Abstract

In this paper, a new amperometric biosensor based upon a conducting polymer with anionic dopant-modified electrode was developed for use in the determination of glucose. Glucose oxidase enzyme was immobilized in polypyrrole–poly(sodium-4-styrenesulphonate) film using the entrapment method. Amperometric determination is based on the electrochemical detection of H2O2 generated in the enzymatic reaction of glucose oxidase. Glucose detection was carried out according to the oxidation of hydrogen peroxide at 0.4 V resulting from the enzymatic reaction on the biosensor surface. Some parameters that affect amperometric response current were investigated in terms of temperature, pH, and substrate concentration. The stability and reproducibility of the biosensor were analyzed. The interference effects were examined using amperometric response of the biosensor. The glucose detection ability of the biosensor was tested in a biological fluid (in blood). The film thickness, morphology, and water contact angle measurements of the polypyrrole–poly(sodium-4-styrenesulphonate) film were characterized by profilometer, atomic force microscope, and water contact angle device, respectively. For the biosensor in this study, the linear range 1 × 10−8–1 × 10−3 M, optimum temperature 25 °C, optimum pH 8, Km value 2.97 mM and Vmax value 0.097 μA was found. The results of the study show that the film can provide suitable biological application and electrochemical microenvironment for immobilization of the enzymes, making this material a perfect candidate for the production of extremely susceptible and selective glucose biosensors.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Diabetes is a pervasive metabolic disease, resulting in serious health complications such as blindness, heart failure, and kidney disease (Calcutt et al. 2009). Therefore, there is an urgent need for an easy, accurate and cost-effective method for the detection of glucose levels and a considerable amount of effort invested in developing glucose biosensors. Modern techniques such as the infrared spectrum for the biosensors developed for glucose determination, the visible spectrum, and the fluorescence spectrum were used (Yoo and Lee 2010; Gruhl et al. 2011; Gifford 2013).

Enzyme-based biosensors have a unique influence on biochemical reactions (Shao et al. 2010; Kuila et al. 2011; Rivas et al. 2007). The performances of the biosensors are strongly dependent upon the immobilization of the enzyme (Sassolas et al. 2012) in a self-assembled mono- or multilayers make the formation of uniform and stable structures (Bucur et al. 2006).

Electrochemical sensors are the most widely used in biosensors (Ozer and Cete 2017; Gorgulu et al. 2013; Yildirimoglu et al. 2009). Enzyme immobilization technique is very important in terms of cost and commercial sensor preparation (Wang et al. 2014, 2017, 2019; Xu et al. 2019; Song et al. 2014, 2016, 2018; Dolmaci et al. 2012; Muhammet et al. 2009; Cete et al. 2007).

Amperometric sensors utilizing immobilized enzyme for the transformation of the target analytes in a biological system into electrochemically detectable compound are the most commonly employed detection methods for the determination of blood glucose. Diverse ways of enzyme immobilization on electrodes have been reported [1 ± 5] by the use of gels, cross-linked polymers, conductive salts or carbon paste or carbon–organic polymer mixtures. The amperometric detection of glucose is carried out by anodic method, but this procedure is significantly interfered by diverse numbers some interferences present in biologic substances (Karyakin 2001; Colak et al. 2012).

Glucose oxidase (EC 1.1.3.4 GOD) uses oxygen as an electron acceptor and breaks down glucose to form gluconic acid and hydrogen peroxide (Ramos and Malcata 2011). This procedure is very popular in fields such as the food industry, medical diagnostics, and environmental conservation (Ren et al. 2006). Glucose oxidase is used as an anti-bacterial agent in the food industry and in the production of gluconic acid (Pluschkell et al. 1996). GOD has a wide employment in medical diagnosis. Especially the amperometric sensors have found wide application for detection of glucose in biologic samples (Gerritsen et al. 2001; Petruccioli et al. 1999). Moreover, GOD has been used to eliminate endocrine disruptors when combined with peroxidase, which is as an advantageous method for the drain treatment (Taboada-Puig et al. 2011) (Fig. 1).

