Abstract

Cholesterol amperometric biosensors constructed with enzymes entrapped in electropolymerized layers of polypyrrole and poly-naphthalene derivative polymers are compared. The biosensors are based on entrapment of cholesterol oxidase and/or cholesterol esterase in monolayer or multilayer films electrochemically synthesised from pyrrole, 1,8-diaminonaphthalene (1,8-DAN), and 1,5-diaminonaphthalene (1,5-DAN) monomers. Seven configurations were assayed and compared, and different analytical properties were obtained depending on the kind of polymer and the arrangement of the layers. The selectivity properties were evaluated for the different monolayer and bilayer configurations proposed as a function of the film permeation factor. All the steps involved in the preparation of the biosensors and determination of cholesterol were carried out in a flow system. Sensitivity and selectivity depend greatly on hydrophobicity, permeability, compactness, thickness, and the kind of the polymer used. In some cases a protective outer layer of non-conducting poly(o-phenylenediamine) polymer improves the analytical characteristics of the biosensor. A comparative study was made of the analytical performance of each of the configurations developed. The biosensors were also applied to the flow-injection determination of cholesterol in a synthetic serum.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cholesterol is a fundamental parameter for the diagnosis of coronary heart disease, arteriosclerosis and other clinical disorders [1]. The importance of the determination of this substrate has been reflected in recent years by an increase in the number of articles dealing with the development of electrochemical devices for the analysis of cholesterol. Recent methods are based on the use of screen printed electrodes [2], hydrogel membranes [3], polymeric membranes [4], self-assembled monolayers [5], composite sol-gel membranes [6], liquid crystal cubic phase matrices [7], and films prepared by the layer-by-layer technique [8].

The development of amperometric biosensors based on organic polymers has greatly increased in the last decade [9]. Electropolymerization of a monomer to form a polymeric layer on an electrode surface is one of the most important methods for immobilization of a biocatalytic reagent on the electrode surface in order to construct an amperometric biosensor, because of its simplicity and the selectivity obtained due to its molecular and charge-exclusion properties (e.g. for electroactive components in biological media). In consequence, electropolymerization is a straightforward method for the preparation of sensors with different configurations which permit tailoring of sensor characteristics such as dynamic range, sensitivity and selectivity [9].

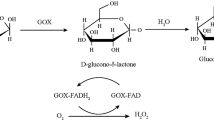

In general, the electrosynthesis of polymeric layers allows the immobilization of enzymes and other compounds like mediators by entrapment within the polymer network during its growth [9]. In recent years, our research group has developed several amperometric cholesterol biosensors based on the electrosynthesis of a variety of polymer films [10]. These biosensors are based on detection of the hydrogen peroxide generated enzymatically by cholesterol oxidase (COx).

Polypyrrole (PPy) films were considered first on account of their conductivity and notable properties for the exclusion of interferences, which can be improved if the polymer is overoxidized. The overoxidation process generates a high electron density in the polymer backbone which endows the polymer with remarkable anion-exclusion properties, but the electronic conductivity disappears [11].

In the search for polymers which afford greater selectivity, electropolymerized films of naphthalene derivatives were also tested [12]. However, these naphthalene derivative monomers have some solubility limitations; recently, electropolymerized films of several aminonaphthalene derivatives have been reported, but the synthesis of these polymers was performed at very extreme pH (1.0) [13] or using acetonitrile as a solvent [14], and in these conditions the simultaneous entrapment of enzymes during growth of the polymer films would cause their denaturation.

The analytical properties of the films formed from the two naphthalene monomer derivatives 1,8-diaminonaphthalene (1,8-DAN) and 1,5-diaminonaphthalene (1,5-DAN) were studied. Preliminary assays for optimizing entrapment of the enzymes and the biosensor responses were carried out. The influence of pH was mainly studied, as well as the concentration of the monomer and thicknesses of the films obtained.

