Abstract

This article proposes a new application of topology optimization to improve the environmental sustainability of mine waste disposal. Typically, mine wastes can be backfilled in the open-pit where the ore was extracted, sometimes surrounded by a pervious surround. This layer of high conductivity creates preferential path for the groundwater and thus permits to reduce advective contaminant transport to the environment. However, conception of the pervious surround suffers from a lack of general guidelines, and only constant width structure was considered in the literature. Improper design could also results in a reduction of the available space for the wastes, increased costs, or even poor performance. In this study, a topology optimization approach was proposed to assess the optimal pervious surround geometry which minimizes advective solute transport between contaminated wastes and the environment. Five case studies were also considered with several pit shapes including conic, elliptic, and one more realistic geometry for various gradient orientations. Results showed that a constant width pervious surround was close to optimality for pits where their major axis formed an angle of less than a \(45^\circ\) with the regional flow direction. However, for an angle of \(90^\circ\), the optimization indicated that the addition of several linear inclusions of high conductivity within the wastes could help reduce advective solute transport by nearly 40%. This paper presents the formulation of the optimization problem and its numerical implementation, details its application for five different pit geometries, and finally discuss the optimal geometries, the performance of the approach and its limitations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Surface mining operations typically generate two types of solid wastes: coarse-grained waste rocks excavated to access ore, and fine-grained tailings produced by ore milling and treatment (Bussière and Guittonny 2020). These two solid wastes are usually disposed of separately on the surface, in either impoundments confined by retaining dikes or waste rock piles, respectively (Blight 2010). Surface storage facilities raise various challenges and are particularly exposed to geotechnical instabilities. In fact, the risk for tailings impoundments failure is around 100 times greater than that of water retention dams (Azam and Li 2010) and can directly be the cause of important environmental damages and even loss of life (Roche et al. 2017). Projected climate changes may also modify the environmental conditions mine wastes storage facilities were designed for, therefore adding further uncertainty to disposal site design and increasing the risks for instabilities (Pearce et al. 2011; Parhizkar et al. 2016; Labonté-Raymond et al. 2020).

Backfilling open pits with mine wastes is an alternative disposal method which has many advantages over traditional surface storage facilities. In-pit backfilling first contributes to physically isolate the wastes by placing them underground, therefore canceling the risk associated with impoundment failure (MEND 2015). In-pit backfilling also improves reclamation performance (mine wastes can be more easily maintained saturated) and increases social acceptance of mining projects (Puhalovich and Coghill 2011; MEND 2015). However, despite the wastes being isolated in the pit, interactions with the groundwater are expected through the fractured rock. As a consequence, influx of dissolved ferric ions or oxygen could contribute to initiate acid mine drainage (AMD) generation (e.g., Santofimia et al. 2013; Villain et al. 2015; Barfoud et al. 2019), and contaminants in the waste pore water (either natural, such as radionuclides, or originating from ore processing treatment, such as cyanides) could be dispersed into the environment (Salama et al. 2002; Ben Abdelghani et al. 2015). Interactions between in-pit backfilled wastes and the groundwater must therefore be controlled.

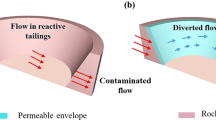

Several methods were proposed to limit the groundwater flow through backfilled wastes (MEND 2015). For example, the pervious surround method (Matich and Tao 1986) consists in placing a more permeable layer of material around the wastes to create preferential flow paths for the groundwater (Fig. 1). The pervious surround can be built using gravel or reusing materials immediately available on-site such as waste rocks if these are not reactive (Thériault 2004). The pervious surround technique can contribute to reduce the groundwater flow rate in backfilled tailings by more than 90% by significantly reducing the hydraulic gradient inside the tailings (Thériault 2004; Rousseau and Pabst 2018), therefore limiting the advective solute transport between the pit and the environment and increasing retention time of contaminants in the pit (Salama et al. 2002; West et al. 2003). The size of the pervious surround, and the permeability contrast between the wastes and the envelope are two of the main factors governing its effectiveness (Misfeldt et al. 1999; Salama et al. 2002; Thériault 2004; Lange and Van Geel 2011; Rousseau and Pabst 2018).

Description of the pervious surround principle: a without preferential path, groundwater flows freely in backfilled contaminated tailings and disperse contaminants into the environment, b the addition of the pervious surround creates preferential paths around backfilled tailings and reduces contaminant transport.

However, previous studies only considered a pervious surround with a constant width (Misfeldt et al. 1999; Salama et al. 2002; West et al. 2003; Thériault 2004; Lange and Van Geel 2011; Rousseau and Pabst 2018), and the influence of its shape was not assessed in detail. Actually (Thériault 2004; Rousseau and Pabst 2018) numerically observed that groundwater flow velocities were varying within the envelope, thus indicating the pervious surround size could be thinner in the areas with low-flow velocities and wider (to increase its transmissivity, i.e., the quantity of water that the pervious surround can transmit) where high flow velocities were simulated. Optimizing the geometry of the pervious surround could therefore contribute to improve its effectiveness, maximize the volume of wastes disposed in the pit, reduce the use of borrowed materials and the overall costs associated with the pervious surround construction, and finally improve the environmental sustainability of mine wastes disposal projects. The objective of this research was thus to determine the optimal geometry for pervious surrounds in backfilled open pits. However, studying the optimal placement for various specific pit geometries may rapidly become tedious. For examples, open pits often have elliptic or non-convex complex shapes. In such cases, the optimal design of the pervious surround may depend on the pit geometry, but also on the flow orientation (either aligned with the pit main axis, orthogonal to it, or in any intermediate directions) and on the properties of geological formation the pit is embedded in. The objective of this research was therefore to develop a rather methodology that could be applied to all types of pit geometries, geological setups, and flow orientations.

A topology optimization approach (Bendsøe and Sigmund 2003; Sigmund and Maute 2013) was chosen to carry out this study. This approach has the advantage of being flexible enough to optimize the pervious surround geometry for any pit shapes, without prior assumptions on the properties of the wastes nor the surrounding rock. Also, the topology optimization approach produces optimized geometries that are not constrained by a predetermined design, at the opposite of parametric optimization often used in hydrogeology (Kimmel et al. 2003; Kiecak et al. 2017; Grajales-Mesa et al. 2020; Singh et al. 2020). In other words, all options were considered using this approach and were not limited to a continuous surround nor placed only along the sides of the pit. Since topology optimization was introduced in 1988 for structural compliance problems (Bendsøe and Kikuchi 1988), the method had been widely applied in the industry to build lighter mechanical parts (Pang and Fard 2020; Manca and Pappalardo 2020), develop more efficient heat exchangers (Haertel et al. 2018), and improve geotechnical engineering foundation design (Pucker and Grabe 2011; Seitz and Grabe 2016; Kammoun et al. 2019). However, this is the first time, to the authors’ knowledge, that the topology optimization approach is applied to a hydrogeological problem.

This paper first presents the formulation of the topology optimization problem applied to the codisposal of non-reactive waste rocks (forming the pervious surround) and contaminated tailings in backfilled pits, followed by its numerical implementation. Then, the optimization approach was applied to two theoretical cases with a conic and an elliptic pit geometries and was extended to a (significantly) more complex real pit geometry. It finally discusses some results of the optimization of the pervious surround geometry to minimize advective solute transport between the backfilled tailings and the environment for the selected pit geometries.

2 Methodology

2.1 Formulation of the optimization problem

The pervious surround principle relies on reducing advective solute transport (West et al. 2003), so objective of the optimization in this study was focused on the reduction of influx of groundwater flow inside the tailings by creating preferential path with inert waste rock (e.g., Thériault 2004). This optimization problem was solved using a density-based topology optimization approach. It consists in searching the repartition of waste rocks and tailings using a meshed representation of the pit and on which each volumic cell was made of either waste rocks, tailings, or a mix of both (Bendsøe and Sigmund 2003; Sigmund and Maute 2013). The main advantage of the density-based approach (which allows such material mixing in the cells) is purely computational, because optimization problems expressed in a continuous form are significantly easier to solve than those using discrete variables (Bendsøe and Sigmund 2003). A continuous material density parameter \(0\le p \le 1\) was therefore introduced for each cell of the meshed pit. A cell with a density parameter \(p=0\) corresponded to tailings (supposed contaminated), while \(p=1\) corresponded to waste rock (inert). The objective of the optimization therefore equated to finding the distribution of the continuous material parameter p in the pit so the groundwater flow in backfilled tailings was minimized.

