Abstract

The former version of this method was initially developed by RILEM following an international trial. This trial showed that the method can reliably differentiate reactive and non-reactive combinations.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Foreword

The former version of this method was initially developed by RILEM following an international trial. This trial showed that the method can reliably differentiate reactive and non-reactive combinations for a range of aggregate compositions from around the world. It was published as a draft for comment in Materials and Structures in 2000 [1]. It has been further developed and amended by RILEM following comments on the draft and the experience of the European PARTNER programme [2] and the storage conditions are now similar to those given in ASTM C1293 [3]. It is one of a suite of test methods for aggregate reactivity developed by RILEM, the combined use of which, for aggregate assessment, is explained in AAR-0.

2 Scope

The method covers the measurement of expansion produced by alkali-aggregate reaction of concrete prisms stored in an environment which accelerates the reaction. It enables the testing of the potential alkali-reactivity of aggregate combinations (Application 1: AAR-3.1). Additionally, the method allows the determination of the alkali threshold of an aggregate combination (Application 2: AAR-3.2).

The method has been developed for normal weight aggregates and is not necessarily applicable for lightweight (oven dry particle density less than 2000 kg/m 3 ) or heavy weight aggregates (oven dry particle density greater than 3500 kg/m 3 ). Additional information concerning the testing methodology is given in Annex A.

3 Principle

In AAR-3.1, concrete test prisms are prepared from the aggregate combination under test (either the standard test with fixed coarse:fine aggregate proportions, or the alternative test with variable aggregate proportions) and are stored in warm (38 °C), humid conditions for 12 months to promote any alkali-aggregate reaction. Measurements are made at periodic intervals to determine whether any expansion has occurred. To promote further any potential for reaction, the prisms are made with a relatively high content of Portland cement with a high alkali content such that the alkali level in the concrete is 5.5 kg sodium oxide equivalent per cubic metre of concrete. Sodium hydroxide is added to the mix when necessary to enhance the alkali level.

In order to identify the effect of specific aggregate combinations and any pessimum effects, there are options to test the coarse and fine test aggregates together or either in combination with a non-reactive material.

For AAR-3.2, the alkali content is adjusted between 2 and 5 kg/m3, using sodium hydroxide added to the mix when necessary to enhance the alkali level.

4 Apparatus

4.1 Sieves

Aperture sizes (mm) 22.4, 16.0, 8.0, 4.0, 2.0, 1.0, 0.5, 0.25 and 0.125 or ASTM equivalents [4].

4.2 Moulds

Three steel moulds suitable for casting concrete prisms of lengths 250 ± 50 mm and cross-section 75 ± 5 mm. The moulds shall have the facility for casting stainless steel reference studs into the mid-points of the end faces of the prisms.

4.3 Length Comparator

The length comparator should be such as to accommodate the shape of the reference studs in the prism and shall incorporate a gauge mounted rigidly in a vertical orientation. The graduation of the gauge shall not be greater than 0.002 mm and the error throughout the range of traverse shall be no more than 0.005 mm. Horizontally mounted comparators are not suitable for this test method.

4.4 Standard Length Gauge

This shall consist of an Invar® rod with ends machined to accommodate the reference studs.

4.5 Weighing Device

Suitable for weighing specimens to the nearest 0.1 g.

4.6 Concrete Mixing and Casting Equipment

This shall be suitable for mixing batches (EN 480-1 [5]) and vibrating into the moulds (EN 12390-2 [6]) or ASTM C 192/C192 M [7].

4.7 Specimen Storage

The specimens shall be stored in roughly cylindrical containers (e.g. plastic pails) with airtight lids. The containers shall be of sufficient size to store three specimens vertically without being in contact with each other or the sides of the container. A perforated rack shall be placed in the bottom of the container so that the prisms are 40–50 mm above the bottom. The container is filled with water to a depth of 25 ± 5 mm above the bottom so that the prisms are approximately 10 mm clear of the water. A wick of absorbent material, e.g. terry cloth, is placed around the wall of the container so that the wick extends into the water (see Annex A4.7).

The containers shall be stored in a room or cabinet capable of being maintained at a temperature of 38 ± 2 °C throughout its storage space.

