fluorescence spectrometry (AFS) [13], are often used as hyphenated techniques [14] for speciation of trace selenium species in biological and environmental samples.

Vapor generation (VG) as a highly efficient sample-introduction technique has been widely used in atomic spectrometry to achieve higher sample-introduction efficiency, and thus lower detection limits (DL), compared with those obtained with a conventional nebulizer. Besides this, efficient matrix separation and special selective reduction of different species are simultaneously achieved [15]. Potassium tetrahydroborate (KBH4)–acid as a highly efficient vapor-generation medium plays a very important role in the determination of vapor-generable elements by atomic spectrometry, and it has also been used as a sample-introduction method in the elemental speciation [16]. On the other hand, however, some drawbacks of KBH4 used for VG are obvious; it is, e.g., unstable and must be prepared daily in alkaline solution. KBH4 is also a potential source of contamination, large consumption of KBH4 in a flow analytical system greatly increases the cost of a determination, and the susceptibility of the KBH4–acid system to interference from transition metals means that masking reagents such as thiourea and L-cysteine must be used. Furthermore, the large amount of hydrogen generated in KBH4–acid systems reduces the stability of the plasma or even extinguishes the plasma when inductively coupled plasmas (ICP), especially low-power microwave induced plasmas (MIP) are used for determination. In order to overcome so many shortcomings of the conventional KBH4–acid system, electrochemical vapor generation (ECVG) was novelly developed by Lin et al. [17] for use in FIA. Vapor species and hydrogen were generated at the cathode in an electrolytic flow-through cell, separated from the liquid phase, then carried by carrier gas into the atomic spectroscopic detector. In general, ECVG is carried out by electrochemical reduction via atomic hydrogen generated on the cathode and no extra reductants such as unstable KBH4 and SnCl2 are introduced; contamination by reagents and the cost of determinations are thus greatly reduced. Only a very small amount of hydrogen gas is generated in the ECVG system, because of the high hydrogen overpotential on the cathode materials [15, 18]. Thus, the ECVG system was thought to be very suitable for ICP [19–21] and MIP [22] AES/MS. Better tolerance of interference from transition metals was also observed in ECVG systems and the susceptibility to transition metals greatly depends on the cathode materials [23, 24]. Results from Ding and Sturgeon [25] showed that SeVI and AsV, which could not be generated efficiently in the KBH4–acid system, were successfully generated into vapor species when lead was used as cathode material in an electrochemical reduction cell.

In recent years ECVG has been used by our group for the determination of trace elements such as arsenic, antimony, mercury, and selenium, etc. However, there are few studies on use of ECVG for organometal species which play important roles in biological and environmental systems. Ding and Sturgeon [25] and Pyell et al. [26] showed the feasibility of ECVG for monomethylarsonic acid (MMA) and dimethylarsinic acid (DMA); Schermer et al. [27] tried to use ECVG for seleno-DL-methionine, but no selenium signal was observed. ECVG as a VG interface between a flow separation and an online specific detection has not yet been reported for elemental speciation. This might be because of very low efficiency of vapor-generation from the element species, which occur in high oxidation states or as organic complexes, not only by use of the KBH4–acid system but also by ECVG. When the KBH4–acid system was applied for selenium determination and speciation, chemical reductants such as more than 6 mol L−1 HCl [11, 28], HBr–KBrO3 [29], and HCl–HBr [30] must be used to reduce SeVI to SeIV. Rubio and Vilanó [13, 31, 32] proposed direct UV irradiation for reduction of selenium species to selenite; this resulted in cleaner and simpler pre-reduction for vapor generation from selenium species by KBH4–acid. Guo et al. [33] developed a novel direct VG technique for SeIV based on UV irradiation without use of KBH4. In our recent work [34], photocatalytic reduction of SeVI based on a newly designed UV/TiO2 photocatalysis reduction device (UV/TiO2 PCRD) was successfully achieved; in this device photogenerated electrons (e−) on the surface of nano TiO2 film were used as the reductant when formic acid was used as a photogenerated hole (h+) scavenger to prohibit the recombination of e− and h+. SeVI such as selenate could be efficiently converted into vapor species by KBH4 via UV/TiO2 PCRD pre-reduction.

