Abstract

The majority of the lightly loaded structures built on expansive soils exhibits swelling behaviour with varying moisture content. To nullify this effect, numerous remedial techniques are evolved. Granular Pile Anchor Foundation (GPAF) is one among the innovative short tensile pile technique that can be promisingly suggested as a foundation method in expansive soil. GPAF traces its origin from the discrete granular pile, which is widely used in soft clays and loose sand. Problems for the foundation in expansive soil are uplift. Hence, the granular piles are provided with anchor rod centrally, which anchors the footing to the anchor plate placed at the bottom. In the year 2006, a research was carried out to study the heave control behaviour of granular pile anchor for footing resting on expansive soil. Outcomes of the research proved the efficacy of GPA over concrete piles. In present work, numerical simulation of the previous field study was made to analyse the heave control phenomena of granular pile anchor using Plaxis 2D, an analysis software based on the finite element method. Performance of Granular Pile Anchor in numerical analysis agrees with that of field test outcomes. Heave control phenomena of Granular Pile Anchor is better than that of concrete piles. This is mainly due to the thorough interlocking of rough-surfaced granular pile material at the interface which is absent in case of concrete pile. Heave of footings is decreasing with increase in length and diameter of the piles used to anchor the footings. The heave values obtained using Plaxis are greater than that from field experiments. This may be due to the empirical assumption of material properties used in the input.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

With ever increasing population and over-exploitation of suitable strata for construction, it is a high time to engineer unsuitable strata to a suitable one, so as to accommodate the foundation with adequate stability. Expansive soil is one among the challenging soil in Geotechnical Engineering. This soil covers about 20% of total land area in India. The damages caused by the swell shrink behaviour of expansive soil estimate about several billions of dollars across the globe. In order to pacify the volumetric changes in expansive soil towards alternate wetting and drying conditions, numerous methods are being evolved by scientists continuously throughout the sphere.

Granular pile anchor is one among the promising heave mitigating techniques in expansive soils, which is highly advantageous compared to the other methods. Several types of research have been carried out since the inception of this novel method on expansive soils by various laboratory investigations to study the heave behaviour and pullout capacity. In order to understand the in situ behaviour of granular anchor piles provided to footings resting on expansive soil towards heave control, a detailed field study was carried out at NIT, Warangal in the year 2006.

In the era of Computational Geotechnics, analysis of any evolving technology may be simplified in terms of time and labour. However, reliability of the method depends on its agreement with the proven facts. Finite element method is a powerful analytical technique that can be used effectively to analyse the soil-pile system in expansive soils. In the present work, numerical heave studies were made using PLAXIS 2D and the results were compared with those of field studies. Also, concrete piles of similar dimension were modelled and compared with those granular piles. The axisymmetric stress condition was used and the vertical ground heave was used to simulate swell behaviour of expansive soil. It is found that granular pile anchors perform better than the concrete pile towards heave control, which agrees with the experimental analysis. The rate of heave reduction increases with increase in dimensions of the piles.

2 Literature Review

The granular anchor pile can be defined as an improved granular pile, which is reinforced with a suitable anchor rod protruding above the pile head whose lower end is fixed with an anchor plate embedded in a predrilled borehole, which is followed by compaction of granular material with an internally operating hammer provided with a central hole for the passage of anchor rod through it. Hence, the granular anchor pile system is installed into the ground by anchoring the foundation to the base anchor plate using an anchor rod. Due to this anchorage action, the resistance to pullout loads gets generated all long the pile-soil interface and will counteract the pullout loads that are acting on these foundation systems. The amount of pullout resistance generated along the pile-soil interface depends on the frictional angle at this interface [8].

Phani kumar has confirmed that the capacity of granular pile anchors in resisting the uplift loads increased with an increase in their length and relative density of the pile material. All his observations are based on laboratory investigations only, which may not reflect the actual field conditions.

Based on the experimental study performed by Subba Rao and Venkatesh [29] on the behaviour of pile embedded in saturated clay, the average unit skin friction increases linearly with shear strength of soil mass. For both smooth and rough piles, the value of skin friction tends to become constant at higher stress levels. In case of rough piles in clay, the failure is observed to take place away from the pile and within the soil rather than along the pile-soil interface as is generally assumed, to compute the shaft resistance. The extent of such failure would essentially depend on the pile roughness and embedment length.

