Abstract

Co-disposition of tailings and waste rocks in open pits in the form of a permeable envelope and/or waste rock inclusions (WRI) can efficiently prevent the transport of contaminants to the environment. Such drainage paths could also accelerate tailings consolidation rate, similarly to WRI in tailings storage facilities, and therefore improve tailings mechanical properties in the short term and maximize the volume of mine waste that can be disposed of. These geotechnical benefits have, however, not been demonstrated yet nor thoroughly investigated. In this research, three-dimensional models were performed to examine the evolution of tailings consolidation in pits under the influences of co-disposed waste rocks. Various disposal scenarios were investigated, including the presence of a permeable envelop only and the addition of WRI as a central inclusion. The influences of operational and practical aspects such as the tailings filling rate, pit slope angles, waste rock and tailings hydro-geotechnical properties, and pit morphology were investigated. Results indicated that a permeable envelope could promote the dissipation of excess pore water pressure (PWP) and accelerate tailings consolidation. The influence zone of the permeable envelope was relatively limited and around 2 times the tailings height. Using a WRI combined with a permeable envelope could be geotechnically beneficial for wide pits whose radius was larger than twice of its depth. Slope angles, filling rate and pit morphology somewhat affected tailings consolidation rate, but their effect was relatively limited and decreased with the increase in the distance to the drainage paths.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The continuously increasing demand for natural resources and minerals has induced a significant increase of the volume of tailings produced by mining operations, therefore also increasing the risks for major failures events of surface tailings storage facilities (TSFs), and encouraging practitioners to find alternative approaches for tailings disposal (Vick 1990; Blight 2010). Innovative integrated mine waste managements techniques include tailings dewatering (Bolduc and Aubertin 2014; Bhuiyan et al. 2015; Abdulnabi et al. 2022), valorization and reuse of mine waste in cover systems (Pabst et al. 2018; Larochelle et al. 2019), or tailings and waste rocks mixing (Wickland et al. 2006; Aubertin 2013). Tailings can also be backfilled either in underground stopes (Li and Aubertin 2009; Cui and Fall 2016; Chai et al. 2023) or disposed in open pits (Cameron and Dave 2015; Rousseau and Pabst 2022). Among them, in-pit disposal is considered an alternative deposition approach for surface mines, and presents many advantages both in terms of environmental, physical and social aspects (McDonald and Lane 2010; Aubertin 2013; Bhuiyan et al. 2015; Cameron and Dave 2015). For example, pit backfill can contribute to stabilize pit walls and reduce long-term management and maintenance costs compared to conventional surface disposal sites (Cameron and Dave 2015; MEND 2015). Once backfilled, the pit can also be reclaimed using engineered cover systems to prevent contaminated mine drainage generation and facilitate its integration into the surrounding landscape (McDonald & Lane 2010). Also, in pit disposal reduces the risk of dam failure (MEND 2015).

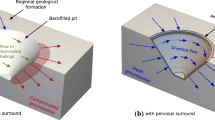

However, in-pit disposal is also facing several challenges and unknowns that somewhat limit its applications. Preventing environmental contamination, for example, can be complex when there is a direct contact between groundwater and backfilled wastes, especially because pit walls are usually strongly disturbed by blasting during operations and therefore become relatively permeable (Cameron and Dave 2015; Rousseau 2021). The concept of an engineered pervious envelope surrounding the tailings mass was thus proposed to control potential environmental contamination by directing the groundwater around the tailings (instead of flowing through them), thus limiting the interactions between groundwater and potential contaminants (e.g., processed pore water or reactive minerals) (Bhuiyan et al. 2015; MEND 2015) (Fig. 1). This can be achieved by placing a more permeable material compared to tailings around the perimeter and at the bottom of the pit (Bhuiyan et al. 2015). Such pervious surround is often made of sand or coarse materials (Cameron and Dave 2015) but using non acid-generating waste rock on site can be more advantageous in some cases. Indeed, waste rocks have adequate properties, and their valorization on site contributes to decrease the volumes of waste rock to be disposed of on the surface (thus also reducing costs and risks). The permeable envelope concept could also be geotechnically beneficial, and contribute to accelerate tailings consolidation rate, which might in turn reduce long-term displacements, maximize storage volume, and allow progressive reclamation (McDonald and Lane 2010; Lévesque 2019).

Permeable envelope concept. a Without a permeable envelope, regional groundwater is expected to flow through tailings disposed of in the pit, thus increasing the risk for contaminant transport to the environment. b With a permeable envelope, groundwater is diverted along the pit walls, and the contact with the tailings is minimized. (modified after (Rousseau 2021))

Additional drainage pathways composed of waste rocks and integrated inside the backfilled pit could further improve the hydrogeological behaviour of backfilled tailings by reducing contaminant transport (Rousseau and Pabst 2022). These waste rock inclusions (WRIs), which were initially developed for surface TSFs, where they can promote dissipation of excess pore water pressure (PWP), accelerate tailings consolidations and improve static and dynamic stability of tailings dams (Aubertin 2013; Ferdosi et al. 2015). WRIs can increase the performance of a permeable envelope if these WRIs are built across the pit and in the same direction as the regional flow (Rousseau 2021). The application of permeable envelope, potentially integrated with WRI, might therefore facilitate the long-term management of mine wastes in pits.

The geotechnical benefits of a permeable envelope combined with multi-drainage paths remain, however, theoretical and research on this aspect are still limited. The advantages and potential limitations of tailings co-disposal with permeable envelope and/or WRI thus need to be evaluated in more details before it can be implemented into practice. Also, the presence of multiple drainage paths could complexify their interactions with tailings thus requiring the use of a 3-D analysis. Several factors influencing the effectiveness of the technique also need to be considered, including the overall slope angles of the pit, variable tailings filling rate (the width of a pit increasing with its elevation, the filling rate will thus decrease during backfilling, assuming a constant production), tailings and waste rocks hydro-mechanical properties, WRI design, and the morphology of the pit.

