Abstract

Quality function deployment (QFD) is a method commonly used in manufacturing industries to identify customer requirements (CRs) and the manufacturing capacity to meet CRs. Importance rate (IR) of CRs plays an important role in the QFD method. The existing methods in determining IR of CRs cannot consider all related factors of customer satisfaction, need importance, personal information, and relationship between customer satisfaction and function implementation. This paper proposes a method to improve the IR accuracy. Based on comments of customers for a product, importance rates of CRs are defined using integrated importance-performance analysis (IPA) and Kano models. IPA and Kano models are integrated by spectral clustering where a similarity matrix W is formed to balance the influence proportion between the IPA and Kano models considering comments of different customers for the product. IR of CRs is used in the QFD method to define functions and structures of the product. The proposed method is compared with several existing methods in case studies of designing an upper limb rehabilitation device and a feed drive system of the CNC machine. Results show that the proposed method has improved accuracy of IR of CRs for the product design and manufacturing.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

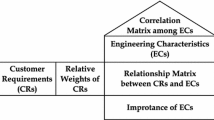

It is essential for industry to develop product that meets customer requirements in the competitive market [1]. Quality function deployment (QFD) provides a guide for industry to transfer customer requirements (CRs) into engineering characteristics of product [2]. CRs are normally defined in QFD by manufacturing experts based on customer needs for a product [3]. Importance rate (IR) of CRs in the QFD method can be used to define the weight of function requirements (FRs) in product design and manufacturing [4]. Therefore, IR of CRs can guide manufacturing industries to produce a satisfied product for customers and improve competitiveness.

As the weight of FRs is defined based on IR of CRs and relationship between CRs and FRs in the QFD method [5], determination of the IR of CRs is a very important step after CRs are identified. Based on the accurate IR, a product can be designed and manufactured to match or exceed customer satisfactions in the target market to achieve competitive advantages [6].

There are two existing approaches to decide IR of CRs including expert evaluation and customer questionnaires. The expert evaluation includes methods of the additive ratio assessment (ARAS), techniques for preference order using similarity (TOPSIS), simple additive weighting (SAW), analytic hierarchy, and analytic network process [7]. Data used in these methods are from designers or experts in a manufacturing company. Solutions of these methods are subjective without considering customers’ opinion. In addition, experts with a certain level of knowledge and experience are sometimes hardly available; conflict attitudes from different experts cannot be easily balanced [8]. Methods based on customer questionnaires include models of SERVQUAL, Kano, IPA, and customer satisfaction index [9]. These methods are based on collected comments of product users, which may sometimes be inaccurate if only based on the response from customers.

The Kano model uses the degree of implemented functions of a product to identify five types of customer requirements that influence ultimate customer satisfactions [10]. Must-be quality (M) is the requirement of customer expectations. One-dimensional quality (O) attributes a satisfaction when it is fulfilled and dissatisfaction when it cannot be fulfilled. Attractive quality (A) provides a satisfaction when CRs are met fully, without dissatisfaction when it is not fulfilled. Indifferent quality (I) refers to aspects that are neither good nor bad, which results in neither customer satisfaction nor dissatisfaction. Reverse quality (R) is for a high degree in dissatisfaction when not all customers are alike [11]. In the exiting research, most of researchers provide a fixed value for 5 types of CRs. However, values in M and A groups can also be influenced by current product performance for meeting CRs [12]. For example, IR of CRs will be very high if the CRs in the M group are not met. Meanwhile, IR of CRs will be normal if the CRs in the M group are fully met. Therefore, it is not accurate to define CRs as a fixed value in M and A groups. A weakness of using the Kano model to define IR of CRs is that the product performance from customer comments is ignored.

The IPA model is also commonly used for identifying customer satisfactions of different CRs of product. IPA is a simple and effective technique to assist practitioners in identifying improvement priorities of a product, which can guide designers to define IR of CRs. Product preference and importance of CRs from customers’ survey can be considered in an IPA model. The IPA model prioritizes product attributes for improvement based on user evaluations. A matrix is used to represent the importance and performance of each quality attribute where the horizontal axis shows the degree of CRs’ performance or satisfaction, and the vertical axis is the degree of the CRs importance [13]. In an IPA model, CRs are divided into 4 categories including concentrating area rated for a mark of 5, keeping up good work for a mark of 4, low priority for a mark of 3 and possible overkill for a mark of 2. The IPA model assumes that the improvement of a product function has a same linear promotion relationship with the overall customer satisfaction, which ignores the nonlinear relationship [14].

Kano and IPA models can be combined to define IR of CRs, which can improve the IPA model that considers only one-dimensional quality and reduce the limitation of the Kano model that neglects the attribute performance. However, the existing methods of combining Kano and IPA models cannot define IR of CRs accurately because of conflict requirements from different customers and too many levels for IR of CRs [15].

