Abstract

Hydrogen is viewed as a clean and sustainable energy alternative of future that may change the present carbon-based economy to hydrogen-based economy in the years to come. Biohydrogen production by various microorganisms has emerged as a new area in energy generation that is moving ahead for industrial application. Cyanobacteria and green algae are photoautotrophic microbes that are capable of hydrogen generation by direct or indirect biophotolysis and photofermentation. Hydrogen production is mediated by hydrogenase and nitrogenase enzyme, both of which are oxygen sensitive. Various pathways and strategies of hydrogen production by these photoautotrophic microorganisms have been discussed in this chapter along with approaches to enhance hydrogen yields for prolonged duration using different photobioreactor designs. The possibility of using cyanobacteria and green algae for integrating hydrogen production with wastewater treatment and environmental implications thereof has also been discussed. In biological hydrogen production, there are no greenhouse gas emissions; thus, switching over to hydrogen as a future energy fuel would also help mitigate the global climate change problem.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

5.1 Introduction

Global economy is largely dependent on energy derived from fossil fuels that is about 80 % of the total energy demands . The carbon-based economy has led to several alarming problems due to emission of various pollutants arising out of combustion of the fossil fuels. The most serious issue associated with fossil fuel consumption, however, is the global climate change problem, resulting from emission of carbon dioxide .

Since magnitude of energy consumption of a nation is generally taken as an index of its development, hence, energy use pattern and the type of energy used is a very important parameter of growth. Considering the finite nature of fossil fuel reserves and the environmental problems associated with their combustion , it has become extremely important to look for new renewable energy resources that would be cleaner alternatives to the fossil fuel energy and help to achieve the sustainability goals.

Hydrogen is considered to have tremendous potential as a clean and sustainable energy carrier that could serve as the fuel of the future leading to a shift from the present carbon-based economy to hydrogen-based economy in the years to come (Reith et al. 2003; Levin et al. 2004). Hydrogen is abundantly present on the earth in the form of water covering about three fourth of the earth’s surface. On combustion , hydrogen produces water as the main product; hence, it is a clean fuel. It has a high calorific value of 3042 cal/m3 with highest gravimetric energy density amongst all fuels known till now. Yet, substituting carbon by hydrogen as a fuel faces several technical challenges of efficient production , safe storage, transmission and distribution (Ren et al. 2011; Ramachandran and Menon 1998). Production of hydrogen at present is mostly by electrolysis of water or by steam reformation of methane .

In the past decade, biohydrogen production has emerged as a new and exciting area of research that is moving ahead for industrial application (Das and Veziroglu 2001) exploring the potential of various microorganisms (Mona and Kaushik 2014). Though there are diverse microorganisms capable of hydrogen production , green algae and cyanobacteria are the only organisms capable of both hydrogen production and photosynthesis . Due to their simple nutritional requirements and low cost of production in diverse climatic conditions, it seems promising to utilise the metabolic pathways of these photoautotrophic microbes for biohydrogen production. Another added advantage is that can be cultivated in open barren areas in tanks or ponds and would not compete with crop plants that need fertile lands to grow.

5.1.1 Biological Hydrogen Production

Biohydrogen can be produced by a variety of microorganisms including bacteria, green algae and cyanobacteria. All such processes producing biohydrogen depend fundamentally on the presence of the enzyme hydrogenase . However, the quantity of this enzyme is not the limiting factor for the amount of hydrogen being produced by any of the systems studied till now (Hallenbeck and Benemann 2002). Basically, hydrogenase enzyme catalyses the simple reaction:

Presently, three enzymes, namely, nitrogenase, Fe-hydrogenase and NiFe-hydrogenase, are recognised as the enzymes involved in biohydrogen production.

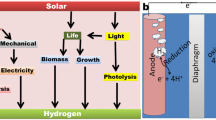

5.2 Biological Hydrogen Production Pathways

The basic biochemical pathways by which hydrogen production takes place are summarised in Table 5.1.

5.2.1 Biophotolysis

Photoautotrophic cyanobacteria and green algae, in the presence of light , break down water into hydrogen and oxygen. During the process of photosynthesis , these photoautotrophs convert the solar energy into biochemical energy. Various processes through which photobiological hydrogen can be produced are depicted in Table 5.1 indicating the basic biological reactions and the microorganisms involved therein.

5.2.1.1 Direct Biophotolysis

Prospects of developing various biological H2 production processes seem attractive because of the renewable energy option and, particularly, because the processes operate under ambient temperature and pressure (Sinha and Pandey 2011). Amongst the various photobiological pathways, hydrogen production by direct biophotolysis is theoretically the simplest as it involves simple splitting of the water molecule by various cyanobacteria and green algae, producing H2.

Cyanobacteria and microalgae possess the photosynthetic pigment chlorophyll that has its absorption maxima in the blue and red region and action spectrum in the visible range of electromagnetic spectrum of sun light. Direct biophotolysis appears to be an attractive process since generation of H2 takes place in this method using abundantly available resources like water and sunlight. However, a major drawback of the process is that along with hydrogen, there is simultaneous production of oxygen. The key enzyme hydrogenase catalysing hydrogen production reaction of the algae is sensitive to oxygen; hence, the oxygen evolved has an inhibitory action on biological hydrogen production, resulting in generally less than 1.5 % conversion efficiency from solar light energy to hydrogen energy. The efficiency can, however, be increased to 3–10 %, if the oxygen produced is immediately removed. Genetic engineering methods may also prove useful to overcome oxygen inhibition of hydrogenase. It is also possible to improve hydrogen production by manipulating the concentrations of certain metals since the same may significantly affect the activity of hydrogenase. Metal ions can significantly influence enzyme activities associated with hydrogen production (Zhao et al. 2012).

5.2.1.2 Indirect Biophotolysis

In order to address the problem of oxygen inhibition of hydrogen production, a system is needed, wherein the two phases involving biological production of hydrogen and oxygen are separated in space or time, a process designated as indirect biophotolysis .

In spatial separation method, the oxygen and hydrogen producing processes of microalgae are spatially separated as demonstrated by Benemann (1997). In the first stage, open ponds were used, in which the microalgae fixed atmospheric CO2 through photosynthesis into carbohydrates and evolved oxygen in the process. In a second phase, dark and anaerobic conditions were maintained using closed bioreactors , where the carbohydrates were degraded into acetic acid and subsequently into hydrogen in the presence of sunlight. It was proposed that the algae could be reused after allowing them to grow again by transferring them to open ponds. The reactions in the various steps are depicted in Table 5.1.

The temporal separation method of indirect biophotolysis was developed using the green microalga Chlamydomonas reinhardtii. Temporal separation of oxygen producing and hydrogen producing processes was achieved by altering the two phases over time. The first phase of photosynthetic O2 evolution along with carbohydrate storage was followed by a second phase in which the growth medium was deprived of sulphur that led to blocking of photosynthesis and thus oxygen evolution (Melis et al. 2000). This facilitated hydrogenase activity in the alga cells and favoured production of hydrogen.