The objective of this research was, therefore, to quantitatively evaluate the effects of a permeable envelope and various co-disposal scenarios on the evolution of tailings consolidation in an open pit using 3-D simulations carried out with the code FLAC3D (Itasca 2021). In this paper, a series of 3-D hydro-geotechnical coupled models were first conducted to examine the interaction between tailings disposed of in a pit and a permeable envelope composed of waste rocks. Various disposal scenarios were investigated, including the addition of WRI across the pit. Finally, a parametric analysis was conducted to evaluate the influence of operational and practical constraints such as the pit depth, the pit wall slope angles, the tailings filling rate, the tailings hydraulic properties and the pit morphology. Results in terms of PWP evolution and degree of consolidation were compared to give recommendations to optimize the approach.

2 Methodology

2.1 Conceptual Models

A 320 m wide × 620 m long × 60 m deep pit, inspired by a real pit in Quebec, Canada, was considered and simulated using FLAC3D (Itasca 2021). The pit usually exhibits somewhat circular corners in practice which was simplified as an orthogonal geometry in these models (i.e., parallelepipedal pit). The effect of this assumption would be discussed later. Considering the symmetry axes, only one fourth of the pit was modelled to reduce computational time without decreasing mesh size nor simulation precision (i.e., around 39,000 zones instead of almost 160,000 zones for a full-pit model) (Fig. 2). The domains were discretized using a hexahedral mesh resulting from the built-in blocks in the software. The angle of the pit wall was 51°, which was slightly smaller than usual slopes in practice (Utili et al. 2022), but this value also aimed to increase the mesh size of the simulated domain. The pit wall is usually constructed with several benches, yet the influences of these benches would be neglected in the case a permeable envelope was constructed, and these benches therefore were not simulated in the models.

Various disposal scenarios were simulated (Table 1 and Fig. 2). Case 1 was the base case scenario, considering the regular deposition of 5 m thick saturated tailings in 12 layers over 12 years for a total height of 60 m. Each layer was deposited instantly, i.e., 5 m at once every year. This was corresponding to a production rate of about 1.3 million m3 of tailings per year, which is somewhat similar to the rate from a mine with a high production rate (Blight 2010). The second case simulated the situation where tailings were co-disposed with an 8 m wide permeable envelope made of coarse waste rock and placed progressively as the tailings were deposited. In the third case, a bottom drainage layer made of coarse waste rocks 5 m thick was added to the permeable envelope, thus representing the typical design of the method in practice. In the fourth case, a WRI alone was considered, placed in the centre of the pit. The WRI has the thickness of 16 m with the same height as the tailings, and there was no interface element used between WRI, permeable envelope and tailings. For simplicity, WRI was represented as parallelepipeds instead of the typical trapezes usually constructed in practice. This assumption had, however, no influence on the results and could actually contribute to reduce numerical instabilities (Bolduc and Aubertin 2014).

Cases combining the permeable envelope, the bottom drainage and the WRI were performed with the tailing thickness of 60 m, 65 m, 70 m, 75 m, and 80 m corresponding to the case 5, 6, 7, 8 and 9 respectively. Rock wall and bottom drain were constructed first, while permeable envelope and WRI were constructed and raised at the same time with tailings. Comparison between deposition scenarios was conducted in terms of tailings consolidation rate, in particular along section A–A′ (in the middle of the pit at y = 160 m) and section B–B′ (in the middle of the pit at x = 80 m) (Fig. 2).

Regarding the parametric analysis, the effects of benches would be negligible when the permeable envelope was constructed, but the overall slopes of the pit wall might affect the consolidation of tailings because of the changes in the length to the drainage paths (Fig. 2). The overall slope angles of the pit with the depth smaller than 100 m can reach up to 70° (Utili et al. 2022), simulations with slopes of the rock walls being 60° and 70° corresponding to cases 10 and 11 respectively were, thus, performed to examine the effect of slope angles on the tailings consolidation when applying permeable envelope concept. Simulations where layer thickness of the first two layers was 7.5 and 10 m respectively (thickness of other following layers were still 5 m) were also carried out (i.e., cases 12 and 13 respectively). These rates were chosen to investigate the potential effects of changes in the filling rate due to change in the pit surface on the evolution of consolidation of tailings.

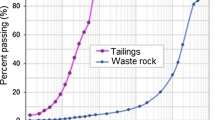

2.2 Material Properties

The gold mine tailings simulated in this study were sampled from Malartic mine site, an open pit gold mine located in Quebec Province, and classified as low plasticity silts (ML) (ASTM D2487-17 2017) (Nguyen 2022). Malartic tailings were characterized in the laboratory (Table 2). Value of D60 (the diameter corresponding to 60% passing in the particle-size distribution curve) was around 0.04 mm, and the value of D10 (the diameter corresponding to 10% passing in the particle-size distribution curve) was around 0.0035 mm, leading to a coefficient of uniformity Cu (Cu = D60/D10) around 11.5 (Fig. 3). Tailings dry density was 1.55 tones/m3. A friction angle of 38° was measured using triaxial test and tailings were considered cohesionless (Boudrias 2018). Initial porosity of tailings was 0.437, and Poisson’s ratio (estimated from internal friction angle) was 0.28.

Initial stiffness and hydraulic conductivity were estimated as 2.2 × 10−7 m/s and this value was typical for hard rock mine tailings (Bussière 2007). However, stiffness and hydraulic conductivity of slurry tailings vary as their void ratio decreases and assuming constant properties in the simulations might not be representative of their actual non-linear behaviour (Somogyi 1980; Schiffman 1982; Townsend and McVay 1990; Morris 2002). Various mathematical formulas relating void ratio with effective stress and hydraulic conductivity with void ratio have been proposed for slurry tailings (Priestley 2011; Agapito and Bareither 2018; Nguyen and Pabst 2023). In this study, the power function was chosen for its simplicity and good representativeness.

Linear elastic-perfectly plastic Mohr–Coulomb model (MC) was first assigned for tailings. Stiffness and hydraulic conductivity of tailings in Mohr–Coulomb model were modified based on non-linear relations between e-σ', k-e and Young modulus—effective stress obtained from compression column tests on the same tailings materials (Nguyen & Pabst 2020). Void ratio was updated based on effective stress following the equation of \(e= 0.814 x {{\sigma }{\prime}}^{-0.058}\), while the relation of hydraulic conductivity and void ratio was expressed as \(k=1.24 x {10}^{-6} {e}^{4.61}\). Finally, Young’s modulus was updated based on the following equation \(E=85.6 x {{\sigma }{\prime}}^{0.74}\). During the simulations, void ratio was updated every iteration based on the value of effective stress, followed by an automatic update of hydraulic conductivity and stiffness. These modifications on the Mohr–Coulomb constitutive model’s properties were executed via FISH in FLAC3D (Nguyen 2022).