Several constraints (inspired by real operational constraints on mine sites) were also considered during the optimization. In particular, too thin (< 6 m wide) waste rock inclusions in the tailings were considered too difficult to build in practice and unrealistic for operational considerations. Therefore, a minimum length scale constraint to control the width of each geometrical feature was considered. Another constraint was also imposed to control the maximum volume of waste rocks disposed in the pit, so that operators can adjust the available volume for tailings disposal in the pit (depending on the type of operations, the ratio between waste rocks and tailings can be different, e.g., Blight 2010).

2.2 Mathematical derivation

Groundwater flow is a potential flow governed by a hydraulic head difference between two points (Bear 1972). For small head gradient, Darcy’s law states velocity v [LT\(^{-1}\)] is linearly linked to the head gradient \(\Delta h\) [-] by a coefficient K [LT\(^{-1}\)] representing the ability of the soil to conduct water, also called the soil hydraulic conductivity (Bear 1972):

In absence of source and sink terms, mass conservation law leads to the following governing equation for groundwater flow (Bear 1972):

The previous equation is usually solved numerically using finite element or finite volume method, which consists in solving a sparse matrix-vector product of the form:

where the \(\varvec{A}(K)\) matrix is assembled using the hydraulic conductivity \(K_i\) of each computational domain element i, H is the vector containing the unknown head \(h_i\) at each cell center and B contains the boundary conditions.

Groundwater flow in the tailings can locally be reduced by minimizing the local head gradient \((\nabla h)_i\) in the tailings portion of each computational cell being optimized (see Equation 1). At the backfilled pit scale, the reduction of groundwater flux through the backfilled tailings was therefore achieved in this study by minimizing the global mean head gradient in the tailings defined as:

with n the number of cells in the discretized optimization domain (the pit) and \(V_i\) the volume of each cell i. Head gradient \((\nabla h)_i\) at the center of the cell i and calculated according to the finite volume Green-Gauss gradient scheme:

where \(j\in \partial i\) is the immediate neighbors j of the cell i and \(A_{ij}\) the area of the shared face between cell i and j.

The minimum pervious surround size constraint was applied implicitly by using an volume averaged version of the density parameter \(\bar{p}\) instead of the raw density parameter p directly (adapted from Bourdin 2001): averaged density parameter \(\bar{p}\) was calculated as a weighted mean of the density parameter p in a given volume:

where R is the ball radius on which to search for the neighboring cell centers for averaging the density parameter, and \(j \in \partial i_R\) stands for every cell j in the optimization domain those center to center distance \(d_{ij}\) is less than the ball radius R. Ball radius R was chosen equal to the minimum size of the pervious surround.

Maximum amount of waste rocks disposed in the pit \(\alpha _{max}\) was expressed considering the averaged density parameter \(\bar{p}\) as:

with \(V_{pit}\) the volume of the (discretized) pit.

The logarithm of the hydraulic conductivity \(K_i\) at cell i was linked to the averaged density parameter \(\bar{p}\) according to the standard isotropic material with penalization (SIMP) scheme (Bendsøe and Sigmund 1999):

where \(K_{wr}\) and \(K_t\) are the hydraulic conductivities of waste rocks and tailings, respectively, and n is a penalization power. A penalization power \(n=3\) was applied in the present study to force the optimization to converge toward nearly discrete design where each cell is made of either purely waste rocks or purely tailings (Sigmund and Maute 2013), so no mixing (with \(0 \le \bar{p} \le 1\)) was allowed in the final designs apart mixing resulting from the application of the minimum size constraint (equation 6).

Minimizing the groundwater flux in backfilled tailings with a pervious surround made waste rocks under a minimum size and a maximum volume constraints could therefore be written:

Cost function (Equation 4) was reformualed to use the averaged density parameter \(\bar{p}\) instead of the raw density parameter p.

2.3 Performing the optimization

The optimization problem (Equation 9) was solved using the globally convergent version of the method of moving asymptote (GC-MMA) gradient descent algorithm (Svanberg 2002). This algorithm requires the total derivative of the cost function \(d\bar{c}/dp\) relative to the raw density parameter, p, which was calculated using the chain rule and the adjoint method (Errico 1997):

where \(\lambda\) is the adjoint vector, and \({\partial g}/{\partial h}\) and \({\partial g}/{\partial K}\) are the derivatives of the residual of the linear system solved (Equation 3) relative to the head and the hydraulic conductivity (i.e., the sensitivities).

At each iteration, the groundwater flow (i.e., solving equation 3) was simulated numerically using the finite volume open-source code PFLOTRAN (Hammond et al. 2012). PFLOTRAN is a hydrogeological code that allows to model subsurface transport processes such as fully saturated groundwater flows as in this study, but also variably saturated and density-dependent flows or reactive solute and heat transports. PFLOTRAN was previously successfully used by the authors to model groundwater flow near backfilled pits (Rousseau and Pabst 2020, 2021) and by other researchers for assessing solute and contaminants transport in the subsurface (Avasarala et al. 2017; Wallace et al. 2020), inversion of geophysical data (Tso et al. 2020), or fault zone hydraulics (Romano et al. 2020; Alt-Epping et al. 2021). However, sensitivities were not available in the public version of PFLOTRAN. The code was thus modified by the authors to add a new process model called SENSITIVITY_ANALYSIS, which calculated these sensitivities by finite difference and saved them in HDF5 binary format. The modifications are available at the following repository: https://bitbucket.org/pflotran/pflotran/branch/moise/make_optimization_v2. Adjoint equation (10) was solved using the BiCGSTAB algorithm (van der Vorst 1992) and with a point Jacobi preconditionner.

Cost function calculation, update of the density parameter p, derivation of the hydraulic conductivity in the domain, and PFLOTRAN simulation at each iteration were carried out automatically using a newly created and open-source Python library named HydrOpTop (see Replication of results section). The Python libraries NumPy (Harris et al. 2020), nlopt (Johnson 2021), and SciPy (Jones et al. 2001) were used to manipulate data arrays during the optimization process, update the density parameter according to the GC-MMA algorithm, and solve the adjoint equation, respectively. The whole process was conducted in eight steps:

-

1.

Initialize the density parameter

-

2.

Average the density parameter

-

3.

Calculate the hydraulic conductivity of each cell according to the averaged density parameter

-

4.

Conduct numerical simulation

-

5.

Calculate objective function and constraints

-

6.

Solve adjoint equation and calculate derivatives

-

7.

Update the density parameter

-

8.

Repeat steps 2 to 7 until the number of iterations (400) was reached or when the relative change in the cost function between two consecutive iterations was less than 1\(\times\)10-6.

At the end of the optimization process, the final geometry of the pervious surround was derived from the averaged density parameter \(\bar{p}\). Cells with an averaged density parameter lower than a threshold \(\bar{p} \le \bar{p}_{thres}\) were considered as waste rocks, and cells with \(\bar{p} \le \bar{p}_{thres}\) were considered as tailings. The threshold \(\bar{p}_{thres}\) was chosen so that the final design respect the maximum volume fraction allowed in the pit (equation 7). This process is equivalent to the application of a volume-preserving Heaviside density filter with infinite steepness as in Xu et al. (2010).

2.4 Optimization case studies

The above topology optimization approach (which was developed to be applicable to any pit geometry and wastes properties) was used to assess the optimal shape of a pervious surround made of waste rocks to minimize the advective solute transport (i.e., groundwater flow in backfilled tailings) in three pit geometries including two idealistic pit geometries and one inspired from a real mine site (Table 1). The first example consisted of a conic pit with a top radius of 250 m, a bottom radius of 50 m, and a depth of 250 m with a global 1.2:1 pit wall slope, representing therefore a volume of nearly 10 million cubic meters. The second example consisted of an elliptic pit characterized by a top-major and minor axis of 450 and 150 m, a bottom-major and minor axis of 350 and 50 m, and a depth of 150 m (pit wall slope of 1.5:1), for a volume of approximately 21 million of cubic meters. In the elliptic case, the flow and the pervious surround geometry may depend on the gradient orientation. Therefore, three gradient orientations were considered: perpendicular to the minor axis, perpendicular to the major axis, and with a \(45^\circ\) orientation. A last example considered a real pit geometry, which consisted of a roughly elliptical pit, 1000 m long, 300 m wide, and 175 m deep, with a mean wall slope of 1:1.7 and a volume of 3.44\(\times\)10\(^{7}\) m\(^{3}\) (see below for a illustration of the pit geometry). Regional groundwater flow in this case formed an angle of \(35^\circ\) with the pit major axis.