The objective of this study was to achieve selenium speciation by HPLC coupled with atomic fluorescence spectrometry (AFS), in which online photolysis of organic selenium species by UV-irradiation, pre-reduction of selenium in high oxidation state by UV/TiO2 PCRD (UV–UV/TiO2 PCRD), and a newly designed electrochemical cell (115 μL) for selenium vapor generation were novelly arranged in series as the interface between HPLC and AFS. UV–UV/TiO2 PCRD has been used with both HPLC–KBH4–acid–AFS and HPLC–ECVG–AFS systems; results showed that UV–UV/TiO2 PCRD–ECVG should be a superior interface compared with UV–UV/TiO2 PCRD–KBH4–acid for selenium speciation. Moreover, the proposed analytical system was successfully applied to the speciation of selenium in the water-soluble extracts from garlic shoots cultured with different selenium species.

Experimental

Instrumentation

A Shimadzu LC-2010A equipped with a quaternary gradient pump, an ultraviolet detector (190–700 nm), an autosampler (0.1–100 μL), and a column oven (277–333 K) was controlled by a Shimadzu Class-VP 6.1 chromatography workstation. A Hamilton PRP X-100 anion-exchange column (150×4.6 mm; particle size, 3 μm; Reno, NV, USA) was used to separate different selenium species. A non-dispersive atomic fluorescence spectrometer (ND-AFS) (Beijing Raileigh Analytical Instrument Corporation) equipped with a high-performance selenium hollow-cathode lamp (196.0 nm, Beijing Institute of Vacuum Electronics Research, China) and a sunlight-blinded photomultiplier tube (PMT, Hamamatsu, Japan) was used for the detection of selenium species; signal acquisition and processing were done by HWH software Version 1.0 [35]. A LEAD-1 peristaltic pump (Baoding Longer Precision Pump Co., China) and a Master C/L peristaltic pump (Cole–Parmer, USA) were used to introduce reagents in the experiments. Selenium species in a sample were separated by HPLC, and directed into the UV photolysis unit, then reduced by UV/TiO2 PCRD. After vapor generation at the cathode of the electrochemical flow-through cell and separation from the catholyte, generated selenium vapor species were carried by argon into a quartz furnace for atomization by a stable Ar–H2 flame and detected by AFS. A schematic diagram of the equipment is shown in Fig. 1 and the optimum operating conditions are listed in Table 1.

UV/TiO2 photocatalysis reduction device (UV/TiO2 PCRD) and UV photolysis unit

UV/TiO2 PCRD consists of a 40-W low-pressure mercury lamp (Xinyuan Appliance Lighting Co., China) 130 mm in length and 25 mm in diameter, glass fibers 130 mm in length and 0.30 mm in diameter with a five-layer nano TiO2 film which were centrally fixed into quartz capillaries (150 mm length, 0.8 mm inner diameter, and 1.6 mm outer diameter) and arranged in parallel around the UV lamp at a distance of 10 mm. The dead volume of the designed UV/TiO2 PCRD is 447 μL [34]. Another UV irradiation device used for photolysis of SeCys and SeMet was the same as that used for UV/TiO2-PCRD except that no glass fiber was fixed into the quartz capillaries.

ECVG cell

The ECVG cell consisted of two PTFE blocks (110×30×10 mm); a straight chamber (602×2 mm, 240 μL) was made in the center of each block to hold electrode materials. Carbon fibers (diameter, 7–8 μm; density, 1.76–1.78 g cm−3, Nantong Senyou Carbon Fibre Co., China) were used as cathode material, and a Pt loop (1.5 mm diameter, 60 mm in length) was used as anode material. Carbon fiber and Pt loop were all fixed and connected to the power supply with Pt wire. The two blocks were separated by a 3361BW cation exchange membrane (115× 35×0.42 mm, Shanghai Shanghua Water Treatment Material Co., China); the dead volume of this ECVG cell was approximately 115 μL. The longitudinal view of the ECVG cell is shown in Fig. 2. The two blocks were fixed by eight specially designed poly(vinyl chloride) (PVC) clips which were tightened by stainless-steel screws. The ECVG cell was powered by a direct current (DC) power supply (TPR3005D, Atten Electronics Co., China).