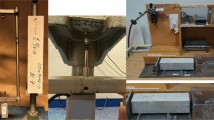

Note 1: A suitable design of container is shown in Fig. 1. Further information on the containers is given in Annex A4.7. Alternatively, a reactor box can be used for storage (see Annex B in AAR-0).

4.8 Casting and Curing Environment

For casting, a room maintained at 20 ± 2 °C (see also Annex A4.8).

The specimens shall be cured in a moist environment held at 20 ± 2 °C and not less than 90 % relative humidity. Initial measurements, immediately after demoulding, shall be made in a room maintained at 20 ± 2 °C and relative humidity not less than 50 % (see also Annex A4.8).

4.9 Measurement Environment

Prior to each measurement at 2, 4, 13, 26 and 52 weeks (see Sect. 8), the specimens are cooled in the sealed containers for 24 ± 2 h in a room at 20 °C, each measurement being made in a room maintained at 20 ± 2 °C and relative humidity not less than 50 % (see also Annex A4.8 for tropical countries).

Application 1—AAR-3.1: Method for Testing Potential Alkali-Reactivity of an Aggregate Combination

5 Materials

5.1 Sodium Hydroxide

Sodium hydroxide of at least technical grade (not less than 98 % sodium hydroxide by mass).

Note 2: Caution—care should be taken when handling this chemical (and concrete containing it) and suitable protective clothing should be worn.

5.2 Portland Cement

A Portland cement (EN197-1 [8] CEM I or ASTM C150 [9] Type I or similar) with total alkali content of 0.9–1.3 % sodium oxide equivalent (see Note 3). If necessary, sodium hydroxide shall be added to the concrete mix water so as to increase the alkali content of the binder to 1.25 ± 0.05 % sodium oxide equivalent and the alkali content of the mix is 5.5 ± 0.2 kg sodium oxide equivalent per cubic metre (see Note 3 and Annex A5.2).

Note 3: Na 2 O equivalent is defined as (% Na 2 O + 0.658 % K 2 O). There is evidence that adding NaOH does not always have the same effect on the concrete pore solution as using a cement manufactured with an equivalent total alkali content. Consequently, the use of a cement with the required high alkali content is preferred to the addition of NaOH. A suitable reference cement is described in AAR-0.

5.3 Aggregates

5.3.1 Standard Aggregate Materials Test

The aggregate combination shall consist of one or more of the following:

-

(i)

fine and coarse test aggregates;

-

(ii)

fine test aggregate combined with a non-reactive coarse aggregate;

-

(iii)

coarse test aggregate combined with a non-reactive fine aggregate.

The non-reactive fine or coarse aggregate shall have expansions in the AAR-2 mortar-bar test of less than 0.05 % at 14 days (Note 5).

Aggregate proportions for Standard Test: When planning the mix design for the standard test, the aggregates shall be combined in the following proportions (calculated on a saturated surface dry basis):

Fine aggregate—40 % (0–4 mm)

Coarse aggregate—60 % (4–22.4 mm)

The total aggregate grading should conform as far as possible to the recommended aggregate grading curve range in Table A.1 given in Annex A5.3. This is to ensure a concrete matrix suited for production of workable and stable concrete.

Note 4: The coarse and fine aggregates should be ‘clean’ (i.e. a controlled content of fines, for example see criteria in EN 12620 [10] or ASTM C33 [11]).

Note 5: This expansion limit is deliberately more restrictive than is generally applied to identify non-reactive aggregate to ensure that the non-reactive aggregate has minimal effect on the results of this test.

5.3.2 Alternative Test with Variable Aggregate Proportions

If it is desired to maximise the proportion of potentially reactive material in the test concrete, the highest amount of the appropriate aggregate fraction should be chosen from Table A.1, for example, 45 % of the total aggregate for a potentially reactive 0–2 mm sand, 55 % for a potentially reactive 0–4 mm sand or 65 % for a potentially reactive coarse aggregate. If there is doubt with respect to what fraction is to be considered as the most potentially reactive, it is recommended to test the possible “worst case” combinations of the fractions in question.