Tsubakihara and Kishida [30] have also stated that, for rough piles, the shear failure occurs within the clay specimen instead of interface sliding. Hence, they concluded that the maximum resistance of friction is upper bounded by the shear strength of clay. Mochtar and Edil (1988) found that the surface of the smooth piles was clear and free from any trace of clay, whereas for the granular pile, it was clearly covered by the clay. This clearly implies that the failure plane was at the pile-clay interface for the smooth piles and out in the clay for the rough piles.

Saad et al. (2014) performed numerical analysis of GPAF system installed on expansive soil under hypothetical field conditions. The results were compared with that of laboratory experiment and a mathematical model was developed using SPSS (17.0) for statistical analysis based on the results of finite element analysis.

2.1 Previous Work

Previously, in order to study the performance of granular anchor piles to control heave of footings resting on expansive soil, a site was chosen near the northern boundary of NIT-Warangal campus by Hari Krishna [8] where the soil profile consists of about 2.0–2.2 m thick black cotton soil followed by murrum up to a depth of 6 m. Hard disintegrated rock follows murrum up to about 12–15 m underlined by fissured and fractured rock to depth of about 18–20 m. The ground is found to heave during the rainy season. During summer, map-type cracks were observed all over the site, indicating the potential for high expansiveness of the soil. Before designing a method for heave control, a study was conducted to understand characteristics and behaviour of soil at the proposed location of site. Heave behaviour of footings provided with different tension piles embedded in expansive soil was studied under laboratory and field conditions.

2.2 Heave Stake Test

In order to determine the percentage free swell in situ Hari et al. (2006) performed the ground heave stake test using precast concrete pedestal inserted at different depths from the surface up to the depth of 2 m as shown in Fig. 1. Over seasons, the heave was measured using the levelling instrument.

The whole area is subjected to alternate wetting and drying condition. The heave measurements were continued till maximum heave is recorded. The uplift movement of the pedestal was found to decrease with increase of depth. The percentage one-dimensional unrestrained or free swell of these soil layers is calculated, which is expressed as a ratio S (%) = (Δh/h) × 100 and the values are listed in Table 1.

3 Methodology

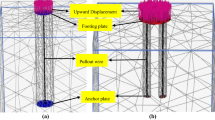

Field setup of footings provided with different tension piles installed in expansive soil was analysed using Plaxis. Cross-sectional view of treated and untreated footings under the site condition as shown in Fig. 2. was considered for modelling. In the field, the pits were filled with water for a period of about 90 days to observe their heave movements and the maximum heaves were observed during that period. Axis symmetric model was used to model the field setup as it is suitable and simple for single pile behaviour.

3.1 Input Data

Corresponding to the field setup as shown in Fig. 2, the geometry of the model was extended to 2.1 m in the vertical direction to represent the depth of expansive soil in field. The size of the footing used in the field was 1.5 m. The width of the model was considered to be three times the width of the footing. Being axisymmetric, the size of the footing was taken as 0.75 m. Hence, the geometry was made up to 2.25 m horizontally, which was three times axisymmetric footing size (3 × 0.75). The geometry of the soil cluster was partitioned in such way to show excavation up to the depth of 0.6 m and width 0.75 m that can be deactivated in the proceeding calculation phase. At the left bottom of the excavation line, the geometry of Granular pile anchor was made with axisymmetric configuration i.e. quarter pile. However, initially the cluster was assigned with expansive soil property so as simulate initial field condition and was later with granular pile material in construction stages (Table 2).

Expansive Soil cluster and granular pile material were modelled using Mohr–coulomb model, which is a nonlinear model. The material type was considered to be drained for granular material and undrained for expansive soil in case of untreated footing and drained for treated footing as the granular material provides passage for draining and the properties of the material are given in Table 3. The concrete pile was modelled as nonporous linear elastic material. Footing and anchor plates of GPA were modelled as plate element and anchor rod was specified as node-to-node anchor.

