Abstract

This paper presents a novel method for fault classification and degradation assessment in rotary machinery through wavelet packet decomposition and data-driven regression methods. Wavelet Packet Decomposition is applied to extract the coefficient and energy based features from vibration signals. During the experiment, we used several machine-learning methods, including Artificial Neural Networks, Support Vector Machine, and K-Nearest Neighbor Classification for degradation assessment and compared the numerical results.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

As the key equipment in many production fields, rotating machinery covers a very broad range of industrial equipment and plays a momentous role in manufacturing application. It is one of the most common classes of mechanical equipment and generally may operate under a tough working environment, which make it vulnerable to types of faults. Moreover, these faults may cause equipment to break down or degrade certain machinery performance like geriatric location, manufacturing quality and operation safety [1].

In most cases, the subsystem in rotary machineries like gear transmission systems are not accessible or hard to inspect the failures directly due to restrictions of disassembly, huge machine size or environmental limitations [2]. Therefore, how to achieve fault detection, classification and degradation assessment failures in rotary machinery is always a hot issue in the research field of mechanical maintenance. Many intelligent approaches for diagnosis or prognosis in rotary machine have been proposed and researched in the recent years [3,4,5]. Lin et al. [3] applied crossover characteristics to extract failure features from nonlinear data to detect faults for rotary machine. Wang et al. [5] proposed a method to selective ensemble neural networks for faults classification in rotary machine. Lu et al. [4] introduced a stacked denoising autoencoder to estimate the health condition of rotary machinery components. All these proposed methods have contributed greatly and achieve certain targets in relevant experiment. However, it still lacks approaches which can accurately classify the failures and assess degradation of certain components or performance for rotary machinery. Therefore, this paper proposed a novel approach based on Wavelet Packet Decomposition (WPD), Artificial Neural Networks (ANN), and K-Nearest Neighbor Classification (KNNC) for fault classification and degradation assessment in rotary machinery.

The rest of this paper is organized as follows: Sect. 2 briefly discusses the importance of vibration condition monitoring in rotary machinery. In Sect. 3, WPD is introduced to extract features from vibration signals for fault diagnosis and prognosis. Sections 4 and 5 describe the set-up and numerical result of the experiment. A comparison is also made with the proposed methods. Conclusions are summarized in the last section of this paper.

2 Vibration Condition Monitoring

The art of anticipating failure in rotary machinery by means of monitoring vibration is widely used in industry as almost 80% of common rotating equipment problems relates to misalignment and imbalance detectable by vibration monitoring. The measured vibration levels will change when a rotary machine has a defect. Vibrations caused by the defects occur at specific vibration frequencies, characteristic of the components, their operation, assembly and wear. The measured vibration levels indicate the severity of the defects [6].

Evaluation criteria for machine vibration is dependent upon a wide range of factors and the criteria adopted vary significantly for different types of machine. According to ISO standard 20816, there are three primary vibration quantities: displacement, velocity and acceleration [7]. However, in most situation, it is hard to give absolute vibration tolerances for any given machine. There is thus an obvious risk of judging measured vibration levels, dangerous when they are not, or the opposite—not dangerous when they are dangerous. Human experience and interpretation of the measured values still plays an important role in vibration condition monitoring. Therefore, how to apply machine-learning approaches for decision making with higher accuracy in vibration condition is always a hot issue.

Electronically measured raw signals are transformed in such a way that levels of these quantities describe the condition of a given rotary machine. Raw vibration signals are transformed using analyzing techniques such as Fast Fourier Transform (FFT), Short Time Fourier Transform (STFT), Wavelet Packet Decomposition (WPD), empirical mode decomposition (EMD), Hilbert-Huang transform (HHT) etc. A common dilemma when analyzing vibration data from rotary machinery is to determine the vibration level acceptance criteria. This paper proposed a novel method based on WPD to analyze vibration data for fault classification and degradation assessment in rotary machinery.

3 Wavelet Packet Decomposition

WPD is a very useful tool to analyze vibration signals. In numerical analysis, the essence of WPD is a wavelet transform where the discrete-time signal is parsed through more filters than the discrete wavelet transform, which can provide a multi-level time-frequency decomposition of signals [8]. It is extended from the wavelet decomposition (WD) and includes multiple bases and different basis, which can result in different classification performance and cover the shortage of fixed time–frequency decomposition in Discrete Wavelet Transform (DWT) [9].