5.2.2 Photofermentation

Photofermentation is the process in which there is conversion of organic compounds like acetic acid into hydrogen and CO2 by bacteria in the presence of sunlight and anaerobic conditions. This process may be coupled to dark hydrogen fermentation in which acetic acid is one of the end products (Yokoi et al. 1998; Hawkes et al. 2002). While this process is more common in bacteria, in the past some researchers have reported photofermentation in cyanobacteria and green algae under conditions of sulphur starvation. Enhanced hydrogen production by Chlamydomonas reinhardtii has been reported under conditions of sulphur deprivation. The sulphur-starved C. reinhardtii cells showed decline in oxygen evolution due to blocking of photosystem II, and anaerobic conditions are developed in the closed culture tubes. Even in the anaerobic conditions, the algae show survival as they shift to photofermentation (Winkler et al. 2002).

Photofermentation has been integrated with dark fermentation for cultivation of certain microalgae like Chlorella vulgaris using different substrates to achieve high biohydrogen yield up to 11.61 mol H2/mol sucrose and production rate of 673.93 ml/h/l during an 80-day cycle of dark and light sequence. Since there was complete consumption of carbon, hence hydrogen produced did not show traces of carbon dioxide as impurity (Lo et al. 2010).

5.2.3 Dark Fermentation

Biomass is being used as both carbon and energy source by various microorganisms under anaerobic conditions leading to generation of biohydrogen by dark fermentation (Cardoso et al. 2014). Various bacteria in swamps, marshes, hot springs and sewage have been found to degrade the available organic matter to produce hydrogen. Some important metabolites like acetic acid, lactic acid, ethanol and amino acids are also produced in the process, which are utilised by methanogenic bacteria coexisting in these habitats. In natural habitats both hydrogen producers and consumers exist together; hence, net hydrogen production is not detected.

For designing a bioprocess to produce hydrogen from biomass, the basic requirement is to separate the processes of hydrogen generation and its consumption. For this we need to design a dual-step bioprocess in which first there is dark fermentation producing hydrogen, while utilisation of this hydrogen for metabolite synthesis is inhibited. The second step involves further transformation of organic metabolites produced in the first fermentation process into hydrogen through photobiological pathway of fermentation.

Approximate H2 yield of the obligate anaerobic bacterium Clostridium is known to be 2 mol per mol glucose, whereas the yield from facultative anaerobes is even less than that. On the other hand, extreme thermophilic anaerobic bacteria have high hydrogen yields that may be very close to the maximum theoretical value of 4 mol H2 mol−1 glucose and are hence found useful for dark fermenters. However, besides optimal molar yields of hydrogen, high rate of hydrogen production is also needed, which needs high cell density. Thermophilic bacteria generally have lower cell densities. Improved cell densities and proper biomass use are important factors for efficient working of dark fermenters (Reith et al. 2003).

A major limitation and challenge of the dark fermentation process is that as the pressure of hydrogen produced in the reactor increases, it starts acting as an inhibitor for the production process, and it becomes absolutely necessary to reduce the pressure by continuously removing the hydrogen at an average of 10–20 k Pa (Reith et al. 2003).

Pretreatment and hydrolysis of biomass is recommended both from a physiological and technological point of view before dark fermentation. While it is the prime aim to convert different types of biomass as a fermentation substrate for hydrogen production, it is also important to look out for methods to utilise the unfermented residual components.

In order to achieve economic viability of the biohydrogen production process, it is important that the other metabolites produced during dark fermentation are also optimally utilised, which is achieved by coupling the process with photofermentation . This ensures complete conversion of the substrate into hydrogen and carbon dioxide, resulting in enhanced hydrogen yield.

Rieth et al. (2003) provided the estimated cost of biohydrogen production as 2.74 Euro kg−1H2 or 19.2 Euro GJ−1, which is almost at par with other carbon neutral technologies known for production of hydrogen. Since several types of wastes can be used as the substrates for biohydrogen production, therefore it may prove to be useful for commercialisation at local and small level. Various small-scale industries having organically rich wastewaters may develop their own waste-to-energy systems that could possibly meet the energy demands of the unit. Further, there are more than one energy options available including production of hydrogen that could be used directly as a source of energy or electricity generation through fuel cell technology, where hydrogen is fed into the cell. One of the countries leading in biohydrogen production is the Netherlands, where thermophilic bacteria are used in the fermentation process. This is especially useful considering the high temperatures of many wastewaters. However, more R&D is needed to transform different waste biomass into usable feedstock with good fermentative characteristics .

5.3 Physiology of Biohydrogen Production

Biological hydrogen production is mediated by hydrogenase and nitrogenase enzymes (Levin et al. 2004) which are discussed here.

5.3.1 Nitrogenase -Catalysed Hydrogen Formation

In the absence of nitrogen in the medium, many filamentous cyanobacteria show nitrogenase activity in some specialised cells known as heterocysts. Nitrogenase catalyses the reaction that converts dinitrogen to ammonia through the process of nitrogen fixation, and hydrogen is also produced in the process. The reaction mediated through use of ATP has been represented as follows (Moezelaar et al. 1996):

The enzyme nitrogenase comprises of two units – the dinitrogenase (220–240 kDa) having Mo-Fe protein moiety, responsible for breaking the triple bond between the two nitrogen atoms, and dinitrogenase reductase (60–70 kDa) with only Fe protein that has a key role in transferring electrons from the donor (ferredoxin or flavodoxin). These units are encoded by specific genes , namely, the nifD and nifK genes and nifH genes, respectively (Orme-Johnson 1992; Flores and Herrero 1994; Masepohl et al. 1997). The dinitrogenases may contain Mo, V or Fe as reported by different researchers (Lambert and Smith 1977; Philips and Mitsui 1983; Heyer et al. 1989; Lindberg et al. 2004).

While nitrogen-containing substrates like CN− and N2O suppress hydrogen production, dinitrogen (N2) does not inhibit hydrogen production even at 50 atm pressure (Rivera-Ortiz and Burris 1975; Simpson and Burris 1984; Jensen and Burris 1986; Liang and Burris 1988).

It has been found that under a high partial pressure of N2O, production of hydrogen becomes N2 dependent (Liang and Burris 1988). Hence, there is always production of hydrogen when nitrogen fixation (reduction) reaction takes place. Interestingly, the H2 produced inhibits reduction of N2, but does not inhibit reduction of protons or other substrates (Wilson and Umbreit 1937).

5.3.2 Hydrogenase-Catalysed Hydrogen Production and Uptake

Hydrogenase catalyses the reversible oxidation of molecular hydrogen (H2), as in Eqs. 5.3 and 5.4:

Two forms of hydrogenase enzyme are known to occur in microalgae and cyanobacteria. These are uptake hydrogenase and bidirectional hydrogenase, which mediate oxidation of hydrogen and production/oxidation of hydrogen, respectively (Tamagnini et al. 2002). The uptake hydrogenases, encoded by hupSL and present in the thylakoid membranes of heterocysts are involved in electron transfer from hydrogen to produce the reducing power (NADH) of the cells. The bidirectional hydrogenases, on the other hand, which are encoded by hox FUYH, are attached to cytoplasmic membrane and mediate acceptance of electrons both from NADH and hydrogen, thereby involved in both hydrogen production and its consumption (Miyake et al. 1989). Thus, uptake hydrogenase uses up the hydrogen produced, resulting in no net hydrogen yield by the microorganism.