To improve accuracy of the IR of CRs in the QFD method, a new IR decision method using integrated IPA and Kano models is proposed using spectral clustering in this research. All factors from different customers in questionnaires are considered in the proposed model. Conflicted comments of customers are processed using the ANOVA method. By considering the type and actual function implementation of CRs, an improved Kano model is proposed to transfer categorical attributes to numerical attributes. A similarity matrix W is proposed to integrate the influence factors in the IPA and Kano models. The final IR of CRs is used in the QFD method to improve the important rating of CRs in design cases of the upper limb rehabilitation and feed drive devices. The solution is verified by comparing with some existing methods.

The following parts of the paper are organized as follows. Literature review of related methods is discussed in Section 2. An improved IR determination method is proposed in Section 3 with an upper limb rehabilitation device design using the proposed IR determination method in defining IR of CRs. Section 4 discusses the design of upper limb rehabilitation devices and feed drive systems of the computer numerical control (CNC) lathe using different IR determination methods to verify the proposed method, followed by the research conclusion and further work in Section 5.

2 Literature review

2.1 Existing methods for combining Kano and IPA models

Integration of Kano and IPA models can improve the IR accuracy in the QFD method, for example, a combined model can balance the percentage of all factors or include more factors to improve the accuracy for IR of CRs. Wu et al. [16] identified key success factors to increase customer satisfactions by integrating Kano and IPA models using improved questionnaires. Tontini et al. [17] identified the impact of incremental innovations on customer satisfactions using a fusion method between IPA and Kano models. Deng et al. [18] combined Kano and IPA models to manage work with limited resources in competitive environments by a partial correlation analysis. Kuo et al. [14] retained original features of Kano and IPA models to comprehensively grasp user perceptions of all quality attributes and corresponding strategies by dividing CRs into 13 clusters based on the proposed IPA-Kano model.

The existing combination methods are mainly used in the service field such as the residence environment, restaurant, and airport services. Yin et al. [19] examined environmental correlations with the residential satisfaction by an IPA–Kano model. Pai et al. [20] combined Kano and IPA models to investigate critical service quality attributes to strengthen advantages of chain restaurants. Wang et al. [21] identified the customer retention for airline services by integrating fuzzy Kano with IPA models.

However, the existing methods for combing Kano and IPA models have following problems. (1) These models divide CRs into too many groups, which is ineffective and inaccurate to define IR of CRs in the process. (2) The existing models cannot combine different comments of customers. Average values of the product importance and performance are used for evaluating comments of customers, which ignores differences of customers. (3) The influence of the function implementation in existing products is not considered in combined IPA and Kano models for defining IRs, Therefore, it is necessary to improve accuracy of the existing methods to combine Kano and IPA models.

2.2 Defining IR of CRs by clustering methods

As clustering methods can combine conflict comments of customers to improve IR accuracy, the existing clustering methods are reviewed for selecting the most suitable method to define IR of CRs. They include fuzzy clustering, K-mean clustering, and spectral clustering methods that are commonly used for the customer segmentation based on characters of customers such as age, income, and education [22].

Fuzzy clustering methods construct clusters with uncertain boundaries for the customer segmentation. Liu et al. [23] proposed a modified fuzzy clustering method to classify various importance groups of CRs, which improved the certainty and precision of QFD. Wang et al. [24] divided customer quality requirements into a hierarchical structure by the fuzzy clustering method to determine weights of the requirements for accurate and reliable information in quality control. Chan et al. [25] segmented the market based on CRs for new product design using fuzzy clustering methods.

The K-mean clustering is an efficient method for the customer segmentation. Alvandi et al. [26] clustered customers based on their contributions to profitability in banking services using a K-mean clustering method. Ho et al. [27] proposed a GA-based K-mean algorithm to cluster customers for developing approximate optimal solutions. Wang et al. [28] proposed improved K-mean algorithms for the market segmentation using silhouette coefficient.

The spectral clustering method uses a similarity matrix to extract important information for improving the clustering accuracy. Wu et al. [29] clustered customers based on their online shopping behaviors, service satisfaction, and internet usage using this method. Sagar et al. [30] proposed a user segmentation model for clustering user trajectories using a feature matrix in the spectral clustering method. Chang et al. [31] applied a spectral clustering technique to cluster customers for determining characters of loyal customers in adjusting a promotion strategy to gain more benefits.

Comparing with other clustering methods, the spectral clustering method can process a huge amount of data easily because a similarity matrix can be used to extract important information and reduce the effect of useless information. In addition, the Laplacian matrix in the spectral clustering method can combine categorical attributes and numerical attributes for clustering, which increases accuracy of clustering. Therefore, the spectral clustering method is selected in our proposed IR determination method to combine all the important factors to cluster CRs, which can solve the three problems in the existing methods for combined IPA and Kano models.

3 Proposed IR method

Raw data used in the proposed method were obtained through a questionnaire survey for customer personal information, data for Kano, and IPA models. Collected raw data are normalized for eliminating the influence of dimensions. The categorical attributes in the Kano model are transferred to numerical attributes by integrating the current function implementation of CRs and categorical attributes of CRs in the Kano model. Conflict comments from different customers are processed using the ANOVA method. A database is created by separating data of conflict comments into different groups to show all important comments of customers.

