Abstract

A salt-tolerant exo-β-1,3-glucosidase (BGL_MK86) was cloned from the xerophilic mold Aspergillus chevalieri MK86 and heterologously expressed in A. oryzae. Phylogenetic analysis suggests that BGL_MK86 belongs to glycoside hydrolase family 5 (aryl-phospho-β-D-glucosidase, BglC), and exhibits D-glucose tolerance. Recombinant BGL_MK86 (rBGL_MK86) exhibited 100-fold higher expression than native BGL_MK86. rBGL_MK86 was active over a wide range of NaCl concentrations [0%–18% (w/v)] and showed increased substrate affinity for p-nitrophenyl-β-D-glucopyranoside (pNPBG) and turnover number (kcat) in the presence of NaCl. The enzyme was stable over a broad pH range (5.5–9.5). The optimum reaction pH and temperature for hydrolysis of pNPBG were 5.5 and 45 °C, respectively. rBGL_MK86 acted on the β-1,3-linked glucose dimer laminaribiose, but not β-1,4-linked or β-1,6-linked glucose dimers (cellobiose or gentiobiose). It showed tenfold higher activity toward laminarin (a linear polymer of β-1,3 glucan) from Laminaria digitata than laminarin (β-1,3/β-1,6 glucan) from Eisenia bicyclis, likely due to its inability to act on β-1,6-linked glucose residues. The β-glucosidase retained hydrolytic activity toward crude laminarin preparations from marine biomass in moderately high salt concentrations. These properties indicate wide potential applications of this enzyme in saccharification of salt-bearing marine biomass.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

β-Glucosidase (β-D-glucopyranoside glucohydrolase, EC 3.2.1.21) is a versatile enzyme found in a variety of microorganisms (Roth et al. 2020; Mesbah 2022). It plays a crucial role in hydrolyzing β-glucosidic linkages between carbohydrate residues in alkyl-β-D-glucosides, short chain oligosaccharides and disaccharides in various physiological conditions (Roth et al. 2020; Mesbah 2022). Because of its versatility, β-glucosidase has gained significant attention in multiple biotechnological processes. For instance, the enzyme is employed in the saccharification of lignocellulosic biomass (Roth et al. 2020; Djelid et al. 2022) and marine biomass (Kim et al. 2013). In addition, it is used for the biotransformation of pharmaceuticals (Wang et al. 2015), fine chemicals (Schwentke et al. 2014), and food ingredients (Tian et al. 2022).

Extremophilic enzymes have become increasingly sought after in biotechnological fields because of their stability and activity in extreme conditions (Mesbah 2022). Microorganisms adapted to extreme conditions, such as thermophilic, acidophilic, alkaliphilic, halophilic, and psychrophilic environments, represent a major source for isolating and purifying extremophilic enzymes (Ortiz-Cortés et al. 2021; Solat and Shafiei 2021), including β-glucosidase. These microorganisms have developed diverse mechanisms and strategies to thrive in their extreme habitats (Mesbah 2022). For example, xerophilic molds, such as Aspergillus glaucus and related species, have shown salt-adaptive properties and are expected to be used in biomass degradation (Esawy et al. 2016; Jiménez-Gómez et al. 2020). Xerophilic molds and their extracellular enzymes possess potential molecular adaptation mechanisms for high salt and/or low water activity conditions and are therefore attractive genetic resources for isolating salt- and/or osmo-adaptive enzymes (Musa et al. 2018; Qiu et al. 2020; Nishikawa et al. 2022; Chung et al. 2022).

This study reports on the biochemical and molecular characterization of a salt-tolerant β-glucosidase (BGL_MK86) from the xerophilic mold A. chevalieri MK86. BGL_MK86 exhibited high salt tolerance, and its hydrolytic activity toward laminarin from marine biomass was examined in the presence and absence of NaCl.

Materials and methods

Organism and culture conditions

A. chevalieri MK86 was isolated from the surface of katsuobushi filet fermented in low water activity conditions (Takenaka et al. 2021). A salt-tolerant β-1,3-glucosidase (BGL_MK86) was purified and its gene was cloned from strain MK86. Strain MK86 was cultivated on katsuobushi solid medium, according to previously described methods (Takenaka et al. 2021). A niaD− derivative strain of A. oryzae NBRC 100959 [a nitrate reductase gene (niaD)-deficient mutant] was used as the recipient strain for heterologous expression (Senba et al. 2023). The expression vector pUNA, containing the amyB promoter and terminator, was newly constructed from pUC118, based on a previously reported expression vector (Senba et al. 2023). A. oryzae transformants were cultivated on DPY medium [2% (w/v) dextrin, 1% (w/v) polypeptone, 1.0% (w/v) yeast extract, 0.5% (w/v) KH2PO4, and 0.05% (w/v) MgSO4·7H2O] (Senba et al. 2023) with shaking at 130 rpm for 3–4 d.