Uptake hydrogenase is a dimeric enzyme, while the reversible or bidirectional hydrogenase is multimeric (Flores and Herrero 1994).

Both nitrogenase and hydrogenase are extremely sensitive to oxygen, and, therefore, oxygen-free or low-oxygen-tension environment is a prerequisite for biological hydrogen production. Microalgae and cyanobacteria are both photoautotrophic in nature, evolving oxygen during the process of photosynthesis . Hence, there is a need to protect the nitrogenase enzyme from oxygen. The cyanobacteria have evolved the following strategies to deal with the problem:

-

(a)

Two types of cells are developed in heterocystous cyanobacteria. The vegetative cells carry out photosynthesis and produce oxygen. The thick-walled heterocysts are the zones of low oxygen tension and contain nitrogenase, which mediate nitrogen fixation and production of hydrogen (Orme-Johnson 1992). This is a spatial separation strategy.

-

(b)

The non-heterocystous cyanobacteria, on the other hand, have developed temporal separation strategy by performing photosynthesis during light hours and enzyme-mediated hydrogen production during night-time when there is dark (Thiel 1993).

The hydrogen uptake reaction (Eq. 5.3) involves production of reductants through transfer of electrons from H2 to some electron acceptors (O2, SO4 2− ,NO3 −, CO2, etc.), whereas the reverse reaction (Eq. 5.4) involves transfer of electrons (from Fd) to H+ to produce H2, mediated via electron transport chain (Vignais et al. 2001).

Depending upon the metal component, Vignais et al. (2001) classified the hydrogenases into three types, namely, [NiFe]-, [FeFe]- and [Fe]-only hydrogenase. As shown in Fig. 5.1, these three types of hydrogenases share certain common features like possessing an active site with metal cluster, where actual catalysis occurs and a few more Fe-S clusters. Each metal forms coordination bonds with carbon monoxide (CO) and cyanide (CN) ligands (Fontecilla-Camps et al. 2007).

Structure of three types of hydrogenase enzymes: (a) [NiFe] hydrogenase, (b) [FeFe] hydrogenase, (c) [Fe] hydrogenase (Adopted from Vignais et al. 2001)

Different functions are performed by different hydrogenases. While both production and uptake of hydrogen are facilitated by [NiFe] hydrogenases , they are more actively involved in the latter process. Greening et al. (2014) observed wide variations in hydrogen affinity of H2-oxidising hydrogenases.

Burgdorf et al. (2005) have discovered a novel hydrogenase from Ralstonia eutropha, which is oxygen tolerant, thus increasing the possibility of efficient utilisation of hydrogenases in photosynthetic production of hydrogen through photolysis of water.

In [FeFe] hydrogenases, a bridging dithiolate cofactor is present, and this type has exhibited a high turnover rate (10,000 s−1) in the case of Clostridium (Madden et al. 2012). Further three subtypes of [FeFe] hydrogenases have been recognised (Berggren et al. 2013), which are (i) monomeric hydrogenases present in the cytoplasm (Clostridium pasteurianum) that catalyse both H2 production and uptake; (ii) periplasmic heterodimeric hydrogenases , catalysing mainly H2 oxidation (Desulfovibrio); and (iii) monomeric hydrogenases, associated with chloroplasts which catalyses H2 evolution (Scenedesmus obliquus). Due to high hydrogen yield facilitated by [FeFe] hydrogenase, more emphasis is now given to this type for sustainable production of H2 (Smith et al. 2012).

Methanogenic bacteria possess [Fe] hydrogenase containing Fe instead of Ni or Fe-S clusters (Shima et al. 2008). The mode of catalysis is yet to be worked out in details. It is probably broken by Fe(II) and then hydride is transferred to the acceptor (Hiromoto et al. 2009).

Hydrogenases have a relatively low over potential and show even more efficient catalytic production of hydrogen than that mediated by platinum (Hinnemann et al. 2005).

[FeFe] hydrogenase is considered most suitable as a part of the solar H2 production system. It is, however, necessary to engineer the hydrogenase enzyme for O2 tolerance so that solar H2 production becomes practically feasible. Efforts are underway to understand the mechanisms involved in O2 inactivation of hydrogenases (Liebgott et al. 2010; Goris et al. 2011). Oxygen is reported to transform into a reactive species as it diffuses into [FeFe] hydrogenase, and then the Fe-S cluster at the active site is damaged (Stripp et al. 2009; Goris et al. 2011). In past few years, certain [NiFe] and [FeFe] hydrogenases have been discovered/developed that can tolerate oxygen, but these are the uptake hydrogenases, thus limiting their use in hydrogen production (Stripp et al. 2009; Bingham et al. 2012).

Since the atmosphere of earth initially had a high concentration of hydrogen , hence, hydrogenases seem to have evolved quite early to produce energy from H2 and favour the growth of microorganisms (Vignais and Billoud 2007). The primary role of hydrogenases thus seems to be energy generation that could be used by the microbes themselves or by other organisms around. Evolution of reversible hydrogenases seems to have helped in regulating the levels of reducing equivalents by acting as “valves” in the photoautotrophs. This type of the function carried out by reverse hydrogenases has been important in anaerobic metabolism and hydrogen production by the microbes (Adams and Stiefel 1998).

In cyanobacteria and green algae, hydrogen production is mediated mainly by nitrogenase and hydrogenase enzyme, respectively (Figs. 5.2 and 5.3).

Hydrogen production pathway in microalgae mediated by hydrogenase (Source: Tiwari and Pandey 2012)

5.3.3 Environmental Factors Influencing H2 Production

Biological hydrogen production has been reported to be largely affected by environmental factors like light intensity , light/dark period, temperature, pH , micronutrients, glucose concentration, anaerobic gas mixture, carbon source , nitrogen source, temperature, salinity , etc. Studies reporting the effects of such factors on hydrogen production rates by microalgae and cyanobacteria are briefly discussed below:

5.3.3.1 Light

Light intensity and duration are important factors influencing algal hydrogen production. For optimal hydrogen production, microalgae have to be cultivated under moderately low light intensity, because as light intensity increases, there is evolution of f oxygen, which nullifies the anaerobic conditions produced by sulphur deprivation. Hydrogen production is significantly influenced by alternate light/dark cycle as photosynthesis takes place in the presence of light producing starch, which is then degraded into acetate, alcohol and hydrogen by fermentation during dark period (Miura et al. 1992). Different light (L) and dark (D) cycles (24D, 21L/3D and 18L/6D) have been reported to favour greater hydrogen production in different green algae and cyanobacteria (Mona et al. 2011), which is an important consideration for prolonged hydrogen production in bioreactors . Practical feasibility of such conditions is generally viewed with respect to the local conditions and availability of sunshine hours and natural light so as to cut on the additional costs on artificial illumination. In short-term experiments, 24 h dark conditions seem favourable for high yield of hydrogen, but such conditions would not give sustained yield because photosynthesis cannot take place in dark, and thus biomass and photosynthetic assimilates would diminish after some time (Kaushik and Anjana 2011).