3.2 Boundary Condition

The standard fixity condition was assigned to the model. (i.e.) Horizontal displacements are considered to be zero at the left and the right boundaries. Also, both horizontal and vertical displacements were taken as zero at the bottom. This assumption agreed with the behaviour in nature where the surrounding soil of large horizontal extent functions as horizontal fixities [13]. After assigning all the necessary inputs to the model, the automated mesh was generated in Plaxis as shown in Fig. 3. Coarse mesh generated was made of 157 elements, 1323 nodes and 1884 stress points.

3.3 Initial Condition

While assigning the initial conditions the water table is assumed to be at the base of model as no water table was found up to the depth of 6 m at the site [8]. Then initial stresses were calculated by assuming coefficient earth pressure at rest, K0 = 1, where K0 = 1-sinφ as given by Jacky’s formula.

3.4 Calculation Phases

In PLAXIS, there is a provision to assign construction in stages. The present analysis was performed in three stages. Of these first two phases were plastic and the third phase was consolidation as in Fig. 4.

In the first phase, similar to the field study, expansive soil model was excavated to a depth of 0.6 m and to a width of 0.75 m in the axisymmetric model from the left boundary (half of the Footing size, 1.5 m) by deactivating the corresponding soil cluster. Then the borehole was made for GPA installation, again by deactivating the respective soil cluster. In the second phase of construction, anchor plate, anchor rod, granular anchor material, footing plate and uniformly distributed load corresponding to the self-weight of the footing (2.4 kN/m2) were activated by defining the parameter through parameter tab.

To account for the time effect, the third phase was performed as a consolidation phase with a time interval of 90 days, which was according saturation period in the field experiment conducted. Also, ultimate heave was witnessed within that period in the field. Hence, in order to simulate heave condition, a volumetric strain of 3.65% was applied to the expansive soil cluster in the model input window. This value was according to the average percentage of free swell at the depth 0.6 m which was obtained from the field prediction of ground heave by Heave stake test after Hari Krishna as given in Table 1. The volumetric strain acts as heave in the vertical direction as the later displacements were arrested by the boundary conditions in the given model.

For the purpose of comparison, concrete piles of equivalent dimension as of GPA were modelled. To understand the relative performance of tension piles in controlling heave of footings resting on expansive soils, footings of different dimensions (1, 1.5, 2.0 m) without piles were also modelled and ultimate heaves were obtained for each case.

4 Results and Discussions

Even though uniform vertical heave was assigned to the model, the vertical displacement was found to decrease with depth due to overburden as given in Fig. 5a, b and c. The ultimate vertical displacement of the footing element is depicted in Fig. 6.

4.1 Swell Potential and Percentage of Heave Reduction

The results from the numerical analysis on the heave behaviour of footings supported by different dimensions of granular pile anchor are given in Table 4. As can be seen from this table, the results of these footings under-treated and untreated conditions were analysed using swell potential and percentage reduction in heave. Hari Krishna [8] used swell potential as the ratio of change in thickness of soil (i.e., heave of footing plate to the original soil thickness).

Hence,

where ΔH is the change in thickness of soil and H is the original soil thickness.

The percentage reduction in heave due to the treatment condition, i.e. difference between heave values of treated (h′) and untreated conditions (h) to the heave of untreated condition (h), expressed as a percentage.

From the table, it can be seen that swell potential decreases with increase in length and diameter of the pile. Percentage reduction in heave increases with increase in dimension of the pile. For granular pile anchor of length 1 m and diameter 200 mm 75% of heave reduction was accounted. About 95% of heave reduction can be witnessed upon providing granular pile anchor throughout the length of the expansive soil. Similarly, the swell potential and the percentage of heave reduction for footings provided with concrete piles of different dimensions are listed in Table 5. In case of concrete pile, only 58% of heave reduction can be seen on providing concrete pile throughout the length of the expansive soil. Decrement of swell potential on increment of dimensions of concrete pile was not that pronounced as in case of GPA. For concrete pile of length 0.5 m and 200 mm diameter, the percentage of heave reduction is about 33%. By providing concrete pile of same diameter and of 1.5 m length throughout the expansive soil layer, heave reduction was increased to just 58%. The efficiency of granular pile anchor in reducing swell potential was about 5 times greater than that of concrete pile when provided throughout the depth of the expansive soil.