A spectral clustering method is used to form a Laplacian matrix for combining kth categorical attributes in the Kano model, hth numerical attributes for importance degree, and mth numerical attributes for satisfaction degrees in the IPA model. Based on characters of CRs, the CRs are clustered into 5 groups by the K-mean method in the feature space. IRs of CRs are defined based on clustering results and then used in the QFD method. Steps of the proposed IR decision method are shown in Fig. 1.

3.1 Collection of raw data using questionnaires based on IPA and Kano models

A questionnaire with three parts is created to conduct a user survey for collecting raw data. The first part is customer personal data related to the use of product. The second part is used for the Kano model. Based on each CR, there are two questions for customers. The first question is the positive question to find the customer feeling if a CR can be met. The second question is the negative question to get the customer comment if the CR cannot be met. The third part is for the IPA model. The current satisfaction degree and importance degree for each CR are defined based on the average value of importance and satisfactory degrees from responses of the questionnaire. Based on requirements of the quantitative evaluation in the design process using the QFD method, five levels of the importance degree (ID) and satisfaction degree (SD) are defined.

3.2 Data transformation

Raw data values of ID and SD with 5 levels in the IPA model are defined and normalized. Values of an ID have 5 levels including very importance (5 marks), importance (4 marks), normal (3 marks), unimportance (2 marks), and very unimportance (1 mark). Values of a SD have 5 levels including very satisfaction (5 marks), satisfaction (4 marks), normal (3 marks), dissatisfaction (2 marks), and very dissatisfaction (1 mark). Dimensions in Kano and IPA models are from 0 to 1 and from 1 to 5, respectively. For comparing data with different dimensions in Kano and IPA models, data in the IPA model are transferred into interval from 0 to 1 using Eq. (1).

Values of CRs in the Kano model are also normalized. As categorical attributes cannot be directly used to search similarity, the categorical attributes are transferred into numerical attributes. The interval for 0 to 1 is suitable for the definition of weight in the field of product design. As categories of O, I, and R are not influenced by the current function implementation degree of CRs, values for CRs in these 3 categories are defined based on characters of product design [10]. The value is stable for CRs in O, I, and R groups. The value of O is assigned as “0.6” as the one-dimensional CRs can promote the product preference when CRs are satisfied. The value of I is defined as “0.2” when indifferent CRs cannot influence the customer satisfaction. The value of R is assigned as “0.1” when the reversed CRs can reduce the customer satisfaction.

Values for CRs belonging to A and M groups are relative to the current function implementation degree of CRs. Based on the slope of characters in the Kano model [10], values of categories A and M are proposed in Eqs. (2) and (3), respectively, where x is the current function implementation degree of CRs for a product. For product design, the x value can be defined into 6 levels as shown in Table 1.

VA is a value of CRs in A group in the Kano model. Based on Eq. (2), values of CRs are higher if a current product from a manufacturing company cannot provide a satisfied function (x is 0, 1, or 2). Values of CRs are lower if the current product provides a satisfied function (x is 3, 4, or 5) as follows.

VM is a value of CRs in M group in the Kano model. Based on Eq. (3), values of CRs have a higher importance if the current product from a manufacturing company cannot provide a satisfied function. For example, VM is very high (VM is equal to 1.0) if current product does not have any function to meet CRs (x is equal to 0).

The average value of all customers’ responses in Kano and IPA models can be determined using results of data transformation from Eqs. (1), (2), and (3).

3.3 Hypothesis testing by the ANOVA method for separating data to describe CRs

Some factors of the demographic and personal information such as customers’ background, expectation, and preference on product can affect results. Thus, the analysis of variance (ANOVA) techniques is used to detail CRs in different conditions [18]. Z score is used to test the data statistical significance by Eq. (4) to decide whether a null hypothesis should be rejected.

where z is the standard score (Z score), x is the raw score of standardization, μ is the mean of data, σ is the standard deviation of the data. Based on z value in Eq. (4), the relationship between p and z values is found using a Z table in the reference [18].

The p value is the probability that falsely rejects the null hypothesis. For a typical analysis, using the standard α = 0.05 cutoff, the null hypothesis is rejected when p < 0.05. The p value of customers’ data from each CR is calculated by the Z table. The number of CRs based on each factor that p value is lower than 0.05 is recorded as shown in Table 2.

If more than 30% of CRs related to the personal information are refused, raw data for describing CRs will be determined separately in Kano and IPA models because customers with different conditions have different comments for requirements of the product. Raw data for defining IR of CRs are shown in Table 2. The characters show factors with conflict comments of different customers. n is the number of CRs for the product.

Algorithm 1 is developed for the data transformation to describe the process descried in Sections 3.1–3.3 as follows.

3.4 the data

Based on data in Table 2, matrix X is formed to represent n CRs. Each CR has t (t = k + h + m) attributes from influence characters in Kano and IPA models. Attributes show the number of characters for each CR, and the matrix is shown in Eq. (5).

