Abstract

Constructed wetland treatment methods have been evolved as a consistent treatment technology treating domestic, industrial and agricultural wastewaters. Special attention has been focused on landfill leachate and storm water runoff. Natural wetlands in general remove pollution, but in CWs the conditions are properly monitored, as a result the efficiency in pollution removal is drastic. Removal of the organics and suspended impurities improves the treatment efficiency. Introducing special media for the absorption of nitrogen and phosphorous is focused for removal, which are available in abundant and observed to be the major pollutant. The cost for operation and maintenance of CWs are lower as it requires very less power consumption compared with conventional treatment systems. In addition the design is framed in such a way that it is involved in maintaining the environment during floods and provides habitat for wildlife through dual or multipurpose ecosystems.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

2.1 Introduction

Insufficient availability of fresh water and poor sanitation are the major problems outbursting in the urbanized world and is observed to be continuing so far; therefore, a proper technology should be adopted. According to WHO and UNICEF report 2017, worldwide 3 out of 10 people are in need of access to fresh drinking water, and every 6 out of 10 are deficient of secure sanitation The increase in water demand is currently being managed by groundwater utility, which is easily available in all geographical areas, though it has been technologically overexploited in all the developing countries (Jiang 2009). Administration of wastewater has been monitored by constructing wastewater treatment plants, but most of the developing countries are giving less priority in treating wastewater (Konnerup et al. 2011; Bharagava et al. 2017; Chowdhary et al. 2017). The outcome of this strategy leads to disposal of untreated wastewater in open streams and lakes (Senzia et al. 2003).

Constructed wetland is considered as potential ecofriendly technology to overcome several environmental issues. This will enhance the wastewater treatment in an innovative, sustainable and cost-effective emerging solution for the environmental protection and restoration (Vymazal 2011a). Natural wetlands have been referred as earth kidneys because they provide the function such as filtering pollutants and nutrients from water that flows through them. Natural wetlands are not to manage wastewater. However, their potential for treating pollutants makes significance in the area of wastewater treatment system. An engineered constructed system imitates the natural wetland functions. This system of treatment unit is intended to progress such as filtration, adsorption, biodegradation, phytoremediation, photo remediation and bioaccumulation with the help of vegetation, soil and microbes for treating wastewater (Chowdhary et al. 2017; Yadav et al. 2017; Mishra et al. 2018).

Conventional system is in regular practice for the treatment of wastewater, but constructed wetlands—the engineered, multidimensional treatment modules which include the unit operation and process—are also observed to be the substitute. The accomplishment is accompanied due to frequent increase in circulation of water, great prospective in water, nutrient reuse, less utilization of energy, less maintenance and effective removal of pollutants (Kadlec and Wallace 2008; Vymazal 2011a; Mishra et al. 2019). The application of this technology in the field of pharmaceutical and personal care products receives wide appreciation by removing the organic and solids contaminant along with toxin metals, nutrients and pathogens (Gikas et al. 2013; Zhang et al. 2014; Yadav et al. 2016a).

The success rate in adopting this technology is due to design and operational variables; its application receives wide appreciation in the field of domestic sewage treatment (Mburu et al. 2013a, b), hospital wastewater (Shrestha et al. 2001), industrial wastewater (Maine et al. 2007; Yadav et al. 2019), agricultural wastewater (He et al. 2006), agricultural runoff (Yang et al. 2008), lake/river water (Li et al. 2009), sludge effluent (Ahmed et al. 2008; Kumari et al. 2016), oil produced wastewater (Ji et al. 2007), storm water runoff (Ávila et al. 2013), sugar factory wastewater (Bojcevska and Tonderski 2007; Bharagava and Chandra 2010), laboratory wastewater (Meutia 2001) and landfill leachate (Nahlik and Mitsch 2006). Phenol removal was the first research work carried out in 1950s in Germany on CWs treating wastewater (Seidel 1961). Meanwhile in the last two or three decades, industrial and agricultural wastewater along with storm water runoff is treated in CWs (Vymazal 2011a).

CW treatment efficiency proves that warm tropical and subtropical climates are essential for treating wastewater (Kivaisi 2001), this is due to exposed sunlight, and have higher microbial action that benefits plant growth round the year, which decrease the time necessary for microbial biodegradation (Zhang et al. 2012). To achieve successful wastewater treatment with CWs, the designs are based on engineered systems that make the most of the usual progression connecting the lowland plant life, earth that is in connection with microbiological throng (Vymazal 2014). Development of treatment capability and to highlight the exact characteristics of wetland ecosystems, the man-made modern treatment wetlands are designed (Kadlec and Wallace 2008). In addition to wetland treatment methods, the advanced constructed wetland treatment is capable of covering a wide variety of priorities that focus on improving the biodiversity and environmental conditions associated with recovering river water quality, accompanying wildlife usage and irrigation of agricultural lands. In connection with treatment terminology, some confusing names have been mentioned such as bio filters, sand filters and green filters.

The CWs are extensive technologies that evolved with time and applications of the hour without the contribution of energy and are the cost-effective and eco-friendly expertise, which supports in removal of pollutants naturally from the wastewater. CWs have some advantages compared to other treatment systems, such as less expensive, natural process, simple construction, less operation and maintenance, stability and cost-effectiveness.

2.2 Current Scenario About Constructed Wetland Treating Industrial Wastewater

This technology deals with minimum energy consumption, using reuse/recyclable materials with renewable sources, without the utilization of chemicals. The effect of a good technology lies in the viability of economical factors protecting the environment with a good acceptance by the community. In treating industrial wastewater, sustainable treatment system associate with the economic growth, environmental and ecosystem protection and public health. CW system can bring the best sustainable treatment to the industries. CWs are known as low-cost and environment friendly engineered system that use vegetation, soil material and microorganism to treat municipal and industrial wastewaters (Nikolaou and Stefanakis 2018). Current studies have focused on exploiting this type of treatment, as it is a better treatment system financially compared with conventional wastewater treatment system.

Normally, the conventional treatments such as activated sludge treatment, trickling filter and anaerobic digestion require more cost investments for their infrastructures. Stefanakis et al. (2014) discussed that the current system of CW gives an efficient method in treating domestic and industrial wastewaters resulting in good effluent quality. These treatments mainly depend on the action of wetland vegetation, microbes and supporting materials. Processes such as adsorption, infiltration and biological degradation are the treatment processes that takes place through vegetation in wetlands (Vymazal 2005). CW is a phytoremediation process that improves the treatment of industrial wastewater (Riggio et al. 2018; Saxena et al. 2019). Phytoremediation is a plant-based significant treatment process in CW to remove pollutants such as organic or inorganic materials and nutrients (Herath and Vithanage 2015; Yadav et al. 2016b). The processes involved in phytoremediation are phytoextraction, phytodegradation, phytostimulation, phytostabilization, rhizofiltration and phytovolatilization (Fig. 2.1).