Genomic DNA and RNA isolation for cloning of BGL_MK86-encoding gene

Strain MA0196 was cultivated in katsuobushi solid medium, described previously (Takenaka et al. 2021). Wild-type β-glucosidases including BGL_MK86 were purified from A. chevalieri MK86 for selection of a salt-tolerant β-glucosidase and protein identification by liquid chromatography-tandem mass spectrometry (LC-MSMS) with Mascot analysis. Procedures for purification of the wild-type enzymes and a summary of the purification are described in the Supplemental Materials (Table S1 and Fig. S1). Genomic DNA was extracted from strain MK86 using a DNeasy Blood & Tissue Kit according to the manufacturer’s instructions (Qiagen, Hilden, Germany). The DNA fragment encoding β-glucosidase BGL_MK86 was amplified using the purified genomic DNA, PrimeSTAR® MAX DNA polymerase, and primers BGL_MK86F (ATGTTTGCCAAACTCTGCGTAA) and BGL_MK86R (TTAGCCGCACTGACCGGGGA), according to the manufacturer’s instructions (Takara Bio Inc., Kusatsu, Japan). Total RNA was extracted from strain MK86 using RNAiso Plus according to the manufacturer’s instructions (Takara Bio Inc.). First-strand cDNA was synthesized using a PrimeScript™ 1st Strand cDNA Synthesis Kit (Takara Bio Inc.). DNA encoding BGL_MK86 was amplified using the cDNA mixture as the template, PrimeSTAR® MAX DNA polymerase, and primers BGL_MK86F and BGL_MK86R. The ligation of PCR products and pMD20 (Takara Bio Inc.) was carried out using a Mighty TA-cloning kit (Takara Bio Inc.). The primers were designed based on our in-house database for strain MK86.

Construction of BGL_MK86 expression vector and transformation of A. oryzae

A DNA fragment encoding BGL_MK86 was amplified using the synthesized cDNA solution (see above), PrimeSTAR MAX DNA polymerase, and primers BGL_MK86F_AO (AAACCCCACAGAAGGCATTTATGTTTGCCAAACTCTCGCGTA) and BGL_MK86R_AO (TCTCCACCCTTCTAGATTAGCCGCACTGACCGGG). According to the user manual of the In-fusion® HD Cloning kit (Takara Bio Inc.), the purified PCR product was ligated into plasmid pUNA linearized using restriction enzymes ApaI and XbaI. The constructed recombinant plasmid was then transformed into Escherichia coli HST08 (Takara Bio Inc.), according to the manufacturer’s instructions. Transformation of A. oryzae was carried out according to previously reported procedures (Senba et al. 2023). The plasmid was linearized by using restriction enzyme XhoI or HpaI and introduced into A. oryzae niaD− by means of niaD-based homologous recombination. Protoplasts were prepared from 1-day old mycelial cultures by treatment with Yatalase (Takara Bio Inc.) for 3 h at 30 °C. Transformants that reintroduced the niaD gene as well as the BGL_MK86 gene were selected on Czapek–Dox minimal agar medium plates containing NaNO3 as the sole N source (Senba et al. 2023). Recombinant BGL_MK86 (rBGL_MK86)-producing transformants were cultured in DPY medium, as described above.

Purification of recombinant BGL_MK86 heterologously expressed by A. oryzae

To collect rBGL_MK86 extracellularly produced by A. oryzae transformants, the liquid culture (20 mL/100 mL flask) was vacuum filtered and the filtered solution was dialyzed against 20 mM Tris–HCl buffer (pH 7.5). The dialyzed solution (the crude enzyme preparation) was used for enzyme assay and purification. The crude enzyme preparation (20 mL) including rBGL_MK86 was loaded onto a DEAE-Toyopearl column (1.5 × 20 cm; Tosoh Corp., Tokyo, Japan) equilibrated with 20 mM Tris–HCl buffer (pH 7.5) (buffer A). After washing with 90 mL of buffer A, the β-glucosidase was eluted with a linear gradient of 0–0.3 M NaCl in buffer A at a flow-rate of 1.0 mL min−1. Tris–glycine-SDS–PAGE was performed to check enzyme purity using a 12.5% precast polyacrylamide gel (e-PAGEL precast gel E-T12.5L) with electrophoresis buffer containing 25 mM Tris, 192 mM glycine, and 0.1% (w/v) SDS and an ATTO AE6530 gel electrophoresis system (ATTO Corp., Tokyo, Japan), used according to the manufacturer’s instructions (Fig. S1).

Enzyme assays

β-Glucosidase activity was assayed using the method developed by Riou et al. (1998) with slight modifications. The activity was measured at 40 °C with 1 mM p-nitrophenyl-β-D-glucopyranoside (pNPBG; Sigma Aldrich, St. Louis, MI) as the substrate in 0.1 mL of 100 mM acetate buffer (pH 6.0) and with appropriately diluted enzyme preparation (10 μL). After incubation for 30 min, the reaction was stopped by adding 0.2 mL of 1 M Na2CO3, and the release of p-nitrophenol was measured by determining the absorbance at 400 nm. The results were calculated using the equation obtained from a standard curve. One unit of β-glucosidase activity was defined as the amount of enzyme that yielded 1 μmol of p-nitrophenol per minute in the assay conditions. Hydrolytic activity toward natural substrates such as soluble starch, sodium carboxymethyl cellulose, and laminarin [from Laminaria digitata (Sigma Aldrich) and Eisenia bicyclis (Tokyo Chemical Industry Co., Ltd., Tokyo, Japan)] was determined using previously described methods (Wang et al. 2008) (see Table 1). Briefly, a reaction mixture (100 µL) consisting of appropriately diluted enzyme preparation, 50 mM sodium–citrate buffer (pH 6.0), and 0.5% (w/v) substrate was incubated at 40 °C for 30 min, and the produced reducing sugar was measured using the 3,5-dinitrosalicylic acid method (Miller 1959). D-Glucose (0 to 6.0 mM) was used as the standard reducing sugar. One unit of hydrolytic activity was defined as the amount of enzyme that produced 1 μmol of reducing sugar per minute. Protein concentration was measured by the Lowry method using bovine serum albumin as a standard.