The permeable envelope and WRI were assumed to be made of the same coarse waste rock and to have homogenous and similar properties in all the models. Waste rock materials were simulated using a simple linear elastic constitutive model with a high Young modulus to represent a very stiff material (E = 500 MPa) and a Poisson's ratio of 0.277 (Bolduc and Aubertin 2014). Waste rocks were assigned a hydraulic conductivity of 2 × 10−6 m/s (i.e., around 20 times greater than that of tailings). This value is significantly lower than the usual hydraulic conductivity of waste rocks which commonly ranges from 10−5 to 10−3 m/s (James 2009; Boudrias 2018), but was chosen to reduce computational time. Indeed, a domain consisting of 2 types of materials with contrastive permeabilities in a model would significantly reduce the time step of the model (Itasca 2021). A limited parametric analysis was also conducted to evaluate the effect of reducing waste rocks’ hydraulic conductivity (see below).

2.3 Boundary and Initial Conditions

Displacement at the bottom of the pit was fixed at zero in all directions, and side boundaries of the models were fixed horizontally as competent rock mass was assumed for the bottom and wall sides of the open pits (Itasca 2021). Rock was considered relatively impermeable (see above) so bottom and side boundaries were assumed impervious. Local groundwater flowed around the pit and assumed to have no interaction with tailings, and thus was expected not to have much impact on the results (Rousseau and Pabst 2022). Zero PWP was assigned at the surface of tailings to represent the groundwater table therefore allowing upward movement of water from the tailings (Ferdosi et al. 2015).

The undrained condition with the generation of excess PWP development was first generated, followed by a dissipation of PWP and consolidation of the materials (Itasca 2021). The convergence criteria for a node (i.e., the ratio of the current mechanical force ratio to the target force ratio of the node) is set to 1 (Itasca 2021).

3 Results

3.1 Effect of Permeable Envelope on Tailings Consolidation Performance

Case 1 and case 2 models were first compared to evaluate the effect of the permeable envelope on the consolidation rate of tailings. One year after the placement of the 12th layer (i.e., t = 12 years), tailings at the bottom of the pit (z = 0 m) had not achieved full dissipation in the case with tailings only (case 1), with a degree of consolidation not exceeding around 80% (Fig. 4a). In other words, the depth of the pit was so important that excess PWP did not have the time to dissipate to the surface of the tailings as it can usually be observed in simulations of TSFs (Jaouhar et al. 2013; Boudrias 2018; Lévesque 2019). Such situation would be unfavourable for reclamation of the pit as post-settlement could continue to occur after the construction of the cover system (McDonald and Lane 2010). The use of a permeable envelope, however, contributed to increase the degree of consolidation of tailings (Fig. 4a). For example, consolidation at z = 0 m and at a horizontal distance of 2, 12, and 32 m along the cross-section A–A′ were around 98%, 95% and 90% respectively after 12 years. The degree of consolidation at X = 52 m was, however, smaller and around 84%, but it was still greater than the case without permeable envelope (= 80%). Similar results were observed throughout the entire pit and at all times (i.e., consolidation was always greater with a permeable envelope than without). A permeable envelope could therefore increase significantly the degree of consolidation of tailings, but this effect tended to decrease further away from the envelope or closer to the tailings surface. 3D effect of the permeable envelope at the corner of the pit on the acceleration of the tailings consolidation would also be discussed in detailed in the discussion session later.

Degree of consolidation in the tailings with a permeable envelope (case 2) at various horizontal distances from the permeable envelope in the longitudinal direction (see Fig. 2) at the bottom of the pit along section A–A′ a after the addition of the 12th layer, b after the placement of the 5th layer and c at various distances from the permeable envelope in the horizontal direction along section B–B′ after the addition of the 10th layer. Results with tailings only (case 1) are also presented for comparison

Not only did the permeable envelope contribute to increase the degree of consolidation, it also accelerated the time required to dissipate excess PWP. For example, time to achieve 90% of consolidation, often noted t90, at 2 and 12 m from the permeable envelope at the base of the pit (z = 0 m) 1 year after the placement of the fifth layer (i.e., t = 5 years) was around 42 and 70 days, respectively, that was 66 and 38 days faster than in the case with tailings only (Fig. 4b). The difference of t90 between the cases with and without a permeable envelope 52 m from the permeable envelope was, however, much less significant, and less than 5%. The zone of influence of the permeable envelope (i.e., the zone where the permeable envelope reduce t90 by at least 5%) was around 2 times the height of tailings filled (Fig. 4b) which was somewhat similar to that of a WRI in surface TSFs (Bolduc and Aubertin 2014). Similar results were obtained along section B-B’ (Fig. 4c). For example, the permeable envelope in the horizontal direction contributed to accelerate the dissipation of PWP after the placement of the 10th layer (i.e., 184 days and 77 days faster than without a permeable envelope at a distance of 2 m and 32 m from the horizontal permeable envelope, respectively). This positive effect, however, became negligible (i.e., less than 5% of difference) at a distance of 102 m from the permeable envelope (Fig. 4c). The zone of influence of the permeable envelope was therefore estimated around 102 m.”

The zone of influence of the permeable envelope after the placement of 60 m of tailings in the pit was therefore around 120 m and thus could not cover the entire width of the pit (i.e., which was around 160 m at its base). Models with combination of a permeable envelope with other drainage pathways (i.e., WRI and bottom drainage) with the aim of accelerating even more the consolidation of tailings were thus investigated.