In phytoextraction, wetland plants absorb the heavy metal through roots from the substance while in phytodegradation, plants accomplished enzymatic breakdown of organic to simpler components either alone or with the help of microbes. Plants in wetland absorb organic materials through roots and release it into atmosphere through transpiration, known as phytovolatilization. Through phytostabilization, plants immobilize the pollutants to diminish the exposure in wetlands. Through phytoremediation, vegetation in CWs enable major mechanisms to remove noxious waste. Thus, treating industrial wastewater in wetland is more economic and environmentally healthy process.

Stefanakis (2018) reported about a free-flow CW system which treating wastewater from oilfields make available of good occupancy for all birds. This shows that CW systems provide a good ecological system by promoting biodiversity. To improve the treatment efficiency, integrated wetland system was developed. Wu (2008) discussed about the integrated vertical flow constructed wetland (IVCW) that merged with an up flow followed by down flow connected in series. Tao et al. (2010) reported that IVCWs are favourable for anammox process. Saeed et al. (2012) reported about a horizontal subsurface flow CW (HSSCW) system made up of different media such as organic pea gravel, cupola slag and organic coco-peat. Saeed and Sun (2013) used sugar bagasse as supporting media in vertical flow stage of hybrid CW (HCW) which supports nitrogen removal and organic removal from textile wastewater. This is due to the greater porosity and organic carbon leaching action of sugar bagasse. The authors also found out that decolourizing is efficient when they use sylhet sand as media in horizontal flow stage of same HCW.

Pretreatment of domestic and dairy wastewater in a proportion is carried out in Imhoff tank which is further subjected to treatment in a two-stage HSSCW-based CW system connected in series and observed 94% output removal efficiency (Mantovi et al. 2003). Single-stage vertical flow-based CW systems followed by Van Oirschot (2015) deal with the treatment of dairy effluent for the past 16 years and observed significant removal of phosphorus and nitrogen along with organic compounds. Low greenhouse gas emissions compared to other conventional methods while treating the wastewater is an advantage for CW treatment system. In various CW types, surface flow CW (SCW) system produce low CO2 emissions while VSSCW produces lowest CH4 emissions, while significant N2O emissions were produced (Mander et al. 2014).

However, HCW systems attain high removal efficiency with low greenhouse gas emission. MFC is an emerging technology treating the wastewater along with power production (Jayashree et al. 2014, 2016). It has an advantage of less sludge production (Tamilarasan et al. 2018; Kumar et al. 2018). A new approach of integrating CW incorporating microbial fuel cell (MFC) in treating industrial wastewater was introduced. Yadav et al. (2012) demonstrated an integrated CW with MFC treating dye wastewater which results in removal efficiency of 75% with the generation of power density in the range of 15.73 m Wm−2. Presence of both the anaerobic and aerobic circumstances in the process will normally develop the in situ CW-MFC (Yadav et al. 2018). This combined system may offer further electron acceptors that favours the anaerobic zone in the system and improve more power production. New operational approaches are needed to enhance the organic removal and other useful end product such as electricity by treating various industrial wastewaters in CW system.

2.3 Constructed Wetland Classifications

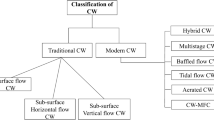

Constructed wetlands (CW) are mainly classified into three systems: (a) surface water flow CW (free water flow) (SCW), (b) subsurface water flow CW (SSCW) and (c) hybrid CW (HCW). In which, first two classifications mainly depend upon their hydrological structure, and the third system is a combination of various CW types. The subsurface water flow also classifies the wetland into two: vertical subsurface water flow CW (VSSCW) and horizontal subsurface water flow CW (HSSCW). Table 2.1 shows the classifications of constructed wetlands.

2.3.1 Surface Water Flow CW (SCW)

SCW are generally a shallow water flow channels or basins with some vegetation which is planted on soil layer (Vymazal 2014). In SCW, water flows horizontally at minimum velocity, forming a water column depth up to 80 cm. This type of CWs is exposed to atmosphere and partially to the sunlight. The wastewater flows through wetland and comes into contact with the vegetation and efficiently removes the pollutants through various physicochemical or biological processes (Wang et al. 2017). Due to the atmospheric diffusion, the upper surface of the wetlands acts as aerobic zones, while the anoxic and anaerobic zones are present nearby the residues. But in high-loading SCW, the anoxic zone is present near the water surface. This type of CWs is used as an advanced wastewater treatment followed by secondary or tertiary treatment. Nitrogen is most effectively removed in SCW by nitrification/denitrification process. Figure 2.2 indicates the schematic representation of surface flow constructed wetland (SCW).

In SCW, nitrifying microbes in aerobic region oxidize NH3, and then in anoxic zone, NO3 is converted to free nitrogen by denitrifying microbes. In SCW, phosphorous is removed by sorption and precipitation. SCW consists of an arrangement of compartments with water regulator which regulate the flow in CW. Typha species and Phragmites australis are the wetland species commonly vegetated in SCW at the water depth of 20–40 cm. Chen (2011) reported that above 70% removal efficiency for total suspended solids (TSS), chemical oxygen demand (COD) and biochemical oxygen demand (BOD) can be achieved in SCW. The author also reported that removal efficiency of 40–50% for nitrogen (N) and 40–90% phosphorous (P) can be achieved in SCW.

2.3.2 Subsurface Flow CW (SSCW)

Subsurface flow CW (SSCW) is a sort of CW, with saturated or unsaturated vegetation which grow on the gravel. In these CWs, wastewater flows vertically or horizontally by which the pollutants comes into contact with microbes that live around the rhizosphere zone (Saeed and Sun 2012). Saeed and Sun (2017) explained about the pollutant removal mechanism of the SSCW as follows: filtration and settling, precipitation and chemical conversion, adsorption on surface of media, plants uptake, organic matter removal by microbes and conversion of nutrients. While removing contaminant, microbial reaction in SSCW is greater than SCW. In SSCW, water flows below the media, and depending on the flow pattern in SSCW, it can be categorized into two groups: (a) vertical subsurface water flow CW (VSSCW) and (b) horizontal flow subsurface water flow CW (HSSCW).

2.3.2.1 Horizontal Subsurface Flow CW (HSSCW)

In horizontal subsurface flow CW (HSSCW), the wastewater enters into the gravel media of CW horizontally and gets treated. Due to subsurface flow, the water is fed into CW below 5 cm from the top layer and not exposed to air. The wastewater reaches into aerobic, anoxic and anaerobic zones. Aerobic zones near the roots drip the oxygen into wastewater (Vymazal 2014). Plant roots release the oxygen which increases the dissolved oxygen (DO) in the upper zone of HSSCW. Lower zone remains as anaerobic region due to poor supply of oxygen. Temperature influences the vegetation activity, while DO content in winter is low but high in summer conditions (Huang et al. 2013). Mburu et al. (2013a, b) reported that horizontal flow decreases the DO level because of high oxygen intake during the degradation. Though nutrient removal is low, HSSCW has been proved very operative in the removal of solids and organics at high rate. Stefanakis (2018) proposed some modifications to advance the efficiency of HSSCW through effluent recirculating, by rising water level or providing step feed and gravity filters. Generally, HSSCW is applied for the treatment of effluents from the industries such as dairy, swine, mine and olive mills. Figure 2.3 represents the horizontal subsurface flow constructed wetland (HSSCW).

