Abstract

Optimum design of structures under time-variable loadings is a difficult task. Time-dependent behavior of constraints and cost of gradients calculations could be mentioned when applying time history loadings in the optimization problems. To overcome these difficulties, the response spectra as a seismic demand are used instead of using time history acceleration in the structural modeling. In this paper, the P-Delta effects are considered in the finite-element modeling of the frames. Furthermore, many practical constraints are included in the optimization formulation according to the Iranian national building code (Standard N. 2800). The developed MATLAB-based computer program is utilized for optimization of the low, intermediate- and relatively high-rise braced and un-braced steel frames. The obtained results of sequential quadratic programing (SQP) method are compared with the results of genetic algorithm (GA) technique for guarantying the global optimal designs. Because of the inexpensive costs of SQP method in comparison with genetic algorithm technique, SQP method could be confidently applied for obtaining the global optimum designs of the steel frames.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The optimum designs of steel frames are often cost minimization with performance and construction criteria. Optimization techniques in structural engineering could be divided generally into three distinct methods: (1) mathematical/gradient-based methods, (2) optimality criteria methods and (3) stochastic search algorithms.

Mathematical techniques are based on the gradients of functions in the solution space. Therefore, the algorithms need continuous functions representing the objective and constraint(s). Numerous researches have been conducted using the mathematical optimization methods [1–5]. Memari and Madhkhan [6] applied the feasible directions method to optimize the braced and un-braced steel frames using equivalent static loading. They concluded that braced frames are more economical than un-braced ones. Akbari and Sadoughi [7] employed SQP method for finding the optimum design of the structures under time history acceleration. They transformed acceleration time histories into the equivalent static loads (ESLs).

The optimality criteria (OC) method is based on the combination of indirect Kuhn–Tucker conditions of nonlinear mathematical programming with Lagrangian multipliers. The OC approach has been the subject of many studies [8]. H.Moharrami and S.A.Alavinasab [9] proposed an improved optimality criteria method for optimum design of steel frames.

Due to the rapid development of computer facilities, new techniques such as genetic algorithms (GA) have been suggested in the field of structural optimization. One of the most important advantages of GA in optimal design of steel frames is using the discrete design variables and its capabilities for finding the global optimums. Optimization using GA has been successfully applied to structural optimization [10–13]. Papadrakakis et al. [14] proposed the Evolution Strategies (ES) algorithm in the optimal design of structures under seismic loading. They used response spectrum modal analysis to evaluate the structural response under seismic loading. Kameshki and Saka [15] presented an optimum design based on GA for the multi-story, non-sway steel frames with different types of bracings. The algorithm considers the serviceability and the strength constraints as specified in the BS 5950, and it was shown that the lightest frame is simple X-bracing system. De Castro [16] implemented GA and obtained the minimum weight of frame structures in free vibration analysis. Salajegheh et al. [17] suggested hybrid RBF-BPSO method for optimal design of structures. Gholizadeh and Salajegheh [18] applied swarm intelligence and advanced meta-model for optimum design of structures subjected to time history loading. Prendes Gero et al. [19] developed an elitist genetic algorithm and compared it with the common commercial solutions for complex structural optimization. Keii and Ikago [20] suggested a model to get optimum designs suitable for practical structural design within the framework of the Building Standard Law of Japan. Chen and Kai Hu [21] presented a GA-based program written in MATLAB for optimization of portal frames. Kripakaran and Hall [22] suggested a computational approach based on GA to implement a decision support system for the design of moment-resisting steel frames. Balogh and Vigh [23] developed a numerical optimization algorithm in MATLAB to find the optimal structural configuration.

In the literature, comprehensive studies have been conducted for optimal design of steel frames under static loading; however, for dynamic loading, some of the researchers [6, 9] applied the equivalent static loading according to the Iranian building regulation [24, 25]. The Codes are based on the translations of some chapters of regulations such as US Building Officials and Code Administrators (BOCA), National Building Code of Canada (NBC), Building Standard Law of Japan (BSL) and regulation of France.

