Abstract

Additive manufacturing (AM) is a group of processes which manufacture a part by adding sequential layers of material on each other. In the last decade, these processes have been extensively applied in industry for constructing small volumes of complex, customized parts. Since parts are built layer-by-layer, the build orientation affects the surface quality and the total cost of the part. The search for optimal build orientation is not trivial since these factors are, typically, in conflict with each other. The major limitation of the methods described in the literature to choose the optimal build direction is in the insufficient accuracy of the estimates of the manufacturing cost and of the surface quality. These factors are very complex to be estimated, and accuracy in their evaluation requires methods that are very time-consuming. On the contrary, in practical use, a multi-objective optimization process requires an objective function that is reliable and easy to be evaluated. In order to overcome these problems, in this paper, original methods to estimate the manufacturing cost and surface quality as a function of build orientation are presented. They are implemented, for the fused deposition modeling (FDM) technology, in a multi-objective optimization problem that is solved by an S-metric selection evolutionary multi-objective algorithm (SMS-EMOA), obtaining an approximation of the Pareto front. The final selection of the recommended orientation is performed by the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) method. Properly designed case studies are used to evaluate the reliability of the proposed method, and the results are compared with the state-of-the-art method to find optimal build orientation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Additive manufacturing (AM) is defined by the ISO/ASTM 52900 [1] as “The process of joining materials to make parts from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing and formative manufacturing methodologies”. These technologies have great potential to produce small volumes of complex, customized parts and have many applications in aerospace, defense, automotive, electronics, tool- and mold-making, energy, and biomedical fields. According to [1], the AM technologies are classified in seven categories: binder jetting, directed energy deposition, material extrusion, material jetting, powder bed fusion, sheet lamination, and vat photo-polymerization. Table 1 shows the most important technologies and used materials for the seven process materials.

All these processes involve the layering of the model, which is a necessary operation to schedule out the actions for the deposition of the material. This operation is performed by assigning a build direction of the object that is orthogonal to the build platform [1]. The selection of the build direction is one of the most important issues involved in AM processes that influences some factors such as the manufacturing cost, build time, support material amount (for technologies such as stereo-lithography (SLA), fused deposition modeling (FDM), and selective laser melting (SLM)), the accuracy, and surface finish of part surfaces [3]. Therefore, the determination of the best build orientation is a challenging problem in the AM setting. Some researchers have focused on obtaining the best or near-optimal build orientation, by considering different objectives. The most important optimization methods published in the related literature can be grouped into three different main categories:

Single-objective optimization [3,4,5,6,7,8]. The optimal build direction is obtained by analyzing separately each of the factors involved in the search for the best direction (volumetric error [1]; cylindricity and flatness errors [5]; support volume [6]; surface quality [7]; build time [8]). The best solution is obtained by optimizing for a single factor, without taking into account the complexity of the conflict with the other factors in the search for the final result.

Multi-objective optimization [9,10,11,12,13,14,15]. By this approach, the objective function is, typically, expressed as a weighted sum of the factors affecting the choice of the optimal build orientation of the part. The weights specify the relative importance of each factor. With the aim to speed-up the identification of the solution, metaheuristics algorithms, such as the genetic algorithm [9, 10, 13, 15] or swarm optimization algorithm [12], are used. These approaches have the problems of convergence and also the low quality of the solutions [16].

Evaluation methods [16,17,18,19,20,21,22]. These are a multi-attribute decision-making problem for which the factors affecting the orientation choice are treated as attributes. Evaluation methods are the most interesting approach to solve the problem here discussed since they analyze the optimization problem in its entirety.

Evaluation methods are based on two main steps [17]:

Identification of a significant set of candidate orientations

Selecting the most suitable one

Both these phases have a significant effect on determining the best build orientation. The candidate orientations are carried out by different criteria, generally using the build time and the surface roughness as attributes of the optimization problem. Padhye and Deb [18, 21] suggested generating the approximations of the Pareto front by means of the non-dominated sorting genetic algorithm-II (NSGA-II) and multi-objective particle swarm optimizers (MOPSO). Khodaygan and Golmohammadi [22] modeled the problem variables by utilizing the Kriging method and the NSGA-II to obtain the Pareto front. Since the qualities of the decision result highly depend on the qualities of predesigned candidates, in order to extend the space of candidate solutions, Qie et al. [16] proposed the PID feedback control technique based on the quaternion rotation and the user’s requirements. The quaternion rotation is described as an ordered pair q = (s, v), where: \( s=\mathit{\cos}\left(\raisebox{1ex}{$\phi $}\!\left/ \!\raisebox{-1ex}{$2$}\right.\right) \), \( \boldsymbol{v}=\boldsymbol{u}\bullet \mathit{\sin}\left(\raisebox{1ex}{$\phi $}\!\left/ \!\raisebox{-1ex}{$2$}\right.\right) \), ϕ = given angle and u = unit vector of the fixed axis.