2.3.2.2 Vertical Subsurface Flow CW (VSSCW)

VSSCW consists of a flatbed topped with gravel and macrophytes planted on the surface of the bed. Wastewater fed into the CW on the top layer and spreads over the other layers of CW. Then wastewater percolates down to reach the outlet through the gravel media due to the gravitational force. In this mode of operation, wastewater moves vertically and shoots out the confined air and pulling the fresh air from the atmosphere into the bed, as a result better aeration is enhanced. In VSSCW, the bed depth varies from 0.45 to 1.20 m and has a slope of 1–2%, which is used to collect the treated water (Stefanakis et al. 2014). For better oxygen transfer in CW, the gravel media is totally drained and permits fresh air to occupy over the media. Oxygen from atmosphere contributes more in bed oxygenation compared to oxygen transferred from the plants. In VSSCW, macrophytes are used to maintain the hydraulic conductivity of the CW. Pempkowiak et al. (2015) reported that VSSCW systems has some advantages such as ability to transport oxygen and significantly smaller than HSSCW systems. Schematic representation of vertical subsurface flow constructed wetland (VSSCW) is shown in Fig. 2.4.

2.3.3 Hybrid Constructed Wetlands (HCW)

For effective wastewater treatment, CWs are combined and form as hybrid CWs. Mostly, HCW consists of the arrangement of VSSCW and HSSCW. Commonly used types of HCW are made up of (a) VSSCW and HSSCW systems in series and (b) HSSCW combined with VSSCW system (Stefanakis et al. 2014). In VSSCW–HSSCW combined system, VSSCW unit placed in first, to remove the suspended solids and organic matter and to provide nitrification. In combination with HSSCW–VSSCW, HSSCW is provided first to remove organic matter and then to achieve denitrification. Then it is followed by VSSCW to enhance the organic removal also to provide good conditions for nitrification. Nguyen et al. (2018) reported that HCW is an efficient treatment method to remove all the pollutants.

2.3.4 Advanced CWs

Other than the main classification of CW, advanced CWs are used to improve organic removal and nutrient removal from various types of wastewater. To achieve efficient removal treatment, improved CWs with artificial aeration, flow with baffle, feed in step mode and flow in circular have been proposed (Wu et al. 2014). Multi-stage CWs comprises more than three stages CWs. For example, Saeed et al. (2012) performed a HCW system that consists of VSSCW, followed by HSSCW and VSSCW. They achieved good removal efficiency of organic materials such as nitrate and phosphorous across the whole hybrid system. Hybrid system of integrated vertical flow CW was introduced to improve the treatment efficiency (Wu 2008). A novel design of HSSCW comprises vertical baffles placed beside the width of CW (Tee et al. 2012). In this design, wastewater is feed into CW as it flows up and down mode and it reaches the outlet. This design type allows wastewater goes in aerobic, anoxic and anaerobic conditions in sequences which allow it to have more contact with rhizosphere. In CW, the recirculation of treated wastewater within the system improves the total nitrogen removal (Stefanakis and Tsihrintzis 2009). This recirculation takes place in well-designed special wetlands, known as circular flow corridor CW (Peng et al. 2012). This wetland avoids the negative influence of particles and colloids on wetland, an advantage of other conventional CWs.

2.4 Factors Influencing the Treatment of Industrial Wastewaters by CW

2.4.1 Organic Loading

Effluents from industries such as food processing, dairy industry and distillery contain biodegradable substances and solids. Food processing industry wastes contain oil and grease substances with organic matters as carbohydrates. Due to the presence of high organic content in industrial effluents, CWs are mostly designed for secondary or tertiary treatment after conventional primary treatments through activated sludge (Calheiros et al. 2014). High organic loading in CWs may affect the treatment efficiency and also the wetland vegetation (Wu et al. 2015). Organic loading also influences the growth of vegetations in CW. Plants near the outlet show better growth than inlet of CW. This is because decreased organic loading in wastewater moving towards the outlet might decrease stress on vegetation growth (Worku et al. 2018).

2.4.2 Clogging

Clogging is a factor which influences the CW performance while treating industrial effluents. Clogging mainly depends on the substrate need to be treated and hydraulic characteristics of CW. Knowles et al. (2011) reported that clogging happens because of the gathering of solids on the surface, low porosity, poor hydraulic conductivity, biofilm formation, precipitates of chemicals and vegetation. In CW, microbial substances are detached from each other and develop into biofilm on the surface of the gravel. The biofilm occupies the pores of gravels and slowly develops into block. Due to the continuous growth of biofilm, it forms into layer which clogs the system and fails the wetland system. Indeed, the amount or degree of clogging is influenced by the accumulation of solids, while the clogging is influenced by the hydraulic behaviour of the CW.

High clogging may occur at the inlet of CW, because the wastewater enters through the inlet where the solids filtered and retained. At this zone solids overloaded, form clogs and affects the infiltration rate (Pedescoll et al. 2013). Clogging reduces the oxygen infiltration in the growth media which may reduce the efficiency of CW and significantly shortening the life span of CW (Nivala et al. 2012). Clogging reduces the longevity of CW into 8 years (Nivala et al. 2012) and 13 years (Vymazal 2018), but generally CW has the longevity of more than 20 years. Varga et al. (2013) reported that pretreatment is needed to avoid clogging and for the long-term operation of CW with better performance. Herrera-Melián et al. (2015) reported that pretreatment is needed to reduce the concentration of solids before treating the high strength WW in CW. The author also discussed that COD also in minimum level to reduce the development of biofilm.

2.4.3 pH

In CW, pH influences the microbial processes. As a result of various pollutants in industrial wastewaters, it may either acidic or alkaline. Saeed and Sun (2012) reported that ammonification process in CW takes place when pH is 6.5–8.5. Normally in wastewater heterotrophic production rates are high in neutral pH than in acidic pH. Hadad et al. (2018) reported that free floating species in CW adversely affected if pH goes lower than 3 or beyond 9. The authors also reported that T. domingensis is a suitable species in treating industrial effluents with high value pH. The most favourable pH range for treatment of wastewater in CW by macrophytes is 6–9. Worku et al. (2018) also discussed that pH was slightly increased from 6.4 at inlet to 8.1 at outlet while treating brewery industry wastewater. This is due to consuming organic acids by microbes in bioremediation process.

2.4.4 Temperature

Temperature effects the microbial growth and metabolic rates in CW. Normally in CW, greater biological activities and growth rates occur at high temperature while low temperature limits the biological activities and leads to organic accumulation (Meng et al. 2014). The author reported that temperature 28–36 °C is optimum for nitrification activity in CW. Temperature above 15 °C is suitable for ammonia oxidizing bacteria in which the bacteria grows faster than nitrite oxidizing; however, the nitrite oxidizing bacteria can be removed at 25 °C. In CW, 15–38 °C is the most favourable temperature range for the wetland plants.

