Abstract

A piezoelectric quartz sensor coated with molecularly imprinted polymer (MIP) for caffeine was developed. The MIP was prepared by co-polymerizing methacrylic acid (MAA) and ethylene glycol dimethacrylate (EDMA) in the presence of azobis(isobutyronitrile) as initiator, caffeine as template molecule, and chloroform as solvent. The MIP suspension in polyvinyl chloride/tetrahydrofuran (6:2:1 w/w/v) solution was spin coated onto the surface of the electrode of a 10 MHz AT-cut quartz crystal. The sensor exhibited a linear relationship between the frequency shift and caffeine concentration in the range of 1×10−7 mg mL−1 up to 1x10−3 mg mL−1 [correlation coefficient (r)=0.9935] in a stopped flow measurement mode. It has a sensitivity of about 24 Hz/ln(concentration, mg mL−1). A steady-state response was achieved in less than 10 min. The performance characteristic of the sensor shows a promising and inexpensive alternative method of detecting caffeine. Surface studies were carried out for the reagent phase of the sensor using SEM, AFM, and XPS analysis in order to elucidate the imprinting of the caffeine molecule. The SEM micrograph, AFM image, and XPS spectra confirmed the removal of caffeine by Soxhlet extraction in the imprinting process and the rebinding of caffeine to the MIP sensing layer during measurement.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Molecularly imprinted polymers (MIPs) have been recognized as a valuable recognition element in chemical sensors. These materials provide an alternative to the expensive and fragile antibodies and enzymes presently employed in chemical sensors. MIPs are synthetic materials that possess tailor-made microcavities with molecular recognition capability for the target molecule. These materials mimic the recognition properties of the biomolecules by using the so-called lock and key combinations.

The formation of MIPs is based on the initial arrangement of monomer units around a template molecule, facilitated by covalent or non-covalent interactions. The monomer units are frozen into these positions through a polymerization reaction involving cross-linking reagents that promote the formation of a rigid macroporous matrix. The template molecule is then extracted from the polymeric matrix, leaving behind a cavity bearing the shape of the template. A schematic representation of the imprinting process is shown in Fig. 1.

The molecular recognition capability of the MIPs has been exploited in a number of chemical sensors [1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 31]. It has been applied in field effect devices, electrochemical sensors, and fluorosensors.

The combination of a piezoelectric quartz crystal transducer and a molecularly imprinted polymer reagent phase was explored in this study for the measurement of caffeine. Quantitation was based on the change in mass of the reagent phase as indicated by the change of the resonant frequency of the piezoelectric quartz crystal. Microscopic and spectroscopic techniques for surface studies were also performed for the MIP materials in order to elucidate the imprinting and rebinding of the caffeine molecule in the polymer matrix.

The measurement and monitoring of caffeine is important in food, beverages, and pharmaceutical industries. In environmental assessment, caffeine has also been used as a marker of fecal contamination source in surface waters, thus providing an indication of its sanitary quality. As one of the natural by-products of human metabolism and activity, caffeine may indicate contamination in water of human origin and from septic tanks [32, 33]. The detection of caffeine usually involves large and costly instrumentation, for example, HPLC, GC-MS, SEC-FTIR, and ELISA [34], and includes tedious steps.

Experimental

Materials

All reagents were prepared from analytical reagent grade chemicals. Methacrylic acid (MAA), ethylene glycol dimethacrylate (EDMA), azobis(isobutyronitrile) (AIBN), caffeine, theophylline, and xanthine were purchased from Sigma Chemicals Co. (St. Louis, MO, USA). Low molecular weight poly(vinyl chloride) (PVC) was purchased from BDH Limited (Poole England). Tetrahydrofuran (THF) was used as received to dissolve PVC.

The buffer solution (pH 8) used for caffeine measurement was prepared from a mixture of 0.2 M boric acid (250 mL), 0.2 M potassium chloride (250 mL), and enough 0.2 M sodium hydroxide to bring the pH of the mixture to the proper value. The mixture was then diluted to 0.80 L.

