Abstract

A simple, yet effective and rapid approach for the synthesis of titanium dioxide nanoparticles (TiO2 NPs) using Streptomyces sp. HC1 was developed. The in vitro activity of TiO2 NPs was demonstrated against human pathogenic bacteria and fungi. The synthesized nanoparticles were characterized using various methods and instruments, such as Zetasizer, X-ray diffraction, Fourier transmission infrared spectroscopy, atomic force microscopy, and scanning electron microscopy. TiO2 NPs were observed to be spherical in shape with size in the range of 30 to 70 nm. Antimicrobial activities of TiO2 NPs against Staphylococcus aureus ATCC 29213, Escherichia coli ATCC 35218, Candida albicans, ATCC 10231, and Aspergillus niger ATCC 6275 were evaluated. It was observed that TiO2 NPs showed higher antimicrobial activity against bacteria (12 mm) than against fungi. Moreover, TiO2 NPs also showed potent antibiofilm activity against Pseudomonas aeruginosa ATCC 27853. Hence, the present study highlights the biological synthesis and characterization of TiO2 NPs, and their applications in the field of biomedical sciences.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nano sciences and nanotechnology have opened several new avenues for research and have led to the development of novel, useful, and sometimes unexpected applications [1]. With the development of nanotechnology, there has been an important growth in the application of nanoparticles for drug delivery systems, antimicrobial materials, cosmetics, sunscreens, electronics, and personal care products [2,3,4,5]. Generally, metallic NPs can be prepared and stabilized using chemical, physical, and biological methods. Chemical approaches, such as chemical reduction, electrochemical techniques, photochemical reduction, and pyrolysis, and physical methods, such as Arc discharge and physical vapor condensation are commonly used. Microorganisms have very big potential for the production of nanoparticles/nanodevices of wide applications [6,7,8]. In modern nanoscience and nanotechnology, the interaction between inorganic NPs and biological structures is one of the most rousing areas of research [9]. Overall, biological materials provide an environment friendly or greener chemical method to produce invaluable materials because biomaterial based synthesis eliminates the need for harsh or toxic chemicals [10]. Among all NPs, TiO2 NPs are one of the most widely manufactured and used in the world [11]. They are used as additives in sunscreen products, paints, printing ink, rubber, paper, sugar, cement, toothpaste, film, biomedical ceramic, implant biomaterials, antimicrobial plastic packaging, and self-cleaning sanitary ceramics [12,13,14]. Methods for biological synthesis of TiO2 NPs using bacteria, yeast, fungi, and plant extracts have been recently reported [15,16,17,18].

2 Materials and Methods

In the present study, a Streptomyces sp. HC1 was used for the production of TiO2 NPs. Different parameters for the synthesis of TiO2 NPs including TiO(OH)2 concentration, time, temperature, and pH were optimized. The antimicrobial activity of biologically synthesized TiO2 NPs was evaluated using the disc diffusion method and the effect of these nanoparticles on biofilm formation was evaluated using 96-well polystyrene flat-bottom plates.

2.1 Bacterial Strains and Media

Microorganisms were isolated from soil samples and 1 gr of soil was suspended in 50 mL serum physiology. For the isolation of bacteria, flasks containing soil suspensions were incubated at 37 °C and 150 rpm overnight. Next, 0.1 mL suspension was transferred to a sterile nutrient broth and the flask was incubated at 37 °C and 150 rpm for 24 h. Next, a loop full of the suspension was transferred onto sterile NA medium and incubated after the incubation bacterial single colonies were obtained.

2.2 Biosynthesis of TiO2 NPs

In order to produce TiO2 NPs, a loop full of each bacterial single colony was cultured in 50 mL sterile nutrient broth and the flask was incubated in a shaker condition at 37 °C and 150 rpm for 24 h. After the required turbidity was achieved, the bacterial cultures were used for TiO2 NP production. For this, 20 mL TiO(OH)2 solution (0.025 M) was added to bacterial cultures in flasks and the flasks were incubated in a steam bath at 60 °C for 30 min. The negative control flasks contained either sterile nutrient broth medium or sterile nutrient broth medium with TiO(OH)2 solution. After incubation, the culture solution was observed to have distinctly markable coalescent white clusters deposited at the bottom of the flask. The precipitate was obtained by centrifugation, and washed with distilled water to maintain neutral pH.