2.5 Pollutant Removal and Operation and Maintenance for CW Treating Industrial Wastewater

CWs are used to remove the pollutants such as organic and inorganic substances, suspended and dissolved solids, pathogens, metals and nutrients from various industrial wastewaters. CW performance may be affected by wetland structure, hydraulic loading, wastewater type, type of vegetation, pollutant concentration and climatic condition (Trang et al. 2010). In particular, pollutant removal in CW mainly depends upon the organic loading, type of wastewater flow and type of vegetation on CW. More hydraulic retention time is required in CW to remove the pollutants efficiently (Kadlec and Wallace 2008). It is necessary to maintain the level of water for the proper development of vegetation growth. Maintaining an optimum loading for flow of substrate and desired vegetation is needed to get good efficient treatment results in CW, otherwise results may lead to system failure. Plantation in CWs plays predominant role in removing pollutants; the key factors identified are conversion of nutrients, converting to low loaded systems by uptaking nutrients, storing of oxygen in root and releasing of organic carbon (Vymazal 2011b). Table 2.2 shows the performance of pilot scale CW treating various industrial wastewater.

CW plants take a main part in pollutant removal by direct intake, by promoting the particle settling and by providing the substrate to microorganisms that break down pollutants. Adsorption, volatilization, degradation, extraction, filtration and sedimentation are the pollutant removal mechanisms take place in CW which is shown in Fig. 2.5. Although nitrogen is removed by various processes like adsorption, volatilization and nitrogen fixation, nitrification and denitrification play a major role in maximum removal of nitrogen in CW compared to other treatment process.

Accumulation of organic matter and development in nutrient removal are promoted due to growth of plants in CWs studied by Tanner (2001) and observed a significant removal of nitrogen treating wastewater (Lv et al. 2013; Chen et al. 2014). HSSF-based CWs treating domestic wastewater was studied by Carballeira et al. (2016) and observed a removal of 91% additional nitrogen, when plotting a graph with the rate of nitrogen removed against the production of biomass. As per plantation and its corresponding reports, it was experimented to be effective in total nitrogen removal, and it ranges from 0.5 to 40.0% (Saeed and Sun 2012). Plants grown above the ground showed sedimentation burial and denitrification which leads to nitrogen removal in CWs with significant improvements (Chen et al. 2014). The increase in nutrient removal shows decline in performance in monitoring the nutrient removal in subsequent year (Zheng et al. 2015). With the help of sedimentation, adsorption, precipitation and dissolution, the microbes in plantation separate phosphorous. Other compounds like phenol are also removed simultaneously.

It was evident that by considering the physicochemical properties, 70% removal was achieved in FCW. Wu et al. (2017) discussed that VSSCW enhances nitrification process by utilizing excess oxygen produced in aeration. Followed by SCW should have a good purpose for ammonia volatilization. Rani et al. (2011) reported about performance of HSSCW treating pulp and paper industry along with the plant species like Typha angustifolia and Canna indica. The authors also reported that there is a sequential relationship between hydraulic retention time (HRT) and the efficiency of removal. The removal efficiency in low HRT is high as compared to the high HRT. It is possibly due to less supply of nutrients to the microbes at high HRT. Instead, low HRT may lead to the washout of biofilm. Also, the removal efficiency is slightly lower in winter compared to summer. This is because of temperature-dependent microbial activities in CW which are better in summer, because high evapo-transpiration in summer reduces the discharge rate compared with other seasons.

Weerakoon et al. (2013) reported that hydraulic loading rate (HLR) influences the pollutant removal, and it is an important parameter for efficient treatment in HSSCW. The authors constructed a lab-scale HSSCW planted with T. angustifolia species which resulted in an efficient removal of pollutants under varying HLR up to 25 cm/day. Appropriate contact of wastewater with the roots of plantation removes the dissolved particles by various microbial communities (Chen et al. 2016). Saeed et al. (2012) performed a HCW system consisting of VSSCW, followed by HSSCW and a VSSCW. The authors used different types of media such as organic coco peat, cupola slag and pea gravel and planted Phragmites australis species in HCW. They achieved the removal efficiency of 86% in NH3–N, 50% in NO3–N, 98% in biochemical oxygen demand (BOD), 98% in chemical oxygen demand (COD) and 87% in PO4. Worku et al. (2018) reported the phytoremediation role played by planted species for organic removal in CWs. The authors planted T. latifolia and P. purpureum in HSSCW for treating brewery industry wastewater, and the removal efficiency of 81% COD and 87% BOD were obtained.

2.6 Economical Consideration of CW for Treating Industrial Wastewater

For the treatment of industrial wastewater through CWs, the investment costs are categorized based on lands, site utility, construction design, earthwork, liners, paving the filtration unit, plantation and equipment dealing with hydraulic monitoring structure, fencing cost and for roads (Wallace and Knight 2006). The proportions of cost for various countries are summarized, and the data available from Vymazal and Kröpfelová (2008) for the United States and the Czech Republic are observed to be in the range of 7–27% followed by Portugal and Spain. The excavation costs ranges between 27 and 53%, liner plantation cost (2–12%), the unit plumbing cost (6–12%), monitoring of structures ranges from (3.1–5.7%) and the mixed costs (1.8–12%). From economical aspects, the total investment for the CW erection in India was observed to be 29 USD for a square metre (Billore et al. 1999) and evident to be 33 USD per square metre in Costa Rica (Dallas et al. 2004) and proved to be the highest in Belgium with 257 EUR per square metre (Rousseau et al. 2004).

The initial investment cost for subsurface flow CWs is as equal to conventional treatment systems, but the CWs with FWS are comparatively lower due to limited usage of media in rooting of bottom beds. The operation and maintenance costs for CWs are very low compared with concrete and steel technologies. The focus areas monitored were under pretreatment maintenance, less pumping energy, fulfilment in scrutinizing the maintenance work of screens, grit chambers and Imhoff tank and comfort in vegetation harvesting (Kadlec and Wallace 2008). Conservative wastewater treatment plant and activated sludge processes are the effective treatment methods followed in urban areas with economic operation cost. But CWs are affordable for small communities with clear improvement in various aspects such as construction, treatment, maintenance of pumps, vegetation, pest control and less utilization of power. It is observed that only one third of the construction cost occurs in constructing CWs compared to WWTP (Liu et al. 2008).

Comparative study on the economic aspects of CW system and activated sludge process confirm that initial investment cost for CW was relatively half of ASP (Wang et al. 2006). An experimental model CW incorporated with 200 m−3 day−1 of unit was constructed along Dao River (Beijing, China), and it was estimated that the construction cost was equal to one fifth of that of the existing WWTP (Chen et al. 2008). Land requirement plays a predominant place in deciding the economy of CWs; it is land intensive and normally requires more space (Brissaud 2007); therefore, the expansion in application is progressed to place where land prices are affordable. It is one of the reasonable and cost-effective among all processes, both in case of land availability and in due course with less land requirement. In general it has been constructed only in densely populated areas. In Southern China, an innovative crossbreed CW scheme was constructed with a combination of vertical-baffled flow and HSSF, and this scheme treated domestic wastewater (Vymazal 2011a). The advantage associated with this scheme is that it occupied less land than conventional treatment.