In order to improve selectivity, several alternatives were considered, e.g. improvement of the exclusion properties of the polymer films by means of multilayer configurations [15]. The sequential electrosynthesis of several polymers, has to fulfil an important requirement: the inner layers should maintain enough conductivity to permit the electrochemical formation of outer layer. The combination of the permselectivity properties of several polymers in multilayer structures makes it possible to achieve greater interference rejection and, hence, greater selectivity. Inner layers of PPy have been successfully combined with outer layers of poly(o-phenylenediamine) (oPPD) or poly(1,8-diaminonaphthalene) (P(1,8-DAN)). o-Phenylenediamine provides non-conducting thin films with self-limited growth with a thickness of around 10 nm, which affords low enzyme loading when applied to enzyme entrapment in the film, but provides an excellent size-exclusion membrane. Polymer films of P(1,5-DAN) and P(1,8-DAN) maintain enough conductivity for their final thickness to be controlled and allow the development of combined multilayer configurations with greater thicknesses than oPPD provides. The presence of two benzene rings gives a closer packing of the polymer chains, these polymers having greater hydrophobicity and lesser permeability (compared with PPy and oPPD), and therefore less diffusion of the solvated interfering compounds through these networks is allowed [13], conferring excellent selectivity to the sensor.

These kinds of polymer have been applied combined with inner layers with COx, using an outer layer to immobilize cholesterol esterase (CE). Several diaminonaphthalene and PPy monolayer and multilayer combined configurations, and monoenzymatic and bienzymatic sensors, have been developed. In all cases the films have been electrochemically synthesised from aqueous solutions of the monomers and enzymes in phosphate buffer at neutral pH, with low concentrations to overcome some solubility limitations of the naphthalene derivatives.

The analytical performance of cholesterol determinations are presented and compared for all the developed biosensors. Significant tendencies with respect to lifetime, sensitivity, selectivity, and reproducibility were observed and are explained for all the configurations studied.

Experimental

Apparatus and reagents

The synthesis of the electropolymerized films and cholesterol determination were performed with a Coulochem II amperometric detector (ESA) in a flow system consisting of a thin-layer cell (Bioanalytical Systems, LC-44) with a dual Pt disc working electrode (3 mm diameter), a stainless steel auxiliary electrode and an Ag/AgCl (3 mol L−1 NaCl) reference electrode. All the potential values indicated in the present work refer to this reference electrode. The volume of the thin-layer cell was adjusted by means of PTFE gaskets located between the auxiliary and the working electrodes. A cell volume of 175 µL was used for the preparation of the biosensor and 20 µL for the determination of cholesterol. Additional components of the flow system included a peristaltic pump (Gilson, Minipuls 3) and a PTFE injection valve (Omnifit) with a 100 µL sample loop volume.

CE (E.C.1.1.13) and COx (E.C.1.1.3.6), both from Pseudomonas fluorescens , cholesterol oleate (C-9253), and cholesterol (C-8667) were purchased from Sigma. Pyrrole (Aldrich) was distilled in vacuo and stored in a nitrogen atmosphere to avoid atmospheric oxidation prior to use. o-Phenylenediamine (Sigma), 1,5-diaminonaphthalene (1,5-DAN), and 1,8-diaminonaphthalene (1,8-DAN) (Fluka) were used as received. Solutions of the monomers were previously deoxygenated by bubbling nitrogen prior to electropolymerization. All other reagents used were of analytical grade and high-purity water from a Milli-Q system was employed throughout. Cholesteryl oleate and free cholesterol solutions were prepared in 0.05 mol L−1 phosphate buffer (pH 7.0) containing 1% (w/v) Triton X-100, as previously optimized [10]. This buffer was also used as the carrier solution in the flow-injection determination of cholesterol.

Preparation of the biosensors and cholesterol determination

Electrosynthesis of the layers and immobilization of the enzymes were performed according to the continuous-flow method described in previous papers [10, 15, 16] which takes place in the same flow system that was subsequently used for the determination of cholesterol, affording excellent reproducibility of the preparation process and control of the analytical properties of the resulting biosensors. The films obtained are thin and consequently usually have fast response times. A solution containing the monomer, the enzyme, and a supporting electrolyte was continuously circulated through the electrochemical cell during the polymer electrosynthesis. Continuous-flow electropolymerization permits lower reagent consumption if compared with conventional batch procedures, and allows more effective control of polymer growth [10, 15, 16].

