Abstract

Beam-column connections have a significant role in the results of the analysis and the design of steel frames. In this paper, a genetic algorithm has been used for the non-linear analysis and design of steel frames. For minimizing the weight of frames, while satisfying the applied constraints and restraints such as the limits of normal and combined stresses, criteria such as target displacement(s) and the number and locations of plastic hinges were used. To analyze and design the frame elements, I and box-shaped standard sections were used for beams and columns, respectively. Finally, some clues for finding optimizing semi-rigid connection stiffness values for beam-to-column connections have been obtained. The degrees of these rigidities are obtained by a genetic algorithm during the procedure of optimization in order to reach a frame with the minimum weight. SAP2000 structural analysis program was used to perform modal analysis and linear and non-linear static solutions as well as the design of the elements. A MATLAB program was written for the process of optimization. The procedure of optimization was based on a weight minimization carried out for 9 steel frames. Thus, the optimum connection stiffness could be obtained for minimizing the weight of the structure. The results show that the non-linear analysis gives less weight for short period frames with semi-rigid connections compared to those of linear ones. However, by increasing the periods of frames, much less weights are obtained in the case of non-linear analysis with semi-rigid connections.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The behavior of totally steel structures depends highly on the connection of beams and columns. Traditionally, in the design of steel frames, beam-to-column connections are assumed to be rigid or pinned (Chen and Lui 1991; Da Silva et al. 2008). Despite this fact, it is largely recognized that most joints do not exhibit such idealized behaviors. The results of experimental studies show that beam-to-column connections are neither fully rigid nor fully pinned, but show semi-rigid behaviors (Jian-Yi 1999). There are two different strategies to reflect connection flexibility in steel frame analyses. One of them is to use new elements for modeling beam-to-column connections (Hsieh and Deierlein 1990).This approach increases computational time (Chen 2000). Another approach which is widely used in steel frame analyses is based on lumped rotational springs with negligible lengths (Kaveh and Moez 2008; Chen and Kishi 1989; Kameshki and Saka 2001, 2003).

Researches have shown that the moment–rotation (M–θ) relationships for some connections are nonlinear and the assumption of a constant value for the stiffness of a connection is not realistic because it changes as the load increases (Nethercot 1985; Ballad and Chen 1995). Laboratory test results have shown that beam-to-column connections are neither completely articulated nor completely restrained, but are practically restrained. Hence, for an accurate response of structural behavior, connections must be considered to be semi-rigid and have nonlinear behavior.

In the research studies on semi rigid connections, there is not enough information on the following items:

-

1.

The effects of semi-rigid non-elastic behavior on seismic performance of steel frames;

-

2.

The optimization of the seismic design of the semi-rigid connections in steel frames;

-

3.

The explicit variables for the effect of semi-rigid connections on the seismic performance of frames (Abdul-Rassak Sultan 2007).

Generally, the optimal design of a framed structure is executed by enhancing a structural analysis program with an optimization method. Machaly (1986) is one of the pioneers in the optimization of the weights of steel frames with semi-rigid beam-to-column connections under static loads.

The genetic method is an effective solution method for discrete optimum design problems. It is an accidental search which is highly capable of solving discontinuous problems (Coello 2002). This optimization method works with the design variables in the form of strings with definite lengths codified as zero and one (binary numbers). Each of these strings is like a chromosome in a living system and zero and one binary codes are like genes (Kameshki and Saka 2007). Each string represents a plan. Genetic techniques have a repetitious nature which works with a number of pre-determined plans. Repetition of each step is called a generation. Considering the qualitative measure called qualification, more desirable plans are selected for genocide and a new generation with a higher qualification is generated by the functions such as reproduction, implant and mutation. Repeating the generations, the plans will be improved and finally the plan will be optimized (Jenkins 1991; Rajeev and Krishnamoorthy 1992).

Assuming the amount of connection flexibility more than its real value, may cause large displacements, and assuming the amount of connection resistance less than its real value, may cause larger forces in the beams in comparison to their real values (Bhatti and Hingtgen 1995).