Pit geometries were modeled and discretized using the open-source CAD software Salome (Ribes and Caremoli 2007) using built-in geometrical objects for both the conic and the elliptic pit and from a topographic map for the real case. Pit walls were simplified and a unique slope was considered (i.e., the benches were not modeled). Conic pit was discretized using an axisymmetric mesh composed of hexahedron and prisms with approximately 264 000 cells (including 189 000 in the pit), and the elliptic and the real pits used a Centroidal Voronoi Tesselation composed of 500 000 cells (418 000 in the pit) for the elliptic case and 640 000 (500 000 in the pit) for the real one.

In all the cases tested, backfilled tailings were considered reactive and pre-oxidized, while the pervious envelope was made of inert waste rocks. A maximum volume fraction of waste rocks equal to 20% of the pit volume (\(\alpha _{max}=0.2\) in equation 7) was considered (this value could be adjusted depending on operational constraints). Tailings and waste rocks were considered to have a hydraulic conductivity of \(K_t=\) 5\(\times\)10-7 m/s and \(K_{wr}=\) 5\(\times\)10-4 m/s, respectively (which are typical values for in hard rock mines; Aubertin et al. 2002; Bussière 2007). The rock surrounding the pit was considered homogenous with a hydraulic conductivity of \(K_r=\) 1\(\times\)10-7 m/s (e.g., Sykes et al. 2009; Zharikov et al. 2014; Cahyadi et al. 2017). Topography around the pits was considered planar and groundwater flow was submitted to a unitary regional head gradient (Table 1). Fully saturated conditions were considered at all times.

The gradient-based algorithm used by the topology optimization problem only can find local optimum, and the solution of the optimization process thus depends of the starting point. Several starting points were therefore considered in this study to search for better optimized geometries and included (1) a homogeneous distribution of density parameter \(p=0.18\) in the pit, (2) a discrete distribution approaching the theoretical pervious surround (i.e., the density parameter p was set to 1 if the cell belonged to the pervious surround, and \(p = 0\) otherwise), (3) several continuous distributions of the raw density parameter in the range \(p \in [0.001, 0.4]\) to respect the volume fraction \(\alpha _{max}\) of 0.2, and (4) several discrete distributions of waste rocks and tailings in the domain (p was either 0 or 1 randomly). Starting points from the pervious surround (case 2) ensured that the optimized geometry would have at least the same performance as the reference pervious, while random starting points (cases 3 and 4) could initiate the emergence of non-conventional geometries. In the rest of the paper, the geometry reducing the most the mean head gradient in the tailings was called the optimal geometry, to clearly differentiate it from other geometries still optimized but less efficient. It is reminded, however, that the optimal geometry determined in this study did not necessarily correspond to the global optimum for the reasons explained above.

The difference between the optimal (best) geometry and the others optimized geometries was evaluated by calculating the volume of waste rock lying outside the optimal geometry noted \(P_d\) (for percentage of dissimilarity). The smaller the percentage of dissimilarity \(P_d\), the higher the considered geometry is similar to the optimal one. The performances of the optimized geometries were also compared to the case where the pit was backfilled with tailings only and with a homogeneous pervious surround of constant width (i.e., 15, 12, and 13 m in the conic, elliptic, and real pit geometries, respectively).

3 Results

3.1 Conic pit

3.1.1 Optimized geometry

Topology optimization of the codisposal of waste rocks forming the inert preferential paths and contaminated tailings was first assessed in the conic pit. Among the various starting points, the optimal geometry (with the lowest mean head gradient) was obtained starting from a random continuous distribution (\(p \in [0.001, 0.4]\)) in the pit (Table 2). The optimization process preferentially placed waste rocks all along the pit wall, therefore forming a pervious surround (Fig. 2a). The width of the pervious surround was, however, not constant and varied radially and with the pit depth. The optimal geometry was also quasi-symmetric respective to the plane perpendicular to the flow direction and passing through the pit center. The symmetry was, however, not exactly perfect, probably because of the non-symmetric starting point. The waste rock width was varying significantly close to the top of the pit and was approximately 9 m wide where the pit walls were perpendicular to the regional flow direction (i.e., 6 m finer than the reference pervious surround of 15 m) and up to 34 m where they were parallel (i.e., 19 m wider than the reference pervious surround). Elsewhere (i.e., in the slopes and on the pit bottom), the optimal width of the pervious surround was 9 m in average and 6 m thinner than the reference regular pervious surround. A bulge was also observed between 200 and 220 m depth (i.e., in the lower 1/5 of the pit) where the pit wall was parallel to the gradient direction (Fig. 2a). With this optimal geometry, the mean head gradient in the tailings was approximately 4.32\(\times\)10\(^{-3}\), i.e., 99 times lower compared to case without pervious surround (4.28\(\times\)10\(^{-1}\)), and 1.9% lower than the reference constant width pervious surround (4.40\(\times\)10\(^{-3}\); Table 2).

Groundwater streamlines entering the tailings were nearly linear, aligned with the simulated regional flow direction, and had a constant velocity. The total flowrate of groundwater entering the tailings was therefore estimated by multiplying the flow velocity by the projected area of the tailings in the plane perpendicular to the flow. The total flowrate entering the tailings was thus approximately 4240 m\(^{3}\)/y, which corresponded to a 6% decrease compared to the constant width pervious surround (4420 m\(^{3}\)/y), reducing by same amount the advective solute transport, and approximately 120 times lower compared to the case without pervious surround (506 000 m\(^{3}\)/y, Table 2).

This first example therefore showed that simple modifications in the pervious surround geometry can contribute to reduce the groundwater flux in backfilled tailings and thus the advective solute transport, therefore slightly improve the performance of the technique.

Optimized pervious surround geometry. a Optimal geometry (starting from a random continuous density parameter), b starting from the pervious surround, c starting from a homogeneous density parameter \(p=0.18\), and d from a discrete distribution of waste rocks and tailings in the pit. Geometries are colored according to the isohydraulic head in the pervious surround, for which groundwater flow is perpendicular with. Measures on geometries a to c locate and indicate the maximum pervious surround width at the top of the pit. Only waste rocks are shown, the rest of the pit volume is occupied by tailings. Black arrows show the regional flow direction, and \(\nabla h\) indicates the head gradient in the tailings. SP starting point

3.1.2 Impact of starting point on optimized geometry

Similar mean head gradient and flowrate through the tailings were also obtained with the optimized geometries emerging from other starting points considered. Indeed, mean head gradient for the other optimized cases (i.e., originating from different starting points) were all comprised between 4.35\(\times\)10\(^{-3}\) and 4.60\(\times\)10\(^{-3}\), which was approximately between 0.75 and 6.6% greater than considering the optimal geometry, while flow rate was between 4300 and 4540 m\(^{3}\) (1.7 to 7.0% greater; Table 2).

Starting from the pervious surround (Fig. 2b), the optimization gave an optimized geometry which was very close to the starting point and the constant width pervious surround. The width of the pervious surround was essentially modified at the top of the pit and was wider (respectively, thinner) of 8 m compared to reference pervious surround where the pit walls were parallel (respectively, perpendicular) to the regional flow direction. Also, starting from an homogeneous distribution \(p=0.18\) everywhere in the pit (Fig. 2c), the optimized geometry was similar to the optimal case. The pervious surround was essentially larger at the top of the pit where it was up to 10 m larger where the pit walls were parallel to the regional flow, and slightly finer elsewhere. The same bulge as in the optimal geometry was also obtained. Lastly, random discrete starting points (three runs) generally created conduit of waste rocks through the tailings (Fig. 2d). They approximately had the form of arches which intercepted each other to form larger conduits in the center of the pit. These arches are represented between 30 and 35% of the total waste rocks volumes in the pit, and their shapes and locations depended on the initial random distribution considered, but with some similarity. For example, all the runs created a pervious surround with a conduit at nearly the same location of the bulge than the optimal case.