Although GOD has a major trading rate, its properties have great back demand for use in a wide range of new implementations. The significance of glucose amount being higher or lower than the normal range of 80–120 mg/dL (4.4–6.6 mM) is an indication of a metabolic disorder (Wang 2008). Furthermore, glucose concentration is important in nutrient (Yildiz et al. 2005).

Therefore, there is a crucial need for the development of selective, sensitive, fast, and cost-effective technique for glucose determination. Conducting polymers-based biosensors are extensively used in biological analyses, health care, and food processing industries for the determination of various analytes (Cesarino et al. 2012; Gerard et al. 2002; Singh et al. 2004). These biosensors are used for an easy, direct, dependable, and low-cost determination of varying analytes and act as very effective analytical tools in the food quality control due to its very high selectivity and sensitivity (Gvozdenović et al. 2011; Kesik et al. 2013; Ramanavičius et al. 2006). Moreover, they act as a three-dimensional matrix for biomolecule deposition. Their charge transfer ability serves as a medium mimicking the enzymes for the biomolecules (Tuncagil et al. 2011; Turkarslan et al. 2009). The characteristics of the enzyme after immobilization depend on factors such as immobilization method, surface film thickness and film layer stability. The structure of the matrix in which the enzyme is immobilized is very important. For example, the permeability of the matrix is suitable for the analyte while it may prevent the permeability of large molecules such as immobilized enzymes and thus make electron transfer difficult. It is also important whether immobilization technique is adsorption, entrapment and covalent. Molecular porous structure increases the immobilization and shelf life of more enzymes on the surface and also reduces the interference effect. It is stated that the chemical or electrochemical synthesis of the matrix affects the sensitivity of the biosensor. The use of BSA (bovine serum albumin) in enzyme immobilization changes the microenvironment of the enzyme and increases the activity and stability of the enzyme. Increasing the amount of glucose oxidase enzyme for glucose biosensor increases activation, while surface film thickness limits the permeability of glucose. Enzyme activity affects the amount of enzyme, pH and BSA concentration (Minkstimiene et al. 2018; German et al. 2019). No one to the best of our knowledge has studied the use of polypyrrole–poly(sodium-4-styrenesulphonate) film in amperometric biosensor application. This study is related with the development of a new amperometric biosensor for the determination of glucose. Therefore, glucose oxidase enzyme was immobilized in polypyrrole–poly(sodium-4-styrenesulphonate) film via the entrapment method. Glucose determination was made on the basis of the oxidation of hydrogen peroxide at a potential of 0.4 V after the enzymatic reaction. The linear working range of the biosensor for glucose was determined. The effects of pH, temperature, reusability, and storage stability were determined for the biosensor. Then the interference effects were examined. And finally, the glucose detection ability of the biosensor was tested in a biological fluid (in blood).

Experimental

All the electrochemical experiments were carried out using a BAS Epsilon-EC-Ver 1.40.67 NT electrochemical analyzer equipped with a conventional three-electrode system with a Pt plate (0.5 cm2), Ag/AgCl (3 M KCl) and a platinum wire as the working, reference and the counter electrodes, respectively. The pH values were measured with an ORION Model 720A pH-ion meter and temperature control was carried out with a Grant W14 thermostat. The film thickness, morphology and water contact angle measurements of the polypyrrole–poly(sodium-4-styrenesulphonate) film were characterized by profilometer, atomic force microscope and water contact angle, respectively. The film thickness was also confirmed by profilometer (Veeco Dektak 150) that takes surface measurements using contact profilometry techniques. Profilometer technique gives general information about the surface roughness measurements and the morphology of the surface. In addition, the Omicron STM/AFM combined instrument was used to perform morphological measurements at room temperature. The AFM scanning area was set at 3 × 3 μm2. The obtained AFM micrographs were used to determine the grain size and the roughness of the samples. The water contact angles were measured with a goniometer (DSA 100, Krüss) equipped with a microliter syringe at room temperature. The wetting liquid procedure was carried out by distilled/deionized water (4 µL, 18 MΩ cm resistivity). Glucose oxidase (EC 1.1.3.4.) was obtained from Sigma. Pyrrole and PSS were supplied from Fluka and all other chemicals were purchased from Sigma. The solutions stored at 4 °C in the fridge.