Dallas et al. (2004) constructed a pilot plant treating grey water in Costa Rica, with specialization in cost-effective and energy consumption unit. A comparative study on constructed wetland and a sequential batch reactor (SBR) was performed based on the economic and environmental cost analysis from an industrial wastewater treatment unit by Di Muro et al. (2014). It was observed that the storm water is also routed through the system and the financial result points towards implementing CWs are between the savings meanwhile implementing SBR leads to excessive wastage of multiple of capital amount. The life cycle assessment (LCA) study insists on less energy usage and substance uptake that lead to low eutrophication. Though CWs have some advantages, some limitations need to be considered such as requirement of large area, design criteria for different types of wastewater need to treat and climatic conditions.

2.7 Future Consideration

The water quality standards for wastewater treatments are stricter in coming days, where CWs still need to improve research and development in the area of design and operation. CW implementations are observed to be the reliable treatment technology treating various industrial wastewaters. The sustainability of this treatment system is highly depended on advances in design, which naturally influence the contaminant removal efficiencies and successful operation. In treating high-strength wastewater, the CW performance is observed to be linear and drastic advancement, which is due to framing optimized hydraulic design, method of operation, maintaining proper organic loading and correct selection of substrates and plants. Selection of plants for cultivation in the CWs seems to play a vital role in removing pollutant; hence, proper care must be taken in selecting good species of macrophytes. In general, these species are responsible for eliminating heavy metals and pharmaceuticals through large biomass production, acceptability of high-pollutant loadings with sufficient oxygen and carbon compounds. With toting up non-conventional methods such as wastes from agricultural and industrial by products, with high sorption capacity, needs to be developed and involved in pollutant removal process.

In optimizing the industrial wastewater treatment performance, the parameters such as environment, hydraulic loading and operating conditions play predominant role in forming pathway and mechanism equivalent in pollutant removal. Sustainable technologies such as introduction of diffused aeration, adding external carbon, loading reactor in rhythm, choosing various plant species, amplification of microorganism, choosing variety of substrate, introducing hybrid and baffled flow CWs may be applied for the development and enhancement of CWs treating industrial wastewater. Attention towards selection of suitable plant species which absorbs nutrients and pollutants should be focused because at the time of its death and decay, an appropriate harvest strategies, reclamation and recycling of resources should be disclosed. CWs treating industrial wastewater offer potential for nitrogen removal through anammox and CANON processes.

The process performance and efficiency of this treatment depend on the condition of growth of anammox bacteria and the construction design favouring the replication. In addition the optimized microbial species favouring nitrogen-removing gene should be studied using biogenetics and gene modification. Study on pretreatment methods, planting on new vegetation, introducing different porous media and change in operational strategy are the research areas where future investigation is to focus on for potential innovative applications associated with CWs.

2.8 Summary and Conclusion

For the last five decades, constructed wetland treatment methods have been evolved as a consistent treatment technology treating domestic, industrial and agricultural wastewaters. Special attention has been focused on landfill leachate and storm water runoff. Natural wetlands in general remove pollution, but in CWs the conditions are properly monitored; as a result, the efficiency in pollution removal is drastic. Removing the organics and suspended impurities improves the treatment efficiency also; it is enhanced by adding various types of CWs in combination mode. Introducing special media for the absorption of nitrogen and phosphorous is focused for removal, which are available abundantly and observed to be the major pollutant. The cost for operation and maintenance of CWs are lower as it requires very less power consumption compared with conventional treatment systems. In addition the design is framed in such a way that it is involved in maintaining the environment during floods and provides habitat for wildlife through dual or multipurpose ecosystems.

This chapter illustrates the types of CWs and its operational factors like selection of plant species, specific substrate and level of water to be maintained, rate of loading and hydraulic retention time. They are the key stones to achieve an efficient treatment performance. In the application of CWs, attention should be taken to implement the plant species and specific substrates under real-life condition optimizing the environmental and operational factors in implementing new advanced technologies and maintaining the strategies. The CWs are made to work in all forms of environmental conditions. The organic contents ranging in the form of SS, COD and BOD are proportionally removed based on the application of CWs considering the appropriate design criteria and provided loading rates. CWs are monitored to be the admired alternative technologies rather than conventional type wastewater treatment, and the results treating various industrial effluents almost project the same operational trouble and their margins.

References

Ahmed S, Popov V, Trevedi RC (2008) Constructed wetland as tertiary treatment for municipal wastewater. Inst Civil Eng 77–84:WR2

Ávila C, Salas JJ, Martín I, Aragón C, García J (2013) Integrated treatment of combined sewer wastewater and stormwater in a hybrid constructed wetland system in southern Spain and its further reuse. Ecol Eng 50:13–20

Bharagava RN, Chandra R (2010) Biodegradation of the major color containing compounds in distillery wastewater by an aerobic bacterial culture and characterization of their metabolites. Biodegrad J 21:703–711

Bharagava RN, Saxena G, Chowdhary P (2017) Constructed wetlands: an emerging phytotechnology for degradation and detoxification of industrial wastewaters. In: Bharagava RN (ed) Environmental pollutants and their bioremediation approaches. CRC Press, Taylor & Francis Group, Boca Raton, pp 397–426

Billore SK, Singh N, Sharma JK, Dass P, Nelson RM (1999) Horizontal subsurface flow gravel bed constructed wetland with Phragmites karka in central India. Water Sci Technol 401:73–171

Bojcevska H, Tonderski K (2007) Impact of loads, season, and plant species on the performance of a tropical constructed wetland polishing effluent from sugar factory stabilization ponds. Ecol Eng 29:66–76

Borin M, Politeo M, De Stefani G (2013) Performance of a hybrid constructed wetland treating piggery wastewater. Ecol Eng 51:229–236

Brissaud F (2007) Low technology systems for wastewater perspectives. Water Sci Technol 55(7):1–9

Calheiros CS, Rangel AO, Castro PM (2014) Constructed wetlands for tannery wastewater treatment in Portugal: ten years of experience. Int J Phytorem 16:859–870

Carballeira T, Ruiz I, Soto M (2016) Effect of plants and surface loading rate on the treatment efficiency of shallow subsurface constructed wetlands. Ecol Eng 90:203–214

Chen H (2011) Surface-flow constructed treatment wetlands for pollutant removal: applications and perspectives. Wetlands 31:805–814

Chen ZM, Chen B, Zhou JB, Li Z, Zhou Y (2008) A vertical subsurface-flow constructed wetland in Beijing. Commun Nonlinear Sci Numer Simul 13:1986–1997

Chen Y, Wen Y, Zhou Q, Vymazal J (2014) Effects of plant biomass on nitrogen transformation in subsurface-batch constructed wetlands: a stable isotope and mass balance assessment. Water Res 63:158–167

Chen Z, Cuervo DP, Müller JA, Wiessner A, Köser H, Vymazal J, Kästner M, Kuschk P (2016) Hydroponic root mats for wastewater treatment—a review. Environ Sci Pollut Res 23(16):15911–15928