3.2 Tailings Consolidation Under Various Drainage Paths

The use of a WRI alone has a similar effect to a permeable envelope and can also contribute to enhance tailings consolidation rate in the pit (case 3). All the results presented hereafter were simulated along section A-A’ but similar results were obtained elsewhere in the model. t90 in the middle of the 1st layer (z = 2.5 m) after the placement of the 10th layer (i.e., t = 10 years) with only WRI ranged from around 133 days (X = 2 m) to 340 days (X = 110 m) (Fig. 5a), which was significantly faster than in the case with tailings only (case 1), and somewhat similar to the case with a permeable envelope (case 2) (Fig. 5a). However, t90 4 m from the permeable envelope was somewhat greater than 4 m from the WRI (i.e., 178 days compared to 133 days), which can be attributed to the difference in terms of geometry of these drainage paths (i.e., inclined envelope compared to the vertical WRI). However, these differences remained limited and usually did not exceed 40 days (25%).

Time t90 along the section A–A′ in the middle of the 1st layer (z = 2.5 m or 7.5 m for case without or with bottom drain respectively) 1 year after the placement of the 10th layer (t = 10 years) for various co-disposal scenario (also see Table 1). a Combined effect of the permeable envelope, WRI and bottom drainage contributed to significantly increase excess PWP dissipation rate, and b vertical evolutions of degree of consolidation at X = 80 m (section A–A′) with drainage paths (case 9) 1 year after the placement of 80 m of tailings

In practice, a permeable envelope is usually combined with a bottom drainage which can contribute to accelerate even more the dissipation of excess PWP and particularly in the bottom half of the pit (case 4). For example, t90 in the middle of the 1st layer (i.e., z = 7.5 m, which is 2.5 m above the bottom drain which was 5 m thick) was around 280 days at horizontal position from 4 to 40 m, which is up to 60 days faster compared to the case with only permeable envelope (Fig. 5a). This effect tended to decrease higher up and farther way from the bottom drain, where t90 then became similar to the case with permeable envelope only (see more discussion below).

Finally, the combination of a permeable envelope, a WRI and a bottom drainage was investigated (case 5). This configuration was the most efficient in terms of acceleration of excess PWP (Fig. 5). For example, t90 of tailings at the middle of the first layer (z = 7.5 m) was 215 days at X = 90 m, which was around 100 days faster than the case with only permeable (case 2), and 135 days faster than the case with no drainage pathway at all (Fig. 5a). The use of various drainage pathways, separately or together, however, depends on site-specific operational aspects which would be discussed later.

From the vertical profile of the degree of consolidation, U, at X = 80 m along section A–A′ for model with only tailings, U was significantly lower compared to that of a model with drainage paths (i.e., 60% compared to around 87%, respectively in the middle of the first layer) 1 year after the placement of 80 m of tailings (i.e., case 9, see Sect. 6.4.1 as well) (Fig. 5b). These differences tended, however, to decrease closer to the tailings surface and were smaller than 5% at z = 60 m). Despite the presence of the bottom drainage paths, the degree of consolidation, U, tended to decrease between z = 5 to 30 m (e.g., the lowest degree of consolidation was around 85% at z = 20 m), and then increased as distances to the surface decreased (Fig. 5b). This therefore indicated that there was an effect of the depth of the pit in the case of using bottom drain (i.e., distance to the drainage path in practice).

4 Parametric Analysis

Based on the results presented above, co-disposal of tailings with waste rock (either in the form of permeable envelope, WRI and/or bottom drain) contributed to significantly accelerate the dissipation of excess PWP, and thus contributed to the reduction of both post-settlement after closure and contact of tailings with local groundwater. Practical constraints that could potentially affect the effectiveness of this technique include the depth of the pit, the change of filling rate, the pit slope angles, the WRI hydraulic properties, the pit morphology, and the tailings properties.

4.1 Effect of the Pit Depth

The disposal scenario with the combination of permeable envelope, WRI and bottom drain at the same time produced the most effective performance in terms of consolidation rate enhancement, at least for the tested conditions. Results also shown, however, that the performance of the technique was strongly dependent on the distance to the drainage paths. The effect of pit depth, and tailings thickness, were therefore investigated.

Simulations showed that if the tailings thickness was greater than 80 m, there were some locations at the middle of the pit where excess PWP in tailings might not fully dissipate after one year of filling (i.e., before the addition of the next layer; Fig. 6). For example, the maximum t90 in the middle of the 1st layer (i.e., 2.5 m above the bottom drain) was around 260 days at X = 100 m after the placement of 60 m of tailings, around 310 days after the placement of 70 m of tailings, and above one year after the placement of 80 m of tailings (degree of consolidation was around 87% after one year) (Fig. 6).

Time t90 along section A–A′ 2.5 m above the bottom drain (z = 7.5 m) 1 year after the placement of the 12th, 14th and 16th layers (i.e., corresponding to a tailings thickness of 60, 70 and 80 m, respectively) in models with the combination of permeable envelope, WRI and bottom drain. Excess PWP was not able to fully dissipate in one year when the tailings thickness was greater than 80 m from horizontal positions of X = 80 m to X = 100 m (the line was cut off at these positions)

From the above results when tailings thickness reached 80 m, some delay in tailings consolidation at the middle positions in the pit can be expected. One solution might be to install additional WRI so that the distance between the tailings and the nearest drainage path never exceed twice their thickness. Such solution would, however, significantly reduce the volume of tailings that can be stored in the pit (also see discussion below).

4.2 Effect of Pit Wall Slope Angle

The pit wall slope usually depends on the distribution characteristic of the ore body and the stability properties of the rock pit wall (Hustrulid et al. 2013), and the pit walls for the pit with the depth of 100 m is usually inclined maximum 70 degrees (Utili et al. 2022). In the previous simulations, the pit wall slope angle was 50°, and additional models with slope angles of 60° and 70° were conducted to evaluate the effect on tailings consolidation rate when using a permeable envelope (lower slopes were not considered because of operational reasons as it might not be economical when a large amount of waste rocks might be generated). Excess PWP dissipation rates tended to slightly increase with the pit wall slope and this effect was more pronounced closer to the permeable envelope (Fig. 7). For instance, the time required to dissipate 90% of excess PWP 2 m from the permeable envelope at the bottom of the pit (z = 0 m) after the placement of the 5th layer was around 44 days for a model with a slope angle of 50° (base case), 37 days for a slope of 60°, and 31 days for a slope angle of 70° (i.e., around 25% faster) (Fig. 7a). This difference decreased as the distance to the permeable envelope increased and become insignificant (< 5%) after around 20 m (Fig. 7a). A similar trend was observed after the placement of the 8th layer (Fig. 7b) and for the rest of the model. The radius of influence of the permeable envelope was also estimated and results indicated that slope angle essentially had no effect on the radius of influence. In conclusion, the slope angle could slightly affect the rate of consolidation close to the permeable envelope, but this effect was limited and decreases with the distance to the envelope.