5.3.3.2 Temperature

Temperature is an important factor that may shift the metabolic pathways in favour of enhanced hydrogen production. Temperature was reported to have a strong influence on hydrogen production by several cyanobacteria and microalgae (Litcht et al. 1997; Kaushik and Anjana 2011). Temperature optima vary with species as evident from various reports (Dutta et al. 2000; Shah 2000; Kaushik and Anjana 2011; Mona et al. 2011). Maximum rate of hydrogen production for Nostoc linckia isolated from the textile mill pond was at a temperature of 31 °C (Mona et al. 2011), whereas the temperature optima reported for Nostoc muscorum is 40 °C (Dutta et al. 2000; Shah 2000). Maximum hydrogen production rates reported for Platymonas subcordiformis is 27 °C, and that for marine green microalgae Tetraselmis subcordiformis is 55 °C (Guan et al. 2004).

5.3.3.3 Carbon Source

Carbon sources used in feedstock are important as they influence nitrogenase activity, which, in turn, affect hydrogen production by the cyanobacteria. Different concentrations of carbon sources cause variation in electron donation capabilities of nitrogenase and thus influence hydrogen production . The initial dose of glucose in the medium/feedstock is found to influence the hydrogen yield during photosynthesis /fermentation (Mona et al. 2011). The production decreases with increasing glucose concentration beyond 10 g L−1 (Alalayah et al. 2014).

5.3.3.4 pH

Hydrogen production has been reported to be influenced by the pH of the culture medium used for algal growth , and the pH requirement is species specific. It is favoured by slightly alkaline pH of 7.7 in microalga Chlamydomonas and 8.0 in Phormidium and Lyngbya (Kosourov et al. 2003; Kaushik and Anjana 2011) but decreases as pH becomes higher in the case of Nostoc (Guan et al. 2004; Mona et al. 2011).

5.3.3.5 Salinity

Dissolved salts have an effect on hydrogen production by cyanobacteria (Boison et al. 1999). The fresh water cyanobacteria show a decline in hydrogen production when dissolved salts in the medium increase. This seems to be due to the fact that some energy is diverted for the efflux and further prevention of influx of sodium ions (Asada and Kawamura 1984).

5.3.3.6 Gaseous Environment

Because of oxygen-sensitive nature of the enzymes involved in hydrogen production, it is important to have an anaerobic atmosphere. Biohydrogen production has been reported to be influenced by gaseous environment (Kaushik and Anjana 2011; Mona et al. 2011). In the presence of different concentrations of inert or anoxic gases like argon, carbon dioxide and methane, production of hydrogen is found to be significantly influenced. Yoon et al. (2002) reported increased hydrogen production by Anabaena variabilis when injected repeatedly with carbon dioxide during growth. When CO2 is administered, production of reductants increases, which give enhanced hydrogen yield on fermentation (Miura et al. 1995). Using suitable combinations of methane and carbon dioxide, hydrogen production by Nostoc linckia was significantly improved (Mona et al. 2011).

5.4 Industrial Approach to Biohydrogen Production by Cyanobacteria and Green Algae

5.4.1 Photofermentation Process Scaleup

In the two-stage biohydrogen reactors, photofermentation is carried out to convert the organic substrate completely into H2 and CO2 (Das and Veziroglu 2008). A basic requirement for scaleup of the system is to acquire a large surface area/volume ratio, which raises the cost of the photobioreactor. Solar collectors may provide an alternative to this; however, their production cost with the currently available technology is still quite high (Tsygankov et al. 1994; Bolton 1996; Fedorov et al. 1998).

Although different types of photobioreactors have been designed, at present the tubular photobioreactor fabricated by the IGV (Institut für Getreideverarbeitung GmbH, Germany) is being used commercially on a limited scale (Das 2009). The reactor has a surface area of 1.2 ha, with a cost of 660 Euro m−2, which is slightly more than that of a system with solar panels on a 3 ha roof structure that costs around 580 Euro m−2 (Reith et al. 2003).

Energy potential of a photobioreactor is influenced by the available solar irradiance in that area (Ren et al. 2011). A thousand hectare photobioreactor system in the Netherlands or in the desert of Australia would perform quite differently producing hydrogen energy equivalent to 3 PJ and 5.3 PJ, respectively, on yearly basis, under conditions of maximum photo-conversion efficiency .

A photobiological system covering 1 ha ground area is found to possess ten times greater energy production potential than that by energy crops occupying same expanse of area. Besides this, hydrogen produced by the photobioreactor system is clean energy that is easy to transport and can be used directly in fuel cells. Reith et al. (2003) have calculated the rough cost of hydrogen production in a photobiological system over a hundred hectare area to be 10–15 Euro/GJ.

5.4.2 Photobioreactor Designs for Growth of Microalgae and Production of Hydrogen

Bioreactors are required for large-scale and prolonged production of hydrogen . Light being an essential factor determining algal and cyanobacterial growth, the photobioreactors have to be transparent (Bishop and Premakumar 1992; Dutta et al. 2000). All photobioreactors require adequate access to light, which is preferably the sunlight but may use controlled artificial light. The local sunshine hours are important in this context. Inside the photobioreactor, there is the illuminated zone, where photosynthesis occurs and the dark zone, where hydrogen is produced.

The hydrogen yield of a photobioreactor is limited by light, and it tends to decrease at higher intensities due to oxygen evolution leading to inactivation of hydrogenase enzyme. As the light intensity is reduced and diffused, production of hydrogen improves. Green algae and cyanobacteria absorb red light in the wavelength 680 nm. Hence, special panels of red light are used in the bioreactors . There is circulation of the algae between the illuminated and the dark zone of the photobioreactor at regular intervals, depending upon the reactor design. Growth of the algae and biological hydrogen generation are largely influenced by light source as well as gas liquid hydrodynamics effects (Ernst et al. 1979).

A photobioreactor is designed based on the following requisitions:

-

(i)

It should have an enclosed system to ensure proper collection of the produced hydrogen.

-

(ii)

There should be maximum surface area for efficient light capture required both for the growth of the algae and for hydrogen production .

-

(iii)

The reactor should have provision for easy sterilization.

-

(iv)

Surface to volume ratio of the reactor should be large.

The photobioreactors (PBRs) are generally categorised into three types: the vertical column type, tubular type and the flat-panel photobioreactor .