We believe that the characteristics of seismic loadings and quasi-static loads are not similar. The stiffness, damping, and mass parameters of structures are usually affected on the structural responses during dynamic excitations. However, for quasi-static case, the system responses are only influenced by the stiffness and the first vibration mode of the systems. Therefore, direct seismic analysis will lead to accurate results in compare with equivalent static approach.

Many studies have been conducted for optimum design of structures for direct time history loadings [26–28]. However, the single time history loading, e.g., acceleration time history, could not be the suitable representative of the seismic demand for a specific area. Therefore, seismic analysis is carried out using the response spectrum analysis because such analysis is more compatible with the structural design requirements under seismic excitations.

The P-Delta effects are usually a crucial issue for intermediate- and high-rise steel frames. In this research, these secondary effects are included in the linear static and dynamic finite-element modeling by considering the geometric stiffness of the structure.

Many constraints have been taken into account in the optimization formulation according to the Iranian NBC code [24]. In addition, optimal designs have been carried out for the combination of dead, live and seismic loadings due to their importance in the design criteria. Consequently, the optimum designs of steel frames under seismic demands are available using the proposed method.

2 Optimization Formulation

The aim in size optimization of steel frames is often weight minimization under certain constraints using cross-sectional areas as the design variables. Therefore, in these cases, the structural optimization problems could be formulated as follows:

where x is the vector of design variables, W(x) is the objective function and g i(x) is the equality and inequality constraint. Here, the size optimizations of multi-bay, multi-story frames are investigated. The objective function is the weight of the structure given below

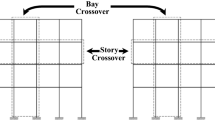

where A i, L i and ρ i are the cross-sectional area, the length and mass density of the ith member, respectively. The constraints for allowable stress design requirements specified by National Building Code [24] for frames with rolled I-shapes, as shown in Fig. 1, are expressed as follows. The constraints for slenderness ratios for all members are

where F y is the yielding strength of steel and K is the effective length factor. The effective length factors (K) have been calculated for un-braced and braced frames [24]. Shear stress constraints could be written as

Constraints for combined bending and axial stresses could be given as

As well, constraints for combined tensile and bending stresses and inter-story drifts are expressed below

where subscript i refers to ith member f a, f t, f b and f v are the applied axial compressive, tensile, bending, and shear stresses, respectively. In addition, F a, F t, F b and F v are the allowable axial compressive, tensile, bending and the yield stresses, respectively, r min is the minimum radius of gyration of cross sections, Δi is the ith story displacement and h i is the height of ith story. Side constraints and the variations of column size constraints along the height of the frames could be expressed as follows:

A Li , A Ui are the lower and upper bounds of cross-sectional areas, respectively. \(A_{{{\text{C}}_{\text{i}} }}\) is the columns’ cross-sectional area for ith story. Allowable axial stress in columns is calculated using the following equation:

where λ max is the maximum slenderness ratio of the member, E is steel modulus and C c = (2π2 E/F y)0.5, F t = 0.6 F y and F b = 0.66 F y. It is necessary to mention that Eqs. (3, 4, 5, 6, 7, 8) are written for allowable stress design method. However, nowadays LRFD method is provided in the last version of NBC. Without losing the generality, using small modification in the constraints the proposed methodologies could be applied for LRFD design approach.

3 Finite-Element Modeling

Finite-element modeling of the structures has been performed using the frame elements with six D.O.F and truss elements with two D.O.F. The numerical models have been verified by S-FRAME [29] and SAP2000 [30]. The S-FRAME software has been used for eigenvalue analyses and static responses verifications. The commercial SAP2000 software has been applied for verifying the developed FEM code for the first mode vibration of the frame. Here, soil structure interaction is not considered in the numerical modeling. The linear behaviors of structures for static and dynamic loadings have been taken into account and the acceleration spectrum is applied in the seismic analysis of the frames. The details of the geometries and the material properties of numerical studies are presented in Sects. 7.1 and 7.2.