Characterization of recombinant BGL_MK86

The enzyme activity toward pNPBG was assayed using rBGL_MK86 purified as described above, unless otherwise stated.

Effect of NaCl concentration on enzyme activity

Enzyme assay with pNPBG or laminarin from the seaweed (kelp) E. bicyclis as substrate was carried out in a reaction mixture containing NaCl [0%‒18.2% (w/v) final concentration].

Effect of glucose concentration on enzyme activity

Enzyme assay was carried out in a reaction mixture containing D-glucose [0‒18.2% (w/v) final concentration].

Effect of pH on enzyme activity and stability

Enzyme assay was carried out at pH 4.0–10.0 in the following 100 mM buffers: sodium acetate (pH 4.0–6.0), MES (2-morpholinoethanesulfonic acid, monohydrate)–NaOH (pH 5.5–7.0), sodium potassium phosphate (pH 5.0–8.0), Tris–HCl (pH 7.5–9.0), and glycine–NaOH (pH 9.0–10.0). The pH stability of the enzyme was determined by dialyzing rBGL_MK86 against the buffers listed above at 4 °C for 15 h and then measuring the residual enzyme activity at pH 6.0 and 40 °C.

Effect of temperature on enzyme activity and stability

The effect of temperature on enzyme activity was determined in the range 20–65 °C. To determine thermal stability, purified enzyme was preincubated at various temperatures (20–95 °C) for 1 h, and residual activities were measured at pH 6.0 and 40 °C.

Determination of kinetic parameters

Kinetic parameters were determined by performing steady-state kinetic studies without and with 3.6%, 7.3%, 10.9%, 14.5%, and 18.2% (w/v) NaCl (see Table 2).

Detection of enzymatic reaction product by thin-layer chromatography (TLC)

A reaction mixture (100 µL) consisting of the enzyme preparation, 50 mM sodium–citrate buffer (pH 6.0), and 10 mg mL−1 laminaribiose or gentiobiose was incubated at 40 °C. The reaction mixture was mixed with an equal volume of ethanol. TLC was performed on Merck silica gel 60F254 plates (Merck KGaA, Darmstadt, Germany). The substrate and its reaction products were chromatographed with mobile solvent (n-butanol/acetic acid/water = 2:1:1, v/v/v). The TLC plate was sprayed with detection reagent (sulfuric acid/ethanol = 1:9, v/v) and incubated on a hotplate at 130 °C.

Hydrolysis of crude and partially purified laminarin from E. bicyclis

Extraction and partial purification of laminarin from E. bicyclis was carried out using a modified version of previously reported procedures (Miyanishi et al. 2004). Briefly, desiccated seaweed samples (2.5 g) were stirred in 25 mL of 0.09 M HCl at 0 °C for 2 h. The resulting solution was centrifuged at 3000 × g for 5 min, and the resulting precipitate was washed twice with 5 mL of 0.05 M HCl. The supernatant and washing solutions were combined to obtain the combined laminarin solution, which was then neutralized with 0.05 M NaOH. This solution was mixed with an equal volume of water to obtain crude laminarin solution 1 (see Table 3). The combined solution was also neutralized with 0.05 M NaOH and then mixed with an equal volume of 100 mM sodium citrate buffer (pH 6.0) to obtain crude laminarin solution 2 (see Table 3). In addition, the combined solution was adjusted to an 85% (v/v) ethanol concentration, and the resulting precipitate was recovered by centrifugation at 3,000 × g for 5 min. The precipitate was washed twice with 5 mL of methanol and five times with 40 mL of ether. Finally, the precipitate was dissolved in 50 mM sodium citrate buffer (pH 6.0) to obtain partially purified laminarin solution (solution 3; see Table 3). The hydrolysis of crude and partially purified laminarin from E. bicyclis was evaluated using the enzyme assay described above.

Statistical analysis

All experiments were performed in duplicate and replicated at least three times. All data were calculated as the mean ± standard deviation. Analysis of variance (ANOVA) was selected to test value differences (p < 0.05). For comparison of different groups, the data were analyzed using one-way ANOVA and Tukey’s multiple comparison. All calculations were conducted using GraphPad Prism software (ver. 6.02 for Windows, La Jolla, CA, USA).

Results and discussion

Isolation of salt-tolerant β-glucosidase from A. chevalieri MK86

LC-MSMS Mascot analysis identified lipolytic enzymes involved in katsuobushi fermentation and ripening, as well as putative β-glucosidases, based on our in-house sequence database of A. chevalieri MK86 (Takenaka et al. 2021). To further investigate these extracellularly produced β-glucosidases, crude enzyme preparations were obtained from solid-state culture of A. chevalieri strain MK86 and active fractions were purified (Fig. S1). From the purified enzymes, a salt-tolerant type of β-glucosidase, designated BGL_MK86, was selected (Fig. S1, Table S1). BGL_MK86 had approximately 110% activity toward pNPBG in the presence of 18.2% (w/v) NaCl compared with the absence of NaCl.