2.3 Identification of Bacteria

DNA extraction was performed using the boiling method. For this, a loop full of each bacterial single colony was cultured in a flask containing 100 mL sterile nutrient broth medium and the flask was incubated in a shaker incubator at 37 °C and 150 rpm for 24 h. All samples were centrifuged at 14,000×g for 1 min. Next, the pellet was washed three times with molecular biology grade water and centrifuged again (14,000×g for 1 min). The pellet was resuspended in 100 µL molecular biology grade water and transferred to a water bath maintained at 100 °C for 5 min. The suspensions were centrifuged and DNA concentration of all samples was determined using a spectrophotometer (Nanodrop) at 260 nm. Primers used for the partial amplification of bacterial 16S rDNA using quantitative polymerase chain reaction (qPCR) were as follows: AGAGTTTGATCCTGGCTCAG, forward primer; AAGGAGGTGATCCAGCCGCA, reverse primer. The CFX Connect Real-Time PCR Detection System (Bio-Rad Laboratories, USA) was used. qPCR reactions were performed as described previously by Dorak. Finally, for PCR product purification, the Biospeedy™ PCR Purification kit was used. Samples for PCR product sequencing were prepared using the ABI prism BigDye Terminator Cycle Sequencing Ready Reaction kit. Finally, data obtained after sequencing were subjected to BLASTn analysis available at National Centre for Biotechnology Information (NCBI; https://blast.ncbi.nlm.nih.gov/Blast.cgi).

2.4 Optimization of Bacterial Culture Conditions and TiO2 NP Synthesis

Among various bacterial strains, a Streptomyces sp. HC1 was allowed to interact with titanium oxide dihydroxide to form coalescent white clustered precipitates. In order to achieve high efficiency, the production conditions of Streptomyces sp. HC1 were optimized. For this, the optimum temperature, pH, and incubation time were investigated. Absorbance was measured using the Shimadzu spectrophotometer at 420 nm. After optimizing the production conditions, different titanium oxide dihydroxide concentrations and pH conditions were evaluated for optimizing the reaction conditions. The measurements were performed using a Zetasizer. After optimization, the product was collected and calcined in order to get TiO2 NP. Yield of the biosynthesized TiO2 NP was directly proportional to the mass of the precipitate after calcination.

2.5 Purification of TiO2 NPs

In order to use the synthesized TiO2 NPs for in vitro studies, they were washed to remove excess TiO(OH)2, enzymes, and other impurities from the bacterial culture supernatants. For this, 30 mL TiO2 NP containing supernatant was centrifuged at 10,000×g for 10 min. The pellet was calcined for the removal of biomass and organic contents to get TiO2 NPs.

2.6 Characterization of TiO2 NPs

TiO2 NPs were characterized using: SEM, FTIR, XRD, and AFM. The dried powder containing TiO2 NPs was further subjected to Fourier transform infrared (FTIR) spectroscopic analysis to determine the components for stabilization of nanoparticles. Briefly, 2 mg sample was taken and pressed to form a thin pellet on a cover slip. The sample was placed on to the sample holder and FTIR spectra were analyzed. The synthesized nanoparticles were freeze-dried, powdered, and subjected to X-ray diffraction (XRD) analysis. The diffraction intensities were recorded from 2θ angles of 0° to 80°. Samples were further characterized using atomic force microscopy (AFM) for analyzing their roughness, particle size, agglomeration, and shape. TiO2 NPs were further analyzed using a scanning electron microscope (SEM), for determining their size, shape, and surface morphology. For AFM and SEM analyses, samples were prepared by sonicating the liquid samples for 5 min to produce a thin film of the pellet on a cover slip.