According to the graph theory in spectral clustering [31], an undirected weight similarity graph G = (V, E) is defined for comparing similarity of CRs. A CR also is defined as a vertex V in G, V = {v1, v2, ⋯, vn}. xnt represents a character of one CR. For each CR, the character includes t factors: vi = {xi1, xi2, ⋯, xit}(i = 1, 2, ⋯, n). Two vertices are connected by edge E. Length of the edge is shown by similarity wij between vertices vi and vj. Thus, the clustering problem is transformed into a graph partitioning problem of G.

The graph Laplace matrix L is defined in Eq. (6), where L is symmetric and positive semi-definite.

The similarity matrix W is calculated as follows.

By combining Kano and IPA models, a similarity matrix W of the spectral clustering algorithm is formed using Eq. (8) where parameters c, d, and f are used to represent the proportion of Kano and IPA models. As the importance of Kano and IPA models is considered same, the value of c for the Kano model is 0.5. Values of d and f in the IPA model are equal to 0.25, respectively.

In Eq. (9), ws is the distance of categorical attributes of CRs based on k characters in the Kano model. K is the number of CRs in Eq. (10). Where, \( {v}_i^k \) and \( {v}_j^k \) shows the k dimension for the Kano model in Table 2.

Equation (11) is formed for the distance wd in numerical attributes of CRs based on h characters for importance degrees in the IPA model. K is the number of CRs in Eq. (12). Where, \( {v}_i^h \) and \( {v}_j^h \) shows the h dimension for ID in Table 2.

Equation (13) is formed for the distance we in numerical attributes of CRs based on m characters for satisfaction degree in the IPA model. K is the number of CRs in Eq. (14). Where, \( {v}_i^m \) and \( {v}_j^m \) show the m dimension for SD in Table 2.

A diagonal matrix D is formed in Eq. (15). The element diiin matrix D is shown in Eq. (16).

3.5 Clustering by the K-mean method in a feature space

A scale of 1 to 5 is used with 5 representing the highest level of importance for IR of CRs. More levels can increase the model complexity to affect the IR accuracy of CRs. Therefore, 5 clusters of CRs are used. Five levels from 1 to 5 are used to define IR of CRs based on 5 clusters obtained from the proposed method.

The eigenvectors of L matrix for the first 5 smallest eigenvalues are used to build a feature space. The number of clustering groups is defined as 5. The K-mean method is used to cluster data into 5 clusters in the feature space because the number of clustering groups is fixed, and the spectral clustering method can avoid the effect of scales and data orders in the K-mean method.

3.6 Definition of IR of CRs using clustering results

Based on different actual function implementations, values of CRs in M and A groups for the Kano model are shown in Fig. 2. IRs of CRs in the 5 clusters are shown in Table 3.

IR determination rules are proposed in Table 3. IRs are divided into 5 levels including very high, high, middle, low, and very low. For ensuring that all CRs can be matched within 5 levels, rules are defined as follows. Based on clusters in Table 3, if over 50% of CRs in each cluster are included in the same level, IR for all CRs will be clustered in this level. If the percentage of CRs in any level is lower than 50%, the clustering is not successful because the value of CRs in these clusters cannot be defined based on the clusters in Table 3. The raw data of CRs will be clustered again until finding a solution.

Algorithm 2 is developed to determine IR of CRs for the process described in Sections 3.4–3.6 as follows.

The result for IR of CRs will be used in the QFD method by manufacturing industry to provide useful product functions for improving customer satisfactions and remove unnecessary functions to reduce the manufacturing cost.

4 Case study

Two case studies are conducted using the proposed method to decide IR of CRs in the design of an upper limb rehabilitation device and a feed drive system of the CNC lathe.

4.1 Case study of rehabilitation devices

As upper limb rehabilitation devices are used to recover patients’ injured joints, design of a rehabilitation device needs to meet CRs for different patients. Existing rehabilitation devices in the market have problems of product function, structure, size, adaptability, portability, and price. They cannot meet different patient requirements [29]. These problems are caused by the low IR accuracy of CRs in the product design stage. We propose the IR determination method to reduce the dependence of experience and to define IR of CRs accurately. Based on collected customer needs for upper limb rehabilitation devices [32], 29 CRs are initialized as shown in Table 4.

A questionnaire to collect user personal data, data for Kano, and IPA models is designed using 29 CRs for customers’ survey as shown in Table 5. Factors of personal information in questionnaires are selected based on potential factors that may cause conflict attitudes for different patients. A total of 262 patients with the upper limb injury were surveyed using online questionnaires and paper questionnaires in hospitals. A total of 215 questionnaires with completed information are used as raw data in the case study.

Data for the IPA model are normalized using Eq. (1). Data for the Kano model are transferred into numerical attributes based on Eqs. (2) and (3). Values of CRs in groups O, I, and R are defined with a stable value according to the proposed method. The value of O is assigned as 0.6, I as 0.2, and R as 0.1. All the classification results of M and A in the Kano model are transferred into numerical results using Eqs. (2) and (3).