A 1359-bp fragment was amplified from genomic DNA of strain MK86 with primers BGL_MK86F and BGL_MK86R, with two introns interrupting the coding sequence. The full-length cDNA of BGL_MK86 was obtained by reverse transcription-PCR using the same primers and contains an open reading frame of 1248 bp (LC767509). SignalP analysis (http://www.cbs.dtu.dk/services/SignalP/) indicated the presence of an N-terminal signal peptide (amino acid residues 1-22). The mature BGL_MK86 protein contains 393 amino acid residues with a calculated molecular mass of 43.4 kDa, which is consistent with the purified enzyme on SDS-PAGE (Fig. S1). Based on analysis using the ExPASy server (http://web.expasy.org/protparam/), the theoretical isoelectronic point (pI), instability index, aliphatic index, and grand average hydropathy of the mature enzyme were 4.51, 24.20, 80.61, and -0.348, respectively. Protein–protein BLAST search against the UniProtKB/SwissProt database, along with the glucose tolerance described below, indicated that BGL_MK86 probably belongs to the aryl-phospho-β-D-glucosidases (also called BglC).

The SWISS-MODEL web server was used to perform structural modeling of BGL_MK86 using BglC from Candida albicans [PDB ID, 2PB1; Global Model Quality Estimate, 0.82; identity, 43% (170/393 amino acids (a.a.))] (Fig. S2), which belongs to glycosyl hydrolase family (GH) 5, as the template. The two catalytic glutamate residues [the nucleophile (Glu209) and proton donor (Glu307)] and other amino acid residues, Arg113, His156, Asn208, His267, Tyr269, and Trp371 in BGL_MK86 were conserved in C. albicans BglC (Cutfield et al. 1999) (Fig. S2). The (β/α)8-barrel structure, commonly observed in structurally characterized clan GH-A β-glucosidases (families GH 1, 5, and 30), was present in the structural model of BGL_MK86. Docking structure analysis of BGL_MK86 with BglC from C. albicans was carried out (Fig. S2). It revealed no significant interaction of the enzymatic reaction product glucose with active site residues, as suggested by Zada et al. (2021) (Fig. S2). This observation could explain the glucose tolerance observed for BGL_MK86.

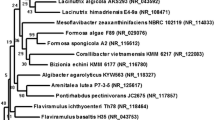

Phylogenetic analysis revealed that BGL_MK86 is closely related to the putative BglCs from A. ruber CBS135680 (XP_040638068) and A. terreus NIH2624 (Q0CR35) that belong to family GH5 (Fig. 1). A. ruber and A. terreus were categorized as xerophilic (Marvig et al. 2014; Oritiz-Lemus et al. 2021) and/or salt-tolerant fungi (Zhao et al 2016). Therefore, these putative BglCs may also be stable and exhibit activity in moderately-high-salt conditions.

Phylogenetic analysis of BGL_MK86 from Aspergillus chevalieri MK86 and β-glucosidases from Aspergillus spp. Multiple alignment of amino acid sequences was performed using GENETYX software ver. 14.0 (Genetyx Corp., Tokyo, Japan) and an unrooted phylogenetic tree was constructed using the neighbor-joining algorithm. Abbreviations: A. chevalieri_BGL_MK86, BglC from A. chevalieri MK86 (this study); A. clavatus_A1CRV0 [origin A. clavatus NRRL1, accession no. A1CRV0, identity (%) with BGL_MK86 56% (235/417 amino acids (a.a.))]; A. fischer_A1D4Q5 [A. fischer NRRL181, A1D4Q5, 56% (238/418 a.a.)]; A. flavus_B8N151 [A. flavus NRRL3357, B8N151, 60% (235/388 a.a.)]; A. fumigatus_Q4WK60 [A. fumigatus Af293, Q4WK60, 56% (236/418 a.a.)]; A. nidulans_Q5B5X8 [A. nidulans FGSC A4, Q5B5X8, 59% (226/378 a.a.)]; A. niger_A2RAR6 [A. niger CBS513.88, A2RAR6, 56% (236/416 a.a.)]; A. oryzae_XP_001820101 [A. oryzae RIB40, XP_001820101, 60% (235/388 a.a.)]; A. ruber_XP_04063068 [A. ruber CBS135.680, XP_04063068, 89% (373/416 a.a.)]; A. sydowii_XP_04073956 [A. sydowii CBS593.65, XP_04073956, 57% (240/416 a.a.)]; A. trreus_Q0CR35 [A. terreus NHI2624, Q0CR35, 56% (237/419 a.a.)]

Characterization of rBGL_MK86

Recombinant BGL_MK86 (rBGL_MK86) was secreted following heterologous expression in A. oryzae and purified through a single-column chromatography step, resulting in a 100-fold purification with an overall yield of 32.5% (Table S2). Notably, rBGL_MK86 production was significantly higher (4.4 mg from 20 mL of filtered culture) than that of the native BGL_MK86 from A. chevalieri strain MK86 (0.11 mg from 150 mL of crude enzyme preparation). rBGL_MK86 showed increasing activity toward pNPBG and laminarin from L. digitata with increasing NaCl concentration, indicating salt-tolerance (Fig. 2a); this salt-tolerance was clear via an increase in both substrate affinity (Km) and the turnover number of rBGL_MK86 (kcat) (Table 2). While salt-tolerant GH1 β-glucosidases have been characterized from Thermobifida halotolerans YIM 90462 (Yin et al. 2021), Alteromonas sp. L82 (Sun et al. 2018), and Bacteroides cellulosilyticus DSM 2522 (Wu et al. 2018), the effect of NaCl on the kinetic parameters of these enzymes is not well understood. The salt-tolerant GH1 β-glucosidase from Bacillus sp. SJ-10 exhibited high activity toward pNPBG in the presence of 15% (w/v) NaCl and a kinetic profile similar to that of rBGL_MK86 (Lee et al. 2015), but the underlying mechanism remains unclear (Lee et al. 2015).