Immobilization of glucose oxidase

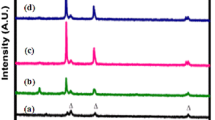

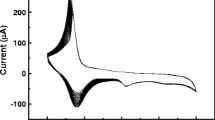

Immobilization process was carried out with the entrapment method. Pt plane working, Ag/AgCl reference, and platinum wire auxiliary electrodes were inserted in a 10 mL three-necked cell containing a solution of 106 μL of pyrrole; 5 mL poly(sodium-4-styrenesulphonate) and 500 μL of glucose oxidase (19.2 units/mL) were dissolved in 4394 mL of purified water. The cell was purged with purified argon for 10 min in order to remove oxygen from the system and the cell blanketed with the inert gas throughout the experiment. The electropolymerization process was performed with cyclic voltammetry for 18 scans between a potential range of − 0.8 V and + 0.8 V s, at a scan rate of 20 mV. The surface of the Pt/polypyrrole poly(sodium-4-styrenesulphonate)-glucose oxidase (Pt/PPy–PSS–GOx) biosensor was kept at + 4 °C in the phosphate buffer in the fridge.

Amperometric current response

In this study, the measured current values were recorded. The current difference between the last measured current value (addition of the substance) and the value of the equilibrium current was calculated. This current was defined as ∆i.

The amount of glucose was found from the anodic oxidation current of H2O2 (Reaction 1) produced in reaction (Cete et al. 2017):

The mixture of aqueous solution of 0.1 M phosphate buffer at (pH 7) and 0.1 M sodium perchlorate were prepared in the cell and glucose was added to it when the background current reached to a stable value. The mixture was thoroughly stirred for 5 min. The response of the biosensor against the addition of 5 × 10−5 M glucose was measured at constant potential of 0.4 V (Ag/AgCl) after 200 s of waiting time. In a previous study, the best potential was found to be 0.4 V (Cete et al. 2017). This study was carried out by the use of a constant concentration of 5 × 10−5 M glucose.

Results and discussion

This article describes a new biosensor for glucose determination prepared with the immobilization of enzyme (GOX) on polypyrrole–poly(sodium 4-styrenesulphonate) (PPy–PSS) composite film. The parameters significant for the functioning of the biosensors were examined in detail.

Profilometer studies of PPy–PSS film

The thickness of PPy–PSS film was measured by a profilometer (A Veeco dektak 150) (Figs. S1 and S2). The profilometer images of PPy–PSS in Figs. S1 and S2 reveal that the thickness of PPy–PSS and PPy–PSS–GOx on film surface was found as ~ 1467 and ~ 2398 nm, respectively. These results show the perfect proof of the immobilization of GOx on the PPy–PSS film.

AFM (atomic force microscope) studies of PPy–PSS–GOD film

In these experiments, AFM JEOL Model 6060 LV was used. The morphologies of PPy–PSS electrode without and with the GOx enzyme were elucidated by the use of AFM micrographs depicted in Figs. S3 and S4. The AFM image (Fig. S3) of the Pt/PPy–PSS electrode has fine microspheres which results in a porous surface.

Enzyme-containing and enzyme-free images are clearly distinguishable from each other. The structure is attributed to the enzymatic structure of randomly dispersed granular structures formed in the structure by the immobilization process of glucose oxidase enzyme. A new morphologic structure has been formed on the surface by adding glucose oxidase enzyme to the structure. As a result, immobilization of glucose oxidase has made the surface smoother. This result was supported by the root mean square (RMS) value, which is the surface roughness value. The RMS value for the scanned image was measured as 69.66 nm and the RMS value for the enzyme-free structure was measured as 269.78 nm.