Preparation of molecularly imprinted polymer

The MIP was prepared according to the method of Lai et al. [35] but with some modifications. MAA monomer (0.54 g), EDMA (5.64 g), and caffeine (0.0282 g) were dissolved in 15 mL of chloroform in a 250-mL flat-bottomed round flask to allow the molecules to interact and form complexes. The initiator AIBN (0.072 g) was then added. The mixture was degassed for 15 min in a sonicating bath under vacuum and subsequently flushed with N2 gas for 5 min. It was then placed in a thermostated water bath kept at 60°C for 24 h during which polymerization occurred. At the end of this period, the resulting polymer was pulverized with a mortar and a pestle and then passed through a 38-µm-mesh sieve. A portion (0.5 g) of the powdered polymer was extracted for 24 h in a Soxhlet apparatus using 150 mL of a 9:1 (v/v) mixture of methanol and acetic acid. The remaining solid was dried at 60°C over a water bath.

A non-imprinted polymer (NIP) was prepared using the same procedure but omitting the addition of caffeine.

Sensor fabrication

A 6:2:1 (w/w/v) mixture of the MIP, polyvinyl chloride, and tetrahydrofuran was prepared. A small amount (10 µL) of this mixture was dropped onto the center of the electrode on one side of a quartz crystal (10 MHz, 8-mm diameter), and spread over the whole surface using a home-made spin coater. The resulting film was allowed to dry at room temperature.

A reference sensor was also prepared by coating one electrode of a quartz crystal with the NIP, using a similar method as in the MIP sensor.

Instrumentation

The instrumentation system consisted of an assembled Pierce oscillator based on CMOS device (CD74HCT04E), a DC power source (Loadstar P50303), and a digital frequency counter (Leader LDC–824). The quartz was encased in a Teflon flow cell such that only the coated electrode is exposed to the measurand solution. A peristaltic pump (Ismatec IPC) was used to deliver the solution to the flow cell. Figure 2 shows a diagram of the instrumentation system.

Measurement procedure

A stopped-flow technique was adopted in the measurements. The sensor was first stabilized by running the buffer solution through the flow cell at a constant flow rate of 1.2 mL min−1 for 1–2 min. The flow was stopped, and the oscillation frequency of the quartz crystal was monitored until a steady frequency reading (F a) was achieved. The caffeine solution was then allowed to flow through the cell for about 1–2 min. After the flow was stopped, the frequency was read until it remained constant and this value (F b) was recorded. The frequency shift for each concentration was calculated as the sensor response:

Surface studies

Surface analysis was carried out on the MIP and NIP using scanning electron microscopy (SEM), atomic force microscopy (AFM), and X-ray photoelectron spectroscopy (XPS). The polymers were analyzed as pellets formed from the powdered material and as a film cast from a suspension in a mixture of polyvinyl chloride and tetrahydrofuran.

SEM was performed with a JEOL JSM-5200 Scanning Microscope, operated at a voltage of 15 kV, a current of 10−12 to 10−9 A, and a magnification of 750–3,500×. The samples were gold sputtered at 15 kV for 200 s using a JEOL JFC-1100E ion sputter (Fine Coat) operated under vacuum (≈10−3 Torr).

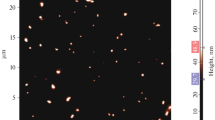

The surface topography of the MIP-PVC cast acetate film was observed in a Digital Instruments Nanoscope IIIa atomic force microscopy using the tapping mode (scan size 10 μm, scan rate 1.197 Hz). The image roughness, R a, was evaluated directly from the AFM image.

XPS studies were conducted in an ultra-high vacuum (10−10 mbar) using a Kratos AXIS surface analysis system.