Chemical reagents

All the chemicals were of analytical-reagent grade and purchased from Shanghai Chemicals unless otherwise related; 18 MΩ Milli-Q water (Millipore, USA) was used throughout this study. Phosphate buffer (40 mmol L−1, pH 7.0) was prepared by dissolving appropriate amounts of KH2PO4 and Na2HPO4 in water and filtered through a 0.22-μm membrane. KBH4 solution (2%) containing 0.2% NaOH was prepared daily by dissolving KBH4 in alkaline solution. A solution containing 3.6 mol L−1 HCl and 1.5 mol L−1 formic acid was used in the KBH4–HCl system. The anolyte solution was 0.9 mol L−1 H2SO4; a solution of 0.9 mol L−1 H2SO4 and 1.5 mol L−1 formic acid was used as the catholyte in the ECVG system. To protect the cation-exchange membrane, both the catholyte and anolyte were cooled in ice water bath to avoid overheating in the ECVG process. Argon (≥99.99%) was used as carrier gas; hydrogen gas (≥99%) was used to maintain a stable Ar–H2 flame. Stock solutions (1 mg mL−1) of SeIV and SeVI were prepared by dissolving appropriate amounts of Na2SeO3 and Na2SeO4, respectively, in water. Seleno-DL-cystine (SeCys) and seleno-DL-methionine (SeMet) were purchased from Sigma Chemicals; their stock solutions (100 μg mL−1 expressed as selenium) were also prepared by water. All stock solutions were stored in polyethylene bottles which were wrapped with aluminium foil and stored at 277 K [36]. Further dilutions were performed daily before use.

Sample preparation

Bulbs of garlic were cultured in water, in 10 μg mL−1 SeIV as Na2SeO3, and in 10 μg mL−1 SeVI as Na2SeO4, in sand, for 30 days. Every 3 days, 100 mL water, Na2SeO3 and Na2SeO4, respectively, were added to the cultured garlic. The garlic shoots were collected and stored at 253 K. After harvest, 1 g of the garlic shoots was frozen with liquid nitrogen and ground in a ceramic mortar, dissolved with 20 mL water, with sonication for 15 min, and continually shaken in dark at 150 rpm for 12 h at 298 K. After these procedures the mixture was centrifuged at 12,000 rpm for 30 min and the supernatant solution was decanted and filtered through a 0.22 μm membrane to furnish a water-soluble extract of the garlic shoots. It was stored in a polyethylene bottle at 277 K before use.

Results and discussion

Electrochemical vapor generation cell

Several types of electrochemical vapor-generation cell have been designed by Lin et al. [17], Brockmann et al. [37], Denkhaus et al. [18], and Šíma et al. [38]. Because of the high hydrogen overpotential and the large specific surface area of carbon fiber, it was chosen as cathode material; platinum was used as anode material in this study. The structure of the ECVG cell designed is shown in Fig. 2. During the generation of selenium vapor in the ECVG cell, atomic hydrogen generated on the cathode plays a very important role and was very dependent on the electrolytic current of the cell. Selenite solution (100 μL) containing 50 ng mL−1 expressed as selenium was tested. The fluorescent intensity of generated selenium vapor species increased from 25.2 to 65.0 when the current was increased from 1 to 3 A. Increasing the current further caused noise to increase and shortened the lifetime of the ion-exchange membrane. An electrolytic current of 3 A was chosen in this study.