Note 6: If a more precise investigation of the pessimum behaviour is desired, other combinations of the reactive and non-reactive aggregates can additionally be tested (see Annex A5.3 Note A17).

6 Concrete Mix Design

(See also Annex A6).

The concrete mix design is given in Table 1.

Note 7: If the requirement for maximum air content is difficult to fulfil, a de-foaming agent should be applied. However, this must not contribute significant alkalis to the concrete. If it does, this must be included in the calculation of the added sodium hydroxide (see Annex A5.2 ).

The mixing procedure is:

First pre-wet the fine aggregate for a period of at least 16 h to a total water content of 5 ± 2 %.

Then proceed as in the sequence shown in Table 2.

Before mixing the concrete, the mixer should be wiped out with wet cotton cloth in order to humidify the mixer.

Note 8: Worked examples of mix design calculation are given in Annex A6.

Note 9: The free (or effective) water is the water available for hydration of cement and for the workability of the fresh concrete. The total water added to the mix is the free water plus water absorbed by the aggregate to bring it to a saturated surface dry condition.

Note 10: It is important that the mix is sufficiently workable (ideally having a slump in the range 100–180 mm) to enable good compaction. With some flaky aggregates the above mix might not be sufficiently workable. If the slump of the concrete is too low, a superplasticizer with a low alkali content (not one combined with an air-entraining agent) should be used. In this case, the (small) amount of alkali contributed by the superplasticizer should be taken into account in calculating the amount of additional sodium hydroxide to be added (see Annex A5.2 ). The free water in the amount of superplasticizer expected to be added should also be taken into account in calculating the total content of water to be added (see Annex A6 ). The slump should not exceed 180 mm (even when using some superplasticizer).

7 Test Specimens

If using mould oil to assist the release of the cast specimens, avoid the use of too much oil and ensure the reference studs are kept free of the oil.

Cast three test prisms from each concrete mix to be investigated, compacting the concrete into the moulds in two layers of equal depth using mechanical vibration. Compact sufficiently, but ensure no segregation and avoid as far as possible smoothing the prisms after vibration.

Cure at 20 ± 2 °C in relative humidity of not less than 90 % under moist covers for 24 ± 1 h (see Annex A4.8).

Record the weights of the covered moulds directly after casting and before demoulding to ensure there has been minimal water loss during the first 24 h curing.

8 Storage and Measurement

8.1 Initial Measurement Procedure

Before demoulding, identify and indelibly mark each concrete prism. After demoulding, identify and indelibly mark the top and the bottom of each concrete prism. Then examine it and record any defects.

Note 11: De-mould and measure the prisms in sets of three. Do not de-mould all the prisms and attempt to measure consecutively as this will result in too much drying which could affect the expansive behaviour.

Immediately weigh the prisms to the nearest ±0.1 g (W0) and measure the initial length (l) of each prism to the nearest 1 mm using a steel rule. Clean the reference studs and take an initial reading on the comparator (Co) using the Invar® rod to calibrate the length of the measuring apparatus. For each measurement, keep the prism in the same position (top and bottom in position, the same prism face towards the operator). Ensure the prism is well located in the measuring apparatus before making any readings. These and all subsequent measurements are to be made at a temperature of 20 ± 2 °C (see also Annex A4.8).

Verify that there is at least 20 mm of water in the container and place the prisms inside. Replace and seal the lid and store the container at 38 ± 2 °C until required for further measurement. 24 ± 2 h before making each set of further measurements, remove the container containing the prisms to be measured from the cabinet or room and allow the prisms to cool at 20 ± 2 °C whilst the prisms remain inside the container.

8.2 Procedures for Length and Weight Measurements

Remove the container from 38 ± 2 °C storage. DO NOT OPEN the container. Store the container at 20 ± 2 °C for 24 ± 2 h.

Make an initial reading on the comparator using the Invar® rod to calibrate the length of the measurement apparatus.

Each prism measurement should take no more than 2 min to avoid excessive drying. Follow the steps 1–5, to measure the prisms in each container:

-

1.

Take a prism from the container, replacing the container cover immediately;

-

2.

