Abstract

The distribution of hydraulic head on the dam foundation plane with curtain grouting is analyzed by the simplified one-dimensional seepage model, also is studied the effect of various parameters of curtain grouting on seepage pressure on the foundation plane. The theory of the optimum thickness of curtain grouting is proposed from the viewpoint of the minimum seepage pressure resultant and proved by the two-dimensional seepage model and the finite element method, which includes two cases of homogenous foundation and layered foundation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

At present, the reduction factor of uplift pressure at the drainage curtain is adopted in the design to reflect the effect of the curtain grouting on seepage pressure on the foundation plane (Qi 1997). By means of this empirical factor, only the whole effect of curtain grouting and drainage curtain is reflected comprehensively (Mao 2003). The quantitative effect of permeability coefficient, thickness and depth of the curtain grouting on seepage pressure on foundation plane is not taken into account (Chai et al. 2005a). Based on the one-dimensional seepage theory, the effect of curtain grouting on seepage pressure on foundation will be analyzed in this paper and the theory of the optimum thickness of curtain grouting is proposed from the viewpoint of the minimum seepage pressure resultant and proved by the two-dimensional seepage model and the finite element method, which includes two cases of homogenous foundation and layered foundation.

Most optimization problems can be formulated as a formal mathematical problem of the form min f(x) subject to g(x) < 0 (Piermatei Filho and Leontiev 2009; Akbari et al. 2010; Fuchs and Shemesh 2004; Zhang et al. 2008). But in this paper, we propose the optimum thickness of curtain grouting on dam foundation from the viewpoint of the minimum seepage pressure resultant (min f(x)) by equating the first derivative to zero, the constraint conditions g(x) < 0 (various parameters of curtain grouting) will be meet by engineering experiences.

2 Effect of the curtain grouting on seepage pressure on the foundation plane

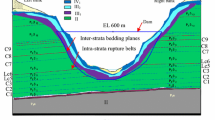

The sketch of a dam foundation with a complete curtain grouting is shown as Fig. 1a, and the symbols and notations are given in Table 1.

The flow in differential depth dz, which is close to the foundation plane, is assumed to be one-dimensional in order to obtain the seepage velocity and unit discharge directly by Darcy’s law.

The unit seepage discharge q 1 through AB is

where \(\emph{v}_{1}\) and J 1 are the seepage velocity and hydraulic gradient of AB, respectively.

We can obtain the unit discharge q 2 and q 3 through BC and CD, respectively, by the same theory as follows,

where \(\emph{v}_{2}\) and J 2 are the seepage velocity and hydraulic gradient of BC, respectively; \(\emph{v}_{3}\) and J 3 are the seepage velocity and hydraulic gradient of CD, respectively.

From the continuity of fluid flow we have

From (1–3) and (4), we have the following equations

Since H 1 and H 2 are unknown, the equations may be solved as follows.

which quantitatively reflects the effect of the thickness of curtain grouting t and permeability coefficient k g of curtain on head distribution of the foundation plane. From (6), the equivalent seepage travel length of curtain is approximately equal to \(\frac{k}{k_g }\) times the actual thickness of curtain t via similar triangles.

The total head h at any point in the seepage field is composed of the pressure head \(( {\frac{p}{\gamma }})\), elevation head z and velocity head \(( {\frac{a\emph{v}^2}{2g}} )\), that is (Chai et al. 1996),

where p is the seepage pressure, γ is the gravity density of water, z is the vertical ordinate, \(\emph{v}\) is the seepage velocity, a is the velocity head modification coefficient, and g is the gravity acceleration.

In general, the seepage velocity \(\emph{v}\) is very small and \(\frac{a\emph{v}^2}{2g}\) is so much smaller that it can be neglected. On the foundation plane the elevation head z = 0. So, the seepage pressure on foundation plane p can be expressed as follows.

Therefore the seepage pressure distribution in the case of the complete curtain grouting can be obtained as shown in Fig. 1b. The seepage pressure p 1 and p 2 at the upstream and downstream curtain face can be expressed as follows.

We can see that p 1 increases and approaches to Hγ and p 2 reduces and approaches to zero when \(\frac{k}{k_g}\) increases gradually or the permeability coefficient k g of curtain grouting decreases gradually.

