Abstract

The present study illustrates cadmium chloride (CdCl2)-doped hydroxypropyl methylcellulose (HPMC) polymer electrolyte films. Solution cast method is employed to prepare polymer electrolyte samples of HPMC complexed with various concentrations of CdCl2 (1–4 %, wt.%). Structural and thermal studies of these polymer samples were investigated using X-ray diffraction (XRD) and differential scanning calorimetry (DSC). XRD results showed that the amorphous domains of HPMC polymer matrix were increased with increase in CdCl2 salt concentration. DSC results revealed that the presence of CdCl2 in the polymer matrix increases the melting temperature; however, it is observed that the heat of fusion (ΔH f ) is high for pure HPMC films. The variation in the film morphology was examined by scanning electron microscopy (SEM). Direct current (dc) conductivity was measured in the temperature range 313–383 K. The magnitude of electrical conductivity was found to be increased with increasing salt concentration and temperature. The activation energy region data (region I and region II) indicated the dominance of ion-type charge transport in these polymer electrolyte films. HPMC polymer electrolytes with 4 % CdCl2 salt concentration exhibit the least crystallinity and the highest conductivity 1.01 × 10−6 Scm−1 at 313 K.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The inevitable studies of Wright and Armand on ion-conducting polymers, called “polymer electrolytes” in the late 1970s have opened an innovative area of materials research with potential applications. They have many advantages such as flexibility, ease of processing into thin films of large surface area, and their potential applications in solid state electrochemical devices [1–4]. Due to the unique electrical, electronic, and optical properties of these conducting polymer materials, several potential, technological, and commercial applications such as fabrication of batteries, electronic devices, displays, sensors, functional electrodes etc. have been reported [5]. Various research groups have studied the effect of inorganic dopants on the polymer hosts. The formation of a complex between the polymer and the dopant results in considerable increase in electron mobility, resulting in enhanced electrical conductivity. Electrical conductivities can be varied to several orders of magnitude by changing dopant concentrations so that electronic property control is feasible over the entire range from insulator to semi-conductor and then to metal. Though the widely studied polymer continues to be poly-ethylene-oxide (PEO) and its modifications, however, there will be a liquid-solid coexistence regime in the phase diagram of many PEO-metal salt complexed systems above ambient temperature [6]. To overcome this drawback, several novel polymers like poly(propylene oxide) (PPO), poly(methylmethacrylate) (PMMA), and poly(vinyl alcohol) (PVA) were utilized for the purpose of designing polymer electrolyte systems [7].

Many research articles are available which incorporate cadmium ion in its polymeric system for its application as polymer electrolyte materials. There also exists some cadmium ion-conducting polymer electrolytes based on poly-ethylene-oxide (PEO) (S Kilarkaje et al.) [8, 9] and polyvinyl alcohol (PVA) (M.B Nanda Prakash et al.) [10]. In the present study, hydroxypropyl methylcellulose (HPMC) polymer electrolytes were prepared by incorporating CdCl2 as the doping salt. HPMC polymer has been chosen because of its appealing properties. HPMC is well known and of major interest to be used as environmentally friendly products. It is proved to be more thermally stable than those derived from cellulose such as carboxymethylcellulose (CMC), hydroxyethylcellulose (HEC), and methylcellulose (MC) [11]. HPMC is a biopolymer, eco-friendly and water soluble [12–14]. It has ability to dissolve high concentrations of a wide variety of metal salts and an excellent film-forming capacity. It has semi-crystalline nature which occurred in two phases (amorphous and crystalline). Amorphous phase enhances higher ionic conduction in the system meanwhile crystalline phase provides strong mechanical support to the polymer electrolytes. Its charge storage capacity can be influenced by the addition of inorganic salt-like CdCl2, to provide good amorphous and compatible nature.

Cadmium chloride is a compound of cadmium and chlorine having rhombohedral symmetry. It is a hygroscopic solid and highly soluble in water. Cadmium is resistant to corrosion, and as a result, it is used as a protective layer when deposited on other metals. It is also used for photocopying, dyeing, and electroplating. It is a fast ion-conducting salt and very malleable in a number of crystalline and amorphous materials. Its incorporation in a polymeric system may be expected to allow the more free charges, and these free charges contribute to development of the charge transportation mechanism and inter-intra electronic transition [8, 15, 16]. In particular, the investigation on the structural, thermal, and conductivity properties of well-defined clusters of CdCl2-doped HPMC has attracted considerable attention. Keeping these aspects in view, this study has been undertaken and efforts have been made to form stable polymer electrolyte complexes. Several experimental techniques like X-ray diffraction (XRD), SEM, differential scanning calorimetry (DSC), and direct current (dc) electrical conductivity were carried out to characterize these polymer electrolyte films.