It is also noted that the slope of the pit in this study had only one bench, while the pit slope was usually composed of several bench levels in practice. However, these benches would be eventually covered by the construction of the permeable envelope along the perimeter of the pit, and they would essentially have no effect on the drainage of tailings materials. More details on the bench effect will also be discussed later.

4.3 Effect of Decreasing Filling Rate with Time

The increase of the surface area of the pit as tailings backfilling progresses could lead to the decrease of the filling rate if the production rate remains constant. Simulations of models with layer thickness of the first two layers being 7.5 and 10 m respectively (thickness of other succeeding layers were still 5 m) were thus carried out to model these changes in the filling rate. Greater thickness of tailings layers closed to the pit bottom led to the increase of the time for excess PWP to dissipate (Fig. 8). For example, the time required to dissipate 90% of excess PWP at the bottom (z = 0 m) after the placement of the 2nd layer 2 m from the permeable envelope was around 9 days for 5 m thick layers, 18 days for 7.5 m thick layers and 31 days for 10 m thick layers, respectively (Fig. 8a). The effect of the thickness layer was similar father away from the envelope. For example, t90 22 m from the envelope was around 21 days for the 5 m thick layer and 65 days (i.e., around 3 times longer) for the 10 m thick layer (Fig. 8a). The increase in the t90 can be attributed to the increase of the excess PWP and the length of drainage paths when tailings layer became thicker due to the increase of the filling rate. A similar trend was also observed after the placement of the next layers, but the effect of the filling rate tended to decrease with the increase of the tailings thickness. t90 22 m from the envelope after the placement of the 5th layer, for example, was 80 days for 5 m thick layers, and 130 days for 10 m thick layers (i.e., around 1.6 times longer) (Fig. 8b). The change in the filling rate, thus, influences on the consolidation rate of tailings.

Evolution of excess PWP at the pit bottom (z = 0 m) as a function of the filling rate (tailings layer thickness) and distance to the permeable envelope after the placement of the a 2nd layer and b 5th layer, corresponding ratio of rate of t90 between models with tailings only and with the permeable envelope, Rt90, for various filling rates after the placement of the c 2nd layer, and d 5th layer. Distance is measured from the permeable envelope

The corresponding ratio of t90 value between models with tailings only and with the permeable envelope, Rt90, after the filling of the 2nd layer was somewhat higher for model with larger filling rate (i.e., 3.3 for the 10 m thick layer compared to 2.6 for the 5 m thick layer models at the position of 2 m at pit bottom) (Fig. 8c). These differences tended to decrease and become essentially identical for various filling rate as distance to the permeable envelope increased (Fig. 8c) and as tailings thickness increased (e.g., after the filling of the 5th layer) (Fig. 8d). Results thus indicated that filing rates of tailings somewhat had an effect on the performance of the permeable envelope at locations close to the permeable envelope, and permeable envelope performance then became independent to the filling rates at locations far away from the permeable envelope and as the tailings thickness increased.

4.4 Effect of Hydraulic Conductivity of the Permeable Envelope

A permeable envelope is often made of coarse waste rocks (MEND 2015), which hydraulic conductivity typically ranges from 10−5 to 10−3 m/s (James and Aubertin 2009). The natural rock mass might also be damaged by the blasting operations during the production, sometimes leading to an increase of their hydraulic conductivity up to 10−2 m/s (Rousseau and Pabst 2020). The hydraulic conductivity of the permeable envelope in this study was around 2 × 10−6 m/s which was not representative of actual waste rocks but was necessary to reduce the computational time. The effect of this choice was evaluated by conducting some models where the conductivity of the of permeable envelope was increased to 4 × 10−6 m/s and 6 × 10−6 m/s.

Simulations indicated that using a reduced value of hydraulic conductivity for the permeable envelope had only a limited influence on the results, and mostly close to the drainage paths. The effect of the hydraulic conductivity of the waste rocks was, however, negligible further than 22 m from the envelope. For example, the time needed to dissipate 90% of the excess PWP in the first layer (z = 0 m) after the placement of the 3rd layer 2 m from the permeable envelope was around 12 days when the waste rock hydraulic conductivity was 6 × 10−6 m/s and around 18 days when it was 2 × 10−6 m/s (Fig. 9). This (small) difference of t90 tended to decrease with the distance from the permeable envelope, and was less than 5% 22 m from the envelope. This effect can be attributed to the fact that farther from the permeable envelope, the drainage of water is mostly controlled by the tailings hydraulic conductivity and not so much by that of drainage path. The same trend was observed for WRI (Case 3) and bottom drain (Case 4). A similar effect was also observed in surface TSF with WRI (Bolduc and Aubertin 2014).

4.5 Effect of Tailings Hydro-Geotechnical Properties

As observed in the previous section, tailings hydraulic conductivity has a significant effect on excess PWP dissipation rate, especially far from the drainage paths. Therefore, another type of gold tailings was also used in the parametric analysis using a permeable envelope, a WRI and bottom drainage at the same time (Case 5). Properties of Westwood gold tailings were obtained from Lévesque (2019) (Table 2). Westwood tailings were finer and less permeable than Malartic tailings, which would induce a slower rate of consolidation. For example, t90 in the middle of the first layer (z = 7.5 m) of Westwood tailings 90 m from the inclusion was around 113 days after the placement of the 5th layer compared to around 98 days of Malartic tailings (Fig. 10). Similar trends were observed elsewhere in the pit. For example, t90 in the same position after the addition of the 10th layer was around 240 days for Westwood tailings and around 215 days (10% faster) for Malartic tailings (Fig. 10). The radius of the influences was also estimated and identical for these 2 types of tailings. These results the consolidation rate of Westwood tailings was somewhat slower than that of Malartic tailings. Accordingly, the application of drainage paths would be more important to dewater finer tailings with low hydraulic conductivity, and more WRI might be needed to enhance the consolidation rate depending on the site-specific operational requirements.