According to (9) and Fig. 1b, we can get the resultant force P (the area of the map 1(b)) of seepage pressure within unit width of dam foundation as follows.

in which

Now we analyze the effect of a 1, k g and t on P, respectively.

-

(1)

From (10), P will increase correspondingly while a 1 increases. When a 1 = 0, the value of P is minimum. But in engineering practice, the curtain grouting cannot begin from heel due to the limits of the construction conditions and so on. So it is better to make a 1 as small as possible in order to reduce the seepage pressure resultant P.

-

(2)

Taking P differentiating with respect to β, we have

$$ \label{eq12} \frac{\partial P}{\partial \beta }=\frac{\gamma H}{2}\cdot \frac{Lt\left( {L-t-2a_1 } \right)}{\left( {t+\beta L} \right)^2}=\frac{\gamma H}{2}\cdot \frac{Lt\left( {a_2 -a_1 } \right)}{\left( {t+\beta L} \right)^2} $$(12)

Generally, a 2 > a 1, so \(\frac{\partial P}{\partial \beta }>0\) and P reduces if β reduces. That is to say, β and total seepage pressure resultant P reduces while k g reduces and the value of \(\frac{k}{k_g }\) increases.

-

(3)

Taking P differentiating with respect to t, we have

We can see from the above equation that when \(t<\left[ {\sqrt {\beta^{_2 }+\beta -2\beta \frac{a_1 }{L}} -\beta } \right]L\), \(\frac{\partial P}{\partial t}<0\), so the seepage pressure resultant P decreases with the thickness of curtain grouting t increasing. But \(\frac{\partial P}{\partial t}>0\) in the case of \(t>\left[ {\sqrt {\beta^{_2 }+\beta -2\beta \frac{a_1 }{L}} -\beta } \right]L\), so the seepage pressure resultant P increases with the thickness of curtain grouting t increasing. Therefore, the thickness of grouting can not be increased infinitely. In theory, the optimum thickness of grouting t opt can be given as follows.

The corresponding minimum seepage pressure resultant \(P_{\rm min}\) is

The optimum thickness of curtain grouting t opt and the corresponding minimum seepage pressure resultant P min are calculated and listed in Table 2 for several cases.

3 Example and validation

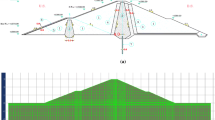

The two-dimensional computational model for calculation example is shown as Fig. 2. In the case of complete curtain grouting, the above model is calculated by two-dimensional finite element method. The dam foundation (seepage area) is divided into 20×20 = 400 elements and 21×21 = 441 nodes. The one-dimensional seepage model theory is verified by two-dimensional finite element method (Chai and Deng 2004; Chai and Li 2004; Chai et al. 2004, 2005b; Piermatei Filho and Leontiev 2009; Akbari et al. 2010; Fuchs and Shemesh 2004; Zhang et al. 2008). The solutions of seepage pressure distribution and the resultant force by two methods are listed in Table 3 under four different cases with different k/k g and t.

It can be seen from Table 3 that the result has a small error and the same law of seepage pressure distribution and resultant force, comparing one-dimensional seepage model with two-dimensional finite element method. Comparing case 1 with case 2, we can see that the seepage pressure resultant P reduces when the thickness of curtain t increases from 0.1L to 0.2L, which is because the optimum thickness t opt is 0.207L under these two cases, P reduces with t arising when t < t opt. Comparing case 3 with case 4, P increases when t increases from 0.1L to 0.2L, which is because t opt is 0.080L under these two cases, P increases with t arising when t > t opt. This indicates the rationality of the optimum thickness theory of curtain grouting from the viewpoint of the minimum seepage pressure resultant.

In addition, comparing case 1 with case 3, and comparing case 2 with case 4, we can know that the total seepage pressure P reduces with k/k g increasing, which also supports the above conclusion.

4 Discussions about the layered foundation

The above discussions are all about simple and homogeneous foundations, but in reality most foundations are layered. The theory of OPTIMUM thickness of curtain grouting based on the one-dimensional theory for a homogeneous case could not apply directly to the multi-layer scenario. Here we show the error and effectivity of the theory of OPTIMUM thickness of curtain grouting in case of the multi-layer scenario. Now we assume that the foundation of the computation model (in Fig. 2) is divided into four layers averagely, and that k 1, k 2, k 3, k 4 are the permeability coefficients of four layers, respectively, from up to down. By the one-dimensional theory and two-dimensional finite element method, we can get the calculating results as Table 4.