This paper presents a genetic algorithm based on an optimum design method for reducing the weights of steel frames having semi-rigid connections. A computer program was written to implement the foregoing algorithm and it was run for nine low to medium rise steel frames to obtain the rigidity of connections that minimizes the weight of the structures. The results obtained for 4 cases, namely, with rigid connections applying static linear analysis, with semi-rigid connections applying static linear analysis, with rigid connections applying non-linear analysis and with semi-rigid connections applying nonlinear analysis, are compared.

2 Backgrounds of genetic algorithm

This computational method has been designed for the natural evolutionary choice. In each repetition which is called a generation, a number of the plans under test are evaluated to complete each other for the purpose of participating in the production of new plans. Each person (frame) is displayed by a string which is a series of codified Figs of designed variables. Normally, the strings are made of Figs on binary basis. A string is expressed with a chromosome which has various genes. Each gene corresponds to the design variable. The strings are selected in proportion to their qualifications for becoming parents and generating children. After selecting the genetic strings, a new combination of them will appear using the implant operator in the manner that the new designs (children) possess some parts of the two previous designs (father and mother). A mutation operator can correct some parts of the new strings in the manner that they may have new combinations which have not been presented in the parents.

3 Optimization of steel frames with semi-rigid connections

Since inelastic behavior is expected in most structures subjected to infrequent earthquake loading, the use of nonlinear analyses is essential to capture the behavior of structures under seismic effects.

The following constraints have been used in the optimum frame design procedure:

-

1.

Control of interactive stresses in the elements (bending stresses + axial stresses);

The combinations of axial and bending stresses of the members are calculated. For members subjected to both axial compression and bending stresses, we have:

For calculating the fitness factor of interactive stresses of frames, the sum of the fit nesses of each individual element were used:

In (1)–(3), C1i is fitness factor of interactive stress for each member, α 1i is value of fitness factor of interactive stress for each member and C1 is fitness factor of interactive stress for each frame.

-

2.

Control of relative displacement of the stories (Drift)

The story drift is defined as the difference of the maximum lateral displacements of any two adjacent floors. Some limiting requirements are needed for the interstory and top deflections of buildings in the earthquake regulations. The maximum interstory drift and top deflection of a building is restricted by earthquake resistant codes (BHRC 2005; Federal Emergency Management Agency, FEMA-356 2000). The interstory drift is not to exceed a certain percentage of the building height.

In (4) and (5), δ n + 1 − δ n is the difference of the deflections between the two neighboring floors, h is the story height, T is the fundamental period of the building and R is the structural response modification factor (Iranian Earthquake Resistant Code, standard No 2800–3rd edition (BHRC 2005)).

To calculate the fitness factor of the interstory drifts of frames, the fit nesses of all interstory drifts were added up.

In (6)–(8), C2i is fitness factor of story drift for each story, α 2i is value of fitness factor of interactive stress for each member and C2 is fitness factor of story drift for each frame.

-

3.

Number of plastic connections created in the elements

Plastic hinge formation is a tool that is used in seismic analysis for determining the inelastic capacity of structural members. The ultimate performance of a structure depends on the location, number, capacity and behavior of plastic hinges. In this paper lumped plastic hinge which is idealized by Federal Emergency Management Agency, FEMA-356 (2000) were used (Fig. 1). The number of plastic hinges affects the collapse mechanism of model frames. For improving the response of a steel frame and achieving a more ductile capacity, it is better to shift the possible locations of the plastic hinges away from the columns and connections.

Plastic hinge property by FEMA 356 (Computers and Structures Inc 2008)

The constraints of combination stresses and relative displacement of stories have been considered according to the regulations of earthquake resistant building code (BHRC 2005; Uniform Building Code, UBC 1997) and the constraint of maximum formation of plastic connection in elements (preferably in beams) as well as the regulations of allocation of connection to frame elements have been considered according to the FEMA-356 recommendation (Federal Emergency Management Agency, FEMA-356 2000).