Chowdhary P, Yadav A, Kaithwas G, Bharagava RN (2017) Distillery wastewater: a major source of environmental pollution and it’s biological treatment for environmental safety. In: Singh R, Kumar S (eds) Green technology and environmental sustainability. Springer International, Cham, pp 409–435

Dallas S, Scheffe B, Ho G (2004) Reedbeds for greywater treatment—case study in Santa Elena-Monteverde, Costa Rica, Central America. Ecol Eng 23:55–61

Di Muro JL, Guertin FM, Helling RK, Perkins JL, Romer S (2014) A financial and environmental analysis of constructed wetlands for industrial wastewater treatment. J Ind Ecol 18(5):631–640

Ding Y, Wang W, Song XS, Wang G, Wang YH (2014) Effect of spray aeration on organics and nitrogen removal in vertical subsurface flow constructed wetland. Chemosphere 117:502–505

Fan J, Liang S, Zhang B, Zhang J (2013) Enhanced organics and nitrogen removal in batch-operated vertical flow constructed wetlands by combination of intermittent aeration and step feeding strategy. Environ Sci Pollut Res 20(4):2448–2455

Gikas P, Ranieri E, Tchobanoglous G (2013) Removal of iron, chromium and lead from waste water by horizontal subsurface flow constructed wetlands. J Chem Technol Biotechnol 88(10):1906–1912

Gomes AC, Silva L, Albuquerque A, Simões R, Stefanakis AI (2018) Investigation of lab-scale horizontal subsurface flow constructed wetlands treating industrial cork boiling wastewater. Chemosphere 207:430–439

Hadad HR, Mufarrege MM, Di Luca GA, Maine MA (2018) Salinity and pH effects on floating and emergent macrophytes in a constructed wetland. Water Sci Technol 2017(1):270–275

He LS, Liu HL, Xi BD, Zhu YB (2006) Effects of effluent recirculation in vertical flow constructed wetland on treatment efficiency of livestock wastewater. Water Sci Technol 54(11–12):137–146

Herath I, Vithanage M (2015) Phytoremediation in constructed wetlands. In: Phytoremediation. Springer, Cham, pp 243–263

Herrera-Melián JA, Torres-Padrón ME, Betancor-Abreu A, Sosa-Ferrera Z, Santana-Rodríguez JJ, Martín-González MA, Araña J, Guedes-Alonso R (2015) Clogging reduction and removal of hormone residues with laboratory-scale vertical flow organic-based filter and hybrid wetland. Int J Environ Sci Technol 12(3):1039–1052

Huang J, Cai W, Zhong Q, Wang S (2013) Influence of temperature on micro-environment, plant eco-physiology and nitrogen removal effect in subsurface flow constructed wetland. Ecol Eng 60:242–248

Hussain Z, Arslan M, Malik MH, Mohsin M, Iqbal S, Afzal M (2018) Treatment of the textile industry effluent in a pilot-scale vertical flow constructed wetland system augmented with bacterial endophytes. Sci Total Environ 645:966–973

Jayashree C, Arulazhagan P, Kumar SA, Kaliappan S, Yeom IT, Banu JR (2014) Bioelectricity generation from coconut husk retting wastewater in fed batch operating microbial fuel cell by phenol degrading microorganism. Biomass Bioenergy 69:249–254

Jayashree C, Tamilarasan K, Rajkumar M, Arulazhagan P, Yogalakhsmi KN, Srikanth M, Banu JR (2016) Treatment of seafood processing wastewater using upflow microbial fuel cell for power generation and identification of bacterial community in anodic biofilm. J Environ Manag 180:351–358

Ji CD, Sun TH, Ni JR (2007) Surface flow constructed wetland for heavy oil produced water treatment. Ecol Eng 98:436–441

Jiang Y (2009) China’s water scarcity. J Environ Manag 90:3185–3196

Kadlec RH, Wallace SD (2008) Treatment wetlands, 2nd edn. CRC Press, Boca Raton

Kapellakis IE, Paranychianakis NV, Tsagarakis KP, Angelakis AN (2012) Treatment of olive mill wastewater with constructed wetlands. Water 4(1):260–271

Kivaisi AK (2001) The potential for constructed wetlands for wastewater treatment and reuse in developing countries: a review. Ecol Eng 16:545–560

Knowles P, Dotro G, Nivala J, García J (2011) Clogging in subsurface-flow treatment wetlands: occurrence and contributing factors. Ecol Eng 37(2):99–112

Konnerup D, Trang NTD, Brix H (2011) Treatment of fishpond water by recirculating horizontal and vertical flow constructed wetlands in the tropics. Aquaculture 313:57–64

Kumar MD, Gunasekaran M, Rajesh Banu J (2018) Generation of electricity from dye industry wastewater in dual chamber fed batch operating microbial fuel cell. Int J Adv Res Ideas Innov Technol 4(4):902–907

Kumari V, Yadav A, Haq I, Kumar S, Bharagava RN, Singh SK, Raj A (2016) Genotoxicity evaluation of tannery effluent treated with newly isolated hexavalent chromium reducing Bacillus cereus. J Environ Manag 183:204–211

Li M, Wu YJ, Yu ZL, Sheng GP, Yu HQ (2009) Enhanced nitrogen and phosphorus removal from eutrophic lake water by Ipomoea aquatica with low energy ion implantation. Water Res 43:1247–1256

Li F, Lu L, Zheng X, Zhang X (2014) Three-stage horizontal subsurface flow constructed wetlands for organics and nitrogen removal: effect of aeration. Ecol Eng 68:90–96

Li M, Wu H, Zhang J, Ngo HH, Guo W, Kong Q (2017) Nitrogen removal and nitrous oxide emission in surface flow constructed wetlands for treating sewage treatment plant effluent: effect of C/N ratios. Bioresour Technol 240:157–164

Liu D, Ge Y, Chang J, Peng C, Gu B, Chan GYS, Wu X (2008) Constructed wetlands in China: recent developments and future challenges. Front Ecol Environ 7:261–268

Lv T, Wu S, Hong H, Chen L, Dong R (2013) Dynamics of nitrobenzene degradation and interactions with nitrogen transformations in laboratory-scale constructed wetlands. Bioresour Technol 133:529–536

Maine MA, Suñe N, Hadad H, Sánchez G (2007) Temporal and spatial variation of phosphate distribution in the sediment of free water surface constructed wetland. Sci Total Environ 380:75–83

Maine MA, Hadad HR, Sánchez GC, Di Luca GA, Mufarrege MM, Caffaratti SE, Pedro MC (2017) Long-term performance of two free-water surface wetlands for metallurgical effluent treatment. Ecol Eng 98:372–377

Mander Ü, Dotro G, Ebie Y, Towprayoon S, Chiemchaisri C, Nogueira SF, Jamsranjav B, Kasak K, Truu J, Tournebize J, Mitsch WJ (2014) Greenhouse gas emission in constructed wetlands for wastewater treatment: a review. Ecol Eng 66:19–35