The selection of the best build direction among the alternative orientations is carried out according to the ranking of results by applying one the following three techniques:

Three decision-making techniques, including aspiration point, marginal utility, and L2 metric [18, 21].

Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS) approach [22].

Ordered weighted averaging (OWA) operator [16].

Since in this optimization problem the influencing factors (typically they are: surface quality, support volume, and build time) must be evaluated on the geometric model of the object to be built, the trustworthiness of the evaluated best build direction strictly depends on the accuracy of the methods used to estimate them. The published methods in the related literature present some algorithms for the estimation of the typical factors used in the optimization problem: surface quality, build time, and support volume.

Surface quality is often evaluated as the surface roughness that does not take into account the staircase effect [23]. The methods for build time evaluation, usually, do not take into account the complexity of the object or/and the time required for support deposition (for technologies that utilize support structures) [24]. The support volume is generally estimated by a simplified approach or roughly by indirect measures (the sum of the height of the triangles’ barycentre or the total area of the overhanging triangles).

In this paper, a new formulation of the models for the total cost of the part and surface quality evaluation is proposed. Based on them, two conflicting objective functions, defined in terms of build direction, are defined. The optimization problem is formulated, in terms of the simultaneous minimization of both these objectives under some constraints, and it is solved by an evaluation method. The identification of alternative orientations is carried out by an approximation of the Pareto front, obtained by the S-metric selection evolutionary multi-objective algorithm (SMS-EMOA). Among the resulting candidate solutions, the best one is selected by the TOPSIS method.

The proposed method, implemented for the fused deposition modeling (FDM or fused filament fabrication FFF) that is the most widespread technology [20] (for its ease of use, no need for supervision, the use of environmentally safe materials and its cost-effectiveness), is tested for some critical cases and compared with the state-of-the-art.

2 Related works

A reliable and implementable optimization method for the search for the optimal deposition direction requires that all the most important influencing factors are taken into account and that these factors are calculated with good reliability and within a reasonable time frame. The most significant factors used to evaluate the quality of the chosen direction are surface quality, support volume, and build time. These factors are nontrivial to determine, and different approaches can be used to determine them. In this section, the most relevant methods, published in the related literature, are presented and discussed.

2.1 Surface quality estimation methods

Typically, the surface quality of an object obtained with an additive manufacturing technology is calculated as the area-weighted average of the estimated roughness of each triangle [7, 16, 18, 22]. All these methods are affected by a fundamental error: they measure the surface quality with the roughness parameter Ra that does not take into account the staircase effect, as demonstrated in [23]. The staircase effect is the most significant component of the typical surface texture of an object build by AM. For this reason, the choice to use Ra to measure the surface quality misrepresents the real extent of the surface defectiveness, since Ra is obtained by applying a high-pass filter to the primary profile. In order to overcome this limitation, Di Angelo et al. [23] proposed the use of the parameter Pa that evaluates the arithmetical mean deviation of the manufactured profile from the expected smooth profile. In addition, to calculate the value of this parameter for the entire range of angle values, they proposed an approximation of the profile with ellipses. This makes it possible to assess with greater reliability the expected manufacturing error produced by the material deposition process.

2.2 Support volume estimation methods

In some additive manufacturing technologies, such as FDM, SLA, and SLM, support structures are required to sustain overhanging features. Support structures require extra material to be added to the part that has to be removed during the post-processing. The building of the supports affects build time, the total cost of the part, and surface quality. The effect of the supports on the build time and total cost can be evaluated as a function of their volume. The volume and the build time of the supports required to manufacture by AM an assigned 3D geometric model can be estimated by a complete simulation of the manufacturing process. This type of analysis is very time-consuming, and, in practice, it is not suitable for estimating data in optimization methods. For this reason, in recent years, several researchers have proposed methods that approximate this factor by simplified approaches. Khodayan and Golmohammad in [22] approximate the amount of support material with a linear dimension that is the sum of the average of vertical coordinates of the barycenter of downward facets, weighted on areas, and multiplied for the deviation of downward faces from the z-axis (deposition direction). Ga et al. in [25] proposed an indirect 2D measurement of support volume: the sum of the projection onto the build platform of each mesh triangle for which the angle between the normal of the triangle and the deposition direction is greater than 135°. Similar approaches are proposed by Zwier et al. [6] and Singhal et al. [11]. Also, these methods do not use a parameter that can be related to the quantity of material since they do not take into account the height of the supports.

