Abstract

The reliability of machine tools is highly influenced by the cutting state. The traditional recognition method of cutting state is emphasized on a single classifier, which has the weakness of low identification accuracy and strong randomness. This paper proposes a cutting-state identification method based on improved Dempster-Shafer (DS) evidence theory. This method is divided into multi-classifier preliminary-diagnosis layer and improved DS information-fusion layer. The wavelet packet analysis method is extracted as the input of multi-classifier (Back Propagation (BP) neural network, genetic algorithm (GA) optimized BP neural network and thinking evolution (mind evolutionary algorithms) MEA optimized BP neural network). After the preliminary judgment, the improved DS information-fusion method is integrated as the final judgment, and finally, the effectiveness and feasibility of the method are verified.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

In the cutting process of machine tools, the cutting state has a great influence on the cutting process, especially the cutting chatter. As a kind of cutting state, its existence has a great influence on the surface quality and machining efficiency of the workpiece and even causes the damage to the tool and the machine tool. Therefore, it is of great significance to monitor and identify the cutting state.

With the continuous development of artificial intelligence technology and bionic optimization technology, artificial intelligence algorithm has been widely used in state recognition. Many scholars have conducted researches in cutting-state identification. Tong et al. analyzed the collected signal by measuring the noise signal in the cutting process, using the time domain and frequency domain methods, and gave suggestions for parameter modification through the analysis results [1]. Xie et al. conducted time–frequency analysis on the cutting signal, divided the cutting process into three states (stability, transition, and chatter), and calculated the root-mean-square values of each state through wavelet packet decomposition, and finally established a (Back Propagation) BP neural network recognition model for state recognition [2]. Li et al. fused wavelet packet and Hilbert-Huang transform extracted signal features from energy frequency and amplitude probability statistics and established fuzzy support vector machine diagnosis model for flutter identification [3]. Somkiat et al. proposed a threshold method to identify the chatter [4]. They calculated the values of three parameters in the cutting process to obtain the reference feature space and determined the threshold for cutting-state classification. Furthermore, they also developed a tool measuring machine to realize recognition and classification in actual turning. Gao H et al. constructed the vibration data sets of different chatter states [5]. They established the support vector machine model of chatter recognition with the physical vibration signal as input. By introducing the support vector machine, the extracted features are classified, and the online cutting chatter recognition algorithm is established. Yunfeng Xie et al. aiming at solving the measurement uncertainty problem in flutter processing signal and the model uncertainty problem in recognition model, the generalized interval uncertainty analysis method is used to extract the time–frequency feature, and the generalized BP neural network recognition model is established for effective recognition [6].

In summary, researchers usually use the time–frequency and energy feature of vibration signal as the recognition benchmark, therefore establishing a single classifier recognition model through artificial intelligence algorithm to identify the cutting state of machine tools. However, the recognition model of a single classifier has the problems of low accuracy, strong randomness, and poor robustness. In order to overcome the defects of single classifier, researchers proposed the method of information fusion. DS (Dempster Shafer) evidence theory information fusion is the most widely used method. Generally, decision fusion methods are divided into neural networks, Bayes, fuzzy probability, and DS theory. Among them, prior data required by the DS theory are more intuitive and easier to obtain than those in probability reasoning theory, and fewer conditions are required compared to the Bayes probability theory. In addition, with the Dempster’s rule, multiple subjects can be integrated and ability to express “uncertainty” directly. Therefore, DS theory has important advantages in decision fusion [7]. It has been widely implemented in many fields, such as the following: mechanical sensor fault diagnosis fusion method based on DS theory [8]. But the traditional DS information fusion method has certain judgment defects in evidence conflict. To address this issue, many improved algorithms have been proposed by scholars, for example: Combined with neural networks, the new DS method is used to diagnosis the bearing fault [9]. Fault diagnosis method of numerically controlled machine tool was based on grey cluster analysis and rough set theory, etc. [10].

In this paper, we propose a machine tool cutting-state recognition method based on an improved DS evidence theory. The state recognition is carried out by establishing a preliminary diagnosis layer combined with wavelet packet and multiple classifiers, and an improved fusion diagnosis layer of DS information fusion. Finally, this method is verified by actual milling experiments.