Experimental

Materials used and preparation of polymer electrolyte films

Pure HPMC and various compositions of complexed films of HPMC with CdCl2 salt were prepared by solution cast method using double distilled water as solvent. Hydroxypropyl methylcellulose (HPMC E15LV), which contained methoxy group (23.8 %) and hydroxypropoxy group (8.3 %), was purchased from Loba Chemicals India. Cadmium chloride (CdCl2) was purchased from S. D. Fine Chemicals India. To prepare the polymer electrolyte films, HPMC polymer was blended with inorganic salt of CdCl2. Here, 5 g of HPMC is dissolved in 100 ml double distilled water. The mixture is homogenized by stirring for 8 h. The completely soluble homogeneous solution was filtered through Whatman No 41 filter paper and degassed. To this clear solution, the desired amounts of CdCl2 (1–4 %) (wt.%) was added and stirred continuously for 2 h. Then, the clear solution of HPMC with various concentrations of CdCl2 was poured on to a clean and leveled glass plates (30 cm × 40 cm) to evaporate at room temperature for 5 days and peeled off from the glass plate. The final films were vacuum dried thoroughly and stored in desiccators to avoid the absorption of moisture.

CdCl2 is hygroscopic in nature, and the higher concentration of CdCl2 has got the tendency to absorb more moisture. However, HPMC:CdCl2 (5:5) polymer films were also prepared, and it was found that with increasing concentration of CdCl2, the films obtained are not stable and are not with uniform thickness. Hence, the optimal doping with CdCl2 is carried out only up to 4 %, and polymer electrolyte films of HPMC:CdCl2 (5:1, 5:2, 5:3, and 5:4) with thickness of 0.2–0.6 mm were prepared.

Instrumentation

The XRD studies of the films were made with an X-ray source with CuKα radiation of wavelength 1.5406 Å. The surface morphology of these polymer films were observed using JEOL 840, resolution at 20 Kv, 10-nm scanning electron microscope (SEM). The samples were gold coated using the sputter coater at 10 mA current under 10−2 torr vacuum for 3 min before imaging. The differential scanning calorimetry (DSC) measurements have been taken in the temperature range of 30–200 °C with the help of differential scanning calorimeter model: METTLER-TOLEDO DSC1 thermal analysis system at a heating rate of 10 °C per minute. The temperature-dependent dc conductivity of the reported polymer electrolyte samples was measured in the temperature range of 313–383 K using Keithley Programmable Electrometer (Model 617). The disk sample (13 mm in diameter) was sandwiched between the finely polished stainless steel electrodes. Silver paste is deposited on both sides of the sample for good electrical contact. The bulk resistance is determined from the intersection of the high-frequency semi-circle with the real axis in the complex impedance plots. The electrical conductivity σ is calculated using the formula

where t is the thickness of the sample in mm, R b is the resistance in MΩ and A is the area of the sample in mm2.