Starting point sensitivity analysis showed that all the geometry included a pervious surround which was larger where the pit walls were parallel to the regional flow direction, thinner when perpendicular, and for most of them, the same increased width/conduits on the lower fifth of the pit. These similarities between optimized and optimal geometries showed both features (pervious surround of a variable width and the bulge) were robust local optimum and contributed to reduce the mean head gradient in the tailings compared to the reference constant width pervious surround. The similar mean head gradient and flow rate in each optimized case also showed that significant changes in the pervious surround design did not drastically modify its hydraulic and advective solute transport performance (the relative changes of mean head gradient and flowrate were lower than 2% and 5%, respectively). In practice, this allows for some flexibility in pervious surround design and construction.

The three optimized geometries starting from random discrete distribution of the density parameter p also constitue examples of how topology optimization can create non-conventional designs. However, in conic pits, performance of such non-conventional designs was between 3.3% and 7.0% lower than the optimal pervious surround in terms of mean head gradient and flow rate. This therefore indicates that the addition of conduits through the tailings was a-priori not necessary and less efficient than a pervious surround only.

3.2 Elliptic pit

3.2.1 Flow parallel to the main axis (\(0^\circ\) gradient orientation)

Optimization of the waste rock placement was then carried out for the elliptic pit geometry and considering first a regional gradient parallel to the pit major axis (0\(^\circ\) gradient). The optimal geometry consisted of a pervious surround and was obtained with the pervious surround starting point (Fig. 3), but other starting points also converged to a similar geometry. The surround width somewhat varied radially, but less than with the conic pit, and was up to 14 m wide (+2 m compared to the constant width pervious surround) where the pit wall was parallel to the regional flow direction and 9 m close to walls perpendicular to the regional flow direction (− 3 m compared to the constant width pervious surround). On the pit floor, the waste rock width was constant and around 12 m (like in the reference case). This optimal geometry was therefore very close to the reference case with a constant width pervious surround (< 4% dissimilarity with the reference case; Table 3).

These small dissimilarities were, however, sufficient to reduce the mean head gradient in the tailings by 3.9% compared to the reference case (Table 3), and by a 60 times factor compared to the case with tailings only. The optimal geometry also contributed to effectively divert the groundwater streamlines toward the sides and the bottom of the pit, and flow rate entering the tailings was also significantly decreased to approximately 4800 m\(^{3}\)/y, i.e., 71 times lower than in the case with tailings only and 5.5% lower than in the constant width pervious surround case (Table 3). Small modifications of the pervious surround width along the wall could therefore lead to a significant reduction of the flowrate through the tailings (and thus of the risk of contamination).

3.2.2 45\(^\circ\) oriented flow

The optimal geometry of the pervious surround in an elliptic pit with a regional gradient oriented 45\(^\circ\) with the pit major axis consisted of an axisymmetric pervious surround and a rectilinear inclusion located in the middle of the pit and on the top of the tailings (Fig. 4). The width of the pervious surround was mainly constant in the slopes (9 m in average, − 3 m compared to the reference constant width pervious surround), but varied radially at the top of the pit. The pervious surround width was maximal (up to 27 m) where the groundwater in the rock flowed tangentially to the pit walls, and minimal (9 m) where groundwater in the pervious surround flowed radially to them (Fig. 4). The planes tangential to the pit walls at these locations, respectively, formed an angle of − 26\(^\circ\) and 78\(^\circ\) with the gradient orientation (in the trigonometric direction; Fig. 4), respectively. The rectilinear inclusion, located on the top of the tailings and at the pit center was approximately 60 m wide, 12 m high, and oriented in the regional flow direction. The pervious surround on the pit bottom showed an alternance of eyes-shaped holes letting tailings directly in contact with the surrounding rock and of pseudo-inclusion up to 22 m high. These inclusions and holes were preferentially aligned with the vertical plane joining the two sides of the pit where the pervious surround width was maximal.

The mean head gradient in the tailings with the optimal waste rocks and tailings geometry was approximately 9.21\(\times\)10\(^{-3}\), which was 60 times lower than in the case with tailings only and 4% better than considering the constant width pervious surround (Table 4). The optimized geometry also contributed to divert the groundwater streamlines toward the bottom of the pit. The few groundwater streamlines still entering the tailings flowed with an angle of -26\(^\circ\) with the regional gradient direction and were also parallel to the plane tangential to the pit walls at the maximum pervious surround width.

Sensitivity analyses performed using other starting points showed that some of the other optimized geometries had very similar performances to the optimal one, with a mean head gradient less than 0.6% greater than the optimal case (Table 4). These geometries were, however, significantly different from the optimal one, with a percentage of dissimilarity of around 15%. The main difference between these geometries and the optimal one described above was the absence of the linear waste rocks inclusion at the surface of the tailings in the middle of the pit, thus indicating that in practice, this only marginally contributed to reduce the mean head gradient in the tailings. However, minimum and maximum pervious surround width locations were still at the same place than in the optimal geometry described above.

Optimal pervious surround for the elliptic pit with a 45\(^\circ\) gradient orientation showing minimum and maximum width at non-trivial location, a linear waste rocks inclusion aligned with the regional flow direction and with various holes on pit bottom. Colored according to the local hydraulic head

3.2.3 90\(^\circ\) gradient orientation optimization

Considering a gradient orientation parallel to the pit minor axis (90\(^\circ\) gradient orientation), the optimal geometry was obtained starting from a random discrete distribution of waste rocks within the tailings. The optimal geometry consisted of a pervious surround, with various waste rocks conduits through the tailings or lying on the pit bottom (Fig. 5). In this case, the pervious surround width along the pit walls was approximately constant and 8 m wide (− 4 m compared to the reference case). There were a total of 10 conduits through the tailings located at variable depth but usually in the top half of the pit (between 0 and 75 m depth). They were also quasi-linear for most of them, usually 25 m wide in diameter, and distant from each other by approximately 50 m. Conduits lying on the pit bottom were approximately 20 m high and separated by several elliptic holes with a variable width along the pit major axis (12 to 30 m) and a nearly constant size along the minor axis (30 m). The pit wall parallel to regional flow direction also showed a bulge between 50 and 70 m depth and nearly 20 m high (Fig. 5).

This optimal geometry gave a mean head gradient in the tailings of 4.14\(\times\)10\(^{-3}\), which corresponded to a decrease of 38% compared to the reference pervious surround case (5.7\(\times\)10\(^{-3}\)), and a decrease by a factor 83 compared to the case with tailings only (Table 5). The increased gradient reduction compared to the other elliptic cases considered above (below 5% in general) could be explained by the relatively short flow distance and by the different flow path taken by the groundwater in the optimal pervious surround, which tended to enter the pervious surround and then continue toward the pit bottom or enter the conduits. Streamlines in the tailings were mainly rectilinear and aligned with the regional gradient direction, and the simulated flowrate was approximately 5340 (m\(^{3}\)/y), i.e., 38% lower than those in the reference pervious surround case and 100 times lower than the case with tailings only, thus decreasing advective solute transport by the same amount.

The sensitivity analysis conducted for the 90\(^\circ\) gradient orientation case showed that all the optimized geometries consisted of a pervious surround, either with a constant or variable width (larger where the pit wall was parallel to regional flow, thinner elsewhere). Nearly all the optimized geometries (except those starting from the pervious surround) also showed waste rock conduits at the surface or through the tailings, which performed better than the reference pervious surround; Table 5). Therefore, these results showed that the width-optimized pervious surround was not the most efficient geometry, even if it contributed to significantly reduce the mean head in the tailings (− 17% compared to the reference case) and that waste rock conduits were necessary to increase the efficiency of the pervious surround. In practice, this implied a pervious surround along with multiple linear inclusion of waste rock through or at the surface of the tailings should be considered in elliptic pit when the regional gradient is parallel to the pit minor axis.