Before film formation the Pt electrode was polished with 1 µm diamond powder (Buehler) and with an aqueous slurry of 0.05 µm alumina (Buehler). The PPy film was deposited on the surface of the Pt electrode by potentiostatic electropolymerization at +0.70 V, continuously circulating, at a flow rate of 0.07 mL min−1, a de-aerated solution consisting of 0.4 mol L−1 pyrrole and 10 units mL−1 COx in a phosphate buffer (0.05 mol L−1 PB + 0.1 mol L−1 KCl. pH 7.0). The electropolymerization was conducted in a buffered medium in order to avoid denaturation of the enzyme by a local decrease of the pH at the surface electrode during polymer formation. The PPy film thickness was estimated as a function of the deposition charge involved in the electropolymerization process [11], and growth of the PPy film was stopped when an optimum charge of 10 mC cm−2 (about 25 nm thickness) was achieved. After the enzymatic layer of PPy was formed, the electrode was rinsed with a stream of phosphate buffer to remove residual monomer or weakly adsorbed enzyme. After preparation of the PPy-monolayered based biosensor, PPy film was overoxidized at +0.70 V in a long-term process to preserve the activity of the enzyme, until the background current fell below 10 nA.

The oPPD outer layer was deposited by using a de-aerated 5 mmol l−1 oPPD solution in 0.1 mol l−1 phosphate buffer at pH 7.0. The film was formed potentiostatically at +0.65 V at a flow rate of 0.1 mL min−1 until the current reached a minimum value, after 10 min electrolysis. Growth of oPPD was self-limited by virtue of its non-conducting nature and formed a uniform film with a thickness of about 10 nm.

Electropolymerization of 1,5-DAN and 1,8-DAN was carried out potentiostatically at +0.65 V while a 3 mmol L−1 de-aerated monomer solution in a phosphate buffer (0.05 mol L−1, pH 7.0), containing 10 units mL−1 of CE and/or 10 units mL−1 of COx, was circulated at a flow rate of 0.07 mL min−1 in the detection cell. The optimum film thickness (controlled via the charge involved during film growth) was established at 25 nm for both polymer monolayers. In order to calculate the polymer thickness, the density of the monomer was taken as being similar to that of the polymer and it was assumed that all the consumed charge is used up in the polymerization process [12].

All the biosensors were stored in phosphate buffer (0.05 mol L−1, pH 7.0) at 4 °C when not in use. The amperometric detection of cholesterol, based on monitoring of the electrochemical oxidation at the Pt electrode of the hydrogen peroxide generated by the enzymatic reaction with COx, was carried out at +0.7 V. The carrier flow rate was set at 0.15 mL min−1 and all measurements were performed at 22 °C. The response provided by the mono and bienzymatic biosensors was flow-dependent and was optimised in order to achieve a balance between sensitivity, linearity, throughput, reproducibility, and selectivity.

Results and discussion

Several configurations for amperometric cholesterol biosensors were designed for study and comparison of their analytical performance: monoenzymatic Pt/PPy-COx, Pt/P(1,5-DAN)-COx, and Pt/P(1,8-DAN)-COx monolayer configurations; monoenzymatic Pt/PPy-COx/oPPD, Pt/P(1,5-DAN)-COx/P(1,8-DAN) and Pt/P(1,8-DAN)-COx/P(1,5-DAN) bilayer configurations; bienzymatic Pt/P(1,5-DAN)-CE+COx and Pt/P(1,8-DAN)-CE+COx monolayer; and bienzymatic Pt/PPy-COx/P(1,8-DAN)-CE bilayer configurations. These can be seen in Fig. 1. The combination of different inner and outer polymers (with one or the two enzymes) give the resulting biosensors interesting different analytical properties, which are described below. General guidelines are also given, in chronological order.

Monolayer poly(pyrrole)-based biosensors

The most simple Pt/PPy-COx serves as a reference biosensor for the other configurations. It has been extensively demonstrated in our previous work that PPy favours the lifetime of the COx [10]. PPy has electronic conducting properties, and so it is easy to control the thickness of the film by measuring the total charge consumed. The influence of PPy film thickness on the cholesterol biosensor response is very important because it determines the enzyme loading, and hence the sensitivity of the biosensor, its selectivity (as indicated before), and the time of response. The highest sensitivity for the Pt/PPy–COx biosensor was obtained at a film thickness corresponding to an overall electropolymerization charge of 10 mC cm−2 (about 25 nm thickness).