Remove any excess of moisture and weigh the prism (Wt where t = time in weeks), to the nearest ±0.1 g;

-

3.

Clean the reference studs carefully;

-

4.

Measure the prism using the comparator (Ct). For each measurement, keep the prism in the same position (top and bottom in position, the same prism face towards the operator). Ensure the prism is well located in the measuring apparatus before making any readings. After each measurement examine the prisms and note and report any cracking, gel exudations, warping or other features;

-

5.

Return the prism to the container, upside down, so that the prisms are inverted after each measurement; then

-

6.

Once all the prisms from one container have been measured, check the reading of the Invar® rod. If the difference is more than 3 μm from the first measurement, re-measure the prisms for this container again, applying steps 1–5;

-

7.

Check the water level in the container (25 ± 5 mm), add water if necessary and replace the container cover.

Repeat steps 1–7 for all containers.

8.3 Measurement Timetable

After demoulding (see Sect. 8.1) and at the end of periods 2, 4, 13, 26 and 52 weeks after mixing (Note 12), measure the prisms (Wt and Ct). Do not remove the prisms from the container before the first 2 weeks of testing is completed. Do not make intermediate measurements.

Note 12: Some types of slowly reacting aggregate may not exhibit deleterious expansion after 52 weeks. Depending on local experience, the duration of the test may be extended.

9 Expression and Reporting Results

9.1 Calculations

Calculate the increase in length and weight for each prism for each period of measurement from the difference between the initial comparator or weight measurement (Co, W0) and the comparator or weight measurement after that period (Ct, Wt). Calculate each length increase as a percentage of the initial length of the corresponding prism to the nearest 0.001 % and the weight increase as a percentage of the initial weight of the corresponding prism to the nearest 0.01 %. Calculate the percentage net weight change for each prism from the beginning (W0) to the end of the measurement (W52).

For example, at 52 weeks the percentage length change E52 of a prism is given by:

where C52 is the comparator measurement at 52 weeks age, Co is the initial comparator measurement of the prism, and l is the initial length of that prism (in mm).

For each measurement age, also calculate the mean length change of the three prisms to the nearest 0.005 % and the mean weight change to the nearest 0.01 %.

For example, at 52 weeks the mean percentage length change mE52 of the three test prisms is given by:

9.2 Reporting

Report each length increase as a percentage of the initial length for the corresponding prism to the nearest 0.001 % and the weight increase as a percentage of the initial weight of the corresponding prism to the nearest 0.01 %.

Measurement of any weight loss (Xt) confirms there is insufficient water present in the system. AAR reactive mixes will not necessarily exhibit expansion if insufficient water is available. If a net weight loss is recorded at the time of executing the last length readings, the measurements relating to these prisms shall be discarded.

Note 13: Re-wetting would not necessarily allow any previous expansive reactions to be reactivated and subsequent results would be unreliable. Experience has shown that weight gain in the test is related to curing conditions; especially, high humidity early curing can later lead to relatively low weight gain in the test, but results associated with unexpectedly low weight gains or even small weight losses should still be treated with caution.

The measurements shall also be discarded if, at any time during the test period, either no water is left in the bottom of the storage container or the water in the bottom of the storage container has increased and reached the prisms allowing them to suck water (in which case the extent of leaching of alkalis from the prisms will be high).

For each measurement age, report the mean length change of the three prisms to the nearest 0.005 % and the mean weight change to the nearest 0.01 %.

Additionally report:

-

the mix design;

-

the prism size used;

-

the cement source and alkali content;

-

any alkali additions;

-

any superplasticizer additions and any alkali contributed by the superplasticizer;

-

the slump of concrete used in the prisms;

-

observations regarding any cracking, gel exudations, warping or other features.

Note 14: If the prisms exhibit an average expansion which is judged to be deleterious, it is recommended that a microscopical examination of the interior of the prism which has expanded the most should be carried out, together with an examination of the internal features and crack pattern, to confirm that the expansion is caused by alkali-silica reaction.

Application 2—AAR-3.2: Method for Determining the Critical Alkali Threshold for an Aggregate Combination

Use materials according to 5 and the concrete mix according to 6.