2.7 Bioactivities

2.7.1 Antimicrobial Activities

Antibacterial activity of TiO2 NPs was evaluated against human pathogenic bacteria (gram-positive, Staphylococcus aureus ATCC 29213; gram-negative, E. coli ATCC 35218), yeast (Candida albicans ATCC 10231), and fungus (Aspergillus niger ATCC 6275) using the agar well diffusion method. Cultures were maintained at − 80 °C as glycerol stocks until further use. The bacterial and fungal cultures were inoculated NB and SDB, respectively. The cultures were incubated under suitable conditions. Bacterial strains were swapped uniformly onto Mueller Hinton agar (MHA), while fungal strains were swapped uniformly onto sabouraud dextrose agar using sterile cotton swabs. TiO2 NPs were loaded into wells in agar plates. Diameter of the zone of inhibition observed around the well after incubation was noted (Table 1).

2.7.2 Antibiofilm Activities

Pseudomonas aeruginosa ATCC 27853 was used for determination of antibiofilm activities of TiO2 NPs. Bacterial cells corresponding to the McFarland optical density standard of 2.0 were inoculated into the Brain Heart Infusion (BHI) broth and incubated at 37 °C for 24 h. After incubation, the culture was diluted (1:100) using fresh BHI medium and added to the wells of a polystyrene plate containing different concentrations of nanoparticles. Next, the plates were incubated for 24 h at 37 °C. Following this, the wells were gently washed, and stained using 1% crystal violet for 45 min at standard room temperature. After washing the wells again, the bound crystal violet in each well was solubilized by adding ethanol (96.6%). In each well, the absorbance due to solubilized crystal violet was measured using a spectrophotometer at 540 nm. Effect of the TiO2 NPs nanoparticles on biofilm is evaluated in this way.

3 Results

3.1 Isolation of Microbial Strains

Among all microorganisms isolated from soil samples, organisms with the ability to synthesize TiO2 NPs were identified on the basis of 16S rRNA sequencing results provided by Bioeksen AR-GE Technologies Company.

BLAST analysis revealed that this sequence was almost identical (99%) to that found in Streptomyces sp. strain HC1 (Accession Numbers: MG786558).

3.2 Biosynthesis of Titanium Dioxide Nanoparticles

Microorganisms for TiO2 NP synthesis were grown on nutrient broth medium. After the required turbidity was achieved, the bacterial cultures were used for TiO2 NP production. For this, 20 mL TiO(OH)2 solution (0.025 M) was added to bacterial cultures and incubated in a steam bath at 60 °C for 30 min. The negative control flasks contained either sterile nutrient broth with TiO(OH)2 solution. After incubation, the culture solution was observed to have distinctly markable coalescent white. Clusters deposited at the bottom of the flask (Fig. 1). The precipitate obtained was centrifuged, and subsequently washed with distilled water to maintain neutral pH.

3.3 Optimization of Bacterial Culture Conditions and Titanium Dioxide Nanoparticles Synthesis

3.3.1 Optimization of Bacterial Strain Production

For highly efficient NP production, the culture conditions for microbial growth were optimized. For this, optimum temperature, pH, and production time were evaluated. During the evaluation stage, reproducibility was measured by spectrophotometer at 420 nm, with the optimum wavelength of the microorganism. Yield of TiO2 NPs synthesized at different temperatures (25, 30, 37, and 40 °C), time durations (24, 48, 72, and 96 h), and pH (5, 6, 7, 8, and 9) are shown in Fig. 2a–c, respectively. Maximum bacterial growth was observed at pH 9 and 25 °C temperature after 72 h cultivation.

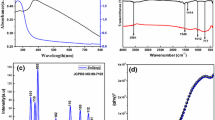

3.3.2 Optimization of Titanium Dioxide Nanoparticle Synthesis

Various concentrations of TiO(OH)2 solution (30:4, 30:6, 30:10, 30:15) and various pH (5, 5.5, 6, 6.5, and 7) conditions were evaluated for the optimization of reaction conditions as shown in Figs. 3 and 4. All measurements were performed using a Zetasizer. TiO(OH)2 solution added to the microbial cultures was analyzed in a Zetasizer as a background (Fig. 5).