In Qie et al. [16], the total volume is evaluated as the sum of the volume of the build platform and the sum of the volume of triangular prisms and pyramids under triangles requiring support. In the implementation reported in the paper, the method does not to take into account the case in which the supporting prism stands on a part of the same object.

Paul and Anand in [2] proposed a voxel-based approach for calculating support structures. In the algorithm, the object defined by 3D-tessellated surfaces is first converted to a voxel representation. Then, the support volume is calculated as the sum of the volume of a trapped empty voxel. The voxelization of tessellated models, typically, has a high computational costs [19] that is not compatible with optimization method which required many iterations.

2.3 Build time estimation methods

Build time is one of the most important factors considered in the estimation of the manufacturing costs of a part produced by using an AM process. The build time estimation methods presented in the literature are of two types: detailed analysis-based and parametric-based approaches. The former needs that all the operations required by the AM process to manufacture the object are known and their execution times are evaluated. These methods can only be used if combined with the tool path generator, dedicated to a specific AM machine. Since, this process for each build direction, the elaboration process takes a few dozen seconds; as a consequence, these methods are in practice unusable to support the search for the optimal deposition direction.

In the last years, researchers aimed their efforts at the development of parametric models in which the build time is expressed as a function of some driving factors, simple to be evaluated from the analysis of the 3D model of the object to be manufactured. Some of the most significant elements which affect build time can be evaluated relatively easily; for example:

Number of slices necessary to build the object and the ratio of the area of the facets that require support to the total one [6].

The height of the object as oriented in the AM machine and the ratio of the area of the facets that require support to the total one [11].

The height of the object as oriented in the AM machine and the mean value of the support height [22].

The height of the object and the diagonal of the bounding box as oriented in the AM [13].

These factors do not include the object complexity that sometimes can affect widely the build time estimations. Di Angelo and Di Stefano [24] proposed a more complete model for build time estimation for the fused deposition modeling (FDM) technology, proposed to be used in e-commerce. Although this method is more complex than others proposed in the literature, it includes parameters that are easy to evaluate. This method requires, however, the generation of the external surfaces of the support volume; this phase is too time-consuming for its implementation in optimization methods.

Based on previous considerations, a modified version of this method has been used to estimate build time in this work.

3 The proposed evaluation method

Most engineering optimization problems have several objectives to be optimized at the same time. The problems in which the objectives are usually conflicting in nature are identified as multi-objective optimization problems (MOPs) and are defined as follows [26]:

involving (p ≥ 2) conflicting objective function fi : ℝn ⟶ ℝ, which must be minimized simultaneously. The decision vectors x = (x1, x2, …., xn)T belong to the nonempty feasible region X ⊂ ℝn. Objective vectors are images of decision vectors and consist of objective values z = F(x) = (f1(x), f2(x), …, fp(x))T. In multi-objective optimization, a decision vector x′ ∈ X is called Pareto optimal solution if:

In this case, F(x′) is called a non-dominated point, and the set of all non-dominated points is called the Pareto front. Since the Pareto front is often an infinite set of points, a suitable approximation must be used to obtain a manageable number of Pareto optimal solutions, whose images under F are uniformly distributed on the complete Pareto front. Then, a decision-maker, by analyzing a specified number of the Pareto optimal solutions, selects a final solution. So, consistently with an evaluation method, the proposed one consists of the following three steps:

Definition of the objective functions.

Solution of the multi-objective optimization problem.

Selection of the recommended orientation.

3.1 Definition of the objective functions

In this paper, the optimization of the build orientation is considered such that the total build cost and surface quality of the part are the objective functions. Both total build cost and surface quality can be evaluated as functions of the object orientation in the AM machine d(θx, θy). The third parameter θz is not considered since, if it is executed as the last transformation after the rotations around x and y, each rotation around the z-axis has no effect on the object manufacturing process (build time and surface quality). The bi-objective optimization problem is formulated as follows:

where the rotation angles around the coordinate axes x and y are the decision variables d(θx, θy), see Fig. 1.