Contact angle experiments

The contact angle studies were carried out with a Kruss model DSA 100 equipment. The contact angles of enzyme-containing and enzyme-free are presented in Figs. S5 and S6. The water contact angles of the enzyme-containing and enzyme-free structures were measured 51° and 17°, respectively. The contact angle image (Fig. S5) obtained for the Pt/PPy–PSS electrode shows the hydrophobicity of the surface. The contact angle of Pt/PPy–PSS–GOD given in the biosensor has a more hydrophilic character than the free enzyme. This result is due to the hydrophilic character of the protein structure.

Effect of pH and temperature

The activity of enzyme is largely dependent upon temperature and pH. The extreme values of these parameters may inactivate the enzyme because enzyme activity differs in the presence of ionizable amino acids in the active center of the enzymes (Bankar et al. 2009).

The effect of the biosensor on pH in 0.1 M phosphate buffer containing fixed glucose (5 × 10−5 M) concentration was investigated. In this study, the maximum response of immobilized glucose oxidase enzyme of the biosensor was found at pH 8 (Fig. 2). In the literature related to pH studies, different pH values for glucose oxidase were determined in the range of pH 5.5 and 8.5 (Calcutt et al. 2009; Yoo and Lee 2010; Gruhl et al. 2011; Gifford 2013; Shao et al. 2010; Kuila et al. 2011). It is reported that the immobilization type and the properties of the polymers used together with the effects of the interactions in the enzymes and immobilization materials can cause changes in the pH values. (Akin 2017; Gholivand and Khodadadian 2014).

Since temperature has a marked effect on enzyme activity, the response of the biosensor was elucidated at different incubation temperatures between 20 and 60 °C using 0.1 M phosphate buffer solution at pH 7.5 containing 5 × 10−5 M glucose (Chauhan et al. 2010). As shown in the graph, the enzyme activity increases as the temperature increases and reaches a maximum of 60 °C (Fig. 3). We found the optimum temperature value to be 60 °C. The temperature value is higher than it is in the literature (Kausaite-Minkstimiene et al. 2010).

Among the glucose biosensors reported in literature and the values reported in the present study there is a great variation (35–40 °C) (Kausaite-Minkstimiene et al. 2010; Sabury et al. 2015). This was attributed to the fact that the used polymer and immobilization materials and the type of immobilization were different. Enzyme can be denatured after a long incubation period at a temperature of 60 °C. At the same time, all other experiments were performed at 25 °C for ease of use.

Studies of substrate concentration

The effect of substrate concentration on the measured current values for the detection of the linear working range of the prepared Pt/PPy–PSS–GOx biosensor was investigated. For this purpose, flow changes were recorded for a series of glucose solutions prepared at a concentration range of 1 × 10−8–1 × 10−3 M (Fig. 4). The resulting Michaelis–Menten graph (Fig. 5) indicates that response curves are stable after the addition of 5.0 × 10−5 M glucose and this shows that the enzyme is saturated with the glucose. Two important kinetic constants, which are the Km(app) and Vmax(app), were investigated. The Km(app) and Vmax(app) values of glucose oxidase were calculated to be 2.97 mM and 0.097 μA using the graph of Fig. 6, respectively. The Km and Vmax values of the literature are quite compatible (Colak et al. 2012; Ngamdee and Ngeontae 2018; Jedrzak et al. 2018).

Linear region was determined using Michaelis–Menten graph. Figure 6 shows that linearity is very good at 1.0 × 10−7 M–5.0 × 10−6 M and this range can be used for quantitative analysis.