Figure 4 clearly indicates that the maximum yield of titanium dioxide nanoparticles was obtained at 30:15 concentration of TiO(OH)2. It has been reported that the effect of TiO(OH)2 concentration on the size distribution of nanoparticles produced using Streptomyces sp. HC1 was negligible. Figure 5 shows that maximum production of nanoparticles was achieved at pH 6.5. It was observed that the amount of titanium dioxide nanoparticles produced increased as the concentration of TiO(OH)2 increased till 30:15 at 6.5 pH; however, after this, despite increasing the concentration of TiO(OH)2, the rate of production of NPs gradually declined.

3.4 Characterization of Titanium Dioxide Nanoparticles

The surface morphology of NPs was examined using an ultra-high resolution field emission scanning electron microscope (SEM) (Quanta 400F Field Emission). The crystal structure of TiO2 NPs was analyzed using X-ray diffraction (XRD) (Rigaku Ultima-IV). To confirm the functional biomolecules associated with TiO2 NPs, FTIR analysis was performed (Nıcolet 6700 FT-IR; Thermo Scientific). Moreover, confirmation of the particle size and morphology of TiO2 NPs was also performed using atomic force microscopy (AFM) (Veeco MultiMode V). The average particle size and particle size distribution were measured using the Zeta-3000HS Zetasizer (Malvern).

3.4.1 SEM Analysis of Titanium Dioxide Nanoparticles

The structural morphology of TiO2 NPs was investigated using SEM, as shown in Fig. 6. SEM analysis showed that particles were spherical in shape and ranged from 43 to 67 nm in size. Agglomeration was observed, with the average size less than 260 nm, which was also supported by the XRD data.

3.4.2 XRD Spectrum of Titanium Dioxide Nanoparticles

XRD analysis is used to determine phase distribution, crystallinity, and purity of the synthesized nanoparticles. XRD spectra (Fig. 7) showed strong diffraction peaks at 2θ values of 25°, 37°, 48°, and 55°, which corresponded to the crystal planes 101, 004, 200, and 211. The diffraction pattern showed that nanoparticles synthesized by bacteria were from the anatase crystalline phase [19]. We concluded that the nanoparticles were crystalline in nature, cubic in shape, and without considerable impurities.

3.4.3 AFM Analysis of Titanium Dioxide Nanoparticles

Confirmation of the particle size and morphology of TiO2 NPs was performed using AFM and the results are shown in Fig. 8. Particle size distribution of TiO2 NPs was observed to be in the range of 32 to 40 nm. Considerably homogenous grooves were observed in the three-dimensional image [20].

3.4.4 FTIR Spectrum of Titanium Dioxide Nanoparticles

FTIR analysis was performed to analyze the peaks indicating TiO2 NPs. Since the FTIR analysis was performed after calcination, most peaks corresponding to organic functional groups were not observed in the spectrum. The peaks corresponding to Ti–O–Ti (1138–1050 cm−1) (Fig. 9) bonding showed high intensity since the analysis was carried out after calcination [21].

3.5 Bioactivities

3.5.1 Antimicrobial Activities

The disk diffusion method was performed using E. coli, S. aureus, C. albicans, and A. niger. The synthesized TiO2 NPs displayed antibacterial activities against pathogenic strains, as shown in Table 1 and Fig. 10. The maximum zone of inhibition was observed for the TiO2 NPs against S. aureus and E. coli.

3.5.2 Antibiofilm Activities

The different treatments were distributed homogeneously in each channels. Antibiofilm activity of NPs against pathogenic strains are presented in Table 2.

Our results showed that the maximum antibiofilm activity was observed for 500 μL TiO2 NPs produced by Streptomyces sp. HC1.