Online UV-photolysis and pre-reduction of selenium species by UV–UV/TiO2 PCRD

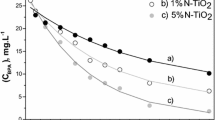

When SeCys, SeMet, and selenate passed through the ECVG cell under the optimum condition for selenite vapor generation, almost no signal was detected by AFS for selenate and SeMet and for SeCys the fluorescent intensity was also very low. These phenomena implied that the ECVG cell was not effective for vapor generation from selenate, SeMet, and SeCys. For this reason online UV-photolysis was employed to break the bond between selenium and carbon in SeCys and SeMet. UV/TiO2 PCRD was arranged in sequence for online pre-reduction of selenate; in this formic acid was used as an effective h+ scavenger to maintain e− for reduction of selenate [34]. The effect of online UV-photolysis and UV/TiO2 PCRD on vapor generation from SeCys, SeMet, and selenate by the ECVG cell was remarkable; a plot of the fluorescent intensity of the selenium species against the concentration of formic acid used is shown in Fig. 3. The fluorescent intensities for SeCys, SeMet, and selenate of 50 ng mL−1 each were respectively improved from 9, 0, and 0 without UV–UV/TiO2 PCRD to 51, 35, and 49 (after subtracting the blank value) under the conditions current 3 A and 1.5 mol L−1 formic acid containing 0.9 mol L−1 H2SO4 as the catholyte and 0.9 mol L−1 H2SO4 as the anolyte.

Performance of the HPLC–(UV–UV/TiO2 PCRD–ECVG)–AFS system

Phosphate buffer, 40 mmol L−1, pH 7.0 [13], was used as mobile phase at 1 mL min−1 to separate the four selenium species. The optimum conditions for HPLC–(UV–UV/TiO2 PCRD–ECVG)–AFS are listed in Table 1. A typical chromatogram obtained from selenium speciation is shown in Fig. 4. The linearity and precision of the HPLC–(UV–UV/TiO2 PCRD–ECVG)–AFS system, listed in Tables 2 and 3, are similar to those obtained by use of the HPLC–(UV–UV/TiO2 PCRD–KBH4–acid)–AFS system. The blank value (fluorescent intensity about 75) of ECVG was almost a factor of two lower than that of the KBH4–acid system (130) and resulted in detection limits for the selenium species in ECVG more than twice as good as those obtained by use of the KBH4–acid system (Table 3). These results indicate that the method proposed in this study should be a superior choice for selenium speciation.

Sample analysis

Selenium species in water-soluble extracts of cultured garlic shoots were analyzed by HPLC–(UV–UV/TiO2 PCRD–ECVG)–AFS; typical chromatograms are shown in Fig. 5. The results obtained are in agreement with those obtained by HPLC–(UV–UV/TiO2 PCRD–KBH4–HCl)–AFS, and are listed in Table 4. The RSD (n=3) was lower than 5% for all the species determined; recovery was measured by spiking four selenium species of 100 ng mL−1 each. All four selenium species were present at higher concentrations in the water-soluble extract of garlic shoots cultured in Na2SeO3 than in those cultured with Na2SeO4. These results indicate that selenite is more easily absorbed by garlic. However, a more intensive biological investigation of the metabolic mechanism of the phenomenon should be carried out.

References

Templeton DM, Ariese F, Cornelis R, Danielsson LG, Huntau H, Leeuwen HP, Lobinski R (2000) Pure Appl Chem 72:1453–1470

Kot A, Namiesnik J (2000) Trends Anal Chem 19:69–79

Crews HM (1998) Spectrochim Acta B 53:512–519

Kobayashi Y, Yasumitsu O, Suzuki T (2001) J Chromatogr B 760:73–81

Guerin T, Asturc A, Asturc M (1999) Talanta 50:1–24

Pyrzynska K (2001) Talanta 55:657–667

Uden PC (2002) Anal Bioanal Chem 373:422–431

Kannamkumarath SS, Wrobel K, Wrobel K, Vonderheide A, Caruso JA (2002) Anal Bioanal Chem 373:454–460

Montes-Bayón M, LeDuc DL, Terryb N, Caruso JA (2002) J Anal At Spectrom 17:872–879

McSheehy S, Yang WJ, Pannier F, Szpunar J, Lobinński R, Auger J, Potin-Gautier M (2000) Anal Chim Acta 421:147–153