In DWT, the original signal will first pass through two complementary filters and emerges as approximation coefficients and detail coefficients, which includes the low frequency and high frequency information about the original signal respectively. The approximation coefficient will further split into a second-level approximation coefficients and detail coefficients. This process may repeat according to the number of decomposition layers. Figure 1 shows the 3-layer structure of signal based on DWT, where approximation coefficients and detail coefficients are labeled as A and D respectively.

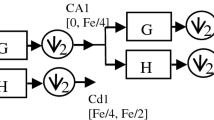

However, WPD decomposes the detail and approximation coefficients simultaneously. Therefore, WPT can construct a complete wavelet packet tree with the same frequency bandwidths in each resolution. WPD can lead to a complete wavelet packet tree as shown in Fig. 2. A wavelet packet is a function with three parameters, i, j and k, which are the modulation, scale and translation parameters respectively.

According to the space partition shown in Fig. 2, we label \(W_{j}^{i}\) to represent the i th subspace of wavelet packet at the j th scale, where \(W_{j,k}^{n} \left( t \right) = 2^{{ - \frac{j}{2}}} \omega^{n} \left( {2^{ - j} t - k} \right)\), k is the shift factor and \(k \in Z\) [10]. It satisfies with Eqs. (1) and (2).

where \(j,k \in Z, n = 0,1,2, \ldots , 2^{i} - 1, h_{0} \left( k \right),h_{1} \left( k \right)\) are low-pass and high-pass filters of wavelet packet. Then the original signal \(f(t)\) can be represented according to j level wavelet packet decomposition as Eqs. (3) and (4). The wavelet packet component \(f_{j}^{i} \left( t \right)\) can be obtained through a linear combination of wavelet packet function \(W_{j,k}^{n} \left( t \right)\) and wavelet packet coefficients \(c_{j,k}^{i}\).

Different types of wavelet functions may cause different time-frequency structures, in this paper, Daubechies 4(DB4) wavelet function has been chosen due to the good performance in estimations of the local properties of signals like breakdown points [11], and the ability to derive a set of conventional and energy based features from signals [12]. During the experiment, we extracted the standard deviations of the coefficients and the percentage of energy corresponding to the approximation and details for fault classification and degradation assessment.

4 Set up and Data Collection

During the experiment, a Bently Nevada Rotor Kit is used to simulate the real working condition of rotary machinery. The sleeve bearing is equipped with 3 accelerometers of Kistler 8702B100, mounted in X, Y, Z direction, to measure the vibration signals from the test rig, as shown in Fig. 3. The sampling frequency is 4096 Hz and the maximum revolving speed is 4000 rpm. The bearing block is tightened down to foundation and can be loosened during the experiment. Rub generator and mass adjustable load can be modulated to simulate types of failures. The vibration monitoring refers to a zero position of the test rig. In this position, signals from the accelerometers are recorded and stored.

During the experiment, we injected three types of failures, bearing loosen, main spindle friction, and load imbalance. For each type of failure, the vibration signals will be measured at different failure degradation and rotating speed by means of acceleration meters and proximity sensors. Figure 4 shows the raw vibration signals and the wavelet coefficients and energy features.

After extracting the wavelet coefficients and energy features from vibration signals, Back-Propagation Neural Networks and Support Vector Machine Regression were applied as data-driven models to classify the failures and estimate the degradation.

5 Numerical Result

During the experiment, a selection of 10,169 samples were applied to establish the data-driven models for failure classification and degradation assessment, respectively. In the failure classification stage, 6033 samples of data are used to train the neural network, and trained network is tested through other 784 samples. All the training samples and testing samples are selected randomly. Figure 5 shows the classification result from the Back-Propagation Neural Network (BPNN) through the wavelet coefficients and energy features. According to the test result, only one sample in the 784 testing samples is misjudged, which means the correctly classification rate is about 98.7%. Since the result from BPNN is already satisfied, we did not use other models to compare in this stage.