2 Construction of cutting-state recognition system

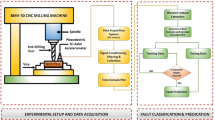

The cutting-state recognition system is shown in Fig. 1. The system includes four parts: cutting table, signal acquisition, signal preprocessing, and model establishment. In the signal acquisition part, the acceleration sensor is used for vibration signal acquisition; in the signal preprocessing part, the wavelet packet analysis method is used to extract the energy feature of the collected cutting-state vibration signal. In the part of model establishment, the initial diagnosis layer of multi-classifier and the fusion diagnosis layer based on improved DS information fusion are established for recognition and judgment.

3 Wavelet packet analysis

In the actual cutting process, the collected cutting vibration signal has the characteristics of nonlinearity and randomness, and the occurrence of chatter state in the cutting process is a process of the energy of acceleration signal moving from high frequency to low frequency, so it is important to select the signal analysis method. In the existing methods, wavelet packet analysis is a more precise analysis method. Compared with Fourier transform, in the occasions of dividing the multi-level signals, wavelet packet analysis can decompose the high-frequency part without multi-frequency subdivision; in the occasions of analyzing the energy characteristics, the frequency band of signal can be adaptively selected according to its signal characteristics [11].

Wavelet packet analysis of vibration signals is divided into two parts: decomposition and reconstruction. The decomposition (Eq. (1)) and reconstruction (Eq. (2)) equations are as follows:

\({a}_{k-2l}\ {and\ b}_{k-2l}\) are the Wavelet packet decomposition coefficients.

Thus, the reconstructed Wavelet Packet Equation is:

4 Improved DS information fusion recognition model

4.1 Improved DS evidence theory

4.1.1 DS theory

DS theory was proposed by Dempster in 1967 and then improved by his student Shafer, which is used to deal with uncertainty problems [12]. It has strong advantages in multi-sensor and multi-classifier information fusion. It mainly includes identification framework, basic probability distribution function BPA (Mass function), reliability function (Bel), and likelihood function (PI).

All sets of the identification framework with uncertainty are set as U, and all possible combinations are 2U. The state identified in this paper is comprised of three structures; thus, different combinations are not involved. The basic probability distribution function is the probability corresponding to a result, which is usually expressed by m function and satisfies:

The reliability function is the sum of probabilities of all subsets of a hypothetical result, and the likelihood function is the sum of probabilities of null intersection with this assumption, which is expressed as:

The key point of DS evidence theory is the combination rule, which is essentially the combination of the output results of multiple subjects. The combination rule between evidence bodies is defined as:

In the formula, k is the conflict factor of evidence theory, and the corresponding 1/(1 − k) is the normalized coefficient, which is the conflict relation between the evidence bodies. The range of 1/(1 − k) is [0,1]; n is the number of large events.

4.1.2 Improved DS evidence theory based on Pearson correlation coefficient

The traditional DS evidence theory has certain defects. When there is a large or complete conflict between the evidence bodies, the fusion results cannot be well judged. Therefore, many researchers pay their attentions on improving the traditional DS information fusion method.

This paper selects the improved DS evidence theory based on Pearson correlation coefficient proposed by Huan Zhang, in which the overall weight ratio column between each evidence body can be calculated and allocated through Pearson correlation coefficient; finally, the basic probability distribution between the original evidence body is corrected [13]. The correlation coefficient S12 is expressed as:

In Formula (8), m1 and m2 are two evidential bodies, cov is the covariance between evidential bodies, and E is the mathematical expectation of evidential bodies. When the evidence is multiple, the correlation coefficient matrix is shown as:

Considering that the value range of Pearson correlation coefficient is [−1,1], the correlation is calculated to be negative or zero, and the assignment is 0.001, at which the zero confidence problem in the combination rules can be avoided and the impact of the overall recognition framework on basic probability can be minimized. The credibility of the evidence mi crew is defined as:

The original basic probability distribution BPA is changed by the credibility of the evidence. The changed BPA * is:

After the correction is completed, the zero-factor correction of the 0 value in BPA is needed again. Finally, the DS combination rule is used to calculate the propositional support value.