4.2 Comparison of Numerical Analysis and Field Study

The heave values of untreated and treated footings obtained from numerical analysis using Plaxis were given in Table 6. The tabulated values were compared against results of field analysis discussed in literature. It was found that in numerical study, heave of the footing was found to increase by 1.4% when footing size was increased by 50%. Also heave was increased by 5.6% when the footing size was doubled. However, in case of field study heave was increased by 18% upon 50% footing size increment and around 49% heave increment was accounted for doubling the footing size. Heave increment upon increase in size of the footing was not pronounced in the field study. This may be due to the fact that heave was modelled as volumetric strain. However, in the field heave increases due to removal of overburden and increase of exposed swell surface.

Heave got decreased with increasing dimensions of the pile (Ala Nasir et al. 2014). The reduction trend followed is on par with the aforesaid field study. For the same surface area, heave reduction is more with the length increment than that of the diameter. This may be attributed to the increased length of interlocking surface. The phenomenon is in line with the findings of Phanikumar [19], Phanikumar et al. [20], Rao et al. [26], Phanikumar et al. [12, 14, 21]. The values of heave obtained from the numerical analysis were on average 1.33 times greater than that of field tests. This can be accounted for the variation of material properties used in FEM analysis for soil clusters, which were basically derived using empirical relation. Also, the exact weather condition prevailed during the field test could not be simulated in the numerical model.

In the case of concrete piles, due to the reduction of strength at the interface, the heave mitigating effect is comparatively less. For the piles provided throughout the length of the expansive soil, the percentage of heave reduction for concrete pile is 58% whereas for GPA it is about 95%. A comparison between results of field test and numerical analysis for piles of different lengths and diameters is shown in Figs. 7 and 8.

5 Conclusions

Performance of Granular Pile Anchor in numerical analysis agrees with that of field test outcomes.

-

1.

Heave control phenomena of Granular Pile Anchor is better than that of concrete piles. This is mainly due to the thorough interlocking of rough-surfaced granular pile material at the interface which is absent in case of concrete pile.

-

2.

Swell potential of footings provided with tensile pile decreases with increase in length and diameter of the pile.

-

3.

Heave of footings is decreasing with increase in length and diameter of the piles used to anchor the footings. And out of the two parameters increase in length of the pile is resulting in more percentage of heave reduction than diameter for the same pile surface.

The heave values obtained using Plaxis are greater than that from field experiments. This may be due to the empirical assumption of material properties used in the input. Also densification of the surrounding medium by ramming of pile material and increase in size of GPA after installation could not be accounted in the numerical analysis. Based on its agreement with field study, analysis may be extended for piles of different lengths and diameter on soils of different swelling behaviour and a mathematical model can be developed which could be used in the design of granular pile anchor for expansive soils.

References

Ambily AP, Gandhi SR (2007) Behavior of stone columns based on experimental and FEM analysis. J Geotech Geoenvironmental Eng

Al-Omari RR, Oraibi WK (2000) Cyclic behaviour of reinforced expansive clay. J Soils Found, Jpn Geotech Soc 40(2):1–8

Bhandari RK, Humad SM, Prakash C (1987) Two New Types of Foundation for Light Structures on Expansive Soils. In: Proceedings of the 6th international conference on expansive soils, New Delhi, India, pp 295–300

Bowles JE (1988) A text book on “Foundation analysis and design”, 4th edn. Mc. Graw–Hill Book Co., New Delhi

Chen FH (1988) A text book on “Foundations on expansive soils”. Elsevier Pub. Co., Amsterdam

Ranjan G, Kumar P (2000) Behavior of granular piles under compressive and tensile loads. Geotech Eng J 31(3)

Hari Krishna P, Murthy VR, Narasimhulu J (2005) Anchored granular micropiles as ground anchors, IGC

Hari Krishna P (2006) A study on the use of granular anchor piles to control heave of footings resting on expansive soils, Ph.D. thesis. NIT Warangal

Hari Krishna P, Murthy VR (2002) In-Situ heave measurements of concrete and anchored granular micropiled footings. In: Proceedings of IGC-2002. Allahabad, India, pp 377–380