In this paper, the P-delta effects have been included in the finite-element modeling. The purpose of the P-delta analysis is determining the displacements and the stresses due to the time-independent loadings. The P-delta analysis, specifically the Two-Cycle Iterative Method (Chen and Lui, 1991) [31], requires a two-stage analysis procedure. In the first phase, for all the user-selected load cases and load combinations, the equilibrium equations for the linear static analysis are solved for the nodal displacements. Once the nodal displacements are obtained, the element membrane forces are calculated and used to form the element geometric stiffness matrices. In the second phase of analysis, the equilibrium equations of the P-delta analysis are considered. Once the nodal displacements are obtained, the element stresses and nodal forces are computed. For the elements at the boundaries, these nodal forces will be in equilibrium with the reactions.

4 Design Under Seismic Loading

Response spectrum analysis is one of the most recommended methods for analyzing or designing of structures against earthquake loadings. In comparison with time history analysis, the advantage of this method is that the stress constraints in the optimization procedure are independent of time domain. Here, acceleration spectra have been utilized and complete quadratic combination rule (CQC) has been used to obtain the maximum responses of the structures. The equation of motion for a dynamic system can be written as follows [32]:

where M, C and K are the mass, damping and stiffness matrices of the system, respectively. P is the external load vector U, \({\dot{\mathbf{U}}}\) and \(\ddot{\mathbf{{U}}}\) are the displacement, velocity and acceleration vectors of system in time domain, respectively. The response spectrum modal analysis is based on the mode superposition approach. In the case of modal analysis, Eq. (9) is modified according to the modal superposition method [32]. The following steps summarize the response spectrum analysis that is utilized in this study:

-

1.

Determining the values of eigenvectors φ i and eigenvalues ω i and normalizing them to transform the Eq. (9) into uncoupled equations.

-

2.

Calculating the modal participation factors and effective modal mass according to the following:

$$\varGamma = \frac{{L_{\text{n}} }}{{M_{\text{n}} }} \, , \, L_{\text{n}} = \varPhi^{T} {\text{Mr }}, \, M_{\text{n}} = \varPhi^{T} M\varPhi \, , \, m_{\text{eff}} = \frac{{L_{\text{n}}^{2} }}{{M_{\text{n}} }}$$(10) -

3.

Computing the displacement–response spectrum in the form of S d = S a/ω 2 and correlation coefficient as follows:

$$\rho_{\text{ij}} = \frac{{8\xi^{2} \left( {1 + r} \right)r^{{{3 \mathord{\left/ {\vphantom {3 2}} \right. \kern-0pt} 2}}} }}{{\left( {1 - r^{2} } \right)^{2} + 4\xi^{2} r\left( {1 + r} \right)^{2} }} \, , \, r = {{\omega_{\text{i}} } \mathord{\left/ {\vphantom {{\omega_{\text{i}} } {\omega_{\text{j}} }}} \right. \kern-0pt} {\omega_{\text{j}} }}$$(11) -

4.

Calculating the modal displacements x i,max = Γ ΦSd and applying CQC rule to calculate the total maximum displacements from the following:

$$X_{\hbox{max} } = \sqrt {\sum\limits_{i = 1}^{m} {x_{i}^{2} + \sum\limits_{i = 1}^{m} {\sum\limits_{j = 1}^{m} {\rho_{\text{ij}} x_{\text{i}} x_{\text{j}} } } } } \,$$(12)

5 Solution of the Optimization Problem

In this study, both sequential quadratic programming (SQP) and genetic algorithm (GA) techniques have been utilized for optimal seismic design of steel frames. The philosophy of applying both SQP and GA methods is finding the global optimal designs. The main drawback of the mathematics-based optimization techniques is that the methods might be trapped in the local optimum points. In spite of gradient-based optimization methods, the heuristic approaches are able to find the global optimum designs.