3.3 Real case geometry

Finally, the topology optimization approach was applied to the pervious surround design in the real pit geometry described above. The optimal geometry was obtained considering the random continuous starting point (\(p\in [0,0.4]\)) and consisted of a pervious surround with a variable width (Fig. 6). Three other starting points (homogeneous, pervious surround, and another random continuous) also gave very similar performance (i.e., less than 0.01% difference) and similar optimized geometry (between 7 and 9% dissimilarity; Table 6). The essential feature of these four optimized geometries was the variable width of the pervious surround, which was 8 m wide alongside the east and west walls of the pit (where the groundwater was entering or leaving the pervious surround), and up to 20 m wide on the north and south walls and on the pit floor (where groundwater was flowing mainly tangentially to the pit wall). Pervious surround width was approximately constant and 16 m thick on pit bottom. Groundwater in the optimal geometry flowed nearly linearly in the tailings, but with a angle of approximately 20\(^\circ\) with the regional flow direction, i.e., an angle of -15\(^\circ\) with the pit major axis (Fig. 6). Mean head gradient in the tailings was approximately 9.52\(\times\)10\(^{-3}\) for all the four optimized geometry, which was 64 lower than the case with tailings only, and 5% lower than with a constant width pervious surround (Table 6). The very similar mean head gradients considering the four starting point indicated that the optimal geometry found in this study was a robust optimum. This also indicates that the little changes between the different geometry did not impact so much their performance, or in other words that construction of the pervious surround would be relatively flexible.

4 Results analysis

4.1 Optimal waste rocks and tailings codiposal geometry

The results of the optimization showed that for all the cases simulated, the optimal geometry for reducing groundwater flow in backfilled tailings consisted of a pervious surround with a variable width, and in few cases with waste rocks conduits through the tailings (i.e., in elliptic pit with gradient along the minor axis). The optimal pervious surround was in general thinner where the groundwater flow entered or exited the pit, and wider where the flow in the pervious surround was tangential to the pit wall. These locations corresponded, respectively, to the direction perpendicular and parallel to the regional flow direction in the cases of conic and elliptic pits when the gradient was aligned with its major or minor axis. However, this was no more the case considering the other gradient orientation for elliptic pits (i.e., the 45\(^\circ\) gradient orientation; Fig. 4) and for the real case inspired pit, for which these locations were no more linked trivially to the pit geometry or to the gradient orientation.

Gradient reduction using the optimized pervious surround was significant, but rather small compared to the constant width reference case for four of the five pit geometries simulated (i.e., between 2 and 5% in conic, elliptic pit with a gradient orientation of less than 45\(^\circ\), and the real pit). This showed, along with the sensitivity analysis regarding the optimization starting point, that significant different geometries could perform similarly. In other words, construction rules for building a pervious surround should be relatively flexible in practice, providing the essential feature of the optimal are built (for example, as long as the pervious surround is thinner where the flow enters the pit, and wider where the flow is parallel to the pit walls). In these cases, the added value of the topology optimization approach was to prove that such a pervious surround was actually a robust optimum which might be close the global optimum of the optimization problem.

Conduits of waste rock running through the tailings were often obtained for several geometries (conic, 45 and 90\(^\circ\) elliptic pit and the real case), especially when using random discrete starting points. In most cases, these waste rock conduits were oriented along the regional flow direction independently of the pit shape, which could give the impression that such design would contribute to reduce the contaminant transport in general. However, such structures contributed to reduce the mean head gradient in the tailings only in the elliptic pit case and when the regional gradient was orientated along the pit minor axis (90\(^\circ\) angle). In this case, gradient was reduced by nearly 17% and flowrate (advective solute transport) by 16% compared to only a variable width pervious surround, to reach a total gradient and flowrate reduction compared to the reference case by 38% (Table 5). In practice, the use of linear inclusions of waste rock therefore appears useful only when the gradient is oriented with the minor axis, and of negligible significance otherwise (while causing some additional challenges in terms of construction, also see discussion below).

4.2 Validation of the optimized geometries with transport simulations

The final purpose of adding a pervious surround structure in the pit was to reduce the total solute transport from the backfilled tailings to the environment (i.e., advective and diffusive). In the previous section, optimization was carried out based on the minimization of hydraulic head in the tailings to reduce advective solute transport (see methodology). Thus, in this section, the optimal geometry of the elliptic pit with a gradient orientation along the minor axis (see section 3.2.3 above) was validated using simplified transport simulations of the dispersion in the environment of a non-reactive contaminant contained in the backfilled tailings and considering advective and diffusive transport mechanisms. Geochemical reactions such as mineral dissolution or precipitation were neglected.

To evaluate the performance of the optimal geometry, total contaminants remaining in the pit and contaminant flux exiting the pit were assessed. Transport simulation considering the optimal pervious surround was compared to the case with tailings only, with a constant width pervious surround, and with the optimized width pervious surround (pervious surround starting point). For the purpose of the demonstration, tailings in the pit were considered to initially have an arbitrary contaminant concentration of 1.0 mol/L, while the background concentration in the rest of the domain and in the waste rocks was considered negligible and set to 1.0\(\times\)10\(^{-9}\) mol/L (at time \(t=0\)). The diffusion coefficient of the contaminant in the water was 1\(\times\)10\(^{-9}\) m\(^{2}\)/s. Isotropic dispersivity coefficients of 0.5 m in the tailings and the waste rocks and of 50 m in the surrounding rock were considered. These values were based on the scale of the transport simulation (Schulze-Makuch 2005), while the choice of an isotropic coefficient was made because the use of Voronoï cells with PFLOTRAN did not allow for an accurate modelization of anisotropic phenomenon (actually, face should be aligned with the principal direction of dispersion; Moukalled et al. 2016). Hydraulic gradient for transport simulations was lowered to 0.01 to represent realistic field conditions.

Transport simulation carried out considering the case with tailings only showed half the contaminant initially in the tailings was dispersed in the environment in approximately 500 years, and that all the contaminant was dispersed after 2000 years. Maximum instantaneous percentage release rate occurred at the start of the transport simulation and was 0.17%/year (dark curve in Fig. 7a and b).

Then, the addition of the pervious surrounds resulted in significant extension of the contaminant retention in the pit and decrease of the solute release rate. Considering the reference (constant width) pervious surround (blue triangle curve in Fig. 7), it took approximately 21,000 years to disperse half of the contaminant initially in the pit to the environment, i.e., 42 times higher than the case with tailings only. Peak percentage release rate with the reference pervious surround reached 0.0071%/year (25 times less than the case with tailings only) at the start of the simulation, and quickly decreased to less than 0.0025%/year after 4000 years, and then slowly toward less than 0.0001%/year after 80,000 years.

Optimization of the pervious surround width only (i.e., geometry without conduits such as starting from the pervious surround geometry) permitted to increase further the retention of half the contaminant by 23% to 26,000 years (red curves in Fig. 7), but also to decrease the instantaneous percentage release rate by up to 20% between 0 and 38,000 years. After that time, the optimized width pervious surround releases more contaminant, but this occurred because it stayed up to 35% more contaminants in the pit considering the width-optimized than the constant width pervious surround at this time (Fig. 7a). Overall, these results showed the reference and especially the optimized width pervious surround were effective to limit contaminant transport between the pit and the environment.