We can see from Table 4 that the permeability of layered foundation has certain effect on seepage pressure. The seepage pressure mainly depends upon the permeability of the top layer. Comparing case 1 with case 3, and case 2 with case 4, it can be seen that the theory of the optimum thickness of curtain grouting on dam foundation is also effective from the viewpoint of the minimum seepage pressure resultant.

5 Conclusions

In this paper we analyze the seepage pressure on the foundation plane with curtain grouting by the one-dimensional theory and propose the optimum thickness of curtain grouting from the viewpoint of the minimum seepage pressure resultant and proved by the two-dimensional seepage model and the finite element method, which includes two cases of homogenous foundation and layered foundation. In engineering practice, it is better to make the distance from curtain grouting to the heel of dam as near as possible (to make a 1 minimum), to make the highest quality of the curtain grouting (to make k g minimum), and to make the thickness of curtain grouting near the optimum thickness t opt, so that the seepage pressure resultant can be minimized. The conclusions have an important value for engineering design of the curtain grouting on dam foundation.

References

Akbari J, Kim NH, Ahmadi MT (2010) Shape sensitivity analysis with design-dependent loadings—equivalence between continuum and discrete derivatives. Struct Multidiscipl Optim 40(1–6):353–364

Chai JR, Deng XH (2004) Analysis of non-Darcy seepage through a kind of Embankment Dam Foundation. In: Feng CG, Huang P, Ma Y, Wan YJ, Li SC, Su Q (eds) Proceedings of the annual conference of China association for science and technology. Qionghai, China, pp 161–165

Chai JR, Li SY (2004) Analysis of seepage through Dam Foundation with closed system of grouting curtain, drainage and pumping measures. In: Martin W, Ren QW, John SY (eds) Proceedings of the 4th international conference on dam engineering. Tan, Nanjing, China, pp 171–176

Chai JR, Han QZ, Kou XZ (1996) Analysis of seepage through dam foundation. Shaanxi Water Power 12(4):47–51

Chai JR, Li SY, Wu YQ (2004) Multi-level fracture network model for coupled seepage and stress fields in rock mass. Commun Numer Methods Eng 20(1):63–74

Chai JR, Li KH, Wu YQ, Li SY (2005a) Coupled seepage and stress fields in roller compacted concrete dam. Commun Numer Methods Eng 21(1):13–21

Chai JR, Li SY, Wu YQ (2005b) Multi-level fracture network model and FE solution for ground water flow in rock mass. J Hydraul Res 43(2):202–207

Fuchs MB, Shemesh NNY (2004) Density-based topological design of structures subjected to water pressure using a parametric loading surface. Struct Multidiscipl Optim 28(1):11–19

Mao CX (2003) Seepage computation analysis & control. China Hydraulic and Hydropower, Beijing

Piermatei Filho O, Leontiev A (2009) An optimization approach for unconfined seepage problem with semipermeable conditions. Struct Multidiscipl Optim 39(6):581–588

Qi QH (1997) Hydraulic structures. China Hydraulic and Hydropower, Beijing

Zhang H, Zhang X, Liu S (2008) A new boundary search scheme for topology optimization of continuum structures with design-dependent loads. Struct Multidiscipl Optim 37(2):121–129

Acknowledgements

The financial support from the Research Fund 20096118110007 for the Doctoral Program of Higher Education of China, the Project 10202015 and 50579092 sponsored by National Natural Science Foundation of China (NSFC), the Project NCET-05-0679 by Program for New Century Excellent Talents in University, the Project 2004ABB012 sponsored by Hubei Provincial Science and Technology Department (HBSTD), the Project 603108, 603402 sponsored by China Three Gorges University (CTGU) and the Scientific Innovation Project 106-210303, 220275 sponsored by Xi’an University of Technology (XAUT) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chai, J., Cui, W. Optimum thickness of curtain grouting on dam foundation with minimum seepage pressure resultant. Struct Multidisc Optim 45, 303–308 (2012). https://doi.org/10.1007/s00158-011-0699-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-011-0699-7