For nonlinear static analysis (pushover), a combination of the capacity spectrum method (CSM) suggested in (ATC-40) (Applied Technology Council ATC-40 1997) and the displacement coefficient method (DCM) suggested in Federal Emergency Management Agency, FEMA-356 (2000) were used.

A number of methods have been proposed for seismic design of structures by investigators in the past. Many traditional procedures for seismic design of buildings have been developed. Some of these are the force-based design (FBD) method (International Conference of Building Official 1997), direct displacement-based seismic design DDBD (Priestley et al. 2007), capacity spectrum methods (Fajfar 1999), energy method (McKevitt et al. 1960) and equal drift (Teal 1975; Lee and Chen 1996). In this paper, for optimum design of steel structures, the formations and locations of plastic hinges were also considered in addition to the previously mentioned factors. This method is a simple and efficient approach for representing inelasticity in frames.

The fitness factor of plastic hinge occurring depend on the ratio of beam and column elements hinge number to whole beam and column element could be defined. In this paper for each element two plastic hinges defined and location and length of hinge which defined approximately 0.5 times the element depth was chosen.

The fitness factor of a plastic hinge depends on the ratio of beam and column elements hinge number. Thus, hinge number to total number of beams and columns could be defined. In this paper, for each element, two plastic hinges are defined and the locations of hinges are approximately 0.5 times the element depth.

In (9), C3 is fitness factor of plastic hinge for each frame, NH column is number of column non-linear hinge and NH beam is number of beam non-linear hinge.

Therefore, for the fitness factor (C) of each frame the following expression was used:

In this paper for b1, b2, b3 (constant factors) after many trial analyses, the values of 1.15, 1.3 and 1.10 were chosen, respectively.

The discrete optimum design problem of nonlinear steel frames with semi rigid connections, in which the minimum weight is considered as the objective, can be stated as follows:

Here, A i is the cross-sectional area, ρ i is the density and L i is the length of member i.

4 Application examples

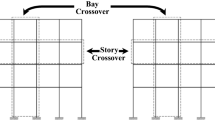

In this paper, for the weight optimization of steel frames with different stiffness values for the connections, nine frames are chosen (Tableqa01).

The spans are 5 m and the heights are 3 m in all frames. The values for dead and live loads are 3,000 and 1,500 Kgf/m, respectively. For seismic load, the Iranian Earthquake Resistant Design Code, standard no 2800–3rd edition (BHRC 2005), which same as UBC 97 (Uniform Building Code, UBC 1997) was used. The load combinations are chosen from the design code (Fig. 2).

Here, V is the base story shear force, C is the base shear cofficient and W is the structure weight.

In this equation, A is peak of ground acceleration PGA, B is reflect factor, I is building importance factor, and R is the response factor of structure in seismic load.

Seismic design spectra “Iranian earthquake resistant code, standard no 2800–3rd edition” (BHRC 2005)

The sizes of population, possibility of mutation, and maximum number of generations are assumed to be equal to 30, 0.005 and 100, respectively. SAP2000 (Ver. 11.07) (Computers and Structures Inc 2008) traditional engineering software is used for modeling the frames, and a program which adapts SAP2000 (Ver. 11.07) (Computers and Structures Inc 2008) is written for the optimization procedure. In genetic algorithm method of generations produced. An increase in population (GA), the population size has an important effect on the values of the optimum weights and on the number size causes a large increase in the number of generations produced and in the computing time, but small decrease in the weight of the frame (Degertekin et al. 2008; Togan and Daloglu 2008). The initial generation critically affects the convergence, the performance and the ability of the GA. If the size of design space is small, these properties of the GA may not be influenced (Kaveh and Kalatjari 2003). For determining size by genetic algorithm, the force method and some concepts of graph theory are used (Saka et al. 2000). To simulate semi-rigid connection, the rotational lumped springs with equivalent rotational stiffness is used (Fig. 3).