5.1 SQP Optimization Method

Sequential quadratic programming (SQP) is one of the most effective methods for nonlinear constrained optimization problems. The method generates steps by solving quadratic sub-problems. The SQP method can be viewed as a generalization of Newton’s method for unconstrained optimization in that it finds a step away from the current point by minimizing a quadratic model of the problem [33]. The main steps of this algorithm are as follows:

-

A.

In the first step, the search direction (S) is obtained by quadratic approximation of objective function and linear approximation of the constrains using Eq. (13). In this step, the Hessian matrix (H) is set to the unit matrix.

$$\begin{aligned} & {\text{minimize }}Q({\mathbf{S}}) = F({\mathbf{x}}^{0} ) + \nabla F^{T} ({\mathbf{x}}){\mathbf{S}} + \frac{1}{2}S^{T} {\mathbf{HS}} \\ & {\text{s}} . {\text{t}} \\ & \nabla g_{\text{j}}^{T} ({\mathbf{x}}){\mathbf{S}} + \delta_{\text{j}} g_{\text{j}} ({\mathbf{x}}^{0} ) \le 0 \; j = 1,N \\ \end{aligned}$$(13)where F(x) is the objective function, ∇g i(x) is ith gradient of constraint and δ i is a constant for remaining the algorithm at the feasible space.

-

B.

After solving the sub-problem of Eq. (13) and finding Lagrangian multipliers λ j, minimization of the Lagrange function (Φ) is carried out using

$$\begin{aligned} & {\text{minimize }}\varPhi (\alpha ) = F(\alpha ) + \sum\limits_{j = 1}^{N} {u_{j} } \hbox{max} [0,g_{j} (\alpha )] \\ & u_{\text{j}} = \left| {\lambda_{\text{j}} } \right| \, j = 1,N{\text{ first iteration}} \\ & u_{\text{j}} = \hbox{max} [\left| {\lambda_{\text{j}} } \right|,\frac{1}{2}(u_{\text{j}}^{*} + \left| {\lambda_{\text{j}} } \right|)] \, j = 1,N{\text{ subsequent iterations}} \\ \end{aligned}$$(14) -

C.

From Eq. (14) the step length α is calculated. Then, updating of H matrix is conducted using Eq. (15) and convergence is controlled.

$$\begin{aligned} {\mathbf{H}}* = {\mathbf{H}} - \frac{{{\mathbf{Hdd}}^{T} H}}{{{\mathbf{d}}^{T} {\mathbf{Hd}}}} + \frac{{{\varvec{\uppsi \uppsi }}^{T} }}{{{\mathbf{d}}^{T} {\varvec{\uppsi}}}} \\ \varvec{d} = {\mathbf{x}}^{q} - {\mathbf{x}}^{q - 1} \, , \, {\varvec{\uppsi}} & = \theta y + (1 - \theta ){\mathbf{Hd}} \, , \, {\mathbf{y}} = \nabla_{x} \varPhi^{q} - \nabla_{x} \varPhi^{q - 1} \, , \, \varPhi = F(x) + \sum\limits_{j = 1}^{N} {\lambda_{j} } g_{j} ({\mathbf{x}}) \\ \theta & = \left\{ \begin{aligned} & 1.0 \,\, if \, {\mathbf{d}}^{T} {\mathbf{y}} \ge 0.2{\mathbf{d}}^{T} {\mathbf{Hd}} \\ & \frac{{0.8{\mathbf{d}}^{T} {\mathbf{Hd}}}}{{{\mathbf{d}}^{T} {\mathbf{Hd}} - {\mathbf{d}}^{T} {\mathbf{y}}}} \, if \, {\mathbf{d}}^{T} {\mathbf{y}} \le 0.2{\mathbf{d}}^{T} {\mathbf{Hd}} \, \\ \end{aligned} \right. \\ \end{aligned}$$(15)