It is well-known that the determination of the concentration of cholesterol in serum samples by amperometric biosensors has an important drawback, namely the interference caused by the presence of other electroactive species at the working potential when hydrogen peroxide is detected. The most significant interferences are due to the presence of endogenous species like ascorbic acid and uric acid in the serum. In order to assess the selectivity of the biosensors, the film permeation factor (%P its percentage value) was taken as the parameter of study [13, 17]. Values are given in Fig. 2. The film permeation factor is defined as the ratio of the current recorded by the biosensor (electrode coated with the corresponding enzymatic film) to the current measured by an identical bare (uncoated) platinum electrode arranged in parallel under the same measurement conditions. The response recorded for injection of hydrogen peroxide was also considered in order to estimate the permeability of the different polymer configurations to the product of the enzymatic process and responsible for the recorded current. The concentrations considered for the interfering endogenous species were those corresponding to their normal upper concentration levels in serum for healthy individuals (50 µmol L−1 ascorbic acid, 0.5 mmol L−1 uric acid).

Biosensor selectivity: comparison of the film permeation factor (%P) for ascorbic acid (50 µmol L−1) and uric acid (0.5 mmol L−1) obtained with the proposed biosensor configurations. Both solutions were prepared in 0.05 mol L−1 phosphate buffer (pH 7.0) with 1% (w/v) Triton X-100. Injected volume: 100 µL

Generally speaking, PPy has a more open structure, which gives much more permeability than the poly(diaminonaphthalene) (P(DAN)) polymers, as will be seen later. These values, however, can be modulated with the thicknesses of the electropolymerized polymers (time of electrolysis and the total charge consumed in the process) in the case of the naphthalene and the Py monomers. Obviously smaller thicknesses will produce greater values of %P. This is important in order to produce the desired characteristics, dependent on the samples for which the biosensors are going to be used.

In addition to the size-exclusion properties of PPy, its ulterior overoxidation introduces a series of carboxyl groups of high electron density that endow the polymer film with anion-exclusion properties [11]; this makes it possible to decrease or even completely eliminate interferences from anionic electroactive species present in serum samples. The %P values obtained for these compounds at a PPy thickness of 10 mC cm−2 are given in Fig. 2. For ascorbic acid, the film permeation factor exceeds 15% and no important reduction was achieved by increasing film thickness. A film permeation factor of 5% was obtained for uric acid and was decreased to 1% by selecting film thicknesses above 20 mC cm−2. In the case of hydrogen peroxide the PPy film offers an appropriate diffusion of this compound across the film, with a %P value of 98.

The Hill equation was used to calculate the kinetic parameters [18]. This equation provides through parameter α, the degree of deviation of the behaviour related to an enzymatic system governed by Michaelis–Menten kinetics:

α values in the 0.90–1.10 range correspond to ideal enzymatic behaviour, with no enzymatic inhibition or limitation due to mass transport of the substrates, the rate of the enzymatic reaction always being the limiting step of the generation process of the sensor response. It should be noted that, rather than being directly related to an enzyme, the K M app value is a characteristic of a biosensor.

The analytical characteristics and kinetic parameters of the Pt/PPy–COx biosensor are given in Table 1. The α value of 0.98 (Hill equation) indicated that no deviations arising from enzyme inhibition or restricted transfer of substrates or co-substrates within the polymer were detected, the enzymatic reaction always being the rate-determining step.

With regard to stability, the biosensor response increased slightly (lower than 8%) during the first few hours of use probably due to swelling of the polymer matrix allowing the enzyme to rearrange itself and adopt a more active conformation following its initial distortion during the entrapment process [19]. Subsequently, the response decreased owing to the desorption of enzyme molecules previously adsorbed on the polymer surface. After adsorbed COx molecules had been released, the biosensor had a constant response for 15 days (about 550 determinations). Storage time had little effect on the stability of the biosensor and it was seen that these biosensors display a similar stability profile when stored for different periods of time—the number of cholesterol determinations carried out is what determines the behaviour observed.

Pt/PPy–COx biosensor was used to determine cholesterol in a synthetic serum. A synthetic serum was prepared containing the main components of human serum at their normal concentration levels in a healthy individual. This serum was spiked with a concentration of 3.96 mmol L−1 free cholesterol. The sample was diluted 50 times in order to accommodate the cholesterol concentration within the biosensor's linear determination range. The results obtained by standard-addition calibration were quite consistent with the actual cholesterol concentration in the sample (P=0.05) with a relative error of −2.27%. On the other hand, the results obtained by direct interpolation in the calibration curve differ significantly from the real concentration value, giving a relative error of around +10% owing to matrix interference from the synthetic serum.