Operational stability and storage stability

Enzymes often form unstable properties in aqueous systems. However, it stabilizes enzymes with free enzyme. The long-term stability for the biosensor is very important. The operational stability of the biosensor was investigated at regular intervals for 32 days. The biosensor remained stable at 93% for 32 days. Standard deviation was observed to be 0.3%. These results show that the prepared biosensor has very good stability and acceptable reproducibility values (Rivas et al. 2007; Sassolas et al. 2012; Campas et al. 2004; Ozer and Cete 2017; Gorgulu et al. 2013; Yildirimoglu et al. 2009). In reproducibility studies, the response of PPy/PSS–GOx glucose biosensor yielded good results with a standard deviation (RSD) of 0.3% (Fig. 7). Similarly, in the storage stability assay, the biosensor maintained its activity at 55% at the end of 32 days. Compared to similar studies, the reproducibility and storage stability values are quite good. These results can be attributed to the polypyrrole–poly(sodium-4-styrenesulphonate) film electrode used in our study and also to the immobilization technique.

Comparison of some analytical characteristics for glucose with different biosensor designs

The linear working range and stability values have been studied for many of the modified materials in literature (Table 1). In these studies, the linear range is between 0.005 and 34 mM and the stability varies between 92 and 98% at the end of 20 days. In this study, the linear range was 1 × 10−4–5 × 10−3 mM and the stability was 55% at the end of 32 days (Fig. 8). The linear working range and stability of the prepared biosensor is consistent with the literature.

Effect of interfering substances on the response of biosensor

In this part of the study, the interference effects of some substances that may interfere with the biosensor prepared in this section were examined. In this section, uric acid, ascorbic acid and acetaminophen and some other interfering substances in biological samples that cause serious interventions were studied (Colak et al. 2012; Ngamdee and Ngeontae 2018). The data obtained are presented in Table 2 and it can be seen that the interference effect of the main interfering substances was 3% and 5%.

Determination of glucose in human serum blood samples were taken from the volunteers from the hospital for glucose analysis in the serum samples. Serum samples were diluted 1/15 and standard addition was used. For this purpose, the standard solution was added to the samples taken in the same quantity at increasing concentrations. It was not added to the first sample solution. The signals of these solutions with the device were measured. The sample was approximately the same as the sample solution. The analyte concentration in the sample was calculated from the cutting point of the X axis of the line.

Each test result was calculated as the average of three measurements. The results were compared with the measured values in the hospital laboratory. When the values were compared, it was seen that the values calculated by the biosensor were acceptable (Table 3).

Conclusion

This study is believed to make a great deal of contribution to the literature with its techniques and findings. First, the biosensor prepared in this study was found to be effective in determining the amount of glucose in the biological samples. Second, the results of the reproducibility studies of the biosensor were very satisfying. Third, the operational stability of the biosensor was quite acceptable. The biosensor performed well and proved to be stable enough. Forth, the method of biosensor preparation is not expensive. The above-mentioned parameters are critical important in preparing an ideal biosensor. Consequently, the prepared biosensor can be used efficiently and cost-effectively for the determination of glucose in both biological samples and food analyses.

References

Akin D (2017) Preparation of a new biosensor based on graphene for glucose detection. Master’s Thesis, Gazi University, Ankara

Bankar SB, Bule MV, Singhal RS, Ananthanarayan L (2009) Glucose oxidase—an overview. Biotechnol Adv 27(4):489–501

Bucur B, Campas M, Prieto-Simón B, Marty JL (2006) Enzymatic biosensors for screening carbamate insecticides: application to environmental and food monitoring. Chemia Inżynieria Ekologiczna 13(5):339–348

Calcutt NA, Cooper ME, Kern TS, Schmidt AM (2009) Therapies for hyperglycaemia-induced diabetic complications: from animal models to clinical trials. Nat Rev Drug Discov 8(5):417

Cesarino I, Moraes FC, Lanza MR, Machado SA (2012) Electrochemical detection of carbamate pesticides in fruit and vegetables with a biosensor based on acetylcholinesterase immobilised on a composite of polyaniline–carbon nanotubes. Food Chem 135(3):873–879