3.1.1 Definition of the surface quality

The surface quality is one of the principal factors to be considered in order to choose the build direction of an object manufactured by AM. Surface quality depends on the type of AM processes, applied material, build orientation, layer thickness, and post-processing requirements. It must be noted that the build orientation and layer thickness are independent variables of the production process to choose, which significantly affects the surface quality of the object. Accordingly, it is essential to use a valid and reliable model for surface quality prediction so that the optimization process can achieve a solution of a real high-quality surface.

In this work, the method proposed by Di Angelo and Di Stefano in [18] is used. They proposed the index Pa (ISO 4287) as a more appropriate index to evaluate the surface quality. Pa is estimated by a model that approximates the surface profile of FDM-produced objects with a set of elliptical arcs reproducing the typical texture surface of AM parts (Fig. 2). This model permits to estimate numerically Pa for the entire range of the orientation of the surface with respect to the growing direction of the object, evaluated as the deposition angle θi = arccos(z • ni(d)). This model performs a good evaluation of the arithmetical mean deviation of the manufactured profile from the smooth ideal profile.

The index to evaluate the surface quality of the part is expressed by the following formulation:

where \( {P}_{a_i}(z) \) is the estimation of the surface quality of the ith triangular face, Ai is the face area, and nT is the number of triangular faces.

3.1.2 Definition of the total build cost of the part

The total build cost includes three main components, pre-build cost, build cost, and post-processing cost. The pre-build cost is related to all preparations done before building the part and is considered as a fixed value to each object produced (for example verification of the integrity of the geometric model and eventual repair, definition of the layers’ thickness and build direction). Due to the pre-build cost being fixed, it does not affect the search for the optimal build direction, so that in the following it is neglected.

The build cost contains the material’s cost, support material’s cost, power consumption, and other fixed costs (such as machine costs). Since the volume of the object does not change when the build direction changes, also this component of the total cost is neglected from the optimization process.

The support material’s cost (Csup) is expressed as:

where

Vsup(d) is the volume of the support material, which is dependent on the build direction (d)

Usup is the relative unit cost of the support material

The power consumption cost (Ccons) and the other fixed costs (Cfixed) are assumed to be proportional to the build time tf (d):

Post-processing costs (Crsup) involve removing the support structures; it is calculated as the product of the unitary cost of surface finishing (Ursup) and the sum of the triangles’ area requiring supports (Asup):

So, the expression of the component (Cd) of the total build cost, which is a function of the build direction d, is as follows:

The total build cost depends on two factors: build time and support volume, and each of them is a function of the build direction. Due to the difficulty to estimate them, appropriate simplified models are required rather than a complete model that is very time-consuming, and, for this reason, they are not useful to be used in an optimization method.

Estimation of the build time

Generally speaking, the build time is the sum of the time to deposit each layer and the delay time between two successive layers. The time to construct each layer is the time required for forming the contours and filling the interior parts with tool path loops (Fig. 3). In addition, the time required to complete one tool path is proportional to the tool path length and to the number of repositioning actions of the forming tool. The delay time between subsequent layers’ deposition, called the recoating time, takes into account the time which is necessary for the cooling or the solidification of the deposited material, the nonproductive time for the prototype’s vertical translation.

Definition of some driving build time factors [19]

From the analysis of the state-of-the-art, reported in Section 2, the most promising parametric method for build time estimation is proposed by the authors in [19]. As previously mentioned, this method takes into account the most important driving factors affecting the build time. An its important limitation is the needing of the voxelization of the supports, which requires a time-consuming computational process, so that it is therefore not suitable for the optimization process involving many processing cycles. Furthermore, the used formulation of driving cost factors does not allow to estimate with the same accuracy the build time of thin and squat objects. This last aspect is due to that, in the contribution of the build time of the hatching, it is not taken in account that the speed of execution of the single tract of the deposition tool path loops depends on the acceleration that it can assume, which is linked its length; the greater the length, the greater the speed attainable from the tool and the lower the execution time.

Based on the previous considerations, considering also the contribution of the support structures, the build time of layer-manufactured objects can result from the sum of seven different components:

where

tc-mat is the total time required for the material contour

th-mat is the total time required for path length of hatching material

trep-mat is the total time required for repositioning of the material deposition tool

tc-sup is the total scanning time of the supports’ contour

th-sup is the total scanning time for path length of hatching supports

trep-sup is the total time required for repositioning of the support deposition tool

tdelay is the total delay time between subsequent layers’ deposition

By using the driving cost factors proposed in [19], the expression of the build time is:

where (Fig. 3)