5.4.3 Vertical Column Reactor (Airlift Loop Reactor and Bubble Column)

These have columns made of transparent high-grade glass having a surrounding water jacket to regulate temperature and light. On the top as well as at the bottom, there is a port for the medium and inlet/outlet for gases (like Ar and H2). Inoculum of desired microbes is added through septum to minimise chances of contamination (Lambert et al. 1979; Rawson 1985). In bubble columns, internal irradiance is increased at sunset and sunrise due to the bubbles. There are seasonal variations in biomass over the year showing peak during summer (Lambert et al. 1979; Rawson 1985). It is important to determine the dimensions of the vertical columns that depend on wind speed and strength of the glass or thermoplastics used in the reactor body. Generally, a diameter of 0.2 m and height of 4 m are considered suitable.

5.4.4 Flat-Panel Photobioreactor

Flat-panel PBR is made of a SS frame and three polycarbonate panels (Weissman and Benemann 1977). The reactor has two units, the front one of which has the culture . Required temperature of the culture is maintained by circulating water through a temperature-controlled water bath.

The source of artificial light is generally from tungsten-halogen lamps (500 W) with average light intensity of 175 W/m2 or from red light emitting diodes (LEDs) put at one end of the reactor. Circulation of the gas is brought out using a pump and pressure is regulated by a pressure valve. Water vapours formed are condensed using a condenser to prevent their entry into the gas circulating system. Prior to use the reactor and the culture medium are autoclaved (Tao et al. 2007).

5.4.5 Tubular Photobioreactors

Tubular PBRs are made of long (10–100 m) transparent tubes (3–6 cm dia), into which the liquid culture is introduced using mechanical or airlift pumps (Molina et al. 2001). The tubes are placed horizontally, vertically or in a fence-like structure. The tubes may be straight or with U-shaped bends, coiled or parallel with multiple connections. Different designs influence the light regime by changing the photon flux density that falls upon the surface of the reactor (Tredici and Zittelli 1998).

Another special type of tubular PBR is the Tredici PBR made of flexible tubular plastic tubes filled with water and has an internal gas exchange system (Tredici et al. 1998). A corrugated plastic roofing sheet houses the tubes and keeps them in straight position. Inclination of the PBR at an angle facilitates free rise of gas bubbles, and a footer with compressed air line allows supply of air at the bottom of the reactor into selected tubes. A degasser at the top allows containment of the fluid displaced during aeration. In between, there are tubes that are not gassed to allow the return of the fluid, which helps in recirculation by airlift. Cooling of the system is through water spraying . The mass transfer characteristics of the tubular photobioreactor depend upon the shape of the reactor and type of mixing used (Ugwu et al. 2002). Different types of hydrogen photobioreactors and their salient features are briefly included in Table 5.2.

5.4.6 Approaches for Enhanced and Prolonged Hydrogen Production

One important method for increasing hydrogen production that has emerged in the last decade is by sulphur deprivation of the medium (Melis et al. 2000). Sulphur deprivation leads to selective and partial inactivation of the photosystem II of the algae, which induces anaerobiosis and hydrogenase expression. Hydrogen photo production through this technique has been demonstrated in Chlamydomonas reinhardtii for several days (Ghirardi et al. 2000).

Optimisation of various physicochemical parameters is also found effective in increasing hydrogen production. It is possible to increase hydrogen yield by manipulating various physicochemical conditions. Using appropriate combination in anoxic gaseous mixture in the bioreactor is found to increase hydrogen production many folds. Methane in headspace helps in scavenging the oxygen produced during photosynthesis and CH4:Ar (11:2 v/v) results in up to eight times more yield as compared to Ar being used as an anoxic sparging gas in the headspace for Lyngbya perelegans (Anjana and Kaushik 2014) and 65 % increase in hydrogen when CO2:N2 (1:1 v/v) were used for Anabaena N7363 (Laurinavichene et al. 2008).

Another approach for increasing hydrogen production involves cell immobilisation in some suitable matrix, which is found to be very useful both for unicellular and filamentous algae and cyanobacteria (Kosourov and Seibert 2009; Anjana and Kaushik 2014). Cell immobilisation offers protection to various enzymes mediating metabolic activities against stress factors and the cells can be used for much longer period.

5.5 Coupling Biological H2 Production with Wastewater Treatment Process

For making commercial application of biological hydrogen production a cost-effective reality, Benemann (2000) proposed that wastewater treatment and hydrogen production by microalgae should be integrated . Biosorption of toxic pollutants like heavy metals and dyes using algae and cyanobacteria has been extensively studied. However, there is a need to systematically study the potential of integrating hydrogen production potential and pollutant bioremoval capacity of algae in combination.

An integrated system of sustainable hydrogen production and textile wastewater treatment technique was developed at lab scale using cyanobacterial biomass of Nostoc linckia by the authors (Kaushik et al. 2011). The cyanobacterium produced hydrogen for 3–4 weeks in a photobioreactor at sustained rates, and the spent biomass was then successfully used for biosorption of some toxic dyes (Reactive Red 198 and Crystal Violet) and heavy metals (chromium and cobalt) from simulated textile effluent in dynamic mode. Spent biomass from the hydrogen bioreactors taken out at different stages of reactor operation was successfully used for removal of desired metals and dyes from wastewater in packed bed biosorption columns (Mona et al. 2013).

In this context, exploitation of cyanobacteria isolated from polluted industrial sites may prove useful. Nostoc linckia isolated from within textile mill sites was reported to produce hydrogen at higher rate even in the presence of dyes and metals (Mona et al. 2011). Several strains of microalgae and cyanobacteria isolated from industrial sites were explored for hydrogen production and pollutant tolerance (Mona and Kaushik 2014). There is a need to look for more such strains for the dual purpose by developing energy self-dependent wastewater treatment techniques .

5.6 Implications of Biohydrogen in Climate Change Mitigation

Capability of algae and cyanobacteria to sequester carbon dioxide during photosynthesis , reduce GHG emissions and produce clean energy in the form of hydrogen is quite attractive. Carbon dioxide, the most important greenhouse gas produced during combustion of fuels, has become a cause of global concern, and the concept of carbon credits has emerged as a result of rising awareness about reducing these emissions. In the Kyoto Protocol, an international agreement was signed by more than 170 countries, and the market mechanisms were evolved through Marrakesh Accords that followed (Hoppe-Seyler 1987).

Farming of algae has come up as an easy and promising GHG reduction technology since the algae can consume tons of CO2 for growth, produce hydrogen, thus reduce harmful greenhouse gases and earn carbon credit. The merits of CO2 sequestration using algae lie in the fact that there is no need for high-purity CO2 gas for cultivation and growth of the algae and, therefore, it is possible to feed the CO2 containing flue gas to the photobioreactor directly and it is a renewable process. Algae have a very wide range of temperature tolerance (<0–70 °C) for their growth and, therefore, have a wide application range. An acre of algae consumes about 60 tons of CO2 in a year (Singh et al. 2014). This suggests that using algae for energy production can go a long way in reducing emissions and the problem of global warming.

5.7 Conclusions and Future Prospects

Hydrogen production by cyanobacteria and microalgae is poised to be a useful, clean and sustainable process that would develop as a commercially usable technology in the years to come. Hydrogen can be used as a substitute for conventional fuel, may be used in fuel cells to generate electricity and can also be utilised for hydrogenation in food and chemical industries.