To analyze and design the frame elements, I and box-shaped standard sections given in SAP2000 Ver. 11.07 (Computers and Structures Inc 2008) data bank, are used for beams and columns, respectively. For first step, the test result of semi-rigid connection stiffness (Nateghelahi and Yazdani 2002) allocated to the frame nodes form Table 2, will be obtained (Fig. 4).

For verifying the method of semi-rigid connection modeling with rotational spring in SAP Ver. 11.07 (Computers and Structures Inc 2008) program, a beam under uniform loading w, with connection characteristic parameters and initial stiffness K i ; (Fig. 5) and definite section and load is analyzed. Then, the results (ultimate moment, Mu) are compared with the results in Abdul-Rassak Sultan (2007).

This comparison is shown in Table 3. The degrees of these stiffnesses are created by genetic algorithm during the procedure of optimization to obtain a frame with the minimum weight.

After the initial allocation of connection stiffness to the joint nodes of each of the frames being studied and performance of optimization operations using genetic algorithms, the following results are obtained after 100 repetitions of generation production.

4.1 Design of three-story frames (one bay, two bays, three bays)

The history of generations for these frames is given in Figs. 6, 7 and 8. The optimum weights of frames with one bay and two bays are closer to each other when linear and nonlinear analyses are applied.

But in the third frame, the nonlinear analysis gives less weight than the linear analysis (Table 4). From the results obtained from Table 4, it can be concluded that in the frames with semi-rigid connections, the periods of frames increased about 20%. The weight of the structure with semi-rigid connections in linear analysis has an increase of about 2.9%. In the nonlinear analysis, an average increase of 5.4% is observed. This depends on the periods of the structures and the design spectrum suggested by the Iranian Earthquake Building Design Code (BHRC 2005).

The local soil type and acceleration constant are considered to be equal for all frames. In the nonlinear analysis an increase in the period of the structure increases the weights of the frames more as compared to that in the linear case. In the case of nonlinear analysis with semi-rigid connections the number of plastic hinges decreased (Fig. 9). The stiffness of beam-column semi-rigid connection in nonlinear analysis about 16% is decreased. After optimization of structure, the stiffness of semi rigid connection at top story is moves towards as compared with first story that of a decrease about 35%.

4.2 Design of six-story frames (one bay, two bays, three bays)

The histories of the generations of these frames with six stories are given in Figs. 10, 11 and 12. As it can be observed in the above diagrams, an increase in the height of the structure increases the difference between the linear and nonlinear analyses. The responses will converge to an optimum amount after a continuous repetition of generation production. Generally, the weight of the structure in the linear analysis is more compared with the non-linear analysis. In the first generation, the difference between the weights of the linear and nonlinear analyses is less than that in the 100th generation.

It is concluded that beginning a search with specific individuals instead of generating the initial population randomly enables reaching the optimum design and/or getting closer to the global optimum with less number of iterations. It is observed that the genetic algorithm is a convenient tool for reaching the optimum design. In Table 5, the results of the nonlinear analysis show that the weight of a structure is going to reach its minimum to obtain the highest economy. The locations and number of plastic hinges are given in Fig. 12. At the end of the optimization, the stiffness of the beam-to-column connections at the top story becomes nearly 50% less compared with that of the first case (Fig. 13).

4.3 Design of nine-story frames (one bay, two bays, three bays)

Table 6 presents the results obtained from the analysis of nine-story frames. In these frames the weights of the structures in the linear analysis case with rigid connections and in the nonlinear analysis case with semi-rigid connections reach maximum and minimum, respectively. In the nonlinear analysis case with semi-rigid connections, the weight of the structure decreases more compared to the other analyses (Figs. 14, 15 and 16).

There would be much more savings in the optimum weights if the process had continued further in the iteration. The effects of the story height and the stiffnesses of the connections on the periods of the structures is not appreciable.