4 Discussion

An important area of research in nanotechnology deals with the synthesis of nanoparticles of different chemical compositions, dimension and controlled monodispersity. In recent years, TiO2 has been extensively used as an environmentally harmonious and clean photocatalyst, because of its optical properties, high chemical stability and nontoxicity [22]. The biosynthetic method using microorganisms has received more attention than chemical and physical methods.

Rajakumar et al. reported that the biosynthesis of TiO2 NPs was achieved using Aspergillus flavus extract as a reducing and capping agent which proved to be a good antibacterial material against E. coli. Razia Khan et al. synthesis the TiO2 nanoparticles by the bacterial strains were isolated from dairy industry wastewater.

Although the average particle sizes of the produced particles are determined nearly 55 nm by SEM analysis the agglomerates with bigger particles sizes are also shown. Particle agglomeration depends upon the nature of extract and compounds present in it [20, 23, 24] attraction of reactivity and functional groups results in the formation of large sized particles. These particles have coatings of different biological compounds having surface hydroxyl groups. Depending on the intramolecular hydrogen bonding between these entities, the particles appear to be agglomerated [20, 23,24,25]. XRD analysis is used to determine phase distribution, crystallinity, and purity of the synthesized nanoparticles. From the spectra of the XRD it is concluded that the nanoparticles were crystalline in nature, cubic in shape, and without considerable impurities. While the results that are obtained from the AFM results are investigated it has been reported that nanoparticles are smaller than the estimated dimensions obtained from SEM images, which may be due to nanoparticle agglomeration [24]. Since the FTIR analysis was performed after calcination, most peaks corresponding to organic functional groups were not observed in the spectrum.

Gelover et al. reported that among all NPs, the TiO2 NPs were most commonly studied for their photocatalytic and antimicrobial activities [26]. According to previous reports, titanium dioxide NPs also inhibited the growth of E. coli and S. aureus [27,28,29]. Nanoparticles are viable and highly potent alternatives to antibiotics [30, 31]. Biofilms are complex bacterial populations that resist the action of antibiotics and responses of the human immune system [32, 33]. Our results showed that the maximum antibiofilm activity was observed for 500 μL TiO2 NPs produced by Streptomyces sp. HC1.

Titanium dioxide nanoparticles are inexpensive, non-toxic, and eco-friendly NPs that are synthesized using microorganisms (such as Streptomyces spp.) and characterized using SEM, AFM, XRD, FTIR, and Zetasizer. Size of the synthesized TiO2 NPs was in the range of 30 to 70 nm. These nanoparticles not only demonstrated antimicrobial activity, but also antibiofilm activity. The method detailed in the present study provides a fast route for preparing pure titanium dioxide nanoparticles. This method is simple and cost effective. Further, this technique can also be used for the synthesis of various other metallic nanoparticles.

References

F. Simonis, S. Schilthuizen, Nanotechnology Innovation Opportunities for Tomorrow’s Defence (TNO Science & Industry, Delft, 2006)

K. Khosravi, M.E. Hoque, B. Dimock, H. Hintelmann, C.D. Metcalfe, A novel approach for determining total titanium from titanium dioxide nanoparticles suspended in water and biosolids by digestion with ammonium persulfate. Anal. Chim. Acta 713, 86–91 (2012)

E.R. Kisin, A.R. Murray, M.J. Keane, X.C. Shi, D. Schwegler-Berry, O. Gorelik, S. Arepalli, V. Castranova, W.E. Wallace, V.E. Kagan, A.A. Shvedova, Single-walled carbon nanotubes: geno- and cytotoxic effects in lung fibroblast V79 cells. J. Toxicol. Environ. Health. A 70, 2071–2079 (2007)

T.A. Robertson, W.Y. Sanchez, M.S. Roberts, Are commercially available nanoparticles safe when applied to the skin? J. Biomed. Nanotechnol. 6, 452–468 (2010)