A hypothesis test for the consistency of customer comments was conducted using Eq. (4) and Z-table in the AVOVA method. The results show different comments for CRs classification in the Kano model from patients with different injured levels and using devices in different places. Patients with different injured levels and in different places using devices have also different comments for importance degrees of CRs and satisfactory degrees of CRs in the IPA model. Characters of each CR with 12 parameters are shown in Table 6.

The spectral clustering method divides the similarity of CRs into 5 clusters. Based on data in Table 4, matrix X is formed to represent 29 CRs with 12 attributes using Eq. (5). Laplace matrix L is formed by a diagonal matrix D and similarity matrix W using Eq. (6).

Similarity matrix W is defined based on the similarity of 29 CRs using Eqs. (7) and (8). The distance of 4 categorical attributes of 29 CRs in the Kano model is decided by Eq. (9). The distance of 4 numerical attributes of 29 CRs for the importance degree in the IPA model is calculated using Eq. (11). The distance of 4 numerical attributes of 29 CRs in the Kano model is decided by Eq. (13). Based on the result of similarity matrix W, a diagonal matrix D is formed using Eqs. (15) and (16).

According to the feature space built by the first 5 smallest eigenvalues, the K-mean method is used to cluster data in the feature space into 5 clusters. Using the IR determination rules in Table 2, results of 5 clusters are defined as follows.

IRs of CRs in each group are determined using the proposed rules in Table 2. Values for IRs of CRs in each cluster are shown in Eq. (22).

The result can then be used in the QFD method for guiding manufacturing companies to determine the function and structure of the upper limb rehabilitation device.

4.2 Solutions and discussion of the rehabilitation device

For verifying advantages of the proposed method, three existing IR methods including the Kano model, IPA model, and existing combined IPA-Kano model are compared with the proposed method in the case study for design of an upper limb rehabilitation device. IRs of CRs for these methods are shown in Table 7.

Based on different IRs of CRs in Table 7, the structure and functions of four rehabilitation devices are designed using QFD and benchmarking methods. As the different IRs of CRs, different IRs of function requirements (FRs) can be defined for four rehabilitation devices using house of quality in the QFD method. The design priority is determined by IRs of FRs. Based on different design priorities, the best components of rehabilitation devices are selected from benchmark products.

Different structures and functions of four rehabilitation devices are shown in Fig. 3 and Table 8. There are 29 CRs in total. 3D models of four devices show the performance of functions related to 19 CRs including CR.1, CR.2, CR.3, CR.6, CR.9, CR.10, CR.11, CR.12, CR.13, CR.14, CR.19, CR.20, CR.21, CR.22, CR.23, CR.24, CR.25, CR.26, and CR.28 in Fig. 3. The product functions related to other 10 CRs are defined and compared by the description in Table 8.

According to the 3D models, the size and weight of the four rehabilitation devices are calculated. D1 is a 6-DOF rehabilitation device designed based on IR from the Kano model. The size is 3.5 × 2.2 × 1.5 m3. The weight is about 110 kg. D2 is a 7-DOF rehabilitation device designed based on IR from the IPA model. The size is 1.8 × 1.7 × 1.4 m3. The weight is about 160 kg. D3 is a 5-DOF rehabilitation device designed based on IR from the existing combined IPA-Kano method. The size is 1.6 × 1.2 × 0.9 m3. The weight is about 70 kg. D4 is a 5-DOF rehabilitation device designed based on IR using the proposed IPA-Kano method. The size is 1.4 × 0.5 × 0.3 m3. The weight is about 35 kg.

The product functions related to other 10 CRs are defined and compared by the description in Table 8. These functions are defined based on IRs of FRs and benchmarking. As functions related to CR.4, CR.5, CR.7, CR.8, CR.17, CR.18, and CR.29 are independent, these functions are defined by IRs of CRs directly. The function related to CR.15 is influenced by the noise of selected motors and rehabilitation device operations. The function related to CR.16 is decided by the cost of raw materials from material suppliers and cost of manufacturing based on the ISO metric standard [33]. The function for CR.27 is provided to meet easy storage of the product.

After determining the structure details and functions of four rehabilitation devices, an analytic hierarchy process (AHP) is used to compare the function implementation for each CR. AHP is developed to derive ratio scales from pairwise comparisons. The AHP method is applied for 29 times to compare performances of four rehabilitation devices in the case study for meeting the 29 CRs. Based on the design solution of 29 CRs, relationships between values of wj and 29 CRs in the design of four upper limb rehabilitation devices are compared in Fig. 4. wj shows the performance of rehabilitation devices.

The average value of wj shows the performance of the four rehabilitation devices as follows.

In the design of rehabilitation devices based on IR from the Kano model [10], the 6-DOF rehabilitation device only focuses on the basic requirement. Because there are 14 must-be requirements with 5 marks. Functions related to basic requirements have a good performance. However, all the attractive functions such as the movement feedback automatic, rehabilitation data record, and easy maintenance are not considered, which reduces competitiveness of the product.