These photoautotrophic microorganisms are easy to grow with simple nutrient requirements; do not compete with crop plants that need to be grown in fertile lands; can sequester carbon dioxide and grow in the presence of flue gases, withstand high temperatures; and can also help in efficient bioremoval of various pollutants from wastewaters. All these features put them at an advantage over other organisms producing hydrogen.

Different designs of photobioreactors have been developed to achieve sustained hydrogen production, and enhanced hydrogen production rates have been achieved by optimising various physicochemical conditions and immobilisation of the algae in some suitable matrix. However, there is a need to reduce the cost of such algal hydrogen reactors and make the process more efficient so that all their microculture benefits are put to maximum use. Small-cell size and low-cell biomass levels in microalgal cultures often become limiting. Hence, there is a need to achieve high cell densities for various microalgal species.

Though the biological systems have relatively lower conversion efficiencies , their energy requirements are less, and the initial investment costs are quite low. The best aspect of the biological hydrogen production system is that it is produced from water that is abundantly available on the earth. To be economically competitive with various other methods of hydrogen production, intensive research is needed to integrate various benefits of these organisms, including flue gas utilisation for CO2 sequestration, wastewater treatment and biomass production along with hydrogen production. From an environmental point of view, systems of microalgae and cyanobacterial cultures should be explored to capture CO2 from industrial emissions consuming the nutrients present in the wastewaters and simultaneously produce hydrogen. From an engineering point of view, the costs associated with various energy intensive processes like harvesting and dewatering need to be reduced.

References

Adams MWW, Stiefel EI (1998) Biological hydrogen production: not so elementary. Science 282(5395):1842–1843

Alalayah WM, Alhamed YA, Al-Zahrani A, Edris G (2014) Experimental investigation parameters of hydrogen production by algae Chlorella Vulgaris. International conference on Chemical, Environment & Biological Sciences (CEBS-2014) Sept. 17–18, 2014 Kuala Lumpur (Malaysia) doi:10.1074/jbc.M111.302125 http://dx.doi.org/10.15242/IICBE.C914010

Anjana K, Kaushik A (2014) Enhanced hydrogen production by immobilized cyanobacterium Lyngbya perelegans under varying anaerobic conditions. Biomass Bioenergy 63:54–57

Arik T, Gunduz U, Yucel M, Turker L, Sediroglu V, Eroglu I (1996) Photoproduction of hydrogen by Rhodobacter sphaeroides O.U.001. In: Proceedings of the 11th world hydrogen energy conference, Stuttgart, Germany, 3:2417–2424

Asada Y, Kawamura S (1984) Hydrogen evolution by Microcystis aeruginosa in darkness. Agric Biol Chem 48:2595–2596

Benemann JR (1997) Feasibility analysis of photobiological hydrogen production. Int J Hydrog Energy 22:979–987

Benemann JR (2000) Hydrogen production by microalgae. J Appl Phycol 12:291–300

Berggren G, Adamska A, Lambertz C, Simmons TR, Esselborn J, Atta A, Gambarelli S, Mouesca JM, Reijerse E, Lubitz W, Happe T, Artero V, Fontecave M (2013) Biomimetic assembly and activation of [FeFe]-hydrogenases. Nature 499:66–69

Bingham AS, Smith PR, Swartz JR (2012) Evolution of an [FeFe] hydrogenase with decreased oxygen sensitivity. Int J Hydrog Energy 37:2965–2976

Bishop PE, Premakumar R (1992) Alternative nitrogen fixation systems. In: Stacey G, Burris RH, Evans HJ (eds) Biological nitrogen fixation. Chapman & Hall, New York, pp 736–762

Boison G, Bothe H, Hansel A, Lindblad P (1999) Evidence against a common use of the diaphorase subunits by the bidirectional hydrogenase and by the respiratory complex I in cyanobacteria. FEMS Microbiol Lett 174:159–165

Bolton JR (1996) Solar photoproduction of hydrogen. Sol Energy 57:37–50

Borodin VB, Tsygankov AA, Rao KK, Hall DO (2000) Hydrogen production by Anabaena variabilis PK84 under simulated outdoor conditions. Biotechnol Bioeng 69:478–485

Burgdorf T, Buhrke T, van-der Linden E, Jones A, Albracht S, Friedrich B (2005) [NiFe]-hydrogenases of ralstonia eutropha H16: modular enzymes for oxygen-tolerant biological hydrogen oxidation. J Mol Microbiol Biotechnol 10:181–196

Cardoso VL, Romao BB, Felipe TM, Silva, Julia G, Santos, Fabiana RX, Batista, Ferreira JS (2014) Hydrogen production by dark fermentation. Chem Engg Trans 38:481–486

Carlozzi P, Ena A, Carnevale S (2005) Hydrodynamic alterations during cyanobacteria (Arthrospira platensis) growth from low to high biomass concentration inside tubular photobioreactors. Biotechnol Prog 21:416–422

Das D (2009) Advances in biohydrogen production processes: an approach towards commercialization. Int J Hydrog Energy 34:7349–7357

Das D, Veziroglu TN (2001) Hydrogen production by biological processes: a survey of literature. Int J Hydrog Energy 26:13–28

Das D, Veziroglu TN (2008) Advances in biological hydrogen production processes. Int J Hydrog Energy 33:6046–6057

Dutta M, Nikki G, Shah V (2000) Cyanobacterial hydrogen production. World J Microbiol Biotechnol 16:8–9

Ernst A, Kerfi W, Spiller H, Boger P (1979) External factors influencing light-induced H2 evolution by the blue-green algae, Nostoc muscorum. Z Naturforsch 34:820–825

Fedorov AS, Tsygankov AA, Rao KK, Hall DO (1998) Hydrogen photoproduction by Rhodobacter sphaeroides immobilised on polyurethane foam. Biotechnol Lett 20:1007–1009

Flores E, Herrero A (1994) Assimilatory nitrogen metabolism and its regulation. In: Bryant DA (ed) The molecular biology of cyanobacteria. Kluwer Academic Publishers, Dordrecht, pp 487–517

Fontecilla-Camps JC, Volbeda A, Cavazza C, Nicolet Y (2007) Structure/function relationships of [NiFe]- and [FeFe]-hydrogenases. Chem Rev 107(10):4273–4303

Ghirardi ML, Zhang L, Lee JW, Flynn T, Seibert M, Greenbaum E, Melis A (2000) Microalgae: a green source of renewable hydrogen. Trends Biotechnol 18:506–511

Goris T, Wait AF, Saggu M, Fritsch J, Heidary N, Stein M, Zebger I, Lendzian F, Armstrong FA, Friedrich B, Lenz O (2011) A unique iron-sulfur cluster is crucial for oxygen tolerance of a [NiFe]-hydrogenase. Nat Chem Biol 7:310–318