Prepare at least four concrete mixes with alkali levels in increments normally between 2 and 5 kg/m3 sodium oxide equivalent. Where possible, it is preferable to blend different Portland cements to achieve the desired alkali contents. If it is necessary to add sodium hydroxide, see examples in A5.2. for calculation of the required amount.

Add the sodium hydroxide, if necessary, to the mixing water before mixing (see Table 2), ensuring complete dissolution before use.

Cast and store the specimens according to 7 and 8 and report the results according to 9. The test period should usually be 52 weeks, but if it is known that the aggregate is of a slow reacting type, the test duration may need to be extended. For example many greywackes react at relatively low alkali levels and may need to be defined as high reactivity, but they need to be tested over a period of 2 years.

The alkali threshold is the highest alkali increment that is found not to give a significant expansion according to the criteria given in AAR-0. The use of the alkali threshold to designate the alkali reactivity is described in AAR 7.1, where the application of a safety margin to the result is explained.

References

RILEM, 2000, Recommended test method TC 106-03, Detection of potentially alkali-reactivity of aggregates: B: Method for aggregate combinations using concrete prisms, Materials and Structures, 33 (229), 290–293.

Lindgård, J, Nixon, P J, Borchers, I, Schouenborg, B, Wigum, B J, Haugen M, Åkesson, U, The EU Partner project – European standard tests to prevent alkali reactions in aggregates, Cement and Concrete Research, 40 (2010) 611–635.

ASTM C1293-08b, Standard test method for determination of length change of concrete due to alkali-silica reaction.

ASTM C136, Standard test method for the sieve analysis of coarse and fine aggregates.

EN 480-1:2014, Admixtures for concrete, mortar and grout. Test methods. Reference concrete and reference mortar for testing.

EN 12390-2:2009, Testing hardened concrete. Making and curing specimens for strength tests.

ASTM C 192/C192M, Standard practice for making concrete test specimens in the laboratory.

EN 197-1:2011, Cement. Composition, specifications and conformity criteria for common cements.

ASTM C150-07, Standard specification for Portland cement.

EN 12620:2013, Aggregates for concrete.

ASTM C33/C33M-08, Standard specification for concrete aggregates.

EN 1097-6:2013, Tests for mechanical and physical properties of aggregates. Determination of particle density and water absorption.

ASTM C127-04, Standard test method for density, relative density (specific gravity), and absorption of coarse aggregate.

ISO 7033:1987 (R08), Fine and coarse aggregates for concrete - Determination of the particle mass-per-volume and water absorption - Pycnometer method.

ASTM C128-07, Standard test method for density, relative density (specific gravity), and absorption of fine aggregate.

EN 1097-5:2008, Tests for mechanical and physical properties of aggregates. Determination of water content by drying in a ventilated oven.

ASTM C566-97(2004), Standard test method for total evaporable moisture content of aggregate by drying.

EN 12350-7:2009, Testing fresh concrete. Air content. Pressure methods.

ASTM C1170-06, Standard test method for determining consistency and density of roller compacted concrete using a vibrating table.

EN 12350-6:2009, Testing fresh concrete. Density.

ASTM C173-01, Standard test method for air content of freshly mixed concrete by the volumetric method.

ASTM C231-04, Standard test method for air content of freshly mixed concrete by the pressure method.

Author information

Authors and Affiliations

Consortia

Corresponding author

Editor information

Editors and Affiliations

Annex A—Additional Information

Annex A—Additional Information

(Comments relate to clauses as numbered in the method)

1.1 A4.7 Specimen Storage

The seal of the airtight lid is critical in preventing significant loss of the water in the pail and hence in maintaining high humidity around the specimens. It is important regularly to check the water level in the container and to refill as necessary.

Plastic racks can be used to hold the prisms in place vertically in the container. The racks with the prisms are placed in the containers which are lined with a layer of either terry cloth or geotextile, ~7 mm in thickness.

The plastic racks should be made in such a way that there is enough clearance at the bottom to keep the prisms about 40–50 mm above the bottom of the pail. About 25 mm of water would then be placed at the bottom of the container.