5.2 Optimization Using GA

Genetic algorithms are based on Darwin’s theory of natural selection. The basic idea of the approach is to start with a set of designs, randomly generated using the allowable values for each design variable. Each design is also assigned a fitness value, usually using the cost function for unconstrained problems or the penalty function for constrained problems. From the current set of designs, a subset is selected randomly with a bias allocated to more fit members of the set. Random processes are used to generate new designs using the selected subset of designs. The size of the set of designs is kept fixed. Since more fit members of the set are used to create new designs, the successive sets of designs have a higher probability of having designs with better fitness values. The process is continued until a stopping criterion is met. According to the above explanations, the main steps for this method are listed as follows [33].

Step 1 Define a schema to represent different design points. Randomly generate N P genetic strings (members of the population) according to the schema, where N P is the population size. Alternatively, use the seed designs to generate the initial population. For constrained problems, only the feasible strings are accepted when the penalty function approach is not used. Set iteration counter K = 0. Define a fitness function for the problem as below

where f i is the cost function (penalty function value for a constrained problems) for the ith design, f max is the largest recorded cost (penalty) function value, and ɛ is a small value (e.g., 2 × 10−7) to prevent numerical difficulties when f i becomes 0.

Step 2 Calculate the fitness values for all the designs in the population. Set K = K + 1, and the counter for the number of crossovers I c = 1.

Step 3 Reproduction: select designs from the current population according to the roulette wheel selection process for the mating pool (next generation) from which members for crossover and mutation are selected.

Step 4 Crossover: select two designs from the mating pool. Randomly choose two sites on the genetic strings and swap strings of 0s and 1s between the two chosen sites. Set I c = I c + 1

Step 5 Mutation: choose a fraction (P m) of the members from the mating pool and switch a 0–1 or vice versa at a randomly selected site on each chosen string. If, for the past I g consecutive generations, the member with the lowest cost remains the same, the mutation fraction P m is doubled. I g is an integer defined by the user.

Step 6 If the member with the lowest cost remains the same for the past two consecutive generations, then increase I max. If I c < I max, go to Step 4. Otherwise, continue.

Step 7 Stopping criterion: if after the mutation fraction P m is doubled, the best value of the fitness is not updated for the past I g consecutive generations, then stop. Otherwise, go to Step 2.

6 Organization of the Developed Program

7 Numerical Examples

In this section, two examples have been considered for obtaining the optimal designs. Braced and un-braced frames are of interest to study from minimum weight point of view. Two types of seismically resistant frame structures are selected: (a) X-braced frame with moment resisting connections, and (b) un-braced frame with moment resisting connections. SQP and GA methods are utilized for weight minimization of the frames, and the obtained results are compared with each other. The horizontal components of El Centro earthquake as shown in Fig. 3 with the time duration of 40s and PGA = 0.31 g are considered and elastic response spectrum is calculated for this record. Damping ratio is assumed to be constant and is set to 5 % (see Fig. 4). The profiles of beams and columns are selected IPB based on the German specifications Stahleisen (1967) (Table 1). The cubic spline data interpolation has been used for reducing the number of unknown design variables [35]. It is shown that this method is much more accurate than the least square approach, which was used in the previous studies (Table 2).

7.1 Case 1

This case is weight minimization of 4-story, 3-bay frame. The members are divided into twelve groups for X-braced frame and eight groups for the un-braced one. The geometry of the frames is illustrated in Fig. 5.