K. Sanders, L.L. Degn, W.R. Mundy, R.M. Zucker, K. Dreher, B.Z. Zhao, J.E. Roberts, In vitro phototoxicity and hazard identification of nano-scale titanium dioxide. Toxicol. Appl. Pharm. 258, 226–236 (2012)

P. Mohanpuria, N.K. Rana, S.K. Yadav, Biosynthesis of nanoparticles: technological concepts and future applications. J. Nanoparticle Res. 10, 507–517 (2008)

V.K. Sharma, R.A. Yngard, Y. Lin, Silver nanoparticles: green synthesis and their antimicrobial activities. Adv. Colloid Interface 145, 83–96 (2009)

A. Tavakoli, M. Sohrabi, A. Kargari, A review of methods for synthesis of nanostructured metals with emphasis on iron compounds. Chem. Pap. 61, 151–170 (2007)

S. Senapati, D. Mandal, A. Ahmad, M.I. Khan, M. Sastry, R. Kumar, Fungus mediated synthesis of silver nanoparticles: a novel biological approach. Indian J. Phys. A. 78, 101–105 (2004)

J.G. Parsons, J.L. Gardea-Torresdey, Use of plants in biotechnology: synthesis of metal nanoparticles by inactivated plant tissues, plant extracts, and living plants. Dev. Environ. Sci. 5, 463–485 (2007)

S. Jomini, H. Clivot, P. Bauda, C. Pagnout, Impact of manufactured TiO2 nanoparticles on planktonic and sessile bacterial communities. Environ. Pollut. 202, 196–204 (2015)

R.P. Hu, X.L. Gong, Y.M. Duan, N. Li, Y. Che, Y.L. Cui, M. Zhou, C. Liu, H. Wang, F.S. Hong, Neurotoxicological effects and the impairment of spatial recognition memory in mice caused by exposure to TiO2 nanoparticles. Biomaterials 31, 8043–8050 (2010)

I. Iavicoli, V. Leso, L. Fontana, A. Bergamaschi, Toxicological effects of titanium dioxide nanoparticles: a review of in vitro mammalian studies. Eur. Rev. Med. Pharmacol. 15, 481–508 (2011)

J.X. Wang, C.Y. Chen, Y. Liu, F. Jiao, W. Li, F. Lao, Y.F. Li, B. Li, C.C. Ge, G.Q. Zhou, Y.X. Gao, Y.L. Zhao, Z.F. Chai, Potential neurological lesion after nasal instillation of TiO2 nanoparticles in the anatase and rutile crystal phases. Toxicol. Lett. 183, 72–80 (2008)

A.K. Jha, K. Prasad, A.R. Kulkarni, Synthesis of TiO2 nanoparticles using microorganisms. Colloid Surf. B. 71, 226–229 (2009)

A.V. Kirthi, A.A. Rahuman, G. Rajakumar, S. Marimuthu, T. Santhoshkumar, C. Jayaseelan, G. Elango, A.A. Zahir, C. Kamaraj, A. Bagavan, Biosynthesis of titanium dioxide nanoparticles using bacterium Bacillus subtilis. Mater. Lett. 65, 2745–2747 (2011)

G. Rajakumar, A.A. Rahuman, B. Priyamvada, V.G. Khanna, D.K. Kumar, P.J. Sujin, Eclipta prostrata leaf aqueous extract mediated synthesis of titanium dioxide nanoparticles. Mater. Lett. 68, 115–117 (2012)

G. Rajakumar, A.A. Rahuman, S.M. Roopan, V.G. Khanna, G. Elango, C. Kamaraj, A.A. Zahir, K. Velayutham, Fungus-mediated biosynthesis and characterization of TiO2 nanoparticles and their activity against pathogenic bacteria. Spectrochim. Acta A-M. 91, 23–29 (2012)

Y. Wang, S.L.I. Chan, R. Amal, Y.R. Shen, K. Kiatkittipong. XRD antisıoptric broading of nano-crystallites. Int. Centre Diff. Data (2011)