Greening C, Berney M, Hards K, Cook GM, Conrad R (2014) A soil actinobacterium scavenges atmospheric H2 using two membrane-associated, oxygen-dependent hydrogenases. Proc Acad Natl Sci USA 111(11):4257–4261

Guan Y, Deng M, Yu X, Zhang W (2004) Two stage photo-biological production of hydrogen by marine green alga Platymonas subcordiformis. Biochem Eng J 19:69–73

Hallenbeck PC, Benemann JR (2002) Biological hydrogen production: fundamentals and limiting processes. Int J Hydrog Energy 27:1185–1193

Hawkes FR, Dinsdale R, Hawkes DL, Hussy I (2002) Sustainable fermentative hydrogen production: challenges for process optimisation. Int J Hydrog Energy 27:1339–1347

Heyer H, Stal LJ, Krumbein WE (1989) Simultaneous heterolactic and acetate fermentation in the marine cyanobacterium Oscillatoria limosa incubated anaerobically in the dark. Arch Microbiol 151:558–564

Hinnemann B, Moses PG, Bonde J, Jørgensen KP, Nielsen JH, Horch S, Chorkendorff I, Nørskov JK (2005) Biomimetic hydrogen evolution: MoS2 nanoparticles as catalyst for hydrogen evolution. J Am Chem Soc 127:5308–5309

Hiromoto T, Warkentin E, Moll J, Ermler U, Shima S (2009) Iron-chromophore circular dichroism of [Fe]-hydrogenase: the conformational change required for H2 activation. Angew Chem Int 48:6457–6460

Hoekema S, Bijmans M, Janssen M, Tramper J, Wijffels RH (2002) A pneumatically agitated flat-panel photobioreactor with gas re-circulation: anaerobic photoheterotrophic cultivation of a purple non-sulfur bacterium. Int J Hydrog Energy 27:1331–1338

Hoppe-Seyler F (1987) Die Methanga¨rung der Essigsaure. Z Phys Chem 11:561–568

Jensen BB, Burris RH (1986) Nitrous oxide as a substrate and as a competitive inhibitor of nitrogenase. Biochemistry 25:1083–1088

Kaushik A, Anjana K (2011) Biohydrogen production by Lyngbya perelegans: influence of physico-chemical environment. Biomass Bioenergy 35(3):1041–1045

Kaushik A, Mona S, Kaushik CP (2011) Integrating photobiological hydrogen production with dye-metal bioremoval from simulated textile wastewater. Biores Technol 102:9957–9964

Kosourov NS, Seibert M (2009) Hydrogen photoproduction by nutrient-deprived Chlamydomonas reinhardtii cells immobilized within thin alginate films under aerobic and anaerobic conditions. Biotechnol Bioeng 102(1):50–58

Kosourov S, Seibert M, Ghirardi ML (2003) Effects of extracellular pH on the metabolic pathways in sulfur deprived, H2 producing Chlamydomonas reinhardtii cultures. Plant Cell Physiol 44(2):146–155

Lambert GR, Smith GD (1977) Hydrogen formation by marine blue-green algae. FEBS Lett 83:159–162

Lambert GR, Daday A, Smith GD (1979) Hydrogen evolution from immobilized cultures of cyanobacterium Anabena cylindrica. FEBS Lett 101:125–128

Laurinavichene TV, Kosourov SN, Ghirardi ML, Seibert M, Tsygankov AA (2008) Prolongation of H2 photoproduction by immobilized, sulfur-limited Chlamydomonas reinhardtii cultures. J Biotechnol 134:275–277

Levin DB, Lawrence P, Murray L (2004) Biohydrogen production: prospects and limitations to practical application. Int J Hydrog Energy 29:173–185

Liang J-H, Burris RH (1988) Interaction among nitrogen, nitrous oxide and acetylene as substrates and inhibitors of nitrogenase from Azotobacter vinelandii. Biochemistry 27:6726–6732

Liebgott PP, Leroux F, Burlat B, Dementin S, Baffert C, Lautier T, Fourmond V, Ceccaldi P, Cavazza C, Meynial-Salles I, Soucaille P, Fontecilla-Camps JC, Guigliarelli B, Bertrand P, Rousset M, Léger C (2010) Relating diffusion along the substrate tunnel and oxygen sensitivity in hydrogenase. Nat Chem Biol 6(1):63–70

Lindberg P, Lindblad P, Cournac L (2004) Gas exchange in the filamentous cyanobacterium Nostoc punctiforme Strain ATCC 29133 and its hydrogenase-deficient mutant Strain NHM5. Appl Environ Microbiol 70:2137–2145

Litcht R, Basin J, Hall DO (1997) The biotechnology of hydrogen production by Nostoc flagelliforme grown under chemostat conditions. Appl Microbiol Biotechnol 47:701–707

Lo YC, Chen CY, Lee CM, Chang JS (2010) Sequential dark–photo fermentation and autotrophic microalgal growth for high-yield and CO2-free biohydrogen production. Int J Hydrog Energy 35:10944–10953

Madden C, Vaughn MD, Díez-Pérez I, Brown KA, King PW, Gust D, Moore AL, Moore TA (2012) Catalytic turnover of [FeFe]-hydrogenase based on single-molecule imaging. J Am Chem Soc 134:1577–1582

Masepohl B, Schoelisch K, Goerlitz K, Kutzki C, Bohme H (1997) The heterocyst-specific fdxH gene product of the cyanobacterium Anabaena sp. PCC 7120 is important but not essential for nitrogen fixation. Mol Gen Genet 253:770–776

Melis A, Zhang L, Forestier M, Ghirardi ML, Seibert M (2000) Sustained photobiological hydrogen gas production upon reversible inactivation of oxygen evolution in the green alga Chlamydomonas reinhardtii. Plant Physiol 122:127–135

Miro’n AS, Go’mez AC, Camacho FG, Grima EM, Chisti Y (1999) Comparative evaluation of compact photobioreactors for large-scale monoculture of microalgae. J Biotechnol 70:249–270

Miura Y, Matsuoka S, Miyamoto K, Saltoh C (1992) Stably sustained hydrogen production with high molar yield through a combination of a marine green alga and a photosynthetic bacterium. Biosci Biotechnol Biochem 56:751–754

Miura Y, Akano T, Fukatsu K, Miyasaka H, Mizoguchi T, Yagi K, Maeda I, Ikuta Y, Matsumoto H (1995) Hydrogen production by photosynthetic microorganisms. Energy Convers Manag 36:903–906

Miyake J, Asada Y, Kawamura S (1989) Nitrogenase. In: Kitani O, Hall CW (eds) Biomass handbook. Gorton and Breach Science Publishers, New York, pp 362–370

Miyamoto K, Benemann JR (1988) Vertical tubular photobioreactor: design and operation. Biotechnol Lett 10:703–710

Moezelaar R, Bijvank SM, Stal LJ (1996) Fermentation and sulphur reduction in the mat-building cyanobacterium Microcoleus chtonoplastes. Appl Environ Microbiol 62:1752–1758

Molina E, Fernández J, Acién FG, Chisti Y (2001) Tubular photobioreactor design for algal cultures. J Biotechnol 92:113–131