During degradation assessment, BPNN, Support Vector Machine Regression (SVMR), and KNNC are applied to estimate the degradation respectively. In this stage, we selected 3089 samples as training samples to train the BPNN and SVMR, and 310 samples as testing samples respectively. All these samples are collected under normal working condition or the failure of load imbalance with different degrees of degradation. The degree of degradation is adjusted by adding weight on the mass adjustable load from 0 to 800 g. Therefore, the inputs of the data driven model are the coefficient and energy based features extracted from WPD, and outputs are the estimated weight on mass adjustable load, which may cause load imbalance. Figure 6 show the testing result of BPNN, SVMR with Gaussian Function and KNNC.

According to the testing result, the Mean Square Error (MSE) during assessment of BPNN and SVMR is about 424.28 and 1275.18 g, respectively. KNNC shares the best performance with 306.05 g in MSE.

6 Conclusion

This paper presents a new method for fault classification and degradation assessment in rotary machinery. At first, Wavelet Packet Decomposition is used to extract the coefficient and energy based features, which can represent the current condition of the rotary machinery. Then several data-driven models are used during the experiment to test their ability to detect, classify and estimate the degree of failures. According to the numerical results, as one of the most popular data-driven method, BPNN has the ability to deal with fault classification with the help of WPD for rotary machinery. However, as to the degradation assessment, we applied several data-driven methods, including BPNN, SVMR, and KNNC. KNNC shares the best performance in the experiment.

References

Lei Y, Lin J, He Z, Zuo MJ (2013) A review on empirical mode decomposition in fault diagnosis of rotating machinery. Mech Syst Signal Process 35(1):108–126

Yang Y, Dong X, Peng Z, Zhang W, Meng G (2015) Vibration signal analysis using parameterized time–frequency method for features extraction of varying-speed rotary machinery. J Sound Vib 335:350–366

Lin J, Chen Q (2014) A novel method for feature extraction using crossover characteristics of nonlinear data and its application to fault diagnosis of rotary machinery. Mech Syst Signal Process 48(1):174–187

Lu C, Wang Z-Y, Qin W-L, Ma J (2017) Fault diagnosis of rotary machinery components using a stacked denoising autoencoder-based health state identification. Sig Process 130:377–388

Wang Z-Y, Lu C, Zhou B (2017) Fault diagnosis for rotary machinery with selective ensemble neural networks. Mech Syst Signal Process

Scheffer C, Girdhar P (2004) Practical machinery vibration analysis and predictive maintenance, Elsevier

ISO 20816-1 (2016) Mechanical vibration—Measurement and evaluation of machine vibration

Zhang Y, Liu B, Ji X, Huang D (2016) Classification of EEG signals based on autoregressive model and wavelet packet decomposition. Neural Process Lett 1–14

Xue J-Z, Zhang H, Zheng C-X, Yan X-G (2003) Wavelet packet transform for feature extraction of EEG during mental tasks. In: Machine learning and cybernetics, 2003 international conference on, IEEE, pp 360–363

Ting W, Guo-zheng Y, Bang-hua Y, Hong S (2008) EEG feature extraction based on wavelet packet decomposition for brain computer interface. Measurement 41(6):618–625

Ferreira CBR, DbL Borges (2003) Analysis of mammogram classification using a wavelet transform decomposition. Pattern Recogn Lett 24(7):973–982

Murugappan M, Ramachandran N, Sazali Y (2010) Classification of human emotion from EEG using discrete wavelet transform. J Biomed Sci Eng 3(04):390

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Li, Z., Pedersen, V.G.B., Wang, K., He, Y. (2018). Fault Classification and Degradation Assessment Based on Wavelet Packet Decomposition for Rotary Machinery. In: Wang, K., Wang, Y., Strandhagen, J., Yu, T. (eds) Advanced Manufacturing and Automation VII. IWAMA 2017. Lecture Notes in Electrical Engineering, vol 451. Springer, Singapore. https://doi.org/10.1007/978-981-10-5768-7_54

Download citation

DOI: https://doi.org/10.1007/978-981-10-5768-7_54

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-5767-0

Online ISBN: 978-981-10-5768-7

eBook Packages: EngineeringEngineering (R0)