α is the proportionality coefficient for the total length of layers’ contour

β is the proportionality coefficient for path length of hatching material

γ is the proportionality coefficient for tip number of repositions

L is slicing thickness

V is volume

\( p=\frac{\sum_{i=1}^{n_T}\sqrt{\left(1-{\left(d\bullet {n}_i\right)}^2\right)}\times {A}_i}{L} \) is the total length of layers’ contour [19]

nT is the number of model triangles

d is the object orientation

Ai is the area of the ith triangular face

ni is the unit normal vector of the ith triangular face

\( {n}_{repos}=\frac{\sum_{i=1}^{n_T}\sqrt{\left(1-{\left(\boldsymbol{d}\bullet {\boldsymbol{n}}_i\right)}^2\right)}\times {A}_i\times \mid \boldsymbol{\tau} \bullet {\boldsymbol{n}}_{i, xy}\mid }{H\times L} \) is the number of repositions [19]

τ is the hatching vector; this model has suited only for rectangular hatching of the contour

ni,xy is the unit normal vector of the ith triangular face projected onto the x-y plane

H is the hatch distance between two subsequent segments of tool path

ID [%] is the infill density

Khat,m is a constant value taking into account the object slenderness

The subscript mat refers to material, and sup refers to support.

In this paper, a new expression of th-mat is implemented compared to the model proposed in [19]: the contribution of the build time due to the material hatching is a function of a constant whose value varies with the ratio (Vmat − pmat • L)/Vmat that is assumed as an indirect measure, together with the number of repositions, of the degree of the slimness of the object. Furthermore, in the proposed method, the trep-sup and tdelay are neglected: the first one since it requires the voxelization of the support structures, and the latter in accordance with an analysis of the independence of the parameters.

Estimation of the support volume

Support structures are used in some AM technologies whenever there are overhanging features. In order to overcome the limitations of the published algorithms for estimation of the support structures (more details are in Section 2.2), in this paper, a new method, suitable for the implementation of multi-objective optimization, is proposed. Its flow-chart is depicted in Fig. 4.

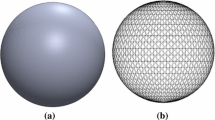

Starting from the 3D model of the object to be manufactured defined in terms of external tessellated surfaces (Fig. 5a), the bounding box is constructed (Fig. 5b). The bounding is defined by considering also the build platform that the machine deposits and on which the object is built. The bounding box is partitioned in number nc cubes (Fig. 5c) whose dimension is defined as follows:

where Vx is the bounding-box volume. On the plane x-y, the center of each square is defined, and each of them is the anchorage point of a ray (ri,j) parallel to the deposition direction (Fig. 5d). For each ray, the Möller–Trumbore algorithm [27] is applied to find the intersections with mesh triangles (Fig. 5e). The intersections, sorted by z-coordinate, divide the ri,j into different tracts. The segments \( {r}_{i,j,k}^{\ast } \) that are internal to the bounding box and external to the geometric model are used to measure the extension of the support structure (Fig. 5f highlighted in green). The volume of supports is determined as follows:

where IDsup [%] is the infill density for the support structures.

3.2 Multi-objective optimization problem

The two objective functions (build cost and surface quality) are very time-consuming to be calculated, and, in the optimization problem here considered, they must be discretely calculated in order to approximate the objective functions in their entire definition field. In order to approximate these nonlinear functions with high accuracy, the radial basis function (RBF) method is employed. In the proposed method, the Gaussian and linear expressions of radial basis functions are used, respectively, to approximate the cost to manufacture the part and the index Pa, each as a function of the deposition direction d.

In this work, in order to obtain an approximation of the Pareto front, the S-metric selection evolutionary multi-objective algorithm (SMS-EMOA) [28] is used. It is a multi-objective evolutionary algorithm that uses the hypervolume indicator as a selection measure during the solution process. The maximum number of the function evaluations is considered as the stop condition in SMS-EMOA, and the population size and the maximum number of the function evaluations are considered to be, respectively, 200 and 10,000.

3.3 Selection of the recommended orientation

All solutions obtained by SMS-EMOA are equally good in the sense of Pareto optimality; the aim of the decision-based method is to choose the better solution among the solutions in the Pareto frontier. Among the decision-based method available in the literature, in this paper the TOPSIS is chosen. It is frequently used ([17, 29]) to rank the obtained solutions and select a solution among the Pareto optimal ones.