4.2 Identification model

4.2.1 Preliminary judgment layer based on multi-classifiers

The preliminary diagnosis layer is divided in two parts. One part is to extract the energy feature of the collected vibration signal of cutting through wavelet packet analysis. The second part is to establish a multi-classifier composed of BP neural network, genetic algorithm (GA), optimized BP neural network, mind evolutionary algorithms (MEA), and optimized BP neural network. The extracted energy features were input into a classifier for preliminary classification and diagnosis, and then the diagnosis results were input as the evidence body of the fusion diagnosis layer.

-

(1)

BP neural network (BP neural network) [14,15,16,17,18] is a kind of error backpropagation neural network. Its structure is a one-way propagation multilayer feed-forward network, also known as multilayer perception, which is widely used in engineering to deal with nonlinear and complex systems. The single classifier established by BP neural network for state recognition is prone to randomness and low recognition rate.

-

(2)

GA-optimized BP neural network obtains the optimal initial weights and thresholds of the network through selection, crossover, and mutation operations. These can effectively solve the problem of slow convergence of the BP network and make the BP network have a certain dynamic adaptability. However, the programming implementation of genetic algorithm is complex, which depends on the initial population, resulting in a long training time for obtaining accurate classification results.

-

(3)

MEA optimized the BP neural network by selecting the reciprocal of the mean square error of the training set as the scoring function of each individual and population, using the mind evolution algorithm, after continuous iteration, the optimal individual is output. And this is used as the initial weight and threshold of the neural network to train the BP neural network. But this thinking evolution is too blind and mechanical when producing subpopulations, which is resulting in duplication in search.

The above three classifiers are widely used in recognition and classification, but they all have their own defects and the accuracy of a single classifier is not high.

4.2.2 Fusion judgment layer based on improved DS evidence theory

The classification results of each classifier in the preliminary diagnosis layer are used as the evidence body of the fusion diagnosis layer, and the information fusion is carried out through the improved DS evidence theory. Specific steps are as follows:

-

a)

Establish a recognition framework based on the type of cutting state, expressed as U = {A1, A2,…, An}, where n is the type of cutting state

-

b)

Evidence extraction input, which inputs the results of the three classifiers at the preliminary diagnostic level into the evidence body, namely Ei (i = 1, 2, 3)

-

c)

Determine the values of basic trust allocation function of the identification framework. Pearson correlation coefficient is used to calculate the correlation between individual evidence bodies, and the basic trust distribution value of evidence bodies is allocated and corrected.

-

d)

Propositional support calculated using DS combination rules.

-

e)

Determine the state type.

In summary, the flowchart of cutting-state recognition based on improved DS evidence theory is shown in Fig. 2.

5 Cutting experimental analysis

5.1 Experimental design

For the cutting-state identification method, an experimental platform for milling is designed and built, shown in Fig. 3. The machine too is Nanjing Sikai VMC600 vertical machining center; the milling cutter is made by cemented carbide, which with the teeth of 3 and with the diameter of 8 mm. The work piece is a 6061 aluminum rectangular block with the cross section of 100 mm × 180 mm, which the longitudinal section is trapezoidal. During the experiment, the workpiece is horizontally placed on the operating platform for planar milling. The vibration signal acquisition sensor CT1010L and the acquisition system adopt the automation studio acquisition system.

In the process of milling, combined with the generation mechanism of cutting chatter, the vibration signals corresponding to the three states of cutting are obtained by artificially changing the cutting tool depths under the condition of constant milling speed, feed per tooth and milling width. After many tests and combined with the actual processing, the cutting depth is chosen at 0.5 mm, 1 mm, and 1.5 mm, the cutting speed is chosen at 800 mm/min, and the feed per tooth is chosen at 0.16 mm with the cutting width of 4 mm.

5.2 Cutting-state signal analysis and feature extraction

5.2.1 Cutting-state signal

The chatter generation process is simulated by changing the cutting depth in turn, and the vibration signals of milling process from stable state to chatter are obtained, as shown in Fig. 4. It can be seen from the figure that the vibration signal diagram is divided into three stages. Part one is the stable state, part two is the transition state, and part three is the flutter state. The vibration signal value changes little under the stable state, which is the normal processing; the transition state can also be called the development process of flutter. The vibration signal has some changes and the amplitude also increases, but the change is not obvious. Compared with the stable and transitional stages, the vibration amplitude of the vibration signal in the flutter state changes significantly, and it is judged by the sound of the field processing. At this time, the processing is abnormal.