Multilayer PPy-inner layer and P(DAN) based cholesterol biosensors

The good selective and conductive properties of PPy have been well known for years, and so it is a very good choice for an inner layer in multilayered electropolymerized biosensors [20]. Obviously, when a second layer has to be deposited, good electrical conductivity of the inner substrate is necessary. An outer layer was also considered and studied in order to improve selectivity and the correct arrangement of the enzymes when a bi-enzymatic COx and CE is designed for the total determination of cholesterol [15]. CE first converts the esterified cholesterol (about 70% percentage in serum) into free cholesterol, COx then catalyses the oxidation of the free cholesterol and the measured current corresponding to this process is related to the total cholesterol concentration of the serum sample.

Within this group, a Pt/PPy-COx/oPPD biosensor and a Pt/PPy-COx/P(1,8-DAN)-CE biosensor were constructed. In the former case, oPPD improves permselectivity considerably, preventing electroactive interferences from reaching the electrode. In the latter case, selectivity also improve with CE immobilized in the P(1,8-DAN) outer layer. With the spatial configuration in Pt/PPy-COx/P(1,8-DAN)-CE, the whole cholesterol concentration of the sample was enzymatically determined with COx on the electrode surface by measuring the current produced by the hydrogen peroxide. Values of film permeation factors (%P) for these configurations are shown in Fig. 2.

The sequence in which the layers are electrodeposited is determined by the respective properties of the two polymers. The non-conducting nature of the oPPD produces an outer film with a low thickness owing to the increasing electrical resistance when covering the entire conductive PPy surface uniformly. Other configurations studied like COx (or CE) immobilized inside oPPD gave bad results, mainly due to the small thickness (about 10 nm) of this polymer [15]. Moreover, the COx is better near the electrode surface because of the improved hydrogen peroxide diffusion and better sensitivity of the biosensor, as the efficacy term (relation of the hydrogen peroxide contributing to the measured current with respect to all enzymatically produced hydrogen peroxide) was improved [15]. It is also shown that oPPD does not noticeable restrict the supply of cholesterol by diffusion towards the inner PPy layer, and, moreover, the hydrogen peroxide loss towards the bulk solution is minimized [15]. Greater stability was also observed with this Pt/PPy-COx/oPPD bilayer configuration if compared with a Pt/PPy-COx monolayer (Fig. 3).

In order to improve biosensor selectivity, the possibility of replacing the non-conducting outer oPPD layer with another film with greater permselectivity was tested. Several aminonaphthalene derivatives produce polymers that have promising permselective properties, as stated before. The possibility of immobilizing enzymes within electropolymerized layers of P(DAN) polymers was also studied. Preliminary tests with the immobilization of glucose oxidase, COx, and CE into a P(1,8-DAN) and P(1,5-DAN) polymers confirmed this possibility, when appropriate experimental electropolymerization conditions are used to avoid denaturation of enzymes.

For this study polymeric films of 1,5-DAN and 1,8-DAN were used to produce a bilayer biosensor by using conditions compatible with the entrapped enzymes. Like o-phenylenediamine (oPD), they have two amino groups which are oxidized during polymerization and, depending on the polymerization medium used, the resulting polymer may be either conducting (a conductivity value of 10−2 S cm−1 in acetonitrile or an acidic aqueous medium at pH<4; the conductivity of PPy is around 100 S cm−1) or non-conducting (for aqueous media at pH>4).

At potentials higher than +0.5 V vs Ag/AgCl, 1,5-DAN and 1,8-DAN are oxidised to cation radicals which dimerise. Dimers are more easily oxidised than monomers, and so chain growth takes place by addition of new radicals to an oligomeric chain under the given oxidation potential [14]. The rate of the polymer formation was significantly different for the two isomers, due to their different configurations, which result in different polymerization mechanisms. For the P(1,5-DAN) both amino groups take part in the coupling [14] while for P(1,8-DAN) only one amino group participates in the polymerization reaction [21]. In both cases, the presence of enzyme molecules in the polymerization electrolyte solution produced partial blocking and delayed the film growth process. The conductivity of the P(DAN) films was around 10−2 S cm−1 under suitable conditions, which allowed the formation of bilayer configurations combining both polymers.