The TOPSIS method selects a solution with the smallest Euclidean distance from the ideal point and the largest Euclidean distance from the nadir point. The nadir point consists of worst values for all objectives in the Pareto front. The ideal point combines the best values for the two objectives, and the nadir point consists of their worst values in the Pareto front. In addition, the decision-based method determines a weighted vector W = [w1, w2]T such that w1 + w2 = 1, in which wi is the relative importance assigned to ith objective function. In the optimization cases performed in this work, the weights are set as w1 = w2 = 0.5.

4 Results

The proposed method has been implemented using original software coded in MATLAB®. It requires that some characteristic technical parameters of the prototyping machine (L, H, τ, W, IDmat, IDsup) and the driving factors for build time and total cost must be specified. All the experiments analyzed refer to FDM technology whose technical specifications are quoted in Table 2.

A specific experimentation was carried out to determine the driving factors for build time estimation as defined in Eq. (4). For this purpose, the set of experiments described in [19] is carried out: the obtained values of the coefficients are reported in Table 3. In Table 4, the economic parameters used for the total build cost evaluation (Eq. (3)) are summarized.

In order to evaluate the accuracy of the proposed method in the identification of the best deposition orientation, selected test cases have been designed (Fig. 6). The first test case (Fig. 6a) is the well-known Stanford bunny (https://www.cc.gatech.edu/~turk/bunny/bunny.html). This model is a critical case, especially for the build time estimation methods, since it has both squat and thin structures, respectively corresponding to the body and the ears. The second test case (Fig. 6b) is a thin-walled cover with external surfaces oriented at different angles with respect to the potential deposition direction. The third and fourth test cases (Fig. 6c, d) are typical covers of industrial products, which have different values of thickness due to the presence of holes or ribs. The fifth test case is taken from the literature ([6, 17]).

In Table 5, the support volume (Vsup, AQ(d0)), the build time (BTAQ(d0)), and the surface quality (\( \overline{P_a}\left({d}_0\right) \)) are estimated for the initial configuration (d0) by using the proposed method. In the same table, the support volume (Vsup, R) and the build time (BTR) are determined by manufacturing each object. The comparison of the proposed method with the real values shows that percentage errors are always low for both, build time and support volume. The maximum error value for support volume is 5.97% for casing cover and for build time is 6.92% for bunny.

In Table 6, the support volume (Vsup, R(dAQ)), the build time (BTR(dAQ)), and the surface quality (\( \overline{P_a}\left({d}_{AQ}\right) \)) obtained by manufacturing the objects in the optimal build orientations (dAQ) as estimated by the proposed optimization method (Fig. 7, AQ method) are compared with Vsup, AQ(dAQ) and BTAQ(dAQ). The percentage errors can be considered very small, since the estimations are obtained by parametric methods that approximate the real values, without implementing the complex strategies performed by an additive manufacturing machine.

The optimal build directions obtained by the proposed method are compared with those obtained with three other methods described in the literature ([6, 10, 17]) and with the software Magics (Materialise Magics® 24.01). The KG method [17] has been implemented by setting wBuildTime = wRoughness = 0.5. For the method proposed by Phanak and Pande in [10] (PP method) and that proposed by Thrimurthulu et al. in [6] (TPR method), the optimal direction are taken from the papers where the methods are described. The related test cases are bunny and base. The tools available in Magics® have been used to search for directions of the deposition so that the height of the object (\( {d}_{M-{z}_{min}} \)) and the surface of the supports (\( {d}_{M-{As}_{min}} \)) are minimal. In Fig. 7, the optimized configurations obtained by the different methods are depicted. The surface quality is evaluated by using the \( \overline{P_a}(d) \) parameter.

In Table 7, the real values of support volume, build time, and surface quality are reported, determined for the different optimal configurations obtained with each method. For each test case, it is highlighted in bold the best values of support volume, build time, and surface quality are evidenced in bold. Generally speaking, Magics® have the limitations of each single-objective optimization method: the best solution is obtained by optimizing for a single factor, without taking into account the complexity of the conflict with the other ones in the search for the final result. Furthermore, it is not always correct to consider the height of the object linked to the build time; the \( {d}_{M-{z}_{min}} \) configuration is not always the shorter time configuration. The \( {d}_{M-{As}_{min}} \) configurations do not seem to minimize any of the factors here considered.

The optimal build orientation found by the AQ method performs, simultaneously, better surface quality (lower level of \( \overline{P_a} \) parameter) and a lower value of support volume and build time for casing cover, lower cover, and base. For the upper cover test case, the AQ method performs a solution that, with respect to that obtained with the KG method, has higher values of build time and support volume but a better quality of the surface. Lastly, for bunny, with the configuration resulting from the AQ method, a surface quality slightly lower (with respect to the PP method) and also significantly shorter build time and lower supports volume are obtained.