Cete S, Yasar A, Arslan F (2007) Immobilization of uricase upon polypyrrole-ferrocenium film. Artif Cell Blood Sub 35(6):607–620

Cete S, Ozyurt M, Yildirim E (2017) Preparation of film electrode using dopant for construction of biosensors sensitive to hydrogen peroxide. GU J Sci 30(4):104–112

Chauhan N, Narang J, Pundir CS (2010) Amperometric determination of serum cholesterol with pencil graphite rod. Am J Anal Chem 1(02):41

Colak O, Yasar A, Cete S, Arslan F (2012) Glucose biosensor based on the immobilization of glucose oxidase on electrochemically synthesized polypyrrole-poly (vinyl sulphonate) composite film by cross-linking with glutaraldehyde. Artif Cell Blood Sub 40(5):354–361

Dai H, Cao P, Chen D, Li Y, Wang N, Ma H, Lin M (2018) Ni-Co-S/PPy core-shell nanohybrid on nickel foam as a non-enzymatic electrochemical glucose sensor. Synth Met 235:97–102

Dolmaci N, Cete S, Arslan F, Yasar A (2012) An amperometric biosensor for fish freshness detection from xanthine oxidase immobilized in polypyrrole-polyvinylsulphonate film. Artif Cell Blood Sub 40(4):275–279

Gerard M, Chaubey A, Malhotra BD (2002) Application of conducting polymers to biosensors. Biosens Bioelectron 17(5):345–359

German N, Ramanaviciene A, Ramanavicius A (2019) Formation of polyaniline and polypyrrole nanocomposites with embedded glucose oxidase and gold nanoparticles. Polymers 11:377–390

Gerritsen M, Kros A, Lutterman JA, Nolte RJM, Jansen JA (2001) A percutaneous device as model to study the in vivo performance of implantable amperometric glucose sensors. J Mater Sci: Mater M 12(2):129–134

Gholivand MB, Khodadadian M (2014) Amperometric cholesterol biosensor based on the direct electrochemistry of cholesterol oxidase and catalase on a graphene/ionic liquid-modified glassy carbon electrode. Biosens Bioelectron 53:472–478

Gifford R (2013) Continuous glucose monitoring: 40 Years, what we′ve learned and what’s next. Chem Phys Chem 14(10):2032–2044

Gorgulu M, Cete S, Arslan H, Yasar A (2013) Preparing a new biosensor for hypoxanthine determination by immobilization of xanthine oxidase and uricase in polypyrrole-polyvinyl sulphonate film. Artif Cell Nanomed B 41(5):327–331

Gruhl FJ, Rapp BE, Länge K (2011) Biosensors for diagnostic applications. Molecular diagnostics. Springer, Berlin, pp 115–148

Guerrieri A, De Benedetto GE, Palmisano F, Zambonin PG (1998) Electrosynthesized non-conducting polymers as permselective membranes in amperometric enzyme electrodes: a glucose biosensor based on a co-crosslinked glucose oxidase/overoxidized polypyrrole bilayer. Biosens Bioelectron 13(1):103–112

Gvozdenović MM, Jugović BZ, Bezbradica DI, Antov MG, Knežević-Jugović ZD, Grgur BN (2011) Electrochemical determination of glucose using polyaniline electrode modified by glucose oxidase. Food Chem 124(1):396–400

Jędrzak A, Rębiś T, Klapiszewski Ł, Zdarta J, Milczarek G, Jesionowski T (2018) Carbon paste electrode based on functional GOx/silica-lignin system to prepare an amperometric glucose biosensor. Sens Actuators, B 256:176–185

Karyakin AA (2001) Prussian blue and its analogues: electrochemistry and analytical applications. Electroanal Int J Devot Fundam Pract Aspects Electroanal 13(10):813–819

Kausaite-Minkstimiene A, Mazeiko V, Ramanaviciene A, Ramanavicius A (2010) Enzymatically synthesized polyaniline layer for extension of linear detection region of amperometric glucose biosensor. Biosens Bioelectron 26(2):790–797