The temperature-controlled room can be either different size ovens (which have a fairly limited capacity in some cases) or walk-in insulated chambers. Figures A.1 and A.2 show a typical laboratory set-up.

1.2 A4.8 Casting, Curing and Measuring Environment

Cooling to a standard temperature is necessary to obtain reproducible results. In countries with hot climates, however, it may occasionally be necessary to allow the casting, curing and measurement to be carried out in a room maintained at a temperature higher than the preferred 20 °C, up to a maximum of 27 ± 2 °C and not less that 65 % ± 5 RH.

Note A15: A controlled temperature of 20 °C is preferred and strongly recommended for this stage of the test. Whatever standard temperature might be adopted (20 °C or another value up to 27 °C) for a particular test, it is essential that the same procedure and the same temperature are used consistently throughout the test. However, use of a temperature other than 20 °C will necessitate reconsideration of the expansion limits.

1.3 A5.2 Calculation of Sodium Hydroxide to Be Added to the Mixing Water

Example calculation for determining the amount of sodium hydroxide (NaOH) to be added to the mixing water to increase the alkali content up to 1.25 % sodium oxide equivalent by mass of cement:

Cement content of 1 m3 of concrete = 440 kg

Assumed content of superplasticizer = 2.0 kg

Specified amount of Na2O eq. in concrete = 440 × 0.0125 = 5.50 kg

Amount of Na2O eq. in cement (1.0 %) = 440 × 0.01 = 4.40 kg

Amount of Na2O eq. in superplasticizer (1.0 %) = 2 × 0.01 = 0.02 kg

Amount of Na2O eq. to be added per m3 = 5.50 – 4.40 – 0.02 = 1.08 kg

The conversion factor Na2O eq. to NaOH is 1.291.

Amount of NaOH required (to be added to the mixing water) = 1.08 × 1.291 = 1.39 kg

The purity of the technical grade NaOH to be used is 98 %

Amount of technical grade NaOH required (to be added and mixed together

with the first half of the mixing water) = (1.39/98) × 100 = 1.42 kg

1.4 A5.3 Aggregates—Standard Aggregate Materials Test

The aggregate fractions should be combined in mass proportion calculated on a saturated surface dry basis according to Table A.1 given below which gives the recommended aggregate grading curve range to achieve a matrix suited for production of workable and stable concrete. In order to meet these requirements, it is necessary to know the particle size distribution curve of each aggregate.

Note A16: Gaps between two fractions should be avoided. For example, sand 0/2 (2–0 mm) should not be tested with an aggregate 8/16 (16–8 mm).

Note A17: With some reactive aggregates it has been found that there is a proportion of reactive constituents in the aggregate that leads to a maximum expansion. This proportion is called the ‘pessimum’ content, and the relationship between expansion and content of reactive constituents is called the ‘pessimum behaviour’ of the reactive aggregate.

1.5 A6 Concrete Mix Design

Preparation of the aggregates

Pre-wetted fine aggregates are used in order to ensure a workable and homogeneous concrete. This shall be done using the following procedure:

Determine the water absorption (WAf) and initial water content (Wi) of the fine aggregate according to the standards/methods valid in the place of use. Weigh out a sufficient quantity of the fine aggregate, place it into a tray and add a sufficient amount of water calculated to achieve a water content of 5 ± 2 %. Mix the wetted fine aggregate thoroughly and store in sealed containers for at least 16 h. Measure the final water content (Wf) of the fine aggregate.

The coarse aggregate should be used without pre-wetting, but the water absorption (WAc) and the water content (Wc) should be measured.

The amount of water added to the mix to achieve the prescribed free water content of 220 kg/m3 is then calculated, taking into account both the water absorption and the measured water content of the fine and coarse aggregates. The water absorptions of most fine aggregates will be less than the intended water content (i.e. 5 ± 2 %). For most coarse aggregates, the water content will be lower than their water absorptions. In the cases where the water content (W) is higher than the water absorption (WA), the contribution from the aggregate (Wfree) to the free water content of the mix can be calculated as:

Contribution from the aggregate = [(measured water content of the aggregate – water absorption of the aggregate)/100] × [calculated mass of the dry aggregate]

or

In the case of where the water absorption of the aggregate is higher than its water content, the extra water needed (Wextra) at the mixing stage, to bring the aggregate to a saturated surface dry state, can be calculated as:

Extra water needed = [(water absorption of the aggregate – measured water content of the aggregate)/100] × [calculated mass of the dry aggregate]

or

Concrete mix design

A worked example is presented below, see Tables A.2, A.3, A.4, A.5 and A.6.