Optimum designs are obtained for two types of load combinations: (1) D + L and (2) 0.75(D + L ± E). The gravity loading for roof includes dead load (D) = 22.2 kN/m and live load (L) = 5.9 kN/m and for other stories dead load = 20.2 kN/m and live load = 7.9 kN/m. The modulus of elasticity is E = 2.1 × 108 kN/m2 and the weight density of steel is ρ = 7850 kg/m3. The program gives the same final optimum design when it is started from any design point. In this case, initial cross-sectional areas are taken as 149 cm2 (IPB300 profile). SQP optimization results under both load combinations are shown in Figs. 6 and 7.

Active constraints are: the lower bounds of the design variables in the braced frame, combined bending and axial stresses and the optional geometrical constraints of column sizes in both frames. The sections with the closest properties will be selected based on the values of the optimum design variables (cross-sectional areas), from the table of available sections. The selected design is checked for satisfying all of the constraints. If any of the constraints is violated, the next best section is tested, and so on. This constitutes one of the limitations of this methodology. Design variables are automatically selected from the available sections in the set of IPB profiles (Table 1).

The minimum weights of X-braced frame and un-braced frame for four-story frame have been exhibited in Table 3. The results show that braced systems are more economical than un-braced ones

In discrete optimization using GA, the population size is taken as 50, the elite numbers 10 and the crossover probability 0.80. The results are shown for (D + L) and 0.75(D + L ± E) in Figs. 8 and 9.

Figures 8, 9 show that for short-period systems, the computational costs or number of iterations for un-braced systems are less than braced ones. From optimization point of view, reaching to the best design of flexural structural systems is simpler than finding the final optimum points of X-brace frames (flexural + brace). The authors’s reason is that the lateral stiffness of a braced frame is affected by axial members (braces) that are not the design variables in the optimization formulation. In Table 2, several data fitting techniques have been compared for the profiles of beams and columns. Therefore, reaching to the optimum designs is easier. As seen from Figs. 6, 7, 8 and 9, in both SQP and GA methods for static loading (D + L) un-braced frames are lighter than the braced ones. In addition, as observed from Figs. 7 and 9 in the loading case 0.75(D + L ± E), the braced frames are more economic than the un-braced frames. In Tables 4 and 5, the optimum results of SQP and GA methods are summarized.

It is seen that the optimum design for SQP and GA procedures is same. Fortunately, the gradient-based optimization method (SQP) has captured the global optimum point for all loading cases. Under static load combination (D + L), the un-braced frame is 23.15 % lighter than the X-braced frame but under the seismic load combination 0.75(D + L ± E), the X-braced frame is 48.06 % lighter than the un-braced one.

7.2 Case 2

This case is also weight minimization of 10-story, 5-bay frame. The members are divided into 15 groups for X-braced frame and 10 groups for the un-braced one. The geometry of frames is shown in the Fig. 10

The gravity loading for roof includes dead load = 26.2 kN/m and live load = 7.4 kN/m and for other stories dead load = 23.8 kN/m and live load = 12.3 kN/m. The rest of the assumptions are same as the previous case. The results of SQP optimization for both load combinations are illustrated in Figs. 11 and 12.

In this case, active constraints are the lower and upper bounds of the design variables. In the braced frame, combined bending and axial stresses for both frames and the optional geometrical constraints of column sizes in the braced frame are active. In the discrete optimization (GA), all the parameters are same except crossover probability is set to 0.85. In Figs. 13 and 14, the histories of fitness function are depicted. Design variables are automatically selected from the available sections in the set of IPB profiles (Table 1).

For seismic loading case, the number of iterations for un-braced systems is less than braced one. The reason of authors is that the lateral stiffness of a X-braced frame is influenced by braces rather than beams or columns. As well, the braces directly are not the design variables in the optimization process. In un-braced frames or flexural systems, the design variables are the profiles of beams and columns, and they are direct design variables, and reaching to the optimum design is faster.

The results of Table 6 indicate that unlike the low-rise frames, for intermediate to high-rise frames, the un-braced frames are economic than X-braced frames.