For an inner layer of P(1,5-DAN) the growth of an outer layer of P(1,8-DAN) takes place, as can be seen from a progressive increase in the deposition charge. The bilayer exhibits permselective behaviour which is different from that of the individual corresponding monolayers. However, with an inner layer of P(1,8-DAN), the subsequent attempt to form an outer layer of P(1,5-DAN) resulted in a negligible increase in the deposited charge and P(1,5-DAN) was hardly formed on the inner P(1,8-DAN). Consequently, the permselective behaviour of Pt/P(1,8-DAN)-COx/P(1,5-DAN) is similar to that of the corresponding Pt/P(1,8-DAN)-COx monolayer configuration, as can be seen in Fig. 2, and greater exclusion of the interfering species was achieved with the more compact P(1,5-DAN) polymer.

The Pt/P(1,5-DAN)-COx/P(1,8-DAN) bilayer configuration showed a considerable improvement in the permselective behaviour reported for the corresponding monolayer biosensors. With regard to the permeability towards hydrogen peroxide, the %P was lower than 2% and 1% for the monolayer and bilayer configurations, respectively, which limited the sensitivity of the biosensors. Bilayers with P(DAN) polymers are therefore not suitable when high sensitivity is needed, but are interesting when increased exclusion of interfering species is more important than sensitivity.

Compared with the biosensors constructed with PPy, the selectivity achieved with Pt/P(1,5-DAN)-COx films was 500 times higher for ascorbic acid and 750 times higher for uric acid [10]. In comparison with Pt/PPy-COx/oPPD bilayer configuration [15], Pt/P(1,5-DAN)-COx sensors have a selectivity 75 times higher for ascorbic acid and five times higher for uric acid.

The analytical properties of the P(DAN)-based biosensors are summarized in Table 1. With regard to sensitivity, the value for Pt/P(1,8-DAN)-COx is almost double the value obtained for Pt/P(1,5-DAN)-COx, due to the better diffusion of the hydrogen peroxide. An outer layer also restricts cholesterol diffusion towards the inner layer (so reduces sensitivity) caused by both enzymes; and a competitive process for the gaps during the polymer network in the CE and COx co-entrapment also causes immobilisation of COx to a lesser extent than the monoenzymatic sensor. Fewer COx active sites available also contributed to lower sensitivity. Cholesterol oleate is also conditioned by the high compactness of the P(DAN) polymer network.

A very slight deviation from ideal enzymatic kinetic behaviour was observed for the Pt/P(1,5-DAN)-CE+COx biosensor, but for the Pt/P(1,8-DAN)-CE+COx biosensor the deviation was considerable, possibly due to limitation of substrate supply to the enzyme sites. With the monoenzymatic biosensors, ideal behaviour of the enzymatic system according to Michaelis–Menten kinetics was observed.

The application of the monoenzymatic cholesterol determination was initially carried out by direct interpolation in the calibration curve obtained for each sensor, resulting in relative errors of −19% for Pt/P(1,5-DAN)-COx and +32% for Pt/P(1,8-DAN)-COx. The results obtained were not significantly comparable to the cholesterol value and so standard addition had to be used. The relative errors obtained using this method were −0.3% for Pt/P(1,5-DAN)-COx and −10% for Pt/P(1,8-DAN)-COx. Given the difference in sensitivity between the two monoenzymatic biosensors, different dilutions of synthetic serum were used: 1:20 for the Pt/P(1,5-DAN)-COx biosensor and 1:50 for Pt/P(1,8-DAN)-COx. A final Triton X-100 content was 1% in all cases because the surfactant content influences sensitivity, as stated before.

Increasing the flow-rate in FIA cholesterol determination decreases the response as a consequence of decreased residence time of the substrate solution in the detection cell, which behaves like an enzyme reactor; it decreases the time of contact with the modified electrode and hence the amount of hydrogen peroxide produced. The response of the bienzymatic biosensors did decrease more with the flow rate than that of the biosensors in which the enzymatic process was only catalysed by COx. When the response was generated by the joint intervention of CE and COx the current value decrease more in proportion to the flow rate, since in this situation both the residence time of the hydrogen peroxide generated in the polymer/solution interface and of the free cholesterol produced in the de-esterification of the oleate by CE contribute to the amperometric signal. The influence of the flow rate is therefore more significant as it has a simultaneous effect on the supply of free cholesterol and hydrogen peroxide. The best compromise was achieved in all cases with optimized flow rates of about 0.15 mL min−1.