5 Final Remarks and Discussion

5.1 Numerical Considerations

An orthogonal corner pit was chosen to simulate pit geometry, which is not necessarily representative of real pit geometries in practice where somewhat circular corner is observed. The practical geometry of a pit was also modelled by Priestley (2011) and Rousseau and Pabst (2022). The geometry of the pit was simplified in this study because of the limitation of the built-in blocks which were used to create the pit geometry. The results are however deemed to reliable when other advanced mesh generation tools are applied. Smaller conceptual models of the pit with orthogonal and circular corners were, therefore, simulated to investigate the potential effect of the geometry on the results. A section near the corner of the pit representing a circular corner with a bottom radius of 40 m and a top radius of 60 m was modelled (Fig. 11a) and compared with a model with an orthogonal corner (Fig. 11b), similar to the geometry used in this study. Tailings were filled in 6 layers of 30 m height over 6 years (i.e., filling rate of 5 m/year). An 8 m wide permeable envelope was simulated along the pit walls.

Materials properties and boundaries were otherwise identical to previous models presented above. Consolidation rate of model for orthogonal corner was faster than that of the circular corner and the difference was insignificant at locations far away from the permeable envelope. For example, t90 after the placement of the 6th layer at 5 m from the permeable envelope (section C–C′) at the bottom of the pit was around 59 days for the circular corner pit, while that of the orthogonal corner pit was around 47 days (Fig. 12). The difference then decreased as the distance to the permeable envelope increased and become negligible after around 26 m (Fig. 12). Thus, the assumption of an orthogonal corner pit somewhat affected the rate of tailings consolidation, but this effect was limited and only close to the permeable envelope (i.e., 20 m from the permeable envelope).

The simulations of tailings consolidation using FLAC3D for the case of co-disposal in a pit took around 2 weeks to run. It was also noticed that the contrastive hydraulic conductivity of tailings and waste rocks significantly increased the computational time for the coupled analysis as discussed in the Sect. 4.4. From a mesh sensitivity analysis, the mesh size in this study was also chosen to ensure a balance of the accuracy of the results and the computational time. Tailings was filled instantaneously in this model instead of progressive placement, yet this assumption has a negligible effect on the calculated results (Nguyen and Pabst 2023).

5.2 Discussion

Results presented in this article showed that using drainage paths composed of waste rocks can contribute to accelerate the consolidation of tailings when co-disposal technique was applied in an open pit. However, some limitations and simplifications must be considered before extrapolating these results to other sites and conditions.

First, relations used to update tailings stiffness and hydraulic conductivity derived from column tests (Essayad and Aubertin 2021; Nguyen 2022), and were, therefore, valid only for the simulated tailings. In practice, these equations will depend on tailings properties and will vary from one site to another. Experiments and characterization are thus recommended for each application. However, trends and general conclusions regarding pervious envelope and drainage paths are deemed applicable for most hard rock mines.

Only one WRI was simulated in this study, but depending on the pit diameter and the available waste rock, several parallel and/or orthogonal inclusions could be used (Aubertin et al. 2016). Also, the pit geometry was simplified to focus on the general behavior of WRI and the pervious envelope. Field application would require a mode precise and site-specific model, together with more advanced mesh generation tools (e.g., Griddle).

Interactions between the tailings, the permeable envelope and the local environment should also be evaluated. For example, fluxes to the surface, WRI and permeable envelope should be monitored to better calibrate simulations by monitering water lux in the modesl. Such parameters would also represent valuable input for field application (e.g., precisely predicting the quantity of water flowing through the drainage paths—pervious envelope and WRI—would help design water management systems).

Simulations have also shown that the corner of the pit could reasonably affect the PWP dissipation rate of tailings. However, this effect is relatively local and becomes negligible above around 20 m from the corners. In other words, 2D models might be sufficient to evaluate co-disposal approaches for large pit with great longitudinal dimensions. However, 3D simulations are recommended for pit with small dimensions.

Pit slopes might be composed of several benches, yet the construction of the permeable envelope would cover and ease the effect of benches. The construction of permeable envelope might then be related to the repose angle of the waste rocks to ensure the overall stability of the envelope if waste rocks were dumped from the pit crest (Maryam 2016). The effect of the benches might be more pronounced when the fractured pit wall was used as a natural permeable envelope or when the aim of the mine site is to increase the steepness of the slope, the permeable envelope would then be constructed in a bench by bench manner and was constructed from the bottom of the pit with the same angle as the benches of natural pit slope (Lévesque 2019). All of the effects of these factors are, however, out of the scope and not simulated in this paper.

Interactions between the tailings, the permeable envelope and the local environment should also be evaluated. For example, fluxes to the surface, WRI and permeable envelope should be monitored to better calibrate simulations by monitering water lux in the modesl. Such parameters would also represent valuable input for field application (e.g., precisely predicting the quantity of water flowing through the drainage paths—pervious envelope and WRI—would help design water management systems).

Finally, intermediate laboratory tests and/or field-scale tests are recommended to validate these 3-D models and capture potential unknowns that can affect the performances of the technique. Scale effect in particular should also be further studied. The range of loading applied in the compression tests indeed usually vary from around 10 kPa (Bhuiyan et al. 2015) to around 200 kPa (Essayad and Aubertin 2021; Nguyen 2022). Loads from the placement of the tailings in a pit could be much higher because of the large depth of the pit. These range of loadings used in the laboratory tests should reasonably reflect the practical conditions (i.e., loads from large tailings thickness) to obtain a better constitutive model for tailings properties.

6 Conclusion

In-pit disposal has been demonstrated to be an encouraging mine waste management approach and can offer various environmental and geotechnical advantages compared to the conventional approaches. Unknowns in terms of behaviour of tailings consolidation under the influences of waste rocks either in the form of permeable envelope and/or inclusion, effects of pit morphology and hydro-geotechnical properties of the materials remained challenging. The objective of this article was to address these above uncertainties to ensure a successful mine waste management. 3-D models were carried out to evaluate the consolidation behaviour of tailings co-disposed with waste rock in an open pit. Various co-disposal approaches such as a permeable envelope, WRI and bottom drain were evaluated. The effect of filling rate, slope angles, and waste rock properties were also considered. Based on these results, the following conclusions can be made.