It is seen from Figs. 11, 12, 13, and 14 that in SQP and GA methods for static loading (D + L) un-braced frame is lighter than the braced frame. In addition, for the loading combination 0.75(D + L ± E), the un-braced frame is more economic than the braced one (see Figs. 11 and 14).

Additionally, in Tables 7 and 8, the optimum results of SQP and GA methods are presented.

It is observed that the results of SQP and GA methods are same. Under gravity load combination (D + L), the un-braced frame is 24.65 % lighter than the X-braced frame and also under the seismic load combination 0.75(D + L ± E), the un-braced frame is 26.48 % lighter than the X-braced one. Fortunately, for this intermediate case study, the gradient-based optimization method (SQP) has reached to the global optimum point for all loading cases.

8 Conclusion

This study employs a systematic method for finding the optimum designs of steel structures under seismic loadings. Minimum weight of the steel frames subject to dead, live and seismic loading is found successfully. The P-Delta effects are included in the linear static and seismic response spectrum analysis of intermediate- and high-rise frames. Most important practical constraints have been included in the optimization formulations according to the Iranian national building code requirements. The proposed method is efficient and has practical advantages. These methodologies could be easily applied to three-dimensional frame structures, as well. All the presented methods have been successfully programmed and tested. Based on the present study, the following conclusions are drawn:

-

1.

In low-rise frames, the results show the superiority of X-braced frames with moment resisting connections in comparison with the un-braced frames with moment resisting connections. However, the superiority of the un-braced frames is observed for intermediate- and high-rise frames.

-

2.

The results of optimum designs for all frames showed that SQP method has enough capability to find the global optimum points. Therefore, it could be confidently applied to optimize the steel frame structures.

-

3.

In compare with SQP method, the costs of computations in GA are relatively significant; especially for high-rise frames, the costs of calculations are too expensive. Therefore, gradient-based algorithms could be applied instead of the heuristic methods to optimize such systems.

-

4.

Characteristics of the seismic loadings and the equivalent static loads are not same. Dynamic loads are usually exerted at the foundations of structures, and stiffness, damping, and mass matrixes influenced the responses. However, the responses are only affected by the stiffness of the system in quasi-static loads. To the best of our knowledge, the optimization results for response spectra are compatible with structural behavior of the buildings. Therefore, acceleration response spectrum has been applied in the optimum design of frames.

References

Gülay G, Boduroğlu H (1989) An algorithm for the optimum design of braced and unbraced steel frames under earthquake loading. Earthquake Eng Struct Dynam 18(1):121–128

Erbatur F, Al-Hussainy M (1992) Optimum design of frames. Comput Struct 45(5):887–891

Thevendran V, Das Gupta NC, Tan GH (1992) Minimum weight design of multi-bay multi-storey steel frames. Comput Struct 43(3):495–503

Dixon AS O’Brien EJ (1994) Optimal plastic design of steel frames for multiple loading. In: Advances in structural engineering computing international conference on computational structures technology, pp 21–26

Hernández S (1998) Optimum design of steel structures. J Constr Steel Res 46(1):374–378

Memari AM, Madhkhan M (1999) Optimal design of steel frames subject to gravity and seismic codes’ prescribed lateral forces. Struct Optim 18(1):56–66

Akbari J, Sadoughi A (2013) Shape optimization of structures under earthquake loading. Struct Multidiscip Optim 47(6):855–866

Grierson DE, Chan CM (1993) An optimality criteria design method for tall steel buildings. Adv Eng Softw 16(2):119–125

Moharrami H, Alavinasab SA (2006) An optimization procedure for automated design of seismic-resistant steel frames. Int J Civil Eng 4:86–105

Jingui L, Yunliang D, Bin W, Shide X (1996) An improved strategy for GAs in structural optimization. Comput Struct 61(6):1185–1191

Yang J, Soh CK (1997) Structural optimization by genetic algorithms with tournament selection. J Comput Civil Eng 11(3):195–200