Results and discussion

X-ray diffraction studies

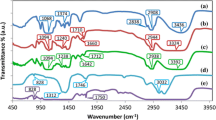

X-ray diffraction is the most employed structural characterization technique, because it informs on formation of intermediate compounds and extended solid solubility between the components and also, more or less reliably, on the mean grain sizes of the two phases. Figure 1 presents the XRD analysis for pure and CdCl2 complexes of HPMC polymer electrolyte films. It was found that pure HPMC shows a broad peak at 2θ = 21.26° (d spacing = 4.175 Å) corresponding to its semi-crystalline nature of the polymer [17]. This diffraction peak is shifted to 20.96° (d spacing = 4.234 Å) in HPMC:CdCl2 complexes of 5:1 system and almost at 19.93° (d spacing = 4.44 Å) and 18.24° (d spacing = 4.91 Å) in 5:2 and 5:3 systems of polymer electrolytes. Whereas for 5:4 system, this diffraction peak almost disappears. There is a nucleation of crystalline order which gives an additional Bragg-like reflection almost at 2θ = 27.83° (d spacing = 3.20 Å) for pure HPMC and is shifted to around 28°–30° in all other complexed systems with broad peaks and with decreasing intensity. The mentioned peaks are less intense and are almost found to be disappearing in the polymer electrolyte systems at higher concentrations of CdCl2 indicating that the addition of the salt causes a decrease in the degree of crystallinity and a simultaneous increase in the amorphicity of the HPMC complexes. Absence of peaks corresponding to the CdCl2 salt in these complexes indicates that the inorganic salt is thoroughly mixed with the host polymer matrices. No sharp peaks were observed for the higher concentration of the salt in the polymer suggesting the dominant presence of amorphous phase [18]. Therefore, it may be confirmed that the complexation has been taken place in the amorphous phase. This amorphous nature results in greater ionic diffusivity with high conductivity for polymer electrolyte systems [19, 20]. From Table 1, it is clear that percentage of crystallinity decreases with the addition of CdCl2 salt and values are in good agreement with the interpreted results from XRD patterns. The percentage of the degree of crystallinity (X c ) was determined from the ratios of the area under the crystalline peak and the respective halos using the method [21, 22].

where A c and A a are the area of crystalline and amorphous (halo) regions, respectively.

Morphological studies

Scanning electron microscopy is often used to study the compatibility between the various components of the polymer electrolytes through the detection of phase separation and interfaces [23, 24]. The compatibility of the polymer matrix and the inorganic dopants has great influence on the properties like mechanical, thermal, and ionic conductivity of the polymer electrolyte systems. The SEM of the pure HPMC and HPMC:CdCl2 complexes of 5:1 and 5:4 polymer electrolytes are shown in Fig. 2. All films had a uniform and homogenous type surface but with different degrees of roughness. SEM of pure HPMC films exhibits no features attributable to any crystalline morphology, so the semi-crystallinity of HPMC is likely to be submicroscopic in nature. The increase in the degree of roughness and dense structure with the increasing concentration of the salt indicates the segregation of the dopant in that host polymer matrix. The two-phase microstructure in the SEM image reflects the phase separation at different concentration (5:1, 5:4) of CdCl2 salt. Therefore, morphological studies clearly indicate the phase segregation phenomenon in these complexed polymer electrolyte systems.

DSC studies

The DSC thermograms for pure HPMC and HPMC:CdCl2, (5:1) and (5:4), are shown in Fig. 3. Pure HPMC shows broad endothermic transition starting from 50 to 91 °C with a broad peak value at 72.16 °C [22]. This shifts to 83 and 103 °C in the HPMC:CdCl2 (5:1, 5:4) systems indicating the presence of CdCl2 in the polymer matrix increases the melting temperature and thermally more stable. Both pure and HPMC:CdCl2 systems show only one endothermic broad peak. This peak shifts towards to higher temperature as the salt concentration increases. The enthalpy was calculated from the heat flow integral. Table 2 shows the enthalpy of fusion (ΔH f ) which is given by the area under the melting endotherm decreases for all HPMC:CdCl2 complexes. Here, the enthalpy of fusion is normalized to the weight of HPMC in the complexes. The relative percentage of crystallinity reduces in all HPMC:CdCl2 polymer films. From Table 1, it is clear that the percentage of crystallinity reduces in all polymer electrolyte complexes when compared with the pure HPMC polymer films. However, the crystallinity reduces to a minimum of 19 % for the HPMC:CdCl2 complex of 5:4 ratio compared with the 65 % crystallinity for the polymer host.

Electrical conductivity studies

The variation of conductivity as a function of temperature for pure HPMC and various concentrations of CdCl2 (1, 2, 3, and 4 wt %)-doped polymer electrolyte films in the temperature range of 313–383 K are as shown in Figs. 4 and 5. The temperature dependence of electrical conductivity (σ) follows Arrhenius eq.