Results and discussion

Molecular imprinting of caffeine

The molecular imprinting of caffeine is facilitated by the interaction of several sites in its structure with molecules of the methacrylic acid monomer, particularly through hydrogen bonding and electrostatic attraction (Fig. 3). The hydrogen atom of the carboxyl group of MAA can form a hydrogen bond with the oxygen atom of the carbonyl group of caffeine. In the presence of the initiator and at a temperature of 60°C, the caffeine–monomer complex undergoes polymerization and forms a rigid matrix wherein caffeine is entrapped.

A molecular modeling (Fig. 4) of the polymer backbone shows the possibility of a conformation wherein the caffeine template molecule is enclosed by the polymer chain and held by molecular interactions. The cross-linker generates branches and eventually causes the formation of a rigid three-dimensional network within the polymer bulk. When the entrapped template molecule is extracted with a suitable solvent, it leaves behind a cavity bearing an imprint of the caffeine molecule.

Sensor response

The oscillator circuit in the instrumentation induced the quartz crystal to oscillate at its characteristic resonant frequency of 10 MHz. When the crystal was coated with the MIP, its oscillation frequency decreased, indicating an increase in the mass on the surface of the crystal. When the MIP-coated crystal was placed in a solution of caffeine, there was a further decrease in the oscillation frequency of the crystal. This decrease in frequency suggests an intake of caffeine by the polymer coating. This change in the oscillation frequency took place slowly, requiring about 10 min to reach a steady-state value. This behavior can be attributed to the characteristics of the kinetics involved in the diffusion and subsequent binding of the caffeine molecules in the cavities of the MIP coating. The frequency shift was reproducible and exhibited a relative standard deviation of 17% for n=3 replicates.

When the reference (i.e., NIP-coated) crystal was immersed in a solution of caffeine, a decrease in oscillation frequency was also observed, but the change was much smaller than that exhibited by the MIP-coated crystal. This lowering of oscillation frequency could be attributed to some changes in the polymer coating (e.g., swelling).

The frequency shift observed with the MIP-coated crystal was very sensitive to the concentration of the caffeine solution. Figure 5 shows the calibration curve that relates the sensor response with the concentration of caffeine. Very good linearity (r=0.9935) was shown in the concentration range of 1×10−9 mg mL−1 up to 1×10−3 mg mL−1, with a sensitivity of 24 Hz/ln(concentration of caffeine, mg mL−1). The detection limit was calculated to be 3.76×10−11 mg mL−1 based on three standard deviations. The NIP-coated sensor exhibited an erratic behavior with the different standard solutions of caffeine.

The sensor response was affected by the pH of the analyte [31]. Figure 6 shows the variation of the sensor response to a 1×10–5 mg mL−1 caffeine standard solution with pH. An abrupt increase in the response was observed at pH 6, above which the magnitude of the response improved only slightly. A pH of 8 was chosen as the optimum and was used in all measurements, since the sensor exhibited the highest sensitivity under this condition. The effect of pH on the response can be traced to the molecular interactions involved in the binding of caffeine to the MIP. Under slightly basic conditions (e.g., pH 8 and 9), caffeine exists in a molecular form that can form hydrogen bonds with the MAA molecule (Fig. 4).

The sensor responded specifically to caffeine. For compounds with structures resembling that of caffeine, such as xanthine and theophylline, the sensor response was similar to that of the reference sensor (i.e., with an NIP coating). Figure 7 shows the selectivity of the developed sensor for caffeine from 1×10−9 mg mL−1 up to 1×10−4 mg mL−1 concentration.

Surface studies

SEM micrographs of the ground MIP revealed that the particles varied in shape and size (Fig. 8). The particle size ranged up to about 50 microns. At higher magnification (3,500×), the presence of a porous surface could be seen from the SEM micrograph. This feature could be associated with the molecular imprints existing in the polymer. A comparison of the surface of the particles before and after exposure to a solution of caffeine is shown in Fig. 9. The surface of the particles exposed to a caffeine solution appeared to be thicker than the unexposed surface. This could be due to the binding of caffeine molecules to the polymer, contributing to slight swelling of the polymer.