A permeable envelope along the pit walls can contribute to accelerate tailings consolidation, thus reducing faster their hydraulic conductivity, and limiting contacts of tailings with the surrounding environment and regional groundwater. The tailings consolidation rate with a permeable envelope was up to 184 days faster than that without a permeable envelope.

The zone of influence of the permeable envelope appears to be around 2 times the tailings thickness. The use of only a permeable envelope might, therefore, not always be sufficient, especially for wide pits whose radius is greater than 2 times of the tailings depth in case the main objective was to reduce the post-deposition settlement as well as potential differential settlement.

Additional drainage pathways such as a WRI or a bottom drain can contribute to further accelerate the consolidation rate of tailings. Consolidation time in the middle of the pit with the combination of all drainage paths (permeable envelope, WRI and bottom drain) was between 110 and 230 days faster (i.e., 1.5 to 3 times faster) than with a permeable envelope only. Steeper slope angles can also result in a 25% faster consolidation rate close to the permeable envelope.

The increase in the filling rate somewhat contributed to decrease the tailings consolidation rate, increased the radius of influence of the permeable envelope and this effect was negligible as tailings thickness increased (i.e., t90 for the 10 m thick layer model might be 3 times higher than that of model with layer thickness of 5 m after the placement of the second layers, while this ratio was only 1.6 after the placement of the fifth layer). The hydraulic conductivity of the permeable envelope affected the tailings consolidation rate (for example, increasing the hydraulic conductivity of waste rock by 3 resulted in a 50% faster consolidation rate), yet this effect was insignificant as distances increased. Tailings hydro-geotechnical properties have an important effect on the rate of consolidation of tailings, and more WRI might be required to enhance dissipation rate of fine tailings materials. Finally, the assumption of an orthogonal corner pit used in this model was deemed reasonable and have little effect on the calculated results.

The application of permeable envelope concepts during in-pit disposal with the combination of WRI and bottom drainage drains therefore appears to be beneficial both in terms of reducing contaminant generation and differential settlement. There might be less space for disposing tailings because of the presence of an envelope and WRI but that could be compensated by other advantages such as the elimination of the need of construction waste rock piles and the prevention of potential contaminants from acid mine drainage when the waste rocks were stored under the water table. These results should be useful for practitioners and contribute to propose efficient codisposal in surface mines. Further research, in particular in the field of complex co-dispose configuration as well as stability analysis of the inclusions could contribute to further optimize in-pit codisposal of tailings and waste rock.

Data Availability

Enquiries about data availability should be directed to the authors.

References

Abdulnabi A, Amoako K, Moran D, Vanadara K, Aldaeef AA, Esmaeilzadeh A, Simms P (2022) Evaluation of candidate polymers to maximize geotechnical performance of oil sands tailings. Can Geotech J 59(3):359–371. https://doi.org/10.1139/cgj-2020-0714

Agapito LA, Bareither CA (2018) Application of a one-dimensional large-strain consolidation model to a full-scale tailings storage facility. Miner Eng 119:38–48. https://doi.org/10.1016/j.mineng.2018.01.013

ASTM D2487-17 (2017) Standard practice for classification of soils for engineering purposes (Unified Soil Classification System). In West Conshohocken, Pa: ASTM International.

Aubertin M (2013) Waste rock disposal to improve the geotechnical and geochemical stability of piles. In: Paper presented at the 23rd World Mining Congress, Montreal, Canada

Aubertin M, Bussière B, Pabst T, James M, Mbonimpa M (2016) Review of reclamation techniques for acid generating mine wastes upon closure of disposal sites. In: Paper presented at the Geo-Chicago 2016, Chicago, Illinois, USA

Bhuiyan I, Azam S, Landine P (2015) Consolidation behavior of a uranium tailings storage facility in Saskatchewan. J Hazard, Toxic, Radioact Waste 19(4):040150051–040150057. https://doi.org/10.1061/(ASCE)HZ.2153-5515.0000281

Blight GE (2010) Geotechnical engineering for mine waste storage facilities. CRC Press, Boca Raton

Bolduc F, Aubertin M (2014) Numerical investigation of the influence of waste rock inclusions on tailings consolidation. Can Geotech J 51(9):1021–1032. https://doi.org/10.1139/cgj-2013-0137

Boudrias G (2018) Évaluation numérique et expérimentale du drainage et de la consolidation de résidus miniers à proximité d'une inclusion de roches stériles. (Mémoire de maîtrise), École Polytechnique de Montréal

Bussière B (2007) Colloquium 2004: hydrogeotechnical properties of hard rock tailings from metal mines and emerging geoenvironmental disposal approaches. Can Geotech J 44(9):1019–1052. https://doi.org/10.1139/t07-040

Cameron H, Dave L (2015) In-pit tailings disposal at langer heinrich—tailings storage facilities in a unique hydrogeological setting. In: Paper presented at the Tailings and Mine Waste Management for the 21st Century Sydney

Chai S, Zheng J, Li L (2023) Kink effect on the stress distribution in 2D backfilled stopes. Geotech Geol Eng 41(5):3225–3238. https://doi.org/10.1007/s10706-023-02434-4

Cui L, Fall M (2016) An evolutive elasto-plastic model for cemented paste backfill. Comput Geotech 71:19–29. https://doi.org/10.1016/j.compgeo.2015.08.013

Essayad K, Aubertin M (2021) Consolidation of hard rock tailings under positive and negative pore-water pressures: testing procedures and experimental results. Can Geotech J 58(1):49–65. https://doi.org/10.1139/cgj-2019-0594

Essayad K, Pabst T, Chapuis RP, Aubertin M (2018) An experimental study of tailings migration through waste rock inclusions. In: Paper presented at the 71st Canadian Geotechnical Conference (GeoEdmonton 2018), Edmonton, AB, Canada

Ferdosi B, James M, Aubertin M (2015) Investigation of the effect of waste rock inclusions configuration on the seismic performance of a tailings impoundment. Geotech Geol Eng 33(6):1519–1537. https://doi.org/10.1007/s10706-015-9919-z