5 Conclusions

The most important factors measuring the performances of an additive manufacturing production are the build costs, the surface quality, and the geometric accuracy. In most of the additive technologies, these factors are mainly affected by the build orientation, which is one the main technological parameters to be settled. In a competitive global market, an accurate prediction of the best build orientation is strategic in order to reduce the offer price and maximizing the object quality.

In order to perform a valid determination of the best build direction, an accurate estimation of above-mentioned critical factors is mandatory that are not trivial to be evaluated. This is especially true when the exact additive manufacturing-based machine activities are unknown, cannot be easily estimated, and it is very time-consuming to perform them without slowing down every iterative optimization procedure. It is a common opinion among researchers, verifiable in the related literature, that the build time, the support volume, and the surface quality significantly affect the evaluation of the costs and quality of many technologies such as SLA, FDM, SLM, etc.

The strength of the method proposed in this paper is in the way it is used to perform an accurate estimate of the previously identified factors (build time, support material, and surface quality). Efficient and general-purpose methods, based on parametric models, are introduced. They are specifically suited to be used in optimization problems where the solution requires a lot of iterations and their repetitive evaluations.

The process to find the best build direction consists of the following three main steps:

Definition of the objective functions and their approximation with the RBFs.

The solution of the multi-objective optimization problem by the SMS-EMOA algorithm, obtaining an approximation of the Pareto front.

Selection of the recommended orientation by the TOPSIS method.

The proposed method, calibrated and tested for the FDM technology, has been compared in the analysis of some critical cases with methods at the state-of-the-art. The obtained results prove that the proposed method estimates build time and the support volume with a smaller percentage error compared with other methods here analyzed. In addition, the considered surface quality criterion is more accurate in evaluating the staircase effect, which is the most important contribution to surface quality loss. All this has clear consequences for the resulting optimized build directions: as it is evident in almost all of the examined cases, the proposed method seems to overcome the limitations of the methods at the state of art, which incorrectly detects the build direction driving factors.

Future efforts will be addressed to introduce specific corrective measures to the proposed models will be introduced for extending this method to other additive manufacturing technologies.

Furthermore, efforts will be addressed to take into account in the optimization process other important factors concerning the quality of the produced object, such as geometric and dimensional errors. At this purpose, the main problem to be solved is in the lack of generality of the models that can be used to predict the geometric deformation. It depends on too many different factors such as the AM technology used and its control parameters, the operating conditions, etc.

References

ISO/ASTM 52900:2015 (ASTM F2792) Additive manufacturing -- General principles – Terminology

Calignano F, Manfredi D, Ambrosio EP, Biamino S, Lombardi M, Atzeni E, Salmi A, Minetola P, Iuliano L, Fino P (2017) Overview on additive manufacturing technologies. Proc IEEE 105(4):593–612

BS EN ISO/ASTM 52910: 2019. Additive manufacturing - Design - Requirements, guidelines and recommendations

Zhang J, Li Y (2013) A unit sphere discretization and search approach to optimize building direction with minimized volumetric error for rapid prototyping. Int J Adv Manuf Technol 67:733–743. https://doi.org/10.1007/s00170-012-4518-0

Paul R, Anand S (2015) Optimization of layered manufacturing process for reducing form errors with minimal support structures. J Manuf Syst 36:231–243. https://doi.org/10.1016/j.jmsy.2014.06.014

Zwier MP, Wits WW (2016) Design for additive manufacturing: automated build orientation selection and optimization. Procedia CIRP 55:128–133. https://doi.org/10.1016/j.procir.2016.08.040

Delfs P, Töws M, Schmid H-J (2016) Optimized build orientation of additive manufactured parts for improved surface quality and build time. Addit Manuf 12:314–320. https://doi.org/10.1016/j.addma.2016.06.003

Nezhad AS, Vatani M, Barazandeh F, Rahimi A (2010) Build time estimator for determining optimal part orientation. Proc Inst Mech Eng Part B J Eng Manuf 224:1905–1913. https://doi.org/10.1243/09544054JEM1913

Thrimurthulu K, Pandey PM, Venkata Reddy N (2004) Optimum part deposition orientation in fused deposition modeling. Int J Mach Tools Manuf 44:585–594. https://doi.org/10.1016/j.ijmachtools.2003.12.004