5.2.2 Feature extraction of cutting state

In order to better identify the accurate state of the cutting process, it is necessary to extract the feature of the collected vibration signal according to the characteristics of the cutting vibration signal. In this paper, the collected vibration signals in the three stages of the cutting chatter occurrence process are divided into 135 groups, 45 groups for each state, and 500 samples for each group. Three-layer wavelet packet analysis and energy feature extraction were performed on each group of signals, and the extraction length was 8. The energy values of each frequency band corresponding to each state obtained by wavelet packet decomposition are shown in Fig. 5.

It can be seen from Fig. 5 that, in the stable stage, the energy is mainly concentrated in the frequency bands of nodes 3 and 6, and in the transition stage, the energy is mainly concentrated in the frequency bands of nodes 2 and 4. Compared with the stable state and the transition stage, the energy in the flutter stage is concentrated on the low frequency bands 2 and 4 as in the transition stage, and its energy ratio is much larger than that in the stable and transition stages, with the maximum ratio of 54%. Overall observation, in the different state of cutting, the proportion of energy value is different; thus, the wavelet packet energy characteristics can be effectively used for state analysis.

5.3 Cutting-state identification

After the feature extraction of three stages of cutting state which is completed by wavelet packet analysis method, the energy features of each group are input into each classifier for preliminary recognition and judgment of cutting state.

In the identification process, each stage also corresponds to 45 groups of feature data, each group containing 8 feature samples, 135 groups in total. In this paper, the first 30 groups of each state are set as the model training set, and the last 15 groups of feature data are set as the model test set. Ninety groups of training sets are trained as the input to each classification model, and the model can identify the bearing state after training. Then 45 groups of test sets are input to the model for testing, and the preliminary identification results are obtained.

Finally, the preliminary identification results of each classifier are used as the evidence body of DS information fusion E = {E1, E2, E3}. E1 is the evidence body constructed by BP neural network, E2 is the evidence body constructed by GA-BP model, and E3 is the evidence body constructed by MEA-BP model. An improved DS information fusion method is used for fusion judgment recognition, and the recognition results are shown in Table 1.

As shown in Table 1, I, II, and III represent the cutting stability state, transition state, and flutter state, respectively. The experimental results show that the cutting-state recognition method based on improved DS information fusion has a remarkable effect. Only one prediction sample in the stable state and two prediction samples in the transition state have recognition errors, and the errors occur at the end of each state, but there is no error in the flutter state recognition. Under the existing experimental samples, the recognition rate of cutting state can reach to 94%. The causes of state recognition errors in the stable and transition stages are analyzed. It can be seen from Figs. 4 and 5 that the signal states of the two state transition parts are similar when intercepting the signal values of the three state stages, which is the main reason of recognition errors.

Finally, under the same experimental conditions, the effectiveness of this method is further proved by comparing the traditional single classifier identification methods (BP, GA-BP, MEA-BP) with the identification methods in this paper. The experimental results are shown in Figs. 6, 7, and 8.

It can be calculated from Figs. 6, 7, and 8 that the prediction accuracy of each classification state under the same experimental conditions and experimental data is shown in Table 2. By comparing with Table 1, it is found that the prediction accuracy of the improved DS information fusion model is much higher than the single one.

6 Conclusions

In this paper, aiming at the problem of cutting-state recognition and the problem of insufficient recognition accuracy of traditional single classifier, a cutting-state recognition method based on multi-classifier and improved DS information fusion is proposed.

-

1)

This method is divided into the preliminary judgment layer and the fusion judgment layer. In the preliminary diagnosis layer, the wavelet packet analysis method is used to analyze the vibration signals of different cutting states and to extract the energy features. The features are used as the input to the multi-classifier model, and the preliminary judgment is made.

-

2)

The preliminary diagnosis results are input as the evidence body of the fusion judgment layer, and the information fusion judgment is carried out through the improved DS evidence theory.