Factors affecting enzymatic activity and stability of rBGL_MK86. a Effect of NaCl The effect of NaCl on hydrolysis of p-nitrophenyl-β-D-glucopyranoside (pNPBG) and laminarin from Laminaria digitata was determined at 40 °C for 30 min in a reaction mixture without and with NaCl. The relative activities were calculated based on the hydrolytic activities toward pNPBG (0.058 U/mg) and laminarin (1.2 U/mg) in the absence of NaCl. b Effect of D-glucose The effect of D-glucose on hydrolysis of pNPBG was determined at 40 °C for 30 min in a reaction mixture without and with D-glucose. The relative activities were calculated based on the hydrolytic activity toward pNPBG (0.058 U/mg). c Effect of pH Enzyme assays using pNPBG were carried out over pH range 4.0–10.0 at 40 °C for 30 min in the following 100 mM buffers: sodium acetate (pH 4.0–6.0, cyan), MES–NaOH (pH 5.5–7.0, orange), sodium potassium phosphate (pH 5.0–8.0, black), Tris–HCl (pH 7.5–9.0, yellow), and glycine–NaOH (pH 9.0–10.0, green). The relative activities were calculated based on the hydrolytic activity toward pNPBG at pH 5.5 (0.063 U/mg). d pH stability The purified enzyme was incubated at various pHs for 15 h, in the following 100 mM buffers: sodium acetate (pH 4.0–6.0, cyan), MES–NaOH (pH 5.5–7.0, orange), sodium potassium phosphate (pH 5.0–8.0, black), Tris–HCl (pH 7.5–9.0, yellow), and glycine–NaOH (pH 9.0–10.0, green); the residual activity toward pNPBG was measured at pH 6.0. The relative activities were calculated based on the hydrolytic activity toward pNPBG of enzyme preincubated at pH 6.5 (0.064 U/mg). e Temperature The effect of temperature on the activity of the purified enzyme was determined at 20–65 °C. The relative activities were calculated based on the hydrolytic activity toward pNPBG at 45 °C (0.067 U/mg). f Thermostability The stability was evaluated by preincubating purified enzyme at 20–95 °C for 30 min; the residual activity toward pNPBG was then measured at pH 6.0. The relative activities were calculated based on the hydrolytic activity of enzyme preincubated at 40 °C (0.058 U/mg)

rBGL_MK86 was categorized as a glucose-tolerant β-glucosidase based on its response to glucose, and as a GH1 family β-glucosidase in clan GH-A (Salgado et al. 2018) (Fig. 2b). Its pH stability was broader than that of the GH1 family β-glucosidases from T. halotolerans YIM 90462, Alteromonas sp. L82, Bacteroides cellulosilyticus DSM 2522, and Bacillus sp. SJ-10 (Fig. 2c and d). However, there were no significant differences in thermostability and optimum reaction temperature among the five enzymes including rBGL_MK86 (Fig. 2e and f). In addition to hydrolyzing pNPBG, rBGL_MK86 showed activity toward p-nitrophenyl-β-D-xylopyranoside and laminaribiose (β-1,3-linked glucose dimer) (Fig. 3), but not cellobiose (β-1,4 linked glucose dimer) or gentiobiose (β-1,6 linked glucose dimer) (Table 1). rBGL_MK86 showed higher activity toward laminarin (a linear polymer of β-1,3 glucan) from the seaweed L. digitata than laminarin (β-1,3/β-1,6 glucan) from E. bicyclis, likely due to its inability to act on gentiobiose. TLC analysis indicated that rBGL_MK86 had transglycosylation activity and produced glucose from laminaribiose, consistent with the properties of exoglucanases (Guo et al. 2015; Jiang et al. 2016; Kim et al. 2018).

Thin-layer chromatography (TLC) analysis of hydrolysis of laminaribiose by rBGL_MK86. Products were analyzed by TLC (Silica Gel 60 F254) with n-butanol-acetic acid–water (2:1:1, v/v/v) as the solvent. Plates were visualized by exposure to 10% sulfuric acid in ethanol. Lanes: G1, D-glucose; L2, laminaribiose; G2, gentiobiose; 0, 0.25, 0.5, 1, and 2, reaction time of incubation of laminaribiose with rBGL_MK86 (in h)

Proposed molecular mechanism of salt adaptation in salt-tolerant BGL

Enzymes that are halophilic or salt-tolerant typically have a higher proportion of acidic amino acids (Asp and Glu) located on the protein surface than non-halophilic/salt-tolerant enzymes (Gao et al. 2018, 2020; Mokashe et al. 2018). This results in a reduction in the theoretical pI and an increase in the hydration of the protein surface (Gao et al. 2018, 2020; Mokashe et al. 2018). As noted above, the molecular mechanism responsible for the salt tolerance of β-glucosidases is not yet fully understood. However, Cai et al. (2019) proposed that Glu492, which is located close to the acid/base active site residue Glu493, may contribute to the halophilic properties of β-glucosidase 2 (MH744150) from A. niger ZJUBE-1 (Cai et al. 2019). Although there is no non-salt-tolerant β-glucosidase that shows high similarity to BGL_MK86, C. albicans BglC was chosen for comparison. The number of acidic amino acid residues in BGL_MK86 and C. albicans BglC was 59 and 45, respectively, and the theoretical pI of BGL_MK86 (4.51) was lower than that of C. albicans BglC (5.35). The pIs of the BglCs from A. ruber CBS135680 and A. terreus NIH2624, which belong to the same group as BGL_MK86 (Fig. 1) were 4.31 and 4.41, respectively. Further experimental studies are needed to test the salt tolerance of C. albicans BglC, but it is possible that acidic amino acid residues contribute to the salt tolerance of BGL_MK86 and other salt tolerant β-glucosidases.