Figure 10 shows the three-dimensional AFM image of the MIP-PVC surface. The image roughness, R a, obtained from a 10 μm×10 μm surface region for the MIP-PVC coating is about 89 nm. The observed rugged features of the surface topography revealing cavities could be attributed to the imprinting of caffeine in the MAA-polymer matrix.

XPS studies were carried out on the polymer to confirm the imprinting process and the rebinding of caffeine to the polymer. The XPS wide scan spectra of the MIP before and after extraction of the caffeine template are shown in Fig. 11. The characteristic XPS wide scan spectra of the polymer before and after extraction featured elemental peaks for C 1 s, O 1 s, N 1 s, and Cl 1 s. The elemental surface composition of both particles includes three types of oxygen atom (O–C=O, C–O, and C=O) and three types of carbon atom (aliphatic carbon, C with N, and carbon with O). The Cl 1 s comes for the PVC used as plasticizer in the polymer mixture. The insignificant difference in chemical composition could support the idea that molecular imprinting affects mainly the three-dimensional arrangement of the polymer which retains its chemical composition [36]. This similarity is also shown in the XPS spectra of the MIP and NIP particles after extraction of the template compound.

A peak for N 1 s in the unextracted MIP could correspond to the nitrogen in caffeine and the initiator. The deconvoluted spectra for N 1 s (Fig. 12) includes contributions from two types of nitrogen atom (i.e., a single-bonded N and a triple-bonded N). The decrease in intensity of the N 1 s peak in the extracted MIP could confirm the removal of caffeine after extraction with methanol–acetic acid. Similarly, the minimal amount of nitrogen present in the unextracted non-MIP particles disappears after extraction (Table 1).

The changes in the XPS wide scan spectra of the MIP brought about by exposure to a solution of caffeine (1×10−3 mg mL−1) are revealed in Fig. 13. The appearance of an N 1 s peak in the wide scan spectra of the polymer after being exposed to caffeine could be traced to the binding of caffeine to the MIP. The deconvoluted spectrum for the N 1 s peak is shown in Fig. 14a. This is narrower than the N 1 s peak of the pure caffeine powder (Fig. 14b) and could be fitted to only one type of nitrogen. Only one type of environment for N is detected after rebinding. This observation could indicate that in the bound caffeine molecule the double-bonded nitrogen atom is transformed into a single-bonded atom. For the NIP, the XPS spectra before and after exposure to caffeine showed no detectable difference, indicated no change in chemical structure, and confirmed no rebinding of caffeine.

Conclusion

A promising biomimetic sensor for caffeine was developed through the incorporation of a film of a molecularly imprinted polymer on the electrode surface of a piezoelectric quartz crystal. The sensor exhibited very good linearity, high sensitivity, and high selectivity. Compared to the other methods that have been employed for the measurement of caffeine, the detection limit of the sensor is lower (Table 2). This sensor presents an inexpensive alternative method for caffeine measurement. Surface characterization using SEM and XPS techniques provided data that elucidated the imprinting and rebinding of caffeine in the MIP sensing layer of the caffeine sensor.

References

Karlsson JG, Andersson LI, Nicholls IA (2001) Anal Chim Acta 435:57

Peng H, Liang C, He D, Nie L, Yao S (2000) Talanta 52:441

Kobayashi T, Murawaki Y, Reddy PS, Abe M, Fujii N (2001) Anal Chim Acta 435:141

Tan Y, Zhou Z, Wang P, Nie L, Yao S (2001) Talanta 55:337

Zi-Hui M, Qin L (2001) Anal Chim Acta 435:121

Subrahmanyam S, Piletsky SA, Piletska EV, Chen B, Karim K, Turner APF (2001) Biosens Bioelectron 16:631

Allender CJ, Brain KR, Ballatore C, Cahard D, Siddiqui A, McGuigan C (2001) Anal Chim Acta 435:107