The optimal pervious surround with conduits did not, however, significantly increase the retention of contaminant in the pit compared to the reference pervious surround (green curve in Fig. 7a), despite a lower contaminant release rate during 90% of the simulation time (i.e., after 9000 years Fig. 7b). This could be explained by the fact that limiting the mean head gradient in tailings might effectively reduce the advective solute transport, but not necessarily the diffusive transport mechanism which can be predominant at early time because of the large concentration gradient at the interface between the tailings and the waste rock (West et al. 2003; Lange and Van Geel 2011). Actually, waste rock conduits through the tailings increased the interface area between the waste rocks and the tailings, which allowed more contaminant to migrate from the tailings to the waste rocks and to the environment. This results in a significant increase of the simulated instantaneous solute release rate by up to 35% before 9000 years compared to the reference case (up to 0.0096 vs. 0.0071%/year; Fig. 7b). Consequently, even if the waste rock conduits contributed to reduce by 40% the mean head gradient in the tailings, it was not effective to limit the overall contaminants transport from the pit to the environment in this case. This finding illustrates the limitations induced by the choice of the objective function and the approach to focus on groundwater flow and advective solute transport only.

a Percentage of solute remaining in the pit and b solute release rate from the tailings to the environment considering no pervious surround (back curves), the constant width reference pervious surround (blue triangle curves), the optimized width pervious surround (red circle curve) and the addition of conduits (green square curves) and for the elliptic pit geoemetry with a gradient orientation along its minor axis. PS pervious surround

4.3 Limits of the approach and discussion

Topology optimization results illustrate how different starting points can sometimes result in significantly different optimized geometries. This is caused by the choice of the gradient descent algorithm to solve the optimization problem which cannot find global, but only local, optima. Starting from a constant width pervious surround only slightly altered the starting geometry but guarantee to decreased the mean head gradient compared to the reference pervious surround, while starting from a random placement of waste rock and tailings in the pit could create unconventional features such as conduits of waste rocks connecting the two sides of the pit. These conduits, however, often did not contribute to decrease significantly the mean head gradient in the tailings (i.e., the advective solute transport between the wastes and the environment), except for some specific cases such as an elliptic pit with a gradient orientation along the minor axis (Fig. 5). In practice, these results show that it is necessary to carry more than one optimization and to use various starting points to obtain the most optimal geometries. Such behavior is often encountered when using the topology optimization approach, and other authors also recommend to vary starting points (Haertel et al. 2018) or the material property parametrization technique (Bendsøe and Sigmund 1999).

The waste rock conduits obtained in this study also illustrate the limitations of the topology optimization approach, as no operational constraints are considered until explicitly specified. For example, such conduits could be difficult to construct when the tailings are disposed as a slurry: tailings may be not passable and waste rocks may sink and be mixed with tailings. Waste rocks must therefore be placed over already placed waste rocks, as fine layers of material are placed over existing material in additive manufacturing. In other words, the pervious surround must be “self-supported.” Additive manufacturing constraints and self-supported structures in topology optimization are, indeed, an active area of research (Garaigordobil et al. 2018; Wang et al. 2018; Zhang et al. 2019; Xiong et al. 2020) which may thus benefit to the codisposition of waste rock and tailings in open pits. Other operational constraints could also be added to address the long-term performance of the pervious surround. For example, the risk for tailings erosion and migration through the waste rocks and potential clogging of the preferential paths might also be limited by constraining the maximum velocity in the pervious surround (e.g., Kassimov and Obnosov 2018).

For some of the cases considered in this study (and especially the elliptic pit case with a gradient orientation along the major axis), the relative change of the width near the pit walls was similar to the mean size of the elements used to discretize the pit. This may indicate that the optimization mesh was not refined enough near the pit wall to precisely capture the optimal size of the pervious surround along the walls. The relatively coarse mesh near the pit wall could also introduce numerical errors on the flow and transport simulations carried out in this study. Actually, Salama et al. (2002) and Rousseau and Pabst (2018) highlighted the influence of the discretization to accurately simulate flow and transport in backfilled pit, which requires at least 16 elements over the pervious surround width while in this study, the optimized pervious surround was sometimes represented using only 4 elements. Unfortunately, further refinement in this case was not possible because of computational limitations. Recommendation for future optimization of codisposal in conic or elliptic pits would thus be to increase the mesh density near the pit walls.

Application of the minimum size constraint using an averaged density parameter \(\bar{p}\) resulted in some cells with intermediate density \(0 \le \bar{p} \le 1\) at the end of the optimization step. Final designs (Figs. 2, 3, 4, 5, 6) were obtained by applying a threshold density to these intermediate density cells. This last operation led, however, to a non-negligible difference in the mean head gradient in the tailings calculated before and after the thresholding process. For example, during the conic pit pervious surround optimization, the optimal geometry was obtained from the homogeneous starting point, while after thresholding, the optimal geometry was obtained starting from a random continuous distribution (Fig. 8 and Table 2). In practice, this indicates that optimizing the pervious surround using the averaged density \(\bar{p}\) design is not equivalent to optimize the discrete design. This difference could have resulted in non-optimal final pervious surround geometries. A way to circumvent this problem could be to project the averaged density parameter \(\bar{p}\) using a smooth Heaviside function and slowly increase its steepness during the optimization process (e.g., Xu et al. 2010).

Convergence history (100 first iterations) of the cost function during optimization of the pervious surround in the conic pit for various starting points. Cost function value calculated using the averaged density parameter \(\bar{p}\) instead of the thresholded optimized pervious surround geometries (see Table 2 for final mean head gradient comparison)

Finally, the objective function and constraints used in this study were simplification of the real objective. As discussed above, reducing the mean head gradient in the tailings effectively reduced the advective solute transport from backfilled tailings to the environment, but not necessarily the diffusive transport. Reducing the diffusive mechanisms could be integrated in the optimization process by adding constraints on the maximum area or a penalizing term in the objective function to minimize the contact area between the tailings and the waste rocks, for example (Fernandes et al. 1999). A more powerful approach would be to carry the optimization directly on the contaminant release rate from the pit to the environment. This would, however, require to further modify the flow solver to output the transport process model sensitivity and to adapt the adjoint method to handle coupled processes and time-dependent solution, which was outside the scope of this study.

5 Conclusion and final remarks

This study proposed a new application of the topology optimization approach to improve the environment sustainability of mine wastes disposal by better designing inert and highly conductive pervious surround around contaminated wastes backfilled in open pits for various pit geometries and hydrogeological setups. The optimization approach was applied to two idealistic pit geometries, and a more realistic geometry inspired from a real case.

Results proved that a constant width pervious surround constitutes a nearly optimal geometry for conic and elliptic pits when the gradient formed an angle of maximum 45\(^\circ\) with the pit minor axis. A variable width pervious surround (wider when parallel to the flow, thinner when orthogonal to the flow) could contribute to further improve the performance of the technique, but it only resulted in a 6% reduction of the advective solute transport between the backfilled wastes and the environment. The pervious surround geometry thus appeared to not strongly affect its performance, indicating there would be some flexibility during its conception and construction in practice. In the case the regional flow direction is aligned with the elliptic pit minor axis, the optimized pervious surround could reduce by up to 17% the advective solute transport. The addition of conduits of waste rocks through the tailings could even increase the performance of the system by 38% compared to the constant width reference case, yet adding construction challenges.

Overall, these results showed the good applicability of the topology optimization approach in hydrogeology at the early stage of conception. The optimized geometries and their non-conventional features (and especially waste rocks conduits) were automatically obtained without previous assumptions on the pit shape, material properties, or hydrogeological conditions in the surrounding rock. However, some of the optimized geometries obtained with this approach could be difficult to construct in practice, as it did not consider constructability constraint (except from those explicitly formulated). In addition, conduits could increase the diffusive solute transport. Further work must focus on improving the developed topology optimization approach by integrating more operational constraints and more specific objective functions to address these challenges.

References

Alt-Epping P, Diamond LW, Wanner C, Hammond GE (2021) Effect of glacial/interglacial recharge conditions on flow of meteoric water through deep orogenic faults: insights into the geothermal system at grimsel pass, switzerland. J Geophys Reshttps://doi.org/10.1029/2020JB021271, https://agupubs.onlinelibrary.wiley.com/doi/abs/10.1029/2020JB021271, https://arxiv.org/abs/https://agupubs.onlinelibrary.wiley.com/doi/pdf/10.1029/2020JB021271

Aubertin M, Bussière B, Bernier L (2002) Environnement et gestion des rejets miniers, manuel sur cédérom. Presses Internationales Polytechnique, Montréal, Canada

Avasarala S, Lichtner PC, Ali AMS, González-Pinzón R, Blake JM, Cerrato JM (2017) Reactive transport of u and v from abandoned uranium mine wastes. Environ Sci Technol 51(21):12,385-12,393. https://doi.org/10.1021/acs.est.7b03823

Ayachit U (2015) The ParaView guide: a parallel visualization application; updated for ParaView version 4.3. Kitware, Clifton Park, NY, oCLC: 915643233

Azam S, Li Q (2010) Tailings dam failures: a review of the last one hundred years. Geotech News 28:50–54

Barfoud L, Pabst T, Zagury GJ, Plante B (2019) Effect of Dissolved Oxygen on The Oxidation of Saturated Mine Tailings. In: Geo-Environmental Engineering 2019, Montréal, Canada, p 7