An example of concrete mix design calculation made with one coarse and one fine aggregate is shown (the calculation is the same for more aggregates).

For the mix design it is necessary to know:

-

The water absorption (WA) of each aggregate. The values can be determined according to EN 1097-6 [12], ASTM C127 [13] or ISO 7033 [14];

-

The densities on an oven dry (ρrd) and saturated surface dry (ρssd) basis of all fractions. The values can be determined according to EN 1097-6 [12], ASTM C127 [13] and 128 [15] or ISO 7033 [14];

-

The water content (W) of each aggregate. The values can be determined according to EN 1097-5 [16] or ASTM C566 [17].

Assume that the content of superplasticizer (with density 1.1 kg/m3 and water content 80 %) required is 2.0 kg/m3 and that the amount of technical grade NaOH (with density 2.1 kg/m3) required is 1.4 kg/m3—see example in Annex A5.2.

The volumetric weight and the air content of the fresh concrete should be measured, according respectively to EN 12350-7 [18]/ASTM C1170 [19] and EN 12350-6 [20]/ASTM C173 [21]/ASTM C231 [22]. The ratio between the theoretical and the measured volumetric weights of the fresh concrete should be 1.000 ± 0.015 (which corresponds to 440 ± 6 kg of cement). This will ensure the correct amount of alkali from the cement in the fresh concrete.

Calculation of the quantity (X) of coarse aggregate (saturated surface dry) in 1 m3 of concrete:

Aggregate volume = 1000 – 143 − 220 − 15 − 2 − 1 = 619 L/m3

(X/2.68 kg/L) + (4/6 × X)/2.68 kg/L = 619 L/m3

X = 995 kg/m3

Calculation of the quantity (4/6 × X) of fine aggregate (saturated surface dry) in 1 m3 of concrete:

4/6 × X = 4/6 × 995 kg/m3 = 663 kg/m3

The contribution from the fine aggregate (Wfree-f) to the free water content can be calculated according to Eq. A.1:

Wfree-f = [(6.2 – 1.1)/100] × [(663)/(1 + 1.1/100)] = 33.4 kg (~33 kg)

The extra water needed (Wextra-c) at the mixing stage to bring the coarse aggregate to a saturated surface dry state can be calculated according to Eq. A.2:

Wextra-c = [(0.8 – 0.3)/100] × [(995)/(1 + 0.8/100)] = 5.0 kg

Example of fresh concrete properties measured:

Slump = 120 mm (target is 100–180 mm)

Air content = 1.4 % (target <3 %)

Measured volumetric weight = 2327 kg/m3

Ratio between the theoretical and measured volumetric weights = (2320/2327) = 0.997 (target is 0.985–1.015).

If the ratio is outside the range, the quantity of aggregate should be increased/decreased (without changing the proportion between the different aggregates) in order to meet the requirement of the weight ratio (0.985–1.015).

Rights and permissions

Copyright information

© 2016 RILEM

About this chapter

Cite this chapter

On behalf of the membership of RILEM TC 219-ACS., Nixon, P.J., Sims, I. (2016). RILEM Recommended Test Method: AAR-3—Detection of Potential Alkali-Reactivity—38 °C Test Method for Aggregate Combinations Using Concrete Prisms. In: Nixon, P., Sims, I. (eds) RILEM Recommendations for the Prevention of Damage by Alkali-Aggregate Reactions in New Concrete Structures. RILEM State-of-the-Art Reports, vol 17. Springer, Dordrecht. https://doi.org/10.1007/978-94-017-7252-5_5

Download citation

DOI: https://doi.org/10.1007/978-94-017-7252-5_5

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-017-7251-8

Online ISBN: 978-94-017-7252-5

eBook Packages: EngineeringEngineering (R0)