Effect of NaCl on hydrolysis of laminarin from E. bicyclis by rBGL_MK86

The halophilic β-glucosidase from Trichoderma harzianum HTASA has shown potential for saccharification of cellulosic raw materials in the presence of NaCl in practical conditions (Sun et al. 2022). To investigate the salt-tolerance characteristics of rBGL_MK86, its hydrolytic activity profiles were examined using various grades of laminarin from E. bicyclis as substrate (Tables 3 and 4). Partially purified laminarin (0.32 g) was obtained from 2.5 g of dried E. bicyclis as described in Materials and methods. Crude laminarin solutions 1 and 2 (see Table 3) were prepared by subjecting the partially purified laminarin to HCl treatment and NaOH neutralization. After neutralization, these solutions contained approximately 0.079 M NaCl [equivalent to 0.46% (w/v) NaCl] and 0.91% (w/v) laminarin. Enzymatic hydrolysis by rBGL_MK86 was performed using this crude laminarin solution diluted twofold with water (to form solution 1) or citrate buffer (solution 2, Table 3). rBGL_MK86 exhibited its highest activity toward partially purified E. bicyclis laminarin (solution 3, Table 3). The hydrolysis of the crude laminarin samples showed no significant difference compared with hydrolysis of commercially obtained E. bicyclis laminarin (solution 4, Table 3). The hydrolysis capability of rBGL_MK86 for the crude laminarin was investigated (Fig. 4). The total sugar content in the crude laminarin solution (solution 2, refer to Table 3), measured using the phenol–sulfuric acid method, was determined to be 8.33 ± 0.55 mg/ml (as D-glucose equivalent). During the 5 h-reaction period, continuous production of reducing sugars, predominantly consisting of D-glucose, was observed through hydrolysis of the crude laminarin by rBGL_MK86 (Fig. 4). However, the increase reached a plateau after that. It was estimated that 37.5% of the crude laminarin in the reaction mixture was released as reducing sugar, mainly D-glucose (Fig. 4). Further investigation of the hydrolysis profiles of the crude laminarin in combination with other endo-acting enzymes is required for efficient saccharification.

Time course of crude laminarin hydrolysis by rBGL_MK86. The reactions were performed in 50 mM citrate buffer (pH 6.0) at 40 °C with the crude laminarin solution s (see Table 3) and the purified rBGL_MK86 (0.4 U/ml). Total sugar content measured by the phenol–sulfuric acid method was 4.16 ± 0.28 mg/ml (as D-glucose equivalent) in the initial reaction mixture. a Measurement of reducing sugars Produced reducing sugars (as D-glucose equivalent) were measured using the 3,5-dinitrosalicylic acid method. b TLC analysis for products The products formed in the reaction mixture were analyzed by TLC, as described in the legend of Fig. 3

Additionally, the effect of NaCl concentration on laminarin hydrolysis was investigated (Table 4). rBGL_MK86 showed approximately 80% relative activity at the same salt concentration as seawater [around 3.5% (w/v) NaCl]. These findings indicate that rBGL_MK86 exhibits salt-tolerant characteristics and can effectively hydrolyze laminarin from E. bicyclis. The ability of the enzyme to tolerate high salt concentrations might provide potential advantages for the production of oligosaccharides from crude and/or pretreated laminarin.

Conclusions

In this study, a salt-tolerant β-glucosidase (named BGL_MK86) from the xerophilic mold A. chevalieri MK86 was identified and characterized. Phylogenetic analysis showed that BGL_MK86 belongs to the aryl-phospho-β-D-glucosidase (BglC) family. The recombinant enzyme (rBGL_MK86) displayed broad pH tolerance and glucose tolerance, making it a versatile enzyme for various biocatalytic applications. Additionally, rBGL_MK86 showed the ability to hydrolyze crude laminarin preparations in the presence of NaCl, indicating its potential for use in the saccharification of marine biomass. Overall, these properties make rBGL_MK86 a promising candidate for inclusion in enzyme cocktails for industrial bioprocessing.

Data availability

No applicable.

References

Cai LN, Xu SN, Lu T et al (2019) Directed expression of halophilic and acidophilic β-glucosidases by introducing homologous constitutive expression cassettes in marine Aspergillus niger. J Biotechnol 292:12–22. https://doi.org/10.1016/j.jbiotec.2018.12.015

Chung D, Yu WJ, Lim JY et al (2022) Characterization of the proteolytic activity of a halophilic Aspergillus reticulatus strain SK1-1 isolated from a solar saltern. Microorganisms 10:29. https://doi.org/10.3390/microorganisms10010029

Cutfield SM, Davies G, Murshudov G et al (1999) The structure of the exo-β-(1,3)-glucanase from Candida albicans in native and bound forms: relationship between a pocket and groove in family 5 glycosyl hydrolases. J Mol Biol 294:771–783. https://doi.org/10.1006/jmbi.1999.3287