Canellidis V, Giannatsis J, Dedoussis V (2009) Genetic-algorithm-based multi-objective optimization of the build orientation in stereolithography. Int J Adv Manuf Technol 45:714–730. https://doi.org/10.1007/s00170-009-2006-y

Singhal SK, Jain PK, Pandey PM, Nagpal AK (2009) Optimum part deposition orientation for multiple objectives in SL and SLS prototyping. Int J Prod Res 47:6375–6396. https://doi.org/10.1080/00207540802183661

Li A, Zhang Z, Wang D, Yang J (2010) Optimization method to fabrication orientation of parts in fused deposition modeling rapid prototyping. In: 2010 international conference on mechanic automation and control engineering. IEEE, pp 416–419. https://doi.org/10.1109/MACE.2010.5535335

Phatak AM, Pande SS (2012) Optimum part orientation in rapid prototyping using genetic algorithm. J Manuf Syst 31:395–402. https://doi.org/10.1016/j.jmsy.2012.07.001

Jaiswal P, Patel J, Rai R (2018) Build orientation optimization for additive manufacturing of functionally graded material objects. Int J Adv Manuf Technol 96:223–235. https://doi.org/10.1007/s00170-018-1586-9

Brika SE, Zhao YF, Brochu M, Mezzetta J (2017) Multi-objective build orientation optimization for powder bed fusion by laser. J Manuf Sci Eng 139:111011. https://doi.org/10.1115/1.4037570

Qie L, Jing S, Lian R, Chen Y, Liu JH (2018) Quantitative suggestions for build orientation selection. Int J Adv Manuf Technol 98:1831–1845. https://doi.org/10.1007/s00170-018-2295-0

Kulkarni P, Marsan A, Dutta D (2000) A review of process planning techniques in layered manufacturing. Rapid Prototyp J 6:18–35. https://doi.org/10.1108/13552540010309859

Padhye N, Deb K (2010) Evolutionary multi-objective optimization and decision making for selective laser sintering. In: Proceedings of the 12th annual conference on genetic and evolutionary computation - GECCO ‘10. ACM, pp 1259–1266. https://doi.org/10.1145/1830483.1830709

Bacciaglia A, Ceruti A, Liverani A (2019) A systematic review of voxelization method in additive manufacturing. Mech Ind 20(6):630

Gibson I, Rosen DW, Stucker B (2010) Additive manufacturing technologies, vol 238. Springer, New York

Padhye N, Deb K (2011) Multi-objective optimisation and multi-criteria decision making in SLS using evolutionary approaches. Rapid Prototyp J 17:458–478. https://doi.org/10.1108/13552541111184198

Khodaygan S, Golmohammadi AH (2018) Multi-criteria optimization of the part build orientation (PBO) through a combined meta-modeling/NSGAII/TOPSIS method for additive manufacturing processes. Int J Interact Des Manuf 12:1071–1085. https://doi.org/10.1007/s12008-017-0443-7

Di Angelo L, Di Stefano P, Marzola A (2017) Surface quality prediction in FDM additive manufacturing. Int J Adv Manuf Technol 93:3655–3662. https://doi.org/10.1007/s00170-017-0763-6

Di Angelo L, Di Stefano P (2010) Parametric cost analysis for web-based e-commerce of layer manufactured objects. Int J Prod Res 48:2127–2140. https://doi.org/10.1080/00207540802183653

Ga B, Gardan N, Wahu G (2018) Methodology for part building orientation in additive manufacturing. Comput Aided Des Appl 16:113–128. https://doi.org/10.14733/cadaps.2019.113-128

Deb K (2014) Multi-objective optimization, In search methodologies (pp. 403–449). Springer, Boston

Möller T, Trumbore B (1997) Fast, minimum storage ray-triangle intersection. J Graph Tools 2:21–28. https://doi.org/10.1080/10867651.1997.10487468

Beume N, Naujoks B, Emmerich M (2007) SMS-EMOA: multiobjective selection based on dominated hypervolume. Eur J Oper Res 181:1653–1669. https://doi.org/10.1016/j.ejor.2006.08.008

Byun H-S, Lee KH (2006) Determination of the optimal build direction for different rapid prototyping processes using multi-criterion decision making. Robot Comput Integr Manuf 22:69–80. https://doi.org/10.1016/j.rcim.2005.03.001

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Di Angelo, L., Di Stefano, P., Dolatnezhadsomarin, A. et al. A reliable build orientation optimization method in additive manufacturing: the application to FDM technology. Int J Adv Manuf Technol 108, 263–276 (2020). https://doi.org/10.1007/s00170-020-05359-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05359-x