Kameshki ES, Saka MP (2001) Optimum design of nonlinear steel frames with semi-rigid connections using genetic algorithms. Comput Struct 79(17):95–105

Pezeshk S, Camp CV, Chen D (2000) Design of nonlinear framed structures using genetic optimization. J Struct Eng 126(3):382–388

Papadrakakis M, Lagaros ND, Plevris V (2001) Optimum design of space frames under seismic loading. Int J Struct Stab Dyn 1(01):105–123

Kameshki ES, Saka MP (2000) A genetic algorithm based optimum bracing design of non-sway tall steel frames. In: International conference on engineering computational technology, pp 111–119

De Castro LCLB, Partridge PW (2006) Minimum weight design of framed structures using a genetic algorithm considering dynamic analysis. Lat Am J Solids Struct 3(2):107–123

Salajegheh E, Gholizadeh S, Khatibinia M (2008) Optimal design of structures for earthquake loads by a hybrid RBF-BPSO method. Earthq Eng Eng Vib 7(1):13–24

Gholizadeh S, Salajegheh E (2009) Optimal design of structures subjected to time history loading by swarm intelligence and an advanced meta model. Comput Methods Appl Mech Eng 198(37):2936–2949

Gero MBP, García AB, del Coz Díaz JJ (2006) Design optimization of 3D steel structures: genetic algorithms vs. classical techniques. J Constr Steel Res 62(12):1303–1309

Keii M, Ikago K (2008) A trial design of steel frame office building based on an optimum design method. In: The 14th world conference on earthquake engineering, 12–17 October, Beijing, China

Chen Y, Hu K (2008) Optimal design of steel portal frames based on genetic algorithms. Front Archit Civ Eng China 2(4):318–322

Kripakaran P, Hall B, Gupta A (2011) A genetic algorithm for design of moment-resisting steel frames. Struct Multidisc Optim 44(4):559–574

Balogh T, Vigh LG (2012) Genetic algorithm based optimization of regular steel building structures subjected to seismic effects. In: Proceedings 15th world conference on earthquake engineering, pp 1–10

INBCSS “Iranian National Building Code for Steel Structures” (2009) Part 10. Ministry of Housing and Urban Development, Tehran, Iran

No S (2005) 2800-05 Iranian code of practice for seismic resistant design of buildings. Third Revision, Building and Housing Research Center, Tehran, Iran

Foley CM, Pezeshk S, Alimoradi A (2007) Probabilistic performance-based optimal design of steel moment frames I: formulation. J Struct Eng 133(6):757–766

Liu M, Burns SA, Wen YK (2005) Multiobjective optimization for performance—based design of steel moment frame structures. Earthq Eng Struct Dyn 34(3):289–306

Kaveh A, Kalateh-Ahani M, Fahimi-Farzam M (2014) Life-cycle cost optimization of steel moment-frame structures: performance-based seismic design approach. Earthq Struct 7(3):271–294

Stylianou MC (2011) S-FRAME R10. SOFTEK Services Ltd, Canada

Computer and Structures, Inc, (2011) Computers and Structures, Inc. official website. Official website summary. Computers and Structures, Inc. Retrieved December 4, 2011

Chen WF, Lui EM (1991) Stability design of steel frames. CRC Press, Boca Raton

Chopra AK (2001) Dynamics of structures: theory and applications to earthquake engineering, 2nd edn. Prentice Hall, Englewood Cliffs

Arora JS (2004) Introduction to optimum design, 2nd edn. Elsevier, San Diego

MATLAB and Optimization Toolbox Release (2012) The MathWorks, Inc., Natick

De Boor C (2001) A practical guide to splines, vol 27. Springer, New York, p 325

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akbari, J., Ayubirad, M.S. Seismic Optimum Design of Steel Structures Using Gradient-Based and Genetic Algorithm Methods. Int J Civ Eng 15, 135–148 (2017). https://doi.org/10.1007/s40999-016-0088-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-016-0088-0