Djelid H, Flahaut S, Wauven CV et al (2022) Production of a halotolerant endo-1,4-β-glucanase by a newly isolated Bacillus velezensis H1 on olive mill wastes without pretreatment: purification and characterization of the enzyme. Arch Microbiol 204:681. https://doi.org/10.1007/s00203-022-03300-2

Esawy MA, Awad GEA, Wahab WAA et al (2016) Immobilization of halophilic Aspergillus awamori EM66 exochitinase on grafted k-carrageenan-alginate beads. 3 Biotech 6:29. https://doi.org/10.1007/s13205-015-0333-2

Gao X, Yin Y, Zhou C (2018) Purification, characterisation and salt-tolerance molecular mechanisms of aspartyl aminopeptidase from Aspergillus oryzae 3.042. Food Chem 240:377–385. https://doi.org/10.1002/jsfa.9553

Gao X, Liu E, Yin Y et al (2020) Enhancing activities of salt-tolerant proteases secreted by Aspergillus oryzae using atmospheric and room-temperature plasma mutagenesis. J Agric Food Chem 68:2757–2764. https://doi.org/10.1021/acs.jafc.9b08116

Guo Y, Yan Q, Yang Y et al (2015) Expression and characterization of a novel β-glucosidase, with transglycosylation and exo-β-1,3-glucanase activities, from Rhizomucor miehei. Food Chem 175:431–438. https://doi.org/10.1016/j.foodchem.2014.12.004

Jiang C, Song J, Cong S et al (2016) Expression and characterization of a novel antifungal exo-β-1,3-glucanase from Chaetomium cupreum. Appl Biochem Biotechnol 182:261–275. https://doi.org/10.1007/s12010-016-2325-z

Jiménez-Gómez I, Valdés-Muñoz G, Moreno-Perlin T et al (2020) Haloadaptative responses of Aspergillus sydowii to extreme water deprivation: Morphology, compatible solutes, and oxidative stress at NaCl saturation. J Fungi 6:316. https://doi.org/10.3390/jof6040316

Kim EJ, Fathoni A, Jeong GT et al (2013) Microbacterium oxydans, a novel alginate- and laminarin-degrading bacterium for the reutilization of brown-seaweed waste. J Environ Manage 13:153–159. https://doi.org/10.1016/j.jenvman.2013.08.064

Kim DH, Kim DH, Lee SH et al (2018) A novel β-glucosidase from Saccharophagus degradans 2–40T for the efficient hydrolysis of laminarin from brown macroalgae. Biotechnol Biofuels 11:64. https://doi.org/10.1186/s13068-018-1059-2

Lee JM, Kim YR, Kim JK et al (2015) Characterization of salt-tolerant β-glucosidase with increased thermostability under high salinity conditions from Bacillus sp. SJ-10 isolated from jeotgal, a traditional Korean fermented seafood. Bioprocess Biosyst Eng 38:1335–1346. https://doi.org/10.1007/s00449-015-1375-x

Marvig CL, Kristiansen RM, Madsen, et al (2014) Identification and characterisation of organisms associated with chocolate pralines and sugar syrups used for their production. Int J Food Microbiol 185:167–176. https://doi.org/10.1016/j.ijfoodmicro.2014.05.017

Mesbah NM (2022) Industrial biotechnology based on enzymes from extreme environments. Front Bioeng Biotechnol 10:870083. https://doi.org/10.3389/fbioe.2022.870083

Miller GL (1959) Use dinitrosalycylic acid reagent of determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Miyanishi N, Inaba Y, Okuma H et al (2004) Amperometric determination of laminarin using immobilized β-1,3-glucanase. Biosens Bioelectron 19:557–562. https://doi.org/10.1016/S0956-5663(03)00253-7

Mokashe N, Chaudhari B, Patil P (2018) Operative utility of salt-stable proteases of halophilic and halotolerant bacteria in the biotechnology sector. Int J Biol Macromol 117:493–522. https://doi.org/10.1016/j.ijbiomac.2018.05.217

Musa H, Kasim FH, Gunny AAN et al (2018) Salt-adapted moulds and yeasts: potentials in industrial and environmental biotechnology. Proc Biochem 69:33–44. https://doi.org/10.1016/j.procbio.2018.03.026

Nishikawa A, Senba H, Kimura Y et al (2022) Isolation and characterization of a salt-tolerant γ-glutamyl transpeptidase from xerophilic Aspergillus sydowii. 3 Biotech 12:253. https://doi.org/10.1007/s13205-022-03259-3

Oritiz-Lemus JF, Campoy S, Martín JF (2021) Biological control of mites by xerophile Eurotium species isolated from the surface of dry cured ham and dry beef cecina. J Appl Microbiol 130(665):676. https://doi.org/10.1111/jam.14839

Ortiz-Cortés LY, Ventura-Canseco LMC, Abud-Archila M et al (2021) Evaluation of temperature, pH and nutrient conditions in bacterial growth and extracellular hydrolytic activities of two Alicyclobacillus spp. strains. Arch Microbiol 203:4557–4570. https://doi.org/10.1007/s00203-021-02332-4

Qiu W, Li J, Wei Y et al (2020) Genome sequencing of Aspergillus glaucus ‘CCHA’ provides insights into salt-stress adaptation. Peer J 8:e8609. https://doi.org/10.7717/peerj.8609

Riou C, Salmon JM, Vallier MJ et al (1998) Purification, characterization, and substrate specificity of a novel highly glucose-tolerant β-glucosidase from Aspergillus oryzae. Appl Environ Microbiol 64:3607–3614. https://doi.org/10.1128/AEM.64.10.3607-3614.1998