Mantovi P, Marmiroli M, Maestri E, Tagliavini S, Piccinni S, Marmiroli N (2003) Application of a horizontal subsurface flow constructed wetland on treatment of dairy parlor wastewater. Bioresour Technol 88(2):85–94

Mburu N, Tebitendwa SM, Rousseau DPL, van Bruggen JJA, Lens PNL (2013a) Performance evaluation of horizontal subsurface flow-constructed wetlands for the treatment of domestic wastewater in the tropics. J Environ Eng 139:358–367

Mburu N, Tebitendwa SM, Van Bruggen JJ, Rousseau DP, Lens PN (2013b) Performance comparison and economics analysis of waste stabilization ponds and horizontal subsurface flow constructed wetlands treating domestic wastewater: a case study of the Juja sewage treatment works. J Environ Manag 128:220–225

Meng P, Pei H, Hu W, Shao Y, Li Z (2014) How to increase microbial degradation in constructed wetlands: influencing factors and improvement measures. Bioresour Technol 157:316–326

Meutia AA (2001) Treatment of laboratory wastewater in a tropical constructed wetland comparing surface and subsurface flow. Water Sci Technol 44(11–12):499–506

Mishra S, Bharagava RN, More N, Yadav A, Zainith S, Mani S, Chowdhary P (2018) Heavy metal contamination: an alarming threat to environment and human health. In: Sobti RS, Arora NK, Kothari R (eds) Environmental biotechnology: for sustainable future. Springer Nature Singapore Pvt. Ltd, Singapore, pp 103–125

Mishra S, Saratale GD, Ferreira LFR, Bharagava RN (2019) Plant-microbe interaction: an eco-friendly approach for the remediation of metal contaminated environments. Elsevier, Academic (in press)

Nahlik AM, Mitsch WJ (2006) Tropical treatment wetlands dominated by free floating macrophytes for water quality improvement in Costa Rica. Ecol Eng 28:246–257

Nguyen XC, Chang SW, Nguyen TL, Ngo HH, Kumar G, Banu JR, Vu MC, Le HS, Nguyen DD (2018) A hybrid constructed wetland for organic-material and nutrient removal from sewage: process performance and multi-kinetic models. J Environ Manag 222:378–384

Nikolaou IE, Stefanakis AI (2018) A novel response of industry to wastewater treatment with constructed wetlands: a managerial view through system dynamic techniques. In: Stefanakis AI (ed) Constructed wetlands for industrial wastewater treatment. Wiley, Hoboken, NJ, pp 529–549

Nivala J, Knowles P, Dotro G, García J, Wallace S (2012) Clogging in subsurface-flow treatment wetlands: measurement, modeling and management. Water Res 46(6):1625–1640

Pedescoll A, Sidrach-Cardona R, Sánchez JC, Carretero J, Garfi M, Bécares E (2013) Design configurations affecting flow pattern and solids accumulation in horizontal free water and subsurface flow constructed wetlands. Water Res 47(3):1448–1458

Pempkowiak HO, Gajewska M, Wojciechowska E, Pempkowiak J (2015) Treatment wetlands for environmental pollution control. Springer, Cham

Peng J, Song Y, Liu Z, Gao H, Yu H (2012) Performance of a novel circular-flow corridor wetland toward the treatment of simulated high-strength swine wastewater. Ecol Eng 49:1–9

Rani N, Maheshwari RC, Kumar V, Vijay VK (2011) Purification of pulp and paper mill effluent through Typha and Canna using constructed wetlands technology. J Water Reuse Desal 1(4):237–242

Riggio VA, Ruffino B, Campo G, Comino E, Comoglio C, Zanetti M (2018) Constructed wetlands for the reuse of industrial wastewater: a case-study. J Clean Prod 171:723–732

Rossmann M, de Matos AT, Abreu EC, e Silva FF, Borges AC (2012) Performance of constructed wetlands in the treatment of aerated coffee processing wastewater: removal of nutrients and phenolic compounds. Ecol Eng 49:264–269

Rousseau DPL, Vanrolleghem PA, De Pauw N (2004) Constructed wetlands in Flanders: a performance analysis. Ecol Eng 23:151–163

Saeed T, Sun G (2012) A review on nitrogen and organics removal mechanisms in subsurface flow constructed wetlands: dependency on environmental parameters, operating conditions and supporting media. J Environ Manag 112:429–448

Saeed T, Sun G (2013) A lab-scale study of constructed wetlands with sugarcane bagasse and sand media for the treatment of textile wastewater. Bioresour Technol 128:438–447

Saeed T, Sun G (2017) A comprehensive review on nutrients and organics removal from different wastewaters employing subsurface flow constructed wetlands. Crit Rev Environ Sci Technol 47(4):203–288

Saeed T, Afrin R, Al Muyeed A, Sun G (2012) Treatment of tannery wastewater in a pilot-scale hybrid constructed wetland system in Bangladesh. Chemosphere 88(9):1065–1073

Saxena G, Purchase D, Mulla SI, Saratale GD, Bharagava RN (2019) Phytoremediation of heavy metal-contaminated sites: eco-environmental concerns, field studies, sustainability issues and future prospects. Rev Environ Contam Toxicol 249:71–131

Seidel K (1961) ZurProblematik der Keim- und Pflanzengewasser. Verh Internat. Verein. Limnology 14:1035–1039

Senzia MA, Mashauri DA, Mayo AW (2003) Suitability of constructed wetlands and waste stabilization ponds in wastewater treatment: nitrogen transformation and removal. Phys Chem Earth 28:1117–1124

Serrano L, De la Varga D, Ruiz I, Soto M (2011) Winery wastewater treatment in a hybrid constructed wetland. Ecol Eng 37(5):744–753

Sharma PK, Minakshi D, Rani A, Malaviya P (2018) Treatment efficiency of vertical flow constructed wetland systems operated under different recirculation rates. Ecol Eng 120:474–480

Shrestha RR, Haberl R, Laber J, Manandhar R, Mader J (2001) Application of constructed wetlands for wastewater treatment in Nepal. Water Sci Technol 44(11–12):381–386

Stefanakis AI (2018) Introduction to constructed wetland technology. In: Stefanakis AI (ed) Constructed wetlands for industrial wastewater treatment. Wiley, Hoboken, NJ, pp 1–21

Stefanakis AI, Tsihrintzis VA (2009) Effect of outlet water level raising and effluent recirculation on removal efficiency of pilot-scale, horizontal subsurface flow constructed wetlands. Desalination 248(3):961–976

Stefanakis AA, Tsihrintzis SC, Vassilios A (2014) Vertical flow constructed wetlands. Elsevier Inc, pp 1–16

Tamilarasan K, Arulazhagan P, Sakthivel S, Jamal TM, Banu JR (2018) Deriving electricity from dye processing wastewater using single chamber microbial fuel cell with carbon brush anode and platinum nano coated air cathode. 3 Biotech 8(10):437

Tanner CC (2001) Growth and nutrient dynamics of soft-stem bulrush in constructed wetlands treating nutrient-rich wastewater. Wetl Ecol Manag 9:49–73

Tao M, He F, Xu D, Li M, Wu ZB (2010) How artificial aeration improved the sewage treatment of an integrated vertical-flow constructed wetland. Pol J Environ Stud 19(1):181–189