In the device designed based on IR from the IPA model [13], the IR determination only focuses on two factors of the current important degree and satisfaction degree. Functions that are important and not satisfied can get a highest priority. However, some improvements of functions are difficult and costly, which causes many problems for the final design of the device. For example, functions for meeting CR.1 and CR.8 are improved based on the high IR for CR.1 and CR.8. However, the weight, size, and portability for the device are affected seriously because of the function improvement for fully meeting CR.1 and CR.8. Therefore, the design based on IR from the IPA model cannot consider all the important factors to design the device.

In the device designed based on IR from the existing combined IPA-Kano method, the performance of the rehabilitation device is better than devices designed by the Kano and IPA models. The existing combined IPA-Kano method can balance more important factors including the relationship between function implement and customer satisfaction for CRs, current important degree, and satisfaction degree for CRs in the design [19]. However, the IR determination is not accurate for CRs if customers have conflict comments for the CRs. For example, CR.11 belongs to one-dimensional quality with a low important degree and low satisfaction degree. According to the raw data, most of serious injured patients believe that portability is not important for the rehabilitation device, because they cannot complete the rehabilitation exercise by themselves and they do not need to take the device with them. However, most of light injured patients believe that portability is very important for rehabilitation because they can change the position of rehabilitation when using the device at home. As 60% of patients are serious injured based on the collected data, the average value shows that CR 13 adaptability is not important for patients. Because of the neglect of conflict comments from different customers, IR of CR.13 is not defined accurately.

In the device designed based on IRs using the proposed method, all the important factors are considered and balanced with IRs of CRs accurately. With the accurate IR, the existing design problems are improved with remaining the existing design advantages. For example, the portability is improved by installing the device on a table. Meanwhile, the existing advantages such as the stable movement, easy maintenance, and light weight are remained. Therefore, the performance of D4 is better than other three devices in many aspects.

As the proposed method considers all the important factors to balance conflict comments of different customers, the overall function performance of D4 is the best in the four devices. The D4 design has the highest customer satisfaction with the lowest cost. Therefore, the proposed method has advantages to define IRs of CRs accurately compared with the existing IR methods.

4.3 Case study of a feed drive system in the CNC lathe

A case study of the feed drive system in the CNC lathe is conducted to further verify the proposed method in applications of industrial equipment. A total of 336 engineers and workers in different manufacturing factories were surveyed using online questionnaires and paper questionnaires with 23 CRs in the first column of Table 9. A total of 273 questionnaires with completed information are used as raw data in the case study.

By a hypothesis test using Eq. (1) to Eq. (4), results show different comments for CR classifications in the Kano model from customers in light and heavy industries. Customers with different frequencies and different places using the feed drive system also have different comments for importance degrees of CRs and satisfactory degrees of CRs in the IPA model. Based on the proposed method using Eq. (5) to Eq. (16), the result is shown in the last column of Table 9.

Based on different IRs of CRs in the last column of Table 9, structures and functions of the feed drive system are proposed using QFD and benchmarking methods.

4.4 Solutions and discussion of the feed drive system

Design solutions are evaluated to compare three existing IR methods and the proposed method. The basic structure of a feed drive system in the CNC lathe is shown in Fig. 5.

For a feed drive system, most CRs are met by the selection of parts from a to g in Fig. 5. Therefore, the design mainly focuses on the selection of these parts. Based on different IRs of CRs in Table 9, design solutions of four feed drive systems are listed in Table 10.

For comparing four design solutions in Table 10, performance measures are evaluated as shown in Table 11. The cost is decided based on quotations from suppliers. Stiffness, positioning accuracy, and maximum feed depth are calculated based on parameters of selected components such as ball screw, bearing, and guide.

In the solution based on the Kano model, the design mainly focuses on CRs in the must-be group. Most of the attractive requirements such as CR.7 and CR.17 are ignored. In the solution based on the IPA model, the design is mainly improvement for CRs that are important and not satisfied. However, CRs such as CR.9 and CR.15 in concenter on group of IPA model are difficult to improve. In addition, improvement of these CRs is also costly, which affects the final design seriously. In the design based on the existing combined IPA-Kano method, the IR determination is not accurate for CRs that have conflict comments from different customers, such as conflict comments of different customers for CR.19 from light and heavy industries. However, the maximum feed depth related to CR.19 is not enough for light industries such as furnishing and textile companies, which reduces the efficiency significantly.

Comparing with above three existing methods, the proposed method can provide a better performance on the design solution because comments from different customers for CRs are balanced accurately. For example, the design by the proposed method has a high accuracy of operations and the large feed rate by selecting a suitable ball screw. Therefore, the system can meet requirements for the high accuracy from heavy industries and large feed rate from light industries at the same time. Therefore, the design can satisfy more customers to improve competitiveness of the product.

In the two case studies, different IRs of CRs lead to different design solutions to best meet customer requirements. Therefore, the proposed IR determination method contributes the product development and finally improves product quality and customer satisfaction.