Sample throughput is dependent on the kinetics of the enzymatic reaction in the sensor response and was obviously greater when CE was used. This parameter is important as it influences the number of samples that can be analysed in a single run. The results are gathered in Table 1. Other results (not shown in the table) were throughput of 70 samples h−1 for the Pt/P(1,5-DAN)-COx/P(1,8-DAN) and Pt/P(1,8DAN)-COx/P(1,5-DAN) monoenzymatic bilayer structures, and 61 samples h−1 for the bienzymatic bilayer Pt/PPy-COx/P(1,8-DAN)-CE. These results are a significant improvement on sample throughput for other bienzymatic configurations—five samples h−1 [2].

Similarly, the response times (t 95%) achieved range from 7 to 15 s for the monoenzymatic and bienzymatic configurations, respectively. These values are lower than those obtained with other biosensors which are around 30 s [3, 4] and 51 s [6], in the latter case due to the mass transfer limitation of the cholesterol through the enzymatic layer.

Biosensor stability and lifetime were studied over a period of two weeks following their preparation, evaluated by taking into account the response to 0.20 mmol L−1 free cholesterol. The sensors were stored in phosphate buffer solution at 4 °C between working times. The results are given in Fig. 3, each point corresponding to the mean value for n=6 determinations and for three identical biosensors prepared under the same experimental conditions. With regard to Pt/P(1,5-DAN)-COx and Pt/P(1,8-DAN)-COx, there is no increase in current after the first day of measurement, which indicates minimal swelling of the enzyme within the P(DAN) which are more closely-packed and compact. A slight initial decrease in response was observed, attributed to a loss of the enzyme adsorbed onto the polymer surface. Biosensor response remained practically constant after the above-mentioned process until around 10 days after signal stabilization. For the bienzymatic biosensors a progressive decrease in response as a function of lifetime was observed, although it could not be related to the number of determinations carried out. This continuous decrease in sensitivity with time is due to a loss of activity of the entrapped CE, as reported for other bienzymatic biosensors [5].

The feasibility of using biosensors for the determination of free cholesterol in a synthetic serum sample was studied. A synthetic serum was prepared containing the main components of human serum at their normal concentration levels in a healthy individual. This serum was spiked with a concentration of 3.96 mmol L−1 cholesterol (30% present in the free form and 70% in the esterified form, made with cholesterol oleate).

When a monoenzymatic biosensor was used with COx, 15 total units of CE enzyme were previously added to the sample solution in order to hydrolyse the esterified cholesterol fraction and so that all the substrate would be in the form of free cholesterol. Cholesterol determination was initially carried out by direct interpolation in the regression curve obtained for each sensor. However, matrix errors were obtained in some cases, and so the standard addition method was considered more suitable.

Given the difference in sensitivity among the biosensors, different dilutions of synthetic serum were used: e.g. 1:20 for the Pt/P(1,5-DAN)-COx biosensor and 1:50 for Pt/P(1,8-DAN)-COx. Measurement of the diluted samples yielded results with relative errors of −19% for Pt/P(1,5-DAN)-COx and +32% for Pt/P(1,8-DAN)-COx (results are not significantly comparable to the cholesterol value). For this reason, calibration by standard addition was considered. The relative errors obtained using this method were −0.3% for Pt/P(1,5-DAN)-COx and −8% for Pt/P(1,8-DAN)-COx.

The PPy/oPPD bilayer configuration and its excellent ability to suppress interferences made it possible to carry out the determination of the substrates in blood serum satisfactorily, even by direct interpolation in the regression curve. The relative errors obtained using the Pt/PPy-COx/oPPD biosensor were +3.03% (calibration graph method) and −2.02% (standard addition method).

Owing to the possible variations in the sensitivity of the cholesterol biosensor as a function of lifetime or different preparations of the sensor (e.g. batch of the enzyme and its activity per mg of solid) and the influence of the sample matrix, the standard addition method was used, with four measurements carried out for each concentration with triple addition of a standard cholesterol solution. In all cases the coefficients of linear regression of the four determinations were higher than 0.998.

Conclusions

The biosensors described, based on physical entrapment of COx and/or CE in a polymer film capable of formation in an aqueous medium in conditions compatible with the activity of both enzymes, act as efficient detectors for the determination of cholesterol in a detection system free from interferences due to the inherent exclusion properties of polymers of diaminonaphthalene derivatives. The monomer used for immobilisation of the enzymes, which permits enzyme entrapment by a simple procedure, plays an important part in the improved selectivity. With the bienzymatic biosensors, stability is determined by CE activity. The high compactness of the resulting polymer structure causes limited diffusion of the substrates of the respective enzymatic reactions which take place in the polymer network.