In fact, by changing the connections of a structure to semi-rigid ones, its stiffness is decreased and its period is increased. The abovementioned factors have a more pronounced role in the frame element design and an appreciable improving effect on the behavior of the structure under earthquake action. For this reason, to control the maximum displacement of the top story and the relative displacements of the neighboring stories, there is a serious need for more improvement in the members and their contribution to the total weight of the structure. By increasing the heights of the lower stories of the structure, in which case the shear forces in those stories need special care, which can be realized by higher stiffnesses in the beam-to-column connections (Fig. 16).

The beam and column profiles dimensions for some of frames which select in this paper, before and after optimization with rigid and semi rigid connection by linear and non-linear analysis are given in Figs. 17, 18, 19 and 20.

5 Summary and conclusion

Considering the presented explanations and examples, it is observed that the application of genetic algorithm in the analysis and design of buildings can change the procedure of the analysis and design in such a way that there will be no need for the initial estimation of sections and control of stresses by the designers. However, naturally, the current initial estimation may reduce the time of analysis. The analysis, design and selection of optimum sections will be performed by the program and the final design will be performed considering the proposed sections by the program and special executive issues of that project which will prevent unnecessary loss of the time of the designers.

Considering the obtained numerical results, tables and figures, the following conclusions can be drawn:

-

1.

In the case of low rise frames with low periods, in which the structure falls in the constant acceleration part of the design spectrum (BHRC 2005), by decreasing the stiffness of the connections, the weight of the structure may increase.

-

2.

In the medium to high rise frames which have long periods, the structure falls in the lower part of the reflection spectrum (constant velocity part of design spectrum) and by decreasing the connection stiff nesses and increasing the period of the structure, the acceleration and force imposed on the structure will decrease, thus, leading to a decrease in the weight of the structure.

-

3.

It should be noted that in cases in which we are in the lower part of the design spectrum, by increasing the period of the structure, there will be a considerable decrease in the rate of acceleration (force) and by increasing the period of the structure, there will be less decrease of acceleration especially in the end sections.

-

4.

Generally, it can be concluded that using semi-rigid connections and nonlinear analysis method in medium to high structures, will cause a decrease in the weight of the structure as well as in its cost. But, using rigid connections and nonlinear analysis method in short structures will result in a cost effectiveness in the design.

-

5.

Considering the shear force, the average stiffness of connections in semi-rigid frames increase more and more in the lower stories finally reaching its maximum close to the restraint border.

-

6.

In the analysis of frames with semi-rigid connections, the optimum stiffness of connections in the linear analysis is more than that in the nonlinear one.

-

7.

In all the frames studied it is observed that the weight of the structure in the nonlinear analysis is generally less than that in the linear one.

-

8.

Nonlinear analysis method is more accurate than the linear one and the elements being used more effectively will lead to a considerable decrease in consumed materials.

References

Abdul-Rassak Sultan S (2007) Performance-based optimal design of semi-rigid connected steel frame under seismic loading. PhD dissertation, Department of Civil Engineering, The Hong Kong Polytechnic University

Applied Technology Council (ATC)-40 (1997) Seismic evaluation and retrofit of concrete buildings, vol I. Report no. ATC 40, Applied Technology Council, California

Ballad KM, Chen WF (1995) Expanded database of semi-rigid steel connections. Comput Struct 564):553–564

Bhatti MA, Hingtgen JD (1995) Effects of connection stiffness and plasticity on the service load behavior of un-braced steel frames. AISC Eng J 32(1):21–33

BHRC (2005) Iranian earthquake resistant code, standard no 2800–3rd edn. Standard no. 2800, Tehran, Iran

Chen WF (2000) Practical analysis for semi-rigid frame design. World Scientific

Chen WF, Kishi N (1989) Semi-rigid steel beam-to-column connections: data base and modeling. J Struct Eng ASCE 155:105–119

Chen WF, Lui EM (1991) Stability design of steel frames. CRC Press, Boca Raton

Coello CA (2002) Theoretical and numerical constraint-handling techniques used with evaluation algorithms: a survey of the state of art. Comput Method Appl Mech Eng 191:132–141

Computers and Structures Inc (2008) CSI analysis reference manual. SAP2000 version 11.07. Berkeley, CA