Asanuma H, Akiyama T, Kajiya K, Hishiya T, Komiyama M (2001) Anal Chim Acta 435:25

Petcu M, Cooney J, Cook C, Lauren D, Schaare P, Holland P (2001) Anal Chim Acta 435:49

Ji HS, McNiven S, Ikebukuro K, Karube I (1999) Anal Chim Acta 390:93

Tan PY, Peng H, Liang C, Yao S (2001) Sens Actuators B 73:179

Andrea P, Miroslav S, Silvia S, Stanislav M (2001) Sens Actuators B 76:286

Svitel J, Surugiu I, Dzgoev A, Ramanathan K, Danielsson B (2001) J Mater Sci Mater Med 12:1075

Yamazaki T, Yilmaz E, Mosbach K, Sode K (2001) Anal Chim Acta 435:209

Kroger S, Turner APE, Mosbach K, Haupt K (1999) Anal Chem 71:3698

Dickert F, Lieberzeit P, Tortschanoff M (2000) Sens Actuators B 65:186

Dickert FL, Forth P, Lieberzelt P, Torischanoff M (1998) Fresenius J Anal Chem 360:759

Dickert FL, Tortschanoff M (1999) Anal Chem 71:4559

Yano K, Karube I (1999) Trends Anal Chem 132:199

Luo C, Liu M, Mo Y, Qu J, Feng Y (2001) Anal Chim Acta 428:143

Kugimiya A, Takeuchi T (2001) Biosens Bioelectron 16:1059

Rachkow A, McNiven S, El’akaya A, Yano K, Karube I (2000) Anal Chim Acta 405:23

Jie Z, Xiwen H (1999) Anal Chim Acta 381:85

Baggiani C, Giraudi G, Trotta F, Giovannoli C, Vanni A (2000) Talanta 51:71

McNiven S, Kato M, Levi R, Yano K, Karube I (1998) Anal Chim Acta 365:69

Dela Cruz EO, Muguruma H, Jose WI, Pederson H (1999) Anal Lett 32:841

Kriz D, Mosbach K (1995) Anal Chim Acta 300:71

Piletsky SA, Piletskaya EV, Sergeyeva TA, Panasyuk TL, El’skaya AV (1999) Sens Actuators B 60:216

Ji HS, McNiven S, Ikebukuro K, Karube (1999) I Anal Chim Acta 390:93

Liang C, Peng H, Zhou A, Nie L, Yao S (2000) Anal Chim Acta 415:135

Kugimiya A, Takeuchi T (1999) Electroanalysis 11:1158

Shuman R, Strand J (1996) Wet weatherx. Water Environment Research Foundation, Fairfax, VA, 1:10

Standley LI, Kaplan LA, Smith D (2000) Environ Sci Techol 34:3124

Liang C, Peng H, Bao X, Nie L, Yao S (1999) Analyst 124:1781

Lai EPC, Fafara A, VanderNoot VA, Kono M, Polsky B (1998) Can J Chem 76:265

Malitesta C, Losito H, Zambonin PG (1999) Anal Chem 71:1366

Zen JM, Ting YS, Shi HY (1998) Analyst 123:1145

Lima JLFC, Deletrue-Matos C, Nouws HDA, Vaz MCVF (1998) Food Addit Contam 15:265

Norton KL, Griffiths PR (1996) J Chromatogr A 731:361

Acknowledgements

The authors are grateful to the Department of Science and Technology, Philippines, for the scholarship granted to B.S.E, and to Dr B. Gong, Center for Surface Science & Technology, UNSW, Sydney and the Research Center for the Natural Sciences, UST, Philippines, for the support given to this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ebarvia, B.S., Binag, C.A. & Sevilla III, F. Biomimetic piezoelectric quartz sensor for caffeine based on a molecularly imprinted polymer. Anal Bioanal Chem 378, 1331–1337 (2004). https://doi.org/10.1007/s00216-003-2433-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-003-2433-9