González LaFuente JM, Dlaska M, Fernández Sánchez ML, Sanz-Medel A (1998) J Anal At Spectrom 13:423–429

Gómez MM, Gasparic T, Palacios MA, Camara C (1998) Anal Chim Acta 374:241–251

Vilanó M, Rubio R (2000) J Anal At Spectrom 15:177–180

Lobinski R, Pereiro IR, Chassaigne H, Wasik A, Szpunar J (1998) J Anal At Spectrom 13:859–867

Sturgeon RE, Mester Z (2002) Appl Spectrom 56:202–213

Howard A (1997) J Anal At Spectrom 12:267–272

Lin YH, Wang XR, Yuan DX, Yang PY, Huang BL, Zhuang ZX (1992) J Anal At Spectrom 7:287–291

Denkhaus E, Golloch A, Guo XM, Huang BL (2001) J Anal At Spectrom 16:870–878

Schickling C, Yang JF, Broekaert JAC (1996) J Anal At Spectrom 11:739–745

Machado LFR, Jacintho AO, Menegário AA, Zagatto EAG, Gin MF (1998) J Anal At Spectrom 13:1343–1346

Bings NH, Stefánka Z, Mallada SR (2003) Anal Chim Acta 479:203–214

Schermer S, Jurica L, Paumard J, Beinrohr E, Matysik FM, Broekaert JAC (2001) Fresenius J Anal Chem 371:740–745

Ding WW, Sturgen RE (1996) J Anal At Spectrom 11:421–425

Bolea E, Laborda F, Bellarra MA, Castillo JR (2001) Spectrochim Acta B 56:2347–2360

Ding WW, Sturgeon RE (1996) Spectrochim Acta B 51:1325–1334

Pyell U, Dworschak A, Nitschke F, Neidhart B (1999) Fresenius J Anal Chem 363:495–498

Schermer S, Jurica L, Paumard J, Matysik EBFM, Broekaert JAC (2001) Fresenius J Anal Chem 371:740–745

Burguera JL, Carrero P, Burguera M, Rondon C, Brunetto MR, Gallignani M (1996) Spectrochim Acta B 51:1837–1847

González LaFuente JM, Fernández Sánchez ML, Marchante-Gayón JM, Sánchez Uria JE, Sanz-Medel A (1996) Spectrochim Acta B 51:1849–1857

Ellend N, Rohrer C, Grasserbauer M, Broekaert JAC (1996) Fresenius J Anal Chem 356:99–101

Rubio R, Padró A, Rauret G (1997) Anal Chim Acta 353:91–97

Vilanó M, Padró A, Rubio R, Rauret G (1998) J Chromatogr A 819:211–220

Guo XM, Sturgeon RE, Mester Z, Gardner GJ (2003) Anal Chem 75:2092–2099

Wang QQ, Liang J, Qiu JH, Huang BL (2004) J Anal At Spectrom 19:715–716

Hong YC, Wang QQ, Yan H, Liang J, Guo XM, Huang BL (2003) Spectrosc Spect Anal 23:354–357

Olivas RM, Quevauviller P, Donard OFX (1998) Fresenius J Anal Chem 360:512–519

Brockmann A, Nonn C, Golloch A (1993) J Anal At Spectrom 8:397–401

Šíma J, Rychlovský P (2003) Spectrochim Acta B 58:919–930

Acknowledgements

This study was partly supported by the National Natural Science Foundation of China (No. 20175019), the Doctoral Research Foundation of the Education Ministry of China (No. 20020384003), and National Basic Research Program of China (2003CCA00500).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liang, J., Wang, Q. & Huang, B. Electrochemical vapor generation of selenium species after online photolysis and reduction by UV-irradiation under nano TiO2 photocatalysis and its application to selenium speciation by HPLC coupled with atomic fluorescence spectrometry. Anal Bioanal Chem 381, 366–372 (2005). https://doi.org/10.1007/s00216-004-2711-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-004-2711-1