Bear J (1972) Dynamics of Fluids In Porous Media. American Elsevier Publishing Company, google-Books-ID: 9JVRAAAAMAAJ

Ben Abdelghani F, Aubertin M, Simon R, René T (2015) Numerical simulations of water flow and contaminants transport near mining wastes disposed in a fractured rock mass. Int J Min Sci Technol 25(1):37–45. https://doi.org/10.1016/j.ijmst.2014.11.003

Bendsøe MP, Kikuchi N (1988) Generating optimal topologies in structural design using a homogenization method. Comp Methods Appl Mech Eng 71(2):197–224. https://doi.org/10.1016/0045-7825(88)90086-2

Bendsøe MP, Sigmund O (1999) Material interpolation schemes in topology optimization. Arch Appl Mech 69(9):635–654. https://doi.org/10.1007/s004190050248

Bendsøe MP, Sigmund O (2003) Topology optimization: theory, methods, and applications. Springer, Berlin, New York

Blight GE (2010) Geotechnical engineering for mine waste storage facilities. CRC Press, Boca Raton, https://www.taylorfrancis.com/books/9780203859407

Bourdin B (2001) Filters in topology optimization. Int J Numer Methods Eng 50(9):2143–2158. https://doi.org/10.1002/nme.116

Bussière B (2007) Colloquium 2004: Hydrogeotechnical properties of hard rock tailings from metal mines and emerging geoenvironmental disposal approaches. Can Geotech J 44(9):1019–1052. https://doi.org/10.1139/T07-040

Bussière B, Guittonny M (2020) Hard Rock Mine Reclamation: From Prediction to Management of Acid Mine Drainage. CRC Press, Boca Raton. https://doi.org/10.1201/9781315166698

Cahyadi TA, Widodo L, Syihab Z, Notosiswoyo S (2017) Hydraulic conductivity modeling of fractured rock at grasberg surface mine. Papua-Indonesia. J Eng Technol Sci 49(1):37–57. https://doi.org/10.5614/J.ENG.TECHNOL.SCI.2017.49.1.3

Errico RM (1997) What is an adjoint model? Bull Am Meteorol Soc 78(11):2577–2592. https://doi.org/10.1175/1520-0477(1997)078<2577:WIAAM>2.0.CO;2

Fernandes P, Guedes JM, Rodrigues H (1999) Topology optimization of three-dimensional linear elastic structures with a constraint on “perimeter’’. Comp Struct 73(6):583–594. https://doi.org/10.1016/S0045-7949(98)00312-5

Garaigordobil A, Ansola R, Santamaría J, de Bustos IF (2018) A new overhang constraint for topology optimization of self-supporting structures in additive manufacturing. Struct Multidisc Optim 58(5):2003–2017. https://doi.org/10.1007/s00158-018-2010-7

Grajales-Mesa SJ, Malina G, Kret E, Szklarczyk T (2020) Designing a permeable reactive barrier to treat TCE contaminated groundwater: numerical modelling. Tecnol Cienc Agua 11(3):78–106. https://doi.org/10.24850/j-tyca-2020-03-03

Haertel JHK, Engelbrecht K, Lazarov BS, Sigmund O (2018) Topology optimization of a pseudo 3D thermofluid heat sink model. Int J Heat Mass Transf 121:1073–1088. https://doi.org/10.1016/j.ijheatmasstransfer.2018.01.078

Hammond GE, Lichtner PC, Lu C, Mills T (2012) PFLOTRAN: reactive flow & transport code for use on laptops to leadership-class supercomputers. In: Zhang F, Yeh GTG, C. Parker J (eds) Groundwater Reactive Transport Models. Bentham Science Publishers, Sharjah, UAE, p 141–159, https://doi.org/10.2174/978160805306311201010141

Harris CR, Millman KJ, van der Walt SJ, Gommers R, Virtanen P,Cournapeau D, Wieser E, Taylor J, Berg S, Smith NJ, Kern R, Picus M, Hoyer S, van Kerkwijk Mh, Brett M, Haldane A, del Río JF, Wiebe M, Peterson P, Gérard-Marchant P, Sheppard K, Reddy T, Weckesser W, Abbasi H, Gohlke C, Oliphant TE (2020) Array programming with NumPy. Nat 585(7825):357–362. https://doi.org/10.1038/s41586-020-2649-2

Hunter JD (2007) Matplotlib: a 2D graphics environment. Comp Sci Eng 9(3):90–95. https://doi.org/10.1109/MCSE.2007.55

Johnson SG (2021) The NLopt nonlinear-optimization package. https://github.com/stevengj/nlopt, original-date: 2013-08-27T16:59:11Z

Jones E, Oliphant E, Peterson P (2001) SciPy: open source scientific tools for python. http://www.scipy.org/

Kammoun Z, Fourati M, Smaoui H (2019) Direct limit analysis based topology optimization of foundations. Soils Found 59(4):1063–1072. https://doi.org/10.1016/j.sandf.2019.05.003

Kassimov A, Obnosov Y (2018) Hydraulically optimal porous liner around a porous lens: Strack’s problem revisited. Taylor and Francis Ltd., J Hydraul Eng publisher. https://doi.org/10.1080/09715010.2018.1516576

Kiecak A, Malina G, Kret E, Szklarczyk T (2017) Applying numerical modeling for designing strategies of effective groundwater remediation. Enviro Earth Sci 76(6):248. https://doi.org/10.1007/s12665-017-6556-2

Kimmel M, Piel B, Baroudi H, Esnault-Filet A, Laloum X, Mazzieri D (2003) Hydrogeologic modelling for permeable reactive barriers design. In: International FZK/TNO Conference on Contaminated Soil, Gand, Belgium, pp 2715–2723. https://hal-ineris.archives-ouvertes.fr/ineris-00972419

Labonté-Raymond PL, Pabst T, Bussière B, Bresson É (2020) Impact of climate change on extreme rainfall events and surface water management at mine waste storage facilities. J Hydrol 590(125):383. https://doi.org/10.1016/j.jhydrol.2020.125383

Lange K, Van Geel PJ (2011) Physical and numerical modelling of a dual-porosity fractured rock surrounding an in-pit uranium tailings management facility. Can Geotech J 48(3):365–374. https://doi.org/10.1139/T10-080

Manca AG, Pappalardo CM (2020) Topology Optimization Procedure of Aircraft Mechanical Components Based on Computer-Aided Design, Multibody Dynamics, and Finite Element Analysis. In: Ivanov V, Pavlenko I, Liaposhchenko O, et al (eds) Advances in Design, Simulation and Manufacturing III. Springer International Publishing, Cham, Lecture Notes in Mechanical Engineering, pp 159–168, https://doi.org/10.1007/978-3-030-50491-5_16

Matich MAJ, Tao WF (1986) Pervious surround method of waste disposal. https://patents.google.com/patent/US4580925A/en

MEND (2015) In-pit disposal of reactive mine wastes: approaches, update and case study results. Tech. rep., Mine Environment Neutral Drainage, Ottawa, http://mend-nedem.org/wp-content/uploads/2.36.1b-In-Pit-Disposal.pdf

Misfeldt G, Loi J, Herasymuik G, Clifton AW (1999) Comparison of tailings containment strategies for in-pit and above-ground tailings management facilities. In: GeoRegina: the 52nd Canadian geotechnical conference, Regina, pp 279–286

Moukalled F, Mangani L, Darwish M (2016) The Discretization Process. In: Moukalled F, Mangani L, Darwish M (eds) The finite volume method in computational fluid dynamics: an advanced introduction with OpenFOAM®and Matlab. Fluid Mechanics and Its Applications, Springer International Publishing, Cham, pp 85–101, https://doi.org/10.1007/978-3-319-16874-6_4

Pang TY, Fard M (2020) Reverse engineering and topology optimization for weight-reduction of a bell-crank. Appl Sci 10(23):8568. https://doi.org/10.3390/app10238568

Parhizkar M, Therrien R, Molson JWH, Lemieux JM, Fortier R, Talbot Poulin MC, Therrien P, Ouellet M (2016) Application of a 3D model to assess the thermo-hydrological effects of climate warming in a discontinuous permafrost zone, Umiujaq, Northern Quebec, Canada. In: AGU Fall Meeting, http://adsabs.harvard.edu/abs/2016AGUFM.H43E1503P