Tee HC, Lim PE, Seng CE, Nawi MAM (2012) Newly developed baffled subsurface-flow constructed wetland for the enhancement of nitrogen removal. Bioresour Technol 104:235–242

Trang NTD, Konnerup D, Schierup HH, Chiem NH, Tuan LA, Brix H (2010) Kinetics of pollutant removal from domestic wastewater in a tropical horizontal subsurface flow constructed wetland system: effects of hydraulic loading rate. Ecol Eng 36:527–535

Van Oirschot D (2015) RietLand vertical flow wetlands: 16 years of experience in the Netherlands and Belgium. In: Proceedings 12th IWA international conference on wetland systems for water pollution control

Varga DL, Díaz MA, Ruiz I, Soto M (2013) Avoiding clogging in constructed wetlands by using anaerobic digesters as pre-treatment. Ecol Eng 52:262–269

Vymazal J (2005) Horizontal sub-surface flow and hybrid constructed wetlands systems for wastewater treatment. Ecol Eng 25:478–490

Vymazal J (2011a) Constructed wetlands for wastewater treatment: five decades of experience. Environ Sci Technol 45(1):61–69

Vymazal J (2011b) Plants used in constructed wetlands with horizontal subsurface flow: a review. Hydrobiologia 674(1):133–156

Vymazal J (2014) Constructed wetlands for treatment of industrial wastewaters: a review. Ecol Eng 73:724–751

Vymazal J (2018) Does clogging affect long-term removal of organics and suspended solids in gravel-based horizontal subsurface flow constructed wetlands? Chem Eng J 331:663–674

Vymazal J, Kröpfelová L (2008) Wastewater treatment in constructed wetlands with horizontal sub-surface flow. Springer, Dordrecht

Wallace SD, Knight RL (2006) Small scale constructed wetland treatment systems. Feasibility, design criteria, and O&M requirements. Water Environment Research Foundation, Alexandria

Wang L, Peng J, Wang BL, Yang L (2006) Design and operation of an ecosystem for municipal wastewater treatment and utilization. Water Sci Technol 54(11–12):429–436

Wang M, Zhang DQ, Dong JW, Tan SK (2017) Constructed wetlands for wastewater treatment in cold climate-a review. J Environ Sci 57:293–311

Weerakoon GMPR, Jinadasa KBSN, Herath GBB, Mowjood MIM, Van Bruggen JJA (2013) Impact of the hydraulic loading rate on pollutants removal in tropical horizontal subsurface flow constructed wetlands. Ecol Eng 61:154–160

Worku A, Tefera N, Kloos H, Benor S (2018) Constructed wetlands for phytoremediation of industrial wastewater in Addis Ababa, Ethiopia. Nanotechnol Environ Eng 3(1):9

Wu ZB (2008) Integrated vertical-flow constructed wetland. Science Press, Beijing

Wu S, Kuschk P, Brix H, Vymazal J, Dong R (2014) Development of constructed wetlands in performance intensifications for wastewater treatment: a nitrogen and organic matter targeted review. Water Res 57:40–55

Wu S, Wallace S, Brix H, Kuschk P, Kirui WK, Masi F, Dong R (2015) Treatment of industrial effluents in constructed wetlands: challenges, operational strategies and overall performance. Environ Pollut 201:107–120

Wu Y, Han R, Yang X, Zhang Y, Zhang R (2017) Long-term performance of an integrated constructed wetland for advanced treatment of mixed wastewater. Ecol Eng 99:91–98

Yadav AK, Dash P, Mohanty A, Abbassi R, Mishra BK (2012) Performance assessment of innovative constructed wetland-microbial fuel cell for electricity production and dye removal. Ecol Eng 47:126–131

Yadav A, Mishra S, Kaithwas G, Raj A, Bharagava RN (2016a) Organic pollutants and pathogenic bacteria in tannery wastewater and their removal strategies. In: Singh JS, Singh DP (eds) Microbes and environmental management. Studium Press (India) Pvt. Ltd, New Delhi, pp 104–130

Yadav A, Raj A, Bharagava RN (2016b) Detection and characterization of a multidrug and multi-metal resistant Enterobacterium Pantoea sp. from tannery wastewater after secondary treatment process. Int J Plant Environ 1(2):37–41

Yadav A, Chowdhary P, Kaithwas G, Bharagava RN (2017) Toxic metals in the environment, their threats on ecosystem and bioremediation approaches. In: Das S, Singh HR (eds) Handbook of metal-microbe interaction and bioremediation. CRC Press, Taylor & Francis Group, Boca Raton, pp 128–141

Yadav AK, Srivastava P, Kumar N, Abbassi R, Mishra BK (2018) Constructed wetland-microbial fuel cell: an emerging integrated technology for potential industrial wastewater treatment and bioelectricity generation. In: Stefanakis AI (ed) Constructed wetlands for industrial wastewater treatment. Wiley, Hoboken, NJ, pp 493–510

Yadav A, Raj A, Purchase D, Ferreira LFR, Saratale GD, Bharagava RN (2019) Phytotoxicity, cytotoxicity and genotoxicity evaluation of organic and inorganic pollutants rich tannery wastewater from a Common Effluent Treatment Plant (CETP) in Unnao district, India using Vigna radiata and Allium cepa. Chemosphere 224:324–332

Yang ZF, Zheng SK, Chen JJ, Sun M (2008) Purification of nitrate-rich agricultural runoff by a hydroponic system. Bioresour Technol 99:8049–8053

Zhang DQ, Tan SK, Gersberg RM, Zhu JF, Sadreddini S, Li YF (2012) Nutrient removal in tropical subsurface flow constructed wetlands under batch and continuous flow conditions. J Environ Manag 96:1–6

Zhang DQ, Gersberg RM, Ng WJ, Tan SK (2014) Removal of pharmaceuticals and personal care products in aquatic plant-based systems: a review. Environ Pollut 184:620–639

Zhang J, Sun H, Wang W, Hu Z, Yin X, Ngo HH, Guo W, Fan J (2017) Enhancement of surface flow constructed wetlands performance at low temperature through seasonal plant collocation. Bioresour Technol 224:222–228

Zheng Y, Wang CX, Ge Y, Dzakpasu M, Zhao Y, Xiong J (2015) Effects of annual harvesting on plants growth and nutrients removal in surface-flow constructed wetlands in north western China. Ecol Eng 83:268–275

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Dinesh Kumar, M., Gopikumar, S., Uan, D.K., Adishkumar, S., Rajesh Banu, J. (2020). Constructed Wetlands: An Emerging Green Technology for the Treatment of Industrial Wastewaters. In: Bharagava, R. (eds) Emerging Eco-friendly Green Technologies for Wastewater Treatment. Microorganisms for Sustainability, vol 18. Springer, Singapore. https://doi.org/10.1007/978-981-15-1390-9_2

Download citation

DOI: https://doi.org/10.1007/978-981-15-1390-9_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-1389-3

Online ISBN: 978-981-15-1390-9

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)