where σ 0 is the pre-exponential factor, E a is the activation energy, k is the Boltzmann constant, and T is absolute temperature. From plots of Fig. 4, it is clear that the conductivity is found to increase with increase in temperature for pure HPMC as well as in all the compositions of HPMC:CdCl2 polymer electrolyte films. The conductivity versus temperature plots follow Arrhenius behavior; similar behavior was observed in number of other polymer electrolyte systems [8, 25–29]. From Table 3, the conductivity of pure HPMC is about 6.530 × 10−9 Scm−1 at temperature 313 K, which shows the polymer is almost non-conducting which may be because at sub-ambient temperature HPMC shows a higher crystalline ratios which decreases the ionic conductivity. However for pure HPMC and HPMC:CdCl2 complexed films, increase in temperature leads to the increase in ionic conductivity, because as the temperature increases, the polymer chain flex at increased rate to produce more free volume resulting in enhanced polymer segmental mobility. This dependence of the dc conductivity at various CdCl2 concentrations from Fig. 5 can be explained as follows. At the beginning, increasing the CdCl2 concentration would result in an increase in the number of charge carriers created. This increasing number of carriers will continue to take place as the salt concentration increases until we approach a situation at which most of the possible charge carriers are already created. After this threshold concentration limit, we might expect no more increase in the dc conductivity, and a saturation limit might be achieved. The increase in conductivity with increase in temperature may be attributed to the transitions from crystalline to semi-crystalline phase and then to amorphous phase and is interpreted as hopping mechanism between local coordinate sites, local structural relaxation, and segmental motion of the polymer [30]. This decrease in the degree of crystallinity and increase in the amorphousity was confirmed with XRD studies. The properties of the amorphous phase obviously play a major role in determining the overall response of the material. As the amorphous region increases progressively, however, the polymer chain acquires faster internal modes in which bond rotations produce segmental motion; this in turn favors the hopping interchain and intrachain ion movements; hence, the conductivity of the polymer electrolytes becomes high. The activation energy E a is a combination of defect formation and defect migration, which can be calculated from the slope of log σ versus 1000/T plots from Fig. 5 using expression

where E a is the activation energy (eV) and k is the Boltzmann constant.

Values of temperature-dependent ionic conductivity and activation energy for pure HPMC as well as CdCl2 complexes of HPMC polymer electrolyte films are listed in Table 3. The activation energies in the two regions (region I and region II) show a decreasing trend as the dopant concentration increases which may be explained in terms of formation of charge transfer complexes. However, for the electrical conductivity at different concentrations of CdCl2-doped HPMC in regions I and II, cadmium ions are coordinated through ionic bonds with the hydroxyl group belonging to the different chains in HPMC. This, in turn, reduces the intermolecular interaction between chains and expands the space between them. In other words, the addition of cadmium increases the volume required for ionic carriers drift in the polymer. This leads to an increase in the ionic mobility and a reduction in the activation energy. This is in complete accordance with the observed results from the graph; also, this is in good agreement with the earlier reported results [8, 9] and indicates the low activation energy for CdCl2 ion transport is due to dominant presence of amorphous nature of polymer electrolyte that facilitates the fast Cd2+ ion motion in polymer network. The amorphous nature also provides a bigger free volume in polymer electrolyte system with the increase in temperature [31]. It is observed that HPMC:CdCl2 (5:4) system has the highest conductivity and low activation energy region when compared with pure and other complexes of HPMC.

Conclusion

The complexation of the salt with the host polymer is confirmed by XRD studies. XRD studies show the decrease in the degree of crystallinity and the simultaneous increase in amorphousity of the HPMC:CdCl2 polymer electrolyte films, as the salt concentration increases. SEM analysis of pure and CdCl2 complexed polymer electrolyte films is of uniform type but with different degrees of roughness and exhibits no features attributable to any crystalline morphology. DSC results revealed that the presence of CdCl2 in the polymer matrix increases the melting temperature of the polymer electrolyte films. It is observed that the heat of fusion (ΔH f ) is high for pure HPMC films. The observed dc conductivity increases with the increasing temperature and the salt concentration. This increase in the ionic conductivity is attributed to the decrease in the degree of crystallinity and the simultaneous increase in amorphousity, also the hopping mechanism of ion movement as ions primarily transport in amorphous phase. The activation energy values obtained from conductivity data for both the regions (region I and region II) decrease as the ionic conductivity increases, which confirms that the conduction in these polymer electrolytes is predominantly ionic. Therefore, this material establishes a new polymer electrolyte system. The HPMC:CdCl2 (5:4) system increases the amorphous phase and enhances the ionic conductivity. Thus, the polymer electrolyte systems HPMC:CdCl2 with an enhanced amorphous phase and conductivity requires further investigation for electrochemical cell device applications.