Pearce TD, Ford JD, Prno J, Duerden F, Pittman J,Beaumier M, Berrang-Ford L, Smit B (2011) Climate change and mining in Canada. Mitig Adapt Strateg Glob Chang 16(3):347–368. https://doi.org/10.1007/s11027-010-9269-3

Pucker T, Grabe J (2011) Structural optimization in geotechnical engineering: basics and application. Acta Geotech 6(1):41–49

Puhalovich AA, Coghill M (2011) Management of mine wastes using pit void backfilling methods – current issues and approaches. In: McCullough C (ed) Mine Pit Lakes: Closure and Management. Australian Centre for Geomechanics, Perth, Australia, p 13, https://acg.uwa.edu.au/shop/plakes/

Ribes A, Caremoli C (2007) Salome platform component model for numerical simulation. In: 31st Annual International Computer Software and Applications Conference (COMPSAC 2007), pp 553–564, https://doi.org/10.1109/COMPSAC.2007.185

Roche C, Thygesen K, Baker E (2017) Mine Tailings Storage: Safety Is No Accident. Tech. rep., UN Environment, GRID-Arendal

Romano V, Bigi S, Carnevale F, De’Haven Hymanb J, Karrab S, Valocchic AJ, Tartarelloa MC, Battagliaa M (2020) Hydraulic characterization of a fault zone from fracture distribution. J Struct Geol. https://doi.org/10.1016/j.jsg.2020.104036

Rousseau M, Pabst T (2018) 3D numerical assessment of the permeable envelope concept for in-pit disposal of reactive mine wastes. In: 71st Canadian Geotechnical Conference and the 13th Joint CGS/IAH-CNC Groundwater Conference, GeoEdmoton 2018, Edmonton, AB, Canada

Rousseau M, Pabst T (2020) Blast damaged zone influence on water and solute exchange between backfilled open-pit and the environment. In: GeoVirtual, Online conference

Rousseau M, Pabst T (2021) Analytical solution and numerical simulation of steady flow around a circular heterogeneity with anisotropic and concentrically varying permeability. Water Res Res. https://doi.org/10.1029/2021WR029978

Salama A, Van Geel PJ, Nguyen TS, Ben Belfadhel M, Flavelle P (2002) Two-dimensional ground flow and solute transport in an in pit tailings management facility: a parametric study. In: Stolle D, Piggott AR, Crowder JJ (eds) 55th Canadian geotechnical and 3rd joint IAH-CNC and CGS groundwater specialty conferences. Niagara Falls, Ontario, pp 1373–1380

Santofimia E, López-Pamo E, Montero E (2013) Environmental management of Aznalcóllar mine and its influence in the hydrogeochemical of the pit lake. Water Environ Res 85(8):706

Schulze-Makuch D (2005) Longitudinal dispersivity data and implications for scaling behavior. Groundw 43(3):443–456. https://doi.org/10.1111/j.1745-6584.2005.0051.x

Seitz KF, Grabe J (2016) Three-dimensional topology optimization for geotechnical foundations in granular soil. Comp Geotech 80:41–48. https://doi.org/10.1016/j.compgeo.2016.06.012

Sigmund O, Maute K (2013) Topology optimization approaches: a comparative review. Struct Multidisc Optim 48(6):1031–1055. https://doi.org/10.1007/s00158-013-0978-6

Singh R, Chakma S, Birke V (2020) Numerical modelling and performance evaluation of multi-permeable reactive barrier system for aquifer remediation susceptible to chloride contamination. Groundw Sustain Dev 10(100):317. https://doi.org/10.1016/j.gsd.2019.100317

Svanberg K (2002) A Class of globally convergent optimization methods based on conservative convex separable approximations. J Optim 12(2):555–573. https://doi.org/10.1137/S1052623499362822

Sykes JF, Normani SD, Jensen M, Sudicky E (2009) Regional-scale groundwater flow in a Canadian Shield setting. Can Geotech J 46(7):813–827. https://doi.org/10.1139/T09-017

Thériault V (2004) Étude de l’écoulement autour d’une fosse remplayée par une approche de fracturation discrète. Master dissertation, École Polytechnique de Montréal. https://publications.polymtl.ca/7210/

Tso CHM, Johnson TC, Song X, Xingyuan C, Kuras O, Wilkinson P, Uhlemann S, Chambers J, Binleya A (2020) Integrated hydrogeophysical modelling and data assimilation for geoelectrical leak detection. J Contaminant Hydrol. https://doi.org/10.1016/j.jconhyd.2020.103679

Villain L, Sundström N, Perttu N, Alakangas L, Öhlander B (2015) Evaluation of the effectiveness of backfilling and sealing at an open-pit mine using ground penetrating radar and geoelectrical surveys, Kimheden, northern Sweden. Environ Earth Sci 73(8):4495–4509. https://doi.org/10.1007/s12665-014-3737-0

van der Vorst HA (1992) Bi-CGSTAB: a fast and smoothly converging variant of bi-cg for the solution of nonsymmetric linear systems. SIAM J Sci and Stat Compu 13(2):631–644. https://doi.org/10.1137/0913035

Wallace CD, Sawyer AH, Barnes RT, Soltanian MR, Gabor RS, Wilkins MJ, Moore MT (2020) A model analysis of the tidal engine that drives nitrogen cycling in coastal riparian aquifers. Water Res Res. https://doi.org/10.1029/2019WR025662

Wang Y, Gao J, Kang Z (2018) Level set-based topology optimization with overhang constraint: Towards support-free additive manufacturing. Comp Methods Appl Mech Eng 339:591–614. https://doi.org/10.1016/j.cma.2018.04.040

West AC, Van Geel PJ, Raven KG, Nguyen ST, Belfadhel MB, Flavelle P (2003) Groundwater flow and solute transport in a laboratory-scale analogue of a decommissioned in-pit tailings management facility. Can Geotech J 40(2):326–341. https://doi.org/10.1139/t02-108

Xiong Y, Yao S, Zhao ZL, Xie M (2020) A new approach to eliminating enclosed voids in topology optimization for additive manufacturing. Addit Manuf 32(101):006. https://doi.org/10.1016/j.addma.2019.101006

Xu S, Cai Y, Cheng G (2010) Volume preserving nonlinear density filter based on heaviside functions. Struct Multidisc Optim 41(4):495–505. https://doi.org/10.1007/s00158-009-0452-7

Zhang K, Cheng G, Xu L (2019) Topology optimization considering overhang constraint in additive manufacturing. Comp Struct 212:86–100. https://doi.org/10.1016/j.compstruc.2018.10.011

Zharikov AV, Velichkin VI, Malkovsky VI, V. M. Shmonov (2014) Experimental study of crystalline-rock permeability: implications for underground radioactive waste disposal. Water Resour 41(7):881–895. https://doi.org/10.1134/S0097807814070136

Acknowledgements

The authors acknowledge the financial support from the Fond de Recherche du Québec - Nature et Technologie (FRQNT, Grant Number 2017-MI-202116) and from the partners of the Research Institute on Mines and the Environment (RIME UQAT- Polytechnique; http://rime-irme.ca/en). 3D visualization was carried out using the Paraview software (Ayachit 2015) and 2D plots were constructed using the Matplotlib Python library (Hunter 2007). Figures were modified using the free software Inkscape www.inkscape.org.

Funding

This work was supported by the Fond de Recherche du Québec - Nature et Technologie (FRQNT, Grant Number 2017-MI-202116) and from the industrial partners of the Research Institute on Mines and the Environment (RIME UQAT- Polytechnique; http://rime-irme.ca/en).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare that is relevant to the content of this article.

Replication of results

HydrOpTop library along with two pervious surround optimization examples is available at the following repository: https://github.com/MoiseRousseau/HydrOpTop. The modified finite volume solver used to carried the numerical simulations is available at: https://bitbucket.org/pflotran/pflotran/branch/moise/make_optimization_v2. Numerical models of the case studies are, however, not published because of storage constraint.

Additional information

Responsible Editor: Seonho Cho.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rousseau, M., Pabst, T. Topology optimization of in-pit codisposal of waste rocks and tailings to reduce advective contaminant transport to the environment. Struct Multidisc Optim 65, 168 (2022). https://doi.org/10.1007/s00158-022-03266-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00158-022-03266-1