The high stability of the Pt/Pt/PPy-COx/oPPD biosensor combined with the possibility of previous pretreatment with CE and dilution in the flow system provide a device for the determination of total cholesterol with good sensitivity and excellent sample throughput, which simplifies pretreatment and minimizes sample handling. The design of biosensors in which both enzymes (COx and CE) usually have low stability, seriously limited by the loss of CE activity, have less than 2 days of lifetime and the biosensor response may be only 15% of its initial value.

The combined exclusion properties of PPy and oPPD enabled the PPy-enzyme/oPPD configuration to increase the selectivity of the biosensor, especially uric acid, which has a negligible permeation factor. These biosensors were satisfactorily applied to the determination of their respective substrates in control serum samples. The oPPD outer layer coating, which does not significantly modify the biosensor response times, makes it possible to improve reproducibility and detection limits with only a slight decrease in sensitivity. It also allows considerable enhancement of the efficacy of the biosensor by increasing the enzymatically generated hydrogen peroxide fraction which contributes to the amperometric measured current.

The P(1,8-DAN) outer layer on a PPy polymer also enhances biosensor selectivity by hindering diffusion of electroxidizable interfering electroactive species to the Pt surface. The outer layer also improves efficacy by restricting the diffusion of enzymatically generated H2O2 towards the solution flow (bulk solution), although sensitivity is slightly decreased owing to the compactness of the P(1,8-DAN). This problem is more marked when multilayers of electropolymerized P(DAN) layers are constructed, obtaining very small sensitivities in these biosensors.

The biosensor configuration shows that the P(DAN) layer does not destroy the catalytic activity of the enzyme COx and/or CE if adequate preparation conditions are used.

References

Ernst ND, Cleeman JI (2002) Curr Opin Lipidol 13:69–73

Foster R, Cassidy J, O'Donoghue E (2000) Electroanalysis 12:716–721

Brahim S, Narinesingh D, Guiseppi-Elie A (2001) Anal Chim Acta 448:27–36

Bongiovanni C, Ferri T, Poscia A, Varalli M, Santucci R, Desideri A (2001) Bioelectrochemistry 54:17–22

Nakaminami T, Ito S, Kuwabata S, Yoneyama H (1999) Anal Chem 71:1068–1076

Yao T, Takashima K (1998) Biosens Bioelectron 13:67–73

Ropers M-H, Bilewicz R, Stébé M-J, Hamidi A, Miclo A, Rogalska E (2001) Phys Chem Chem Phys 3:240–245

Ram MK, Bertoncello P, Ding H, Paddeu S, Nicolini SC (2001) Biosens Bioelectron 16:849–856

Wallace GG, Smyth M, Zhao H (1999) Trends Anal Chem 18:245–251

Vidal JC, Garcia E, Castillo JR (1999) Anal Chim Acta 385:213–222

Farrington AM, Slater JM (1997) Electroanalysis 9:843–847

Vidal JC, Espuelas J, Garcia-Ruiz E, Castillo JR (2002) Anal Lett 35:837–853

Murphy LJ (1998) Anal Chem 70:2928–2935

Jackowska K, Skompska M, Przyluska E (1996) J Electroanal Chem 418:35–39

Vidal JC, Garcia E, Castillo JR (1999) Sens Actuators B 57:219–226

Vidal JC, Garcia E, Castillo JR (1998) Biosens Bioelectron 13:371–382

Kubiak WW, Wang J (1996) Anal Chim Acta 329:181–189

Kurganow BI, Lobanov AV, Borisov IA, Reshetilow AN (2001) Anal Chim Acta 427:11–19

Hämmerle M, Schuhmann W (1992) Sens Actuators B 6:106–112

Vernitskaya TV, Efimov ON (1997) Russ Chem Rev 66:443–457

Skompska M, Hillman R (1996) J Chem Soc Faraday Trans 92:4101–4108

Acknowledgements

This work was financially supported by the DGI of the Spanish Ministry of Science and Technology, in the framework of the Project BQU2002/02240.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vidal, J.C., Garcia-Ruiz, E., Espuelas, J. et al. Comparison of biosensors based on entrapment of cholesterol oxidase and cholesterol esterase in electropolymerized films of polypyrrole and diaminonaphthalene derivatives for amperometric determination of cholesterol. Anal Bioanal Chem 377, 273–280 (2003). https://doi.org/10.1007/s00216-003-2120-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-003-2120-x