Mona S, Kaushik A (2014) Screening metal-dye-tolerant photoautotrophic microbes from textile wastewaters for biohydrogen production. J Appl Phycol 27(3):1185–1194

Mona S, Kaushik A, Kaushik CP (2011) Hydrogen production and metal-dye bioremoval by a Nostoc linckia strain isolated from textile mill oxidation pond. Biores Technol 102:3200–3205

Mona S, Kaushik A, Kaushik CP (2013) Prolonged hydrogen production by Nostoc in photobioreactor and multi-stage use of the biological waste for column biosorption of some dyes and metals. Biomass Bioenergy 50:27–35

Orme-Johnson WH (1992) Nitrogenase structure: where to now? Science 257:1639–1640

Phlips EJ, Mitsui A (1983) Role of light intensity and temperature in the regulation of hydrogen photoproduction by the marine cyanobacterium Oscillatoria sp. Strain Miami BG7. Appl Environ Microbiol 45:1212–1220

Ramachandran R, Menon RK (1998) An overview of industrial uses of hydrogen. Int J Hydrog Energy 23:593–598

Rawson DM (1985) The effects of exogenous amino acids on growth and nitrogenase activity in the cyanobacterium Anabena cylindrica PCC 7122. J Gen Microbiol 134:2544–2549

Reith JH, Wijffels RH, Barten H (2003) Status and perspectives of biological methane and hydrogen production. Dutch Biological Hydrogen Foundation, The Netherlands ECN, The Hague

Ren N, Guo W, Liu B, Cao G, Ding J (2011) Biological hydrogen production by dark fermentation: challenges and prospects towards scaled-up production. Curr Opin Biotechnol 22:365–370

Rivera-Ortiz JM, Burris RH (1975) Interactions among substrates and inhibitors of nitrogenase. J Bacteriol 123:537–545

Shah V (2000) Exploitation of cyanobacteria for photohydrogen production and wastewater treatment. Ph.D. thesis, Sardar Patel University, VallabhVidyanogar, India

Shima S, Pilak O, Vogt S, Schick M, Stagni MS, Meyer-Klaucke W, Warkentin E, Thauer RK, Ermler U (2008) The crystal structure of [Fe]-hydrogenase reveals the geometry of the active site. Science 321(5888):572–575

Simpson FB, Burris RH (1984) A nitrogen pressure of 50 atmospheres does not prevent evolution of hydrogen by nitrogenase. Science 224(4653):1095–1097

Singh SK, Kishor K, Sundaram S (2014) Photosynthetic microorganisms mechanism for carbon concentration. Springer Cham Heidelberg, New York, pp 1–113

Sinha P, Pandey A (2011) An evaluative report and challenges for fermentative biohydrogen production. Int J Hydrog Energy 36:7460–7478

Smith PR, Bingham AS, Swartz JR (2012) Generation of hydrogen from NADPH using an [Fe Fe] hydrogenase. Int J Hydrog Energy 37:2977–2983

Stripp ST, Goldet G, Brandmayr C, Sanganas O, Vincent KA, Haumann M, Armstrong FA, Happe T (2009) How oxygen attacks [FeFe] hydrogenases from photosynthetic organisms. Proc Natl Acad Sci 106:17331–17336

Tamagnini P, Axelsson R, Lindberg P, Oxelfelt F, Wunschiers R, Lindblad P (2002) Hydrogenases and hydrogen metabolism of cyanobacteria. Microbiol Mol Biol Rev 66:1–20

Tao Y, Chen Y, Wu Y, He Y, Zhou Z (2007) High hydrogen yield from a two-step process of dark- and photo-fermentation of sucrose. Int J Hydrog Energy 32:200–206

Thiel T (1993) Characterization of genes for an alternative nitrogenase in the cyanobacterium Anabaena variabilis. J Bacteriol 175:6276–6286

Tiwari A, Pandey A (2012) Cyanobacterial hydrogen production – a step towards clean environment. Int J Hydrog Energy 37:139–150

Tredici MR, Zittelli GC (1998) Efficiency of sunlight utilization: tubular versus flat photobioreactors. Biotechnol Bioeng 57:187–197

Tredici MR, Zittelli GC, Benemann JR (1998) A tubular internal gas exchange photobioreactor for biological hydrogen production: preliminary cost analysis. In: Zaborsky O et al (eds) Bio hydrogen. Plenum Press, New York, pp 391–402

Tsygankov AA, Hirata Y, Miyake M, Asada Y, Miyake J (1994) Photobioreactor with photosynthetic bacteria immobilized on porous glass for hydrogen photoproduction. J Ferment Bioeng 77:575–578

Ugwu CU, Ogbonna JC, Tanaka H (2002) Improvement of mass transfer characteristics and productivities of inclined tubular photobioreactors by installation of internal static mixers. Appl Microbiol Biotechnol 58:600–607

Vignais PM, Billoud B (2007) Occurrence, classification, and biological function of hydrogenases: an overview. Chem Rev 107:4206–4272

Vignais PM, Billoud B, Meyer J (2001) Classification and phylogeny of hydrogenases. FEMS Microbiol Rev 25(4):455–501

Weissman JC, Benemann JR (1977) Hydrogen production by nitrogen starved cultures of Anabaena cylindrica. Appl Environ Microbiol 33:123–131

Wilson PW, Umbreit WW (1937) Mechanism of symbiotic nitrogen fixation. III. Hydrogen as a specific inhibitor. Arch Microbiol 8:440–457

Winkler M, Hemschemeier A, Gotor C, Melis A, Happe T (2002) [Fe]-hydrogenases in green algae: photo-fermentation and hydrogen evolution under sulfur deprivation. Int J Hydrog Energy 27:1431–1439

Yokoi H, Mori M, Hirose J, Hayashi S, Takasaki Y (1998) H2 production from starch by a mixed culture of Clostridium butyricum and Rhodobacter sp. M-19. Biotechnol Lett 20:895–899

Yoon JH, Sim SJ, Kim MS, Park TH (2002) High cell density culture of Anabaena variabilis using repeated injections of carbon dioxide for the production of hydrogen. Int J Hydrog Energy 27:1265–1270

Zhao X, Xing D, Liu B, Lu L, Zhao J, Ren N (2012) The effects of metal ions and L-cysteine on hydA gene expression and hydrogen production by Clostridium beijerinckii RZF-1108. Int J Hydrog Energy 37:1711–1717

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer India

About this chapter

Cite this chapter

Kaushik, A., Sharma, M. (2017). Exploiting Biohydrogen Pathways of Cyanobacteria and Green Algae: An Industrial Production Approach. In: Singh, A., Rathore, D. (eds) Biohydrogen Production: Sustainability of Current Technology and Future Perspective. Springer, New Delhi. https://doi.org/10.1007/978-81-322-3577-4_5

Download citation

DOI: https://doi.org/10.1007/978-81-322-3577-4_5

Published:

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-3575-0

Online ISBN: 978-81-322-3577-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)