I. Bibi, N. Nazar, M. Iqbal, S. Kamal, H.N. Bhatti, S. Nouren, Y. Safa, K. Jilani, M. Sultan, S. Ata, F. Rehman, M. Abbas, Green and eco-friendly synthesis of cobalt-oxide nanoparticle: characterization and photo-catalytic activity. Adv. Powder Technol. 28, 2796–2796 (2017)

R. Khan, M.H. Fulekar, Biosynthesis of titanium dioxide nanoparticles using Bacillus amyloliquefaciens culture and enhancement of its photocatalytic activity for the degradation of a sulfonated textile dye Reactive Red 31. J. Colloid Interface Sci. 475, 184–191 (2016)

Z. Shervani, Y. Yamamoto, Size and morphology controlled synthesis of gold nanoparticles in green solvent effect of reducing agents. Mater. Lett. 65(92–95), 22 (2011)

G. Bhumi, M. Linga Rao, N. Savithramma, Green synthesis of silver nanoparticles from the leaf extract of adhatoda vasica nees and assessment of its antibacterial activity. Asian J. Pharm. Clin. Res. 8, 62–67 (2014)

H.H. Chang, T.J. Cheng, C.P. Huang, G.S. Wang, Characterization of titanium dioxide nanoparticle removal in simulated drinking water treatment processes. Sci. Total Environ. 601, 886–894 (2017)

M.I. Din, R. Rehan, Synthesis, characterization, and applications of copper nanoparticles. Anal. Lett. 50, 50–62 (2017)

S. Gelover, L.A. Gomez, K. Reyes, M.T. Leal, A practical demonstration of water disinfection using TiO2 films and sunlight. Water Res. 40, 3274–3280 (2006)

D. Mitoraj, A. Janczyk, M. Strus, H. Kisch, G. Stochel, P.B. Heczko, W. Macyk, Visible light inactivation of bacteria and fungi by modified titanium dioxide. Photochem. Photobiol. Sci. 6, 642–648 (2007)

Y. Ohko, Y. Utsumi, C. Niwa, T. Tatsuma, K. Kobayakawa, Y. Satoh, Y. Kubota, A. Fujishima, Self-sterilizing and self-cleaning of silicone catheters coated with TiO2 photocatalyst thin films: a preclinical work. J. Biomed. Mater. Res. 58, 97–101 (2001)

K. Shiraishi, H. Koseki, T. Tsurumoto, K. Baba, M. Naito, K. Nakayama, H. Shindo, Antibacterial metal implant with a TiO(2)-conferred photocatalytic bactericidal effect against Staphylococcus aureus. Surf. Interface Anal. 41, 17–22 (2009)

R.J.B. Pinto, P. Marques, C.P. Neto, T. Trindade, S. Daina, P. Sadocco, Antibacterial activity of nanocomposites of silver and bacterial or vegetable cellulosic fibers. Acta Biomater. 5, 2279–2289 (2009)

M.K. Rai, S.D. Deshmukh, A.P. Ingle, A.K. Gade, Silver nanoparticles: the powerful nanoweapon against multidrug-resistant bacteria. J. Appl. Microbiol. 112, 841–852 (2012)

K. Markowska, A.M. Grudniak, K.I. Wolska, Silver nanoparticles as an alternative strategy against bacterial biofilms. Acta. Biochim. Pol. 60, 523–530 (2013)

M.G. Vincent, N.P. John, M. Sevanan, In vitro study on the efficacy of zinc oxide and titanium dioxide nanoparticles against metallo beta-lactamase and biofilm producing Pseudomonas aeruginosa. JAPS 4, 41–46 (2014)

Funding

This study was funded by Scientific Research Project Coordination Units of Hacettepe University (Grant Number FHD-2016-12767).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ağçeli, G.K., Hammachi, H., Kodal, S.P. et al. A Novel Approach to Synthesize TiO2 Nanoparticles: Biosynthesis by Using Streptomyces sp. HC1. J Inorg Organomet Polym 30, 3221–3229 (2020). https://doi.org/10.1007/s10904-020-01486-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-020-01486-w