Da Silva JGS, de Lima LRO, da S Vellasco PCG, de Andrade SAL, de Castro RA (2008) Nonlinear dynamic analysis of steel portal frames with semi-rigid connections. Eng Struct 30:2566–2579

Degertekin SO, Saka MP, Hayalioglu MS (2008) Optimal load and resistance factor design of geometrically nonlinear steel space frames via tabu search and genetic algorithm. Eng Struct J 30:197–205

Fajfar P (1999) Capacity Spectrum method based on inelastic demand spectra. Earthquake Eng Struct Dyn 28(9):79–93

Federal Emergency Management Agency, FEMA-356 (2000) Prestandard and commentary for seismic rehabilitation of buildings. Washington (DC)

Hsieh SH, Deierlein CG (1990) Nonlinear analysis of three-dimensional steel frames with semi-rigid connections. Comput Struct 41(5):995–1009

International Conference of Building Official (1997) 1997 Uniform building code, vol 2. Whittier, CA

Jenkins WM (1991) Towards structural optimization via the genetic algorithm. Comput Struct 40(5):1321–1327

Jian-Yi W (1999) Nonlinear behaviour of semi-rigid composite joints under lateral loading (Experimental and Theoretical Study). PhD dissertation, Department of Civil and Engineering, The Hong Kong Polytechnic University

Kameshki ES, Saka MP (2001) Optimal design of nonlinear steel frames with semi-rigid connections using a genetic algorithm. Comput Struct 79:1593–1604

Kameshki ES, Saka MP (2003) Genetic algorithm based optimum design of nonlinear planar steel frames with various semi-rigid connections. J Construct Steel Res 59:109–134

Kameshki ES, Saka MP (2007) Optimum geometry design of nonlinear braced domes using genetic algorithm. Comput Struct 85:71–79

Kaveh A, Kalatjari V (2003) Topology optimization of trusses using genetic algorithm, force method and graph theory. Int J Numer Methods Eng 58(5):771–791

Kaveh A, Moez H (2008) Minimal cycle bases for analysis of frames with semi-rigid joints. Comput Struct 86:503–510

Lee W, Chen C (1996) A seismic assessment on long period reinforced concrete high-rise frames by pseudo-elastic equal drift method. Struct Eng J 11(4):5–7

Machaly ESB (1986) Optimum weight analysis of steel frames with semi rigid connections. Comput Struct 23(4):461–474

McKevitt WE, Anderson DL, Cherry S (1960) Hysteretic energy spectra in seismic design. In: 2nd WCEE, Tokyo and Kyoto, Japan, Tokyo, pp 487–494, 11–18 July

Nateghelahi A, Yazdani M (2002) Seismic behavior semi rigid connection for steel structures. International Institute of Earthquake Engineering and Seismology. ISBN: 964-6490-13-1

Nethercot DA (1985) Steel beam-to-column connection a review of test data. CIRIA, London

Priestley MJN, Calvi GM, Kowalsky MJ (2007) Direct displacement-based seismic design of structures. IUSS Press

Rajeev S, Krishnamoorthy CS (1992) Discrete optimization of structures using genetic algorithms. J Struct Eng ASCE 118(5):1233–1250

Saka MP, Daloglu A, Malhas F (2000) Optimum spacing design of grillage systems using a genetic algorithm. Adv Eng Softw 31:863–873

Teal EJ (1975) Seismic drift control criteria. AISC, 2 quarter

Togan V, Daloglu AT (2008) Optimal load and resistance factor design of geometrically nonlinear steel space frames via tabu search and genetic algorithm. Eng Struct J 30:197–205

Uniform Building Code, UBC (1997) International conference of building officials. Whitter, CA

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oskouei, A.V., Fard, S.S. & Aksogan, O. Using genetic algorithm for the optimization of seismic behavior of steel planar frames with semi-rigid connections. Struct Multidisc Optim 45, 287–302 (2012). https://doi.org/10.1007/s00158-011-0697-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-011-0697-9