Roth JCG, Hoeltz M, Benitez LB (2020) Current approaches and trends in the production of microbial cellulases using residual lignocellulosic biomass: a bibliometric analysis of the last 10 years. Arch Microbiol 202:935–951. https://doi.org/10.1007/s00203-019-01796-9

Salgado JCS, Meleiro LP, Carli S et al (2018) Glucose tolerant and glucose stimulated β-glucosidases–A review. Bioresour Technol 267:704–713. https://doi.org/10.1016/j.biortech.2018.07.137

Schwentke J, Sabel A, Petri A et al (2014) The yeast Wickerhamomyces anomalus AS1 secretes a multifunctional exo-β-1,3-glucanase with implications for winemaking. Yeast 31:349–359. https://doi.org/10.1002/yea.3029

Senba H, Nishikawa A, Kimura Y et al (2023) Improvement in salt-tolerance of Aspergillus oryzae γ-glutamyl transpeptidase via protein chimerization with Aspergillus sydowii homolog. Enzym Microb Technol 167:110240. https://doi.org/10.1016/j.enzmictec.2023.110240

Solat N, Shafiei M (2021) A novel pH and thermo-tolerant halophilic alpha-amylase from moderate halophile Nesterenkonia sp. strain F: gene analysis, molecular cloning, heterologous expression and biochemical characterization. Arch Microbiol 203:3641–3655. https://doi.org/10.1007/s00203-021-02359-7

Sun J, Wang W, Yao C et al (2018) Overexpression and characterization of a novel cold-adapted and salt-tolerant GH1 β-glucosidase from the marine bacterium Alteromonas sp. L82. J Microbiol 56:656–664. https://doi.org/10.1007/s12275-018-8018-2

Sun N, Liu X, Zhang B et al (2022) Characterization of a novel recombinant halophilic β-glucosidase of Trichoderma harzianum derived from Hainan mangrove. BMC Microbiol 22:185. https://doi.org/10.1186/s12866-022-02596-w

Takenaka S, Ogawa C, Uemura M et al (2021) Identification and characterization of extracellular enzymes secreted by Aspergillus spp. involved in lipolysis and lipid-antioxidation during katsuobushi fermentation and ripening. Int J Food Microbiol 353:109299. https://doi.org/10.1016/j.ijfoodmicro.2021.109299

Tian YF, Chen YX, Tong X et al (2022) Flavor differences of soybean and defatted soybean fermented soy sauce and its correlation with the enzyme profiles of the kojis. J Sci Food Agric 103:606–615. https://doi.org/10.1002/jsfa.12172

Wang CM, Shyu CL, Ho SP et al (2008) Characterization of a novel thermophilic, cellulose-degrading bacterium Paenibacillus sp. strain B39. Lett Appl Microbiol 47:46–53. https://doi.org/10.1111/j.1472-765X.2008.02385.x

Wang DD, Kim YJ, Hoang VA et al (2015) Paenibacillus puernese sp. nov., a β-glucosidase-producing bacterium isolated from Pu’er tea. Arch Microbiol 198:211–217. https://doi.org/10.1007/s00203-015-1180-6

Wu J, Geng A, Xie R et al (2018) Characterization of cold adapted and ethanol tolerant β-glucosidase from Bacillus cellulosilyticus and its application for directed hydrolysis of cellobiose to ethanol. Int J Biol Mcromol 109:872–879. https://doi.org/10.1016/j.ijbiomac.2017.11.072

Yin YR, Sang P, Xiao M et al (2021) Expression and characterization of a cold-adapted, salt- and glucose-tolerant GH1 β-glucosidase obtained from Thermobifida halotolerans and its use in sugarcane bagasse hydrolysis. Biomass Convers Biorefin 11:1245–1253. https://doi.org/10.1007/s13399-019-00556-5

Zada NS, Belduz AO, Güler HI et al (2021) Cloning, expression, biochemical characterization, and molecular docking studies of a novel glucose tolerant β-glucosidase from Saccharomonospora sp. NB11. Enzyme Microb Technol 148:109799. https://doi.org/10.1016/j.enzmictec.2021.109799

Zhao C, Guo L, Wang L et al (2016) Improving the yield of (+)-terrein from the salt-tolerant Aspergillus terreus PT06-2. World J Microbiol Biotechnol 32:77. https://doi.org/10.1007/s11274-016-2029-0

Acknowledgements

This work was supported by the Japan Society for the Promotion of Science KAKENHI [grant number, 20K05808]. We thank James Allen, DPhil, from Edanz (https://jp.edanz.com/ac) for editing a draft of this manuscript.

Funding

Funding was supported by Japan Society for the Promotion of Science KAKENHI (20K05808).

Author information

Authors and Affiliations

Contributions

HS and DS: Conceptualization, Molecular Biology, Data collection, Writing–original draft preparation. YK, ST, and MD: Conceptualization, Reviewing–original draft. ST: Conceptualization, Bioinformatics, Writing –Reviewing and Editing. All authors reviewed the final version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The author declares that have no conflict of interest.

Additional information

Communicated by Nischitha R.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Senba, H., Saito, D., Kimura, Y. et al. Heterologous expression and characterization of salt-tolerant β-glucosidase from xerophilic Aspergillus chevalieri for hydrolysis of marine biomass. Arch Microbiol 205, 310 (2023). https://doi.org/10.1007/s00203-023-03648-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00203-023-03648-z