Finally, the experimental verification is carried out, and the comparison test of each single classifier is carried out. The results show that the recognition accuracy of the proposed recognition method can reach over 94%, which effectively solves the problems of insufficient recognition accuracy and strong randomness of the single classifier, and thus, the effectiveness of the recognition method we proposed is proved.

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

Tong R, Liu Q (2015) Chatter recognition and suppression system of NC machining. Modul Mach Tool Autom Manuf Techn 2:117–121

Xie F, Cao Q, Huang Z (2015) Chatter monitoring based on wavelet packet and BP neural network. Instrum Techn Sensor 10:88–90

Li R, Liu Q (2015) Chatter identification in CNC milling based on wallet packet and Hilbert-Huang transform. Comput Integr Manuf Syst 21(1):204–216

Tangjitsitcharoen S, Moriwaki T (2008) Intelligent monitoring and identification of cutting states of chips and chatter on CNC turning machine. J Manuf Process 10(1):40–46

Gao HN, Shen DH, Yu L et al (2020) Identification of cutting chatter through deep learning and classification. Int J Simul Model 19(4):667–677

Xie F, Jiang W et al (2018) Cutting chatter recognition based on generalized BP neural network. JShock Vib 37(5):65–70

Gaoa X, Jiang P, Xie W et al (2021) Decision fusion method for fault diagnosis based on closeness and Dempster-Shafer theory. J Intell Fuzzy Syst 6:1–10

Hui HK, Lim MH, Leong S (2017) Dempster-Shafer based sensor fusion approach for machinery fault diagnosis. In: Proceedings of the ASME 2017 Power Conference, Charlotte, North Carolina, USA

Hui KH, Ooi CS, Meng HL et al (2016) A hybrid artificial neural network with Dempster-Shafer theory for automated bearing fault diagnosis. J Vibroeng 18(7):4409–4418

Ren X, Chen L, Li DS et al (2019) Fault decision of computer numerical control machine system using grey clustering analysis and rough set theory. Adv Mech Eng 11(5):16–87

Wang EH, Bo W et al (2016) Chatter detection in end milling processes based on wavelet packet decomposition and singular spectrum analysis. Mach Tool Hydraul 44(17):191–199

Zhao G, Chen A, Lu G, Liu W (2020) Data fusion algorithm based on fuzzy sets and D-S theory of evidence. Tsinghua Sci Technol 25(1):12–19

Zhang H, Lu J, Tang X (2020) An improved DS evidence theory algorithm for conflict evidence. J Beijing Univ Aeronaut Astronaut 46(3):616–623

Zhang A, Cheng Q, Qi B, Tao Z et al (2021) A general approach for the machining quality evaluation of S-shaped specimen based on POS-SQP algorithm and Monte Carlo method. J Manuf Syst 60:553–568

Niu P, Cheng Q, Zhang C et al (2021) A novel method for machining accuracy reliability and failure sensitivity analysis for multi-axis machine tool. Int J Adv Manuf Technol 152:1–14

Niu P, Cheng Q, Liu Z et al (2021) A machining accuracy improvement approach for a horizontal machining center based on analysis of geometric error characteristics. Int J Adv Manuf Technol 112(9):2873–2887

Qi BB, Cheng Q, Li SL et al (2021) Precision loss of ball screw mechanism under sliding-rolling mixed motion behavior. J Cent South Univ 28(5):1357–1376

Cheng Q, Qi B, Liu Z et al (2019) An accuracy degradation analysis of ball screw mechanism considering time-varying motion and loading working conditions. Mech Mach Theory 134:1–23

Funding

The project is supported by Transformation Program of Scientific and Technological Achievements of HeBei Provence.” The production, integration, and application of the industrial robot” (19041827Z).

Author information

Authors and Affiliations

Contributions

A diagnosis method of cutting state of machine tools based on improved DS algorithm is proposed. By collecting the vibration information of the machine tools and using the DS classifier for information fusion diagnosis, the final machining state of the equipment is accurately judged. Compared with the traditional single classifier, this method greatly improved the reliability of diagnosis.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, B., Sun, Y. Cutting-state identification of machine tools based on improved Dempster-Shafer evidence theory. Int J Adv Manuf Technol 124, 4099–4106 (2023). https://doi.org/10.1007/s00170-022-09056-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09056-9