References

Armand MB (1993) J Solid State Ionics 9/10:745

Papke BL, Ratner MA, Shriver DF (1992) J Electrochem Soc 129:1694

Berthier C, Gorecki W, Miner M, Amand MB, Chabagno JM, Riguad P (1983) J Solid State Ionics 11:91

Armand MB (1986) Annu Rev Mater Sci 16:245–261

Chaubey A, Gerard M, Singhal R, Singh VS, Malhotra BD (2000) J Electrochim Acta 46:723

Lascaud S, Perrier M, Vallee A, Besner S, Prud home J, Armand M (1994) J Macromol 27:7469

Balaki Bhargav P, Madhu Mohan V, Sharma AK, Rao VVRN (2007) J Ionics 13(3):173–178

Subramanya Kilarkaje V, Manjunatha S, Raghu MVN, Prasad A, Devendrappa H (2011) J Phys D: Appl Phys 44:105403

Subramanya K, Raghu S, Devendrappa H (2012) AIP Conf Proc Vol., 1447 , 965

Nanda Prakash MB, Manjunath A, Somashekar R (2013) J Adv Condens Matter Phys 35:1–6

Rotta J, Minatti E, Barret PLM (2011) J Cienc Tecnol Aliment Campinas 31(2):450–455

Honary S, Ebrahimi P, Emrani N (2010) J Pharma Bio Sci V1(2):1–8

Hardy IJ, Cook WG, Melia CD (2006) J Pharma Bio Sci 311(1–2):26–32

Bruce PG, Vincent CA (1993) J Chem Soc Faraday Trans 89:3187–3203

Colin, Durizot E (1994) J Mater Sci 9:8

Liu B, Xu GQ, Gan LM, Chew CH, Li WS, Shen ZX (2001) J Appl Phys 89:1059

Yukoh S, Sumihiro S, Makoto O (2006) Int J Pharm 317(2):120–126

Madhu Mohan V, Raja V, Sharma AK, Narasimha Rao VVRN (2004) J Mater Chem Phys 94:177

Bhargav PB, Mohan VM, Sharma AK, Rao VVRN (2009) J Curr Appl Phys 9:165–171

Malathi J, Kumaravadivel M, Brahmanandhan GM, Hema M, Baskaran R, Selvasekarapandian S (2010) J Non-Cryst Solids 356:2277–2281

Hermans PH, Weidinger A (1961) J Macromol Chem 24:44

Sangappa D et al (2008) J Nucl Inst Methods Phys Res 266:3975–3980

Zhang S, Lee JY, Hong L (2004) J Power Sources 126(1–2):125–133

Chu PP, Reddy MJ (2003) J Power Sources 115:288

Karmakar A, Ghosh A (2011) J Nanoparticle Res 13:2989–2996

Subba R, Sharma AK, Narasimha Rao VVR (2006) J Polym Sci 47:1318

HiranKumar G, Selvasekarapandian S, Kuwata N, Kawamura J, Hattori T (2005) J Power Sources 144:262

Chakraborty G et al (2011) J Solid State Commun 151:754–758

Janaki Rami Reddy T, Achari VBS, Sharma AK, Rao VVRN (2007) J Ionics 13:435–439

Omed Gh A, Tahir DA, Ahmad SS, Ahmad HT (2013) IOSR-JAP 4:52–57

Devendrappa H, Subba Rao UV, Ambika Prasad MVN (2006) J Power Sources 155(2):368

Acknowledgments

Authors acknowledge all the support and the useful discussion by Professor Srikantaiah, retired Scientist, BARC, Mumbai. Thanks to the technical staff at SID and Material Science Department, IISc, Bangalore for DSC and SEM analysis. We thank Grian Technologies Pvt. Limited, Bangalore for their support in electrical conductivity studies. A special thanks to Dr Shibu M Eappen, Scientist in charge, SAIF Cochin University of Science and Technology, Cochin, for XRD measurements.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Rani, N.S., Sannappa, J., Demappa, T. et al. Effects of CdCl2 concentration on the structural, thermal and ionic conductivity properties of HPMC polymer electrolyte films. Ionics 21, 133–140 (2015). https://doi.org/10.1007/s11581-014-1151-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-014-1151-y