Kesik M, Kanik FE, Hizalan G, Kozanoglu D, Esenturk EN, Timur S, Toppare L (2013) A functional immobilization matrix based on a conducting polymer and functionalized gold nanoparticles: synthesis and its application as an amperometric glucose biosensor. Polymer 54(17):4463–4471

Kuila T, Bose S, Khanra P, Mishra AK, Kim NH, Lee JH (2011) Recent advances in graphene-based biosensors. Biosens Bioelectron 26(12):4637–4648

Minkstimiene AK, Glumbokaite L, Ramanaviciene Dauksaite E, Ramanavicius A (2018) An amperometric glucose biosensor based on poly(pyrrole-2-carboxylic acid)/glucose oxidase biocomposite. Electroanalysis 30:1642–1652

Muhammet SM, Cete S, Arslan F, Yasar A (2009) Amperometric cholesterol biosensors based on the electropolymerization of pyrrole and aniline in sulphuric acid for the determination of cholesterol in serum. Artif Cell Blood Sub 37(6):273–278

Ngamdee K, Ngeontae W (2018) Circular dichroism glucose biosensor based on chiral cadmium sulfide quantum dots. Sens Actuators, B 274:402–411

Ozer BO, Cete S (2017) Development of a novel biosensor based on a polypyrrole–dodecylbenzene sulphonate (PPy–DBS) film for the determination of amperometric cholesterol. Artif Cell Nanomed B 45(4):824–832

Palod PA, Singh V (2015) Improvement in glucose biosensing response of electrochemically grown polypyrrole nanotubes by incorporating crosslinked glucose oxidase. Mater Sci Eng, C 55:420–430

Petruccioli M, Federici F, Bucke C, Keshavarz T (1999) Enhancement of glucose oxidase production by Penicillium variabile P16. Enzyme Microb Tech 24(7):397–401

Pluschkell S, Hellmuth K, Rinas U (1996) Kinetics of glucose oxidase excretion by recombinant Aspergillus niger. Biotechnol Bioeng 51(2):215–220

Ramanavičius A, Ramanavičienė A, Malinauskas A (2006) Electrochemical sensors based on conducting polymer—polypyrrole. Electrochim Acta 51(27):6025–6037

Ramos OS, Malcata FX (2011) Food-grade enzymes. Comp Biotechnol 3:555–569

Ren G, Xu X, Liu Q, Cheng J, Yuan X, Wu L, Wan Y (2006) Electrospun poly (vinyl alcohol)/glucose oxidase biocomposite membranes for biosensor applications. React Funct Polym 66(12):1559–1564

Rivas GA, Rubianes MD, Rodriguez MC, Ferreyra NF, Luque GL, Pedano ML et al (2007) Carbon nanotubes for electrochemical biosensing. Talanta 74(3):291–307

Sabury S, Kazemi SH, Sharif F (2015) Graphene–gold nanoparticle composite: application as a good scaffold for construction of glucose oxidase biosensor. Mater Sci Eng C 49:297–304

Sassolas A, Blum LJ, Leca-Bouvier BD (2012) Immobilization strategies to develop enzymatic biosensors. Biotechnol Adv 30(3):489–511

Shao Y, Wang J, Wu H, Liu J, Aksay IA, Lin Y (2010) Graphene based electrochemical sensors and biosensors: a review. Electroanal Int J Devot Fundam Pract Aspects Electroanal 22(10):1027–1036

Singh S, Chaubey A, Malhotra BD (2004) Amperometric cholesterol biosensor based on immobilized cholesterol esterase and cholesterol oxidase on conducting polypyrrole films. Anal Chim Acta 502(2):229–234

Song Y, Liu H, Tan H, Xu F, Jia J, Zhang L, Li Z, Wang L (2014) pH-switchable electrochemical sensing platform based on chitosan-reduced graphene oxide/concanavalin a layer for assay of glucose and urea. Anal Chem 86(4):1980–1987