Hughes JM, Withers NJ (1974) Reinforcing of soft cohesive soils with stone columns, ground engineering, London, 17(3):42–49

Ibrahim SF, Aljorany AN, Aladly AI (2014) Heave behavior of granular pile anchor-foundation (GPA-foundation) system in expansive soil. J Civil Eng Urban 4(3):213–222

Ismail MA, Shahin M (2011). Finite element analysis of granular pile anchors as a foundation option for reactive soils. In: International conference on advances in geotechnical engineering. Perth, Australia

Kaufmann KL, Nielsen BN, Augustesen AH (2010) Finite element investigations on the interaction between a pile and swelling clay. In: Aalborg: Department of Civil Engineering, Aalborg University. (DCE Technical Reports; No. 104)

Krishna PH, Murty VR, Vakula J (2013) A filed study on reduction of flooring panels resting on expansive soils using granular anchor piles and cushions. Int J Eng Sci (IJES) 2(3):111–115

Mitchell JK, Huber TR (1985) Performance of a stone column foundation. J Geotech Engrg 111–2:205–223

Mohammed Zein YEA, Mohammed MG, Sharief AMEI (1991) Finite element analysis of short piles in expansive soils. J Comput Geotech Elsevier, 231 –243

Murthy Srinivasa BR, Nagaraj TS (1987) Prediction of heave in swelling soils. In: 6th international conference on expansive soils

O’Neill MW, Poormoayed N (1980) Methodology for foundation on expansive clays. J Geotec Eng, Proc ASCE 106(GT12)

Phanikumar BR (1997) A study of swelling characteristics of and granular pile-anchor foundation system in expansive soils. Ph.D thesis, JNTU, Hyderabad, India

Phani Kumar BR, Sharma RS, Rao AS, Madhav MR (2004) Granular pile anchor foundation (GPAF) system for improving the engineering behavior of expansive clay beds. Geotech Test J 27(3):279–287

Phanikumar BR, Rao AS, Suresh K (2008) Field behavior of granular pile anchors in expansive soils. Ground Improv J Proceeding Inst Civ Eng (ICE) 4:199–206

Plaxis 2D version 8 Manual

Poulos HG, Davis EH (1980) Pile foundation analysis and design. Wiley, New York

Kumar P, Ranjan G, Saran S (2003) GAP system for resistance of uplift forces. In: Proceedings of IGC-2003, pp 597–602

Ranjan G (1989) Ground treated with granular piles and its response under load. Indian Geotech J 19(1):1–86

Rao AS, Phanikumar BR, Babu RD, Suresh K (2007) Pullout behavior of granular pile anchors in expansive clay beds In-situ. J Geotech Geoenvironmental Eng, ASCE 133(5):531–538, Via Iraqi Virtual Science Library (IVSL)

Snethen DR et al (1979) An evaluation of methodology for prediction and minimization of detrimental volume change of expansive soils in highway subgrades, Research report, vol 1, Prepared for federal highway administration

Sridharan A, Rao VG (1987) Mechanism controlling swelling of clays, IISC Bangalore

Subba Rao KS, Venkatesh KH (2003) Laboratory investigations on the bearing capacity of buried piles in clay. In: Proceedings of IGC-2003, Roorkee, pp 125–128

TsubakiharaY, Kishida H (1993) Frictional behaviour between NC clay and steel by two direct shear type apparatuses. Soils Found, Jpn Soc Soil Mech Found Eng 33(2):1–13

Author information

Authors and Affiliations

Corresponding authors

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sangeetha, S., Hari Krishna, P. (2020). Analysis of Heave Behaviour of Expansive Soil Provided with Granular Pile Anchors Using Plaxis. In: Prashant, A., Sachan, A., Desai, C. (eds) Advances in Computer Methods and Geomechanics . Lecture Notes in Civil Engineering, vol 55. Springer, Singapore. https://doi.org/10.1007/978-981-15-0886-8_32

Download citation

DOI: https://doi.org/10.1007/978-981-15-0886-8_32

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-0885-1

Online ISBN: 978-981-15-0886-8

eBook Packages: EngineeringEngineering (R0)