Hustrulid W, Kutcha M, Martin R (2013) Open pit mine planning and design. CRC Press, Boca Raton

Itasca (2021) FLAC3D 7.0 (Fast Lagrangian Analysis of Continua in 3 Dimensions) User Manual

James M (2009) The use of waste rock inclusions to control the effects of liquefaction in tailings impoundments. ( Ph.D. ), École Polytechnique de Montréal, Qc, Canada

James M, Aubertin M (2009) The use of waste rock inclusions in tailings impoundments to improve geotechnical and environmental performance. In: Paper presented at the Tailings and Mine Waste 2009, Banff, Alberta

Jaouhar EM, Aubertin M, James M (2013) The effect of tailings properties on their consolidation near waste rock inclusions. In: Paper presented at the 66th Canadian Geotechnical Conference (GeoMontréal 2013), Montréal, Canada

Larochelle CG, Bussière B, Pabst T (2019) Acid-generating waste rocks as capillary break layers in covers with capillary barrier effects for mine site reclamation. Water Air Soil Pollut 230(3):57. https://doi.org/10.1007/s11270-019-4114-0

Lévesque R (2019) Consolidation des résidus miniers dans les fosses en présence d’inclusions de roches stériles. (Mémoire de maîtrise), Ecole Polytechnic Montreal

Li L, Aubertin M (2009) Horizontal pressure on barricades for backfilled stopes. Part I: fully drained conditions. Can Geotech J 46(1):37–46. https://doi.org/10.1139/T08-104

Maryam, M. (2016). Slope stability analysis of waste rock piles under unsaturated conditions following large precipitations. (PhD Ph.D.), Polytechnique Montreal,

McDonald L, Lane JC (2010) Consolidation of in-pit tailings. In: Paper presented at the Mine Waste 2010, Perth, Australia

MEND (2015) MEND report 2.36.1 in-pit disposal of reactive mine wastes: approaches, update and case study results

Morris PH (2002) Analytical solutions of linear finite-strain one-dimensional consolidation. J Geotech Geoenviron Eng 128(4):319–326. https://doi.org/10.1061/(ASCE)1090-0241(2002)128:4(319)

Nguyen D, Pabst T (2020) Comparative experimental study of consolidation properties of hard rock mine tailings. In: Paper presented at the 73rd Canadian Geotechnical Conference (GeoVirtual 2020), Online

Nguyen ND, Pabst T (2023) Consolidation behavior of various types of slurry tailings co-disposed with waste rock inclusions: a numerical study. Environ Earth Sci 82(2):65. https://doi.org/10.1007/s12665-023-10750-4

Nguyen ND (2022) 3D numerical evaluation of consolidation of tailings co-disposed with waste rocks in open pits (Ph.D. Ph.D.), Polytechnique Montréal, Retrieved from https://publications.polymtl.ca/10564/

Pabst T, Bussière B, Aubertin M, Molson J (2018) Comparative performance of cover systems to prevent acid mine drainage from pre-oxidized tailings: a numerical hydro-geochemical assessment. J Contam Hydrol 214:39–53. https://doi.org/10.1016/j.jconhyd.2018.05.006

Priestley D (2011) Modeling multidimensional large strain consolidation of tailings. (Master), University of British Columbia

Rousseau M, Pabst T (2020) Blast damaged zone influence on water and solute exchange between backfilled open-pit and the environment. In: Paper presented at the 73rd Canadian Geotechnical Conference (GeoVirtual 2020), Online

Rousseau M (2021) Étude numérique de la réduction du transport advectif de contaminants entre les fosses remblayées et l’environnement par l’utilisation de chemins d’écoulements préférentiels. (Ph.D.), École polytechnique Montréal

Rousseau M, Pabst T (2022) Topology optimization of in-pit codisposal of waste rocks and tailings to reduce advective contaminant transport to the environment. Struct Multidiscip Optim 65(6):168. https://doi.org/10.1007/s00158-022-03266-1

Schiffman RL (1982) The consolidation of soft marine sediments. Geo-Mar Lett 2(3–4):199–203. https://doi.org/10.1007/bf02462763

Somogyi F (1980) Large strain consolidation of fine grained slurries. In: Paper presented at the Presentation at the Canadian Society for Civil Engineering, Winnipeg, Manitoba

Townsend FC, McVay MC (1990) SOA: large strain consolidation predictions. J Geotech Eng 116(2):222–243. https://doi.org/10.1061/(ASCE)0733-9410(1990)116:2(222)

Utili S, Agosti A, Morales N, Valderrama C, Pell R, Albornoz G (2022) Optimal pitwall shapes to increase financial return and decrease carbon footprint of open pit mines. Min, Metall Explor 39(2):335–355. https://doi.org/10.1007/s42461-022-00546-8

Vick SG (1990) Planning, design and analysis of tailings dams. BiTech Publishers Ltd, Vancouver, BC

Wickland BE, Wilson GW, Wijewickreme D, Klein B (2006) Design and evaluation of mixtures of mine waste rock and tailings. Can Geotech J 43(9):928–945. https://doi.org/10.1139/t06-058

Acknowledgements

The authors are thankful to the financial support from Fonds de recherche du Québec—Nature et Technologies (FRQNT) (Grant No. 2017-MI-202116) and partners of Research Institute on Mines and the Environment (RIME UQAT—Polytechnique; http://rime-irme.ca/en). The authors also gratefully acknowledge Dr. Huy Tran, Dr. Kazim and Itasca technical support team for their valuable support and comments to improve the code in this study.

Author information

Authors and Affiliations

Contributions

NDN: Conceived and designed the analysis; Collected the data from literature; Performed the numerical simulations; Data curation; Writing—original draft. TP: Conceived and designed the analysis; Developed an approach for analysis of the results; Supervision; Writing—Review & Editing; Funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nguyen, N.D., Pabst, T. Acceleration of Consolidation of Tailings in a Pit Using Waste Rocks Co-disposal. Geotech Geol Eng 42, 1593–1609 (2024). https://doi.org/10.1007/s10706-023-02633-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-023-02633-z