Song Y, Lu X, Li Y, Guo Q, Chen S, Mao L, Hou H, Wang L (2016) Nitrogen-doped carbon nanotubes supported by macroporous carbon as an efficient enzymatic biosensing platform for glucose. Anal Chem 88(2):1371–1377

Song Y, Xu M, Gong C, Shen Y, Wang L, Xie Y, Wang L (2018) Ratiometric electrochemical glucose biosensor based on GOD/AuNPs/Cu-BTC MOFs/macroporous carbon integrated electrode. Sens Actuators B Chem 257:792–799

Taboada-Puig R, Junghanns C, Demarche P, Moreira MT, Feijoo G, Lema JM, Agathos SN (2011) Combined cross-linked enzyme aggregates from versatile peroxidase and glucose oxidase: production, partial characterization and application for the elimination of endocrine disruptors. Bioresour Technol 102(11):6593–6599

Tuncagil S, Ozdemir C, Demirkol DO, Timur S, Toppare L (2011) Gold nanoparticle modified conducting polymer of 4-(2, 5-di (thiophen-2-yl)-1H-pyrrole-1-l) benzenamine for potential use as a biosensing material. Food Chem 127(3):1317–1322

Turkarslan O, Kayahan SK, Toppare L (2009) A new amperometric cholesterol biosensor based on poly (3, 4-ethylenedioxypyrrole). Sens Actuators B 136(2):484–488

Wang J (2008) Electrochemical glucose biosensors. Chem Rev 108(2):814–825

Wang L, Zhang Q, Chen S, Xu F, Chen S, Jia J, Tan H, Hou H, Song Y (2014) Electrochemical sensing and biosensing platform based on biomass-derived macroporous carbon materials. Anal Chem 86(3):1414–1421

Wang L, Yu J, Zhang Y, Yang H, Miao L, Song Y (2017) Simple and large-scale strategy to prepare flexible graphene tape electrode. ACS Appl Mater Interfaces 9(10):9089–9095

Wang L, Xu M, Xie Y, Qian C, Ma W, Wang L, Song Y (2019) Ratiometric electrochemical glucose sensor based on electroactive Schiff base polymers. Sens Actuators B Chem 285:264–270

Xu GQ, Lv J, Zheng ZX, Wu YC (2012) Polypyrrole (PPy) nanowire arrays entrapped with glucose oxidase biosensor for glucose detection. In: 2012 7th IEEE international conference on nano/micro engineered and molecular systems (NEMS). IEEE, pp 511–514

Xu M, Wang L, Xie Y, Song Y, Wang L (2019) Ratiometric electrochemical sensing and biosensing based on multiple redox-active state COFDHTA-TTA. Sens Actuators B Chem 281:1009–1015

Yang Z, Zhang C, Zhang J, Bai W (2014) Potentiometric glucose biosensor based on core–shell Fe3O4–enzyme–polypyrrole nanoparticles. Biosens Bioelectron 51:268–273

Yildirimoglu F, Arslan F, Cete S, Yasar A (2009) Preparation of a polypyrrole-polyvinylsulphonate composite film biosensor for determination of cholesterol based on entrapment of cholesterol oxidase. Sensors 9(8):6435–6445

Yildiz HB, Kiralp S, Toppare L, Yagci Y (2005) Immobilization of glucose oxidase in conducting graft copolymers and determination of glucose amount in orange juices with enzyme electrodes. Int J Biol Macromol 37(4):174–178

Yoo EH, Lee SY (2010) Glucose biosensors: an overview of use in clinical practice. Sensors 10(5):4558–4576

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cete, S., Ozyurt, M., Yildirim, E. et al. A novel biosensor with the use of polypyrrole–poly(sodium-4-styrenesulphonate) as a dopant in the determination of glucose. Chem. Pap. 74, 799–808 (2020). https://doi.org/10.1007/s11696-019-00907-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-019-00907-6