5 Conclusions and further work

This research proposed a new IR determination method to meet CRs in the QFD method. CRs were classified by a spectral clustering method based on categorical attributes in the Kano model and numerical attributes in the IPA model. A Laplacian matrix was designed to improve accuracy of the classification by considering the conflict comments from different customers. Results of the classification were used to define IR of CRs. The IR of CRs was used in QFD for manufacturing companies to define product function, structure, and manufacturing process.

For verifying advantages of the proposed method, four upper limb rehabilitation devices and four feed drive systems were designed based on IRs of CRs using three existing IR determination methods and the proposed method. Results show that the design of rehabilitation devices and feed drive systems based on IRs of CRs from the proposed method has the best function for completing the rehabilitation exercise or machining operations. Therefore, the proposed method can determine IRs of CRs accurately to improve competitiveness of both consumer and industrial products for manufacturing industries.

Main contributions of this paper are summarized as follows. (1) Efficiency of defining IR of CRs is improved by clustering CRs automatically using a spectral clustering method. (2) Accuracy of defining IR of CRs is improved by combining different comments of customers using a similarity matrix in the spectral clustering method. (3) Industry can improve customer satisfactions in the product design using the accurate IR of CRs decided by our proposed method.

The future work will consider other factors based on different stakeholders. The environment requirements can be combined with customer requirements to further improve the proposed IR determining method for guiding the product design and manufacturing. Data mining methods will be applied to improve understanding customers for customer classifications and changeable requirement predictions.

References

Jin J, Liu Y, Ji P, Liu H (2016) Understanding big consumer opinion data for market-driven product design. Int J Prod Res 54(10):3019–3041. https://doi.org/10.1080/00207543.2016.1154208

Sousa-Zomer TT, Miguel PAC (2017) A QFD-based approach to support sustainable product-service systems conceptual design. Int J Adv Manuf Technol 88(1–4):701–717. https://doi.org/10.1007/s00170-016-8809-8

Alinezad A, Seif A, Esfandiari N (2013) Supplier evaluation and selection with QFD and FAHP in a pharmaceutical company. Int J Adv Manuf Technol 68(1–4):355–364. https://doi.org/10.1007/s00170-013-4733-3

Madzík P (2018) Increasing accuracy of the Kano model–a case study. Total Qual Manag Bus Excell 29(3–4):387–409. https://doi.org/10.1080/14783363.2016.1194197

Parezanović T, Petrović M, Bojković N, Pamučar D (2019) One approach to evaluate the influence of engineering characteristics in QFD method. Eur J Ind Eng 13(3):299–331. https://doi.org/10.1504/EJIE.2019.100013

Chong YT, Chen CH (2010) Customer needs as moving targets of product development: a review. Int J Adv Manuf Technol 48(1–4):395–406. https://doi.org/10.1007/s00170-009-2282-6

Büyüközkan G, Ertay T, Kahraman C, Ruan D (2004) Determining the importance weights for the design requirements in the house of quality using the fuzzy analytic network approach. Int J Intell Syst 19(5):443–461. https://doi.org/10.1002/int.20006

Franceschini F, Galetto M, Maisano D, Mastrogiacomo L (2015) Prioritisation of engineering characteristics in QFD in the case of customer requirements orderings. Int J Prod Res 53(13):3975–3988. https://doi.org/10.1080/00207543.2014.980457

Bi JW, Liu Y, Fan ZP, Cambria E (2019) Modelling customer satisfaction from online reviews using ensemble neural network and effect-based Kano model. Int J Prod Res:1–21. https://doi.org/10.1080/00207543.2019.1574989

Chaudha A, Jain R, Singh AR, Mishra PK (2011) Integration of Kano’s model into quality function deployment (QFD). Int J Adv Manuf Technol 53(5–8):689–698. https://doi.org/10.1007/s00170-010-2867-0

Yadav HC, Jain R, Singh AR, Mishra PK (2013) Aesthetical design of a car profile: a Kano model-based hybrid approach. Int J Adv Manuf Technol 67(9–12):2137–2155. https://doi.org/10.1007/s00170-012-4636-8

Zhou Q, He L (2017) Research on customer satisfaction evaluation method for individualized customized products. Int J Adv Manuf Technol:1–10. https://doi.org/10.1007/s00170-017-1192-2

Deng WJ, Chen WC, Pei W (2008) Back-propagation neural network based importance–performance analysis for determining critical service attributes. Expert Syst Appl 34(2):1115–1125. https://doi.org/10.1016/j.eswa.2006.12.016

Kuo YF, Chen JY, Deng WJ (2012) IPA–Kano model: a new tool for categorising and diagnosing service quality attributes. Total Qual Manag Bus Excell 23(7–8):731–748. https://doi.org/10.1080/14783363.2011.637811

Mikulić J, Prebežac D (2016) The Kano model in tourism research: a critical note. Ann Tour Res 61:25–27. https://doi.org/10.1016/j.annals.2016.07.014

Wu HH, Tang YT, Shyu JW (2010) An integrated approach of Kanos model and importance-performance analysis in identifying key success factors. Afr J Bus Manag 4(15):3238–3250

Tontini G, Picolo JD (2014) Identifying the impact of incremental innovations on customer satisfaction using a fusion method between importance-performance analysis and Kano model. Int J Qual Reliab Manag. https://doi.org/10.1108/IJQRM-05-2012-0062

Deng WJ, Kuo YF, Chen WC (2008) Revised importance–performance analysis: three-factor theory and benchmarking. Serv Ind J 28(1):37–51. https://doi.org/10.1080/02642060701725412

Yin J, Cao XJ, Huang X, Cao X (2016) Applying the IPA–Kano model to examine environmental correlates of residential satisfaction: a case study of Xi’an. Habitat Int 53:461–472. https://doi.org/10.1016/j.habitatint.2015.12.013

Pai FY, Yeh TM, Tang CY (2018) Classifying restaurant service quality attributes by using Kano model and IPA approach. Total Qual Manag Bus Excell 29(3–4):301–328. https://doi.org/10.1080/14783363.2016.1184082

Wang CH, Fong HY (2016) Integrating fuzzy Kano model with importance-performance analysis to identify the key determinants of customer retention for airline services. J Ind Prod Eng 33(7):450–458. https://doi.org/10.1080/21681015.2016.1155668

Liu Y, Zhang Z, Liu Z (2011) Customized configuration for hierarchical products: component clustering and optimization with PSO. Int J Adv Manuf Technol 57(9–12):1223–1233. https://doi.org/10.1007/s00170-011-3346-y

Liu HT (2009) The extension of fuzzy QFD: from product planning to part deployment. Expert Syst Appl 36(8):11131–11144. https://doi.org/10.1016/j.eswa.2009.02.070

Ning W, Ji-chao X, Yu-fan W (2012) Integrated approach of quality function deployment to quality assurance of service products design. In 2011 International Conference on Computer And Management (CAMAN). https://doi.org/10.1109/CAMAN.2011.5778891

Chan KY, Kwong CK, Hu BQ (2012) Market segmentation and ideal point identification for new product design using fuzzy data compression and fuzzy clustering methods. Appl Soft Comput 12(4):1371–1378. https://doi.org/10.1016/j.asoc.2011.11.026

Alvandi M, Fazli S, Abdoli FS (2012) K-mean clustering method for analysis customer lifetime value with LRFM relationship model in banking services. Int Res J Appl Basic Sci 3(11):2294–2302

Ho GT, Ip WH, Lee CKM, Mou WL (2012) Customer grouping for better resources allocation using GA based clustering technique. Expert Syst Appl 39(2):1979–1987. https://doi.org/10.1016/j.eswa.2011.08.045

Wang H, Huo D, Huang J, Xu Y, Yan L, Sun W, Li X (2010) An approach for improving K-means algorithm on market segmentation. In 2010 International Conference on System Science and Engineering (pp. 368-372). IEEE. https://doi.org/10.1109/ICSSE.2010.5551709

Wu RS, Chou PH (2011) Customer segmentation of multiple category data in e-commerce using a soft-clustering approach. Electron Commer Res Appl 10(3):331–341. https://doi.org/10.1016/j.elerap.2010.11.002

Sagar S, Lundberg L, Skold L, Sidorova J (2017, June) Trajectory segmentation for a recommendation module of a customer relationship management system. In 2017 IEEE International Conference on Internet of Things (iThings) and IEEE Green Computing and Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom) and IEEE Smart Data (SmartData) (pp. 1150-1155). IEEE. https://doi.org/10.1109/iThings-GreenCom-CPSCom-SmartData.2017.177

Chang EC, Huang SC, Wu HH, Lo, CF (2007) A case study of applying spectral clustering technique in the value analysis of an outfitter’s customer database. In 2007 IEEE international conference on industrial engineering and engineering management (pp. 1743-1746). IEEE. https://doi.org/10.1109/IEEM.2007.4419491

Maciejasz P, Eschweiler J, Gerlach-Hahn K, Jansen-Troy A, Leonhardt S (2014) A survey on robotic devices for upper limb rehabilitation. J Neuroeng Rehabil 11(1):3. https://doi.org/10.1186/1743-0003-11-3

Mickaël C, Bernard A (2012) 3D ISO manufacturing specifications with vectorial representation of tolerance zones. Int J Adv Manuf Technol 60(5–8):577–588. https://doi.org/10.1007/s00170-011-3638-2

Funding

The authors wish to acknowledge that this research has been supported by the Discovery Grants (RGPIN-2015-04173) from the Natural Sciences and Engineering Research Council (NSERC) of Canada, University of Manitoba Graduate Fellowship (UMGF) and the Graduate Enhancement of Tri-Council Stipends (GETS) program from the University of Manitoba.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shi, Y., Peng, Q. A spectral clustering method to improve importance rating accuracy of customer requirements in QFD. Int J Adv Manuf Technol 107, 2579–2596 (2020). https://doi.org/10.1007/s00170-020-05204-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05204-1