Abstract

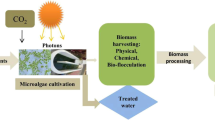

Microalgae are used as food, feed, and fodder and also used to produce a wide range of metabolites such as, proteins, carbohydrates, lipids, carotenoids, vitamins, fatty acids, sterols, etc. They are able to enhance the nutritional content of conventional food and feed preparations and hence positively affect humans and animal health including aquaculture animals. They also provide a key tool for phycoremediation of toxic metals and nanometal production. The use of microalgae in nanotechnology is a promising field of research with a green approach. The use of genetically modified algae for better production of different biotechnological compounds of interests is popular nowadays. Microalgal biomass production for sustainable biofuel production together with other high-value compounds in a cost-effective way is the major challenge of algal biotechnologists. Microalgal biotechnology is similar to conventional agriculture but has received quite a lot of attention over the last decades, because they can reach substantially higher productivities than traditional crops and can use the wastelands and the large marine ecosystem. As history has shown, research studies on microalgae have been numerous and varied, but they have not always resulted in commercial applications. The aim of this review is to summarize the commercial applications of microalgae.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

2.1 Introduction

Algae including cyanobacteria are the most primitive plants that appeared on the earth’s surface at least 3500 Ma ago. They are chlorophyll-bearing photosynthetic organisms which built up the oxygen in the atmosphere. The algae comprise one of the most diverse plant groups and constitute a species range of 40,000–10,000,000, with majority being the microalgae (Hawksworth and Mound 1991; Metting 1996). Traditionally, “algae” include the prokaryotic cyanobacteria and other eukaryotic members of Chlorophyta, Rhodophyta, Heterokontophyta, etc. Therefore, in general, algae include photosynthetic prokaryotic and eukaryotic organisms as well as the heterotrophic members. On the basis of molecular phylogeny, many of these groups are widely scattered on the “tree of life.” As a result, the term “algae” refers to a polyphyletic, artificial assemblage of organisms. But in recent terminology “algae” excludes cyanobacteria. They are described as “lower” plants that never have true stems, roots, and leaves, and they are normally capable of photosynthesis. Plant bodies are thalloid, and there are members with coccoid, capsoid, amoeboid, palmelloid, colonial, plasmodial, filamentous, and parenchymatous (tissue like) organizational levels. The size of algae ranges from tiny single-celled species to gigantic multicellular organisms (few micron to few meters). Algae of different sizes and shapes not only occupy all aquatic ecosystems but also occur in almost all other habitats. Algae are one of the earth’s most important natural resources that contribute to approximately 50 % of global photosynthetic activity. The first use of microalgae by humans dates back 2,000 years to the Chinese, who used Nostoc to survive during famine. However, microalgal biotechnology only really began to develop in the middle of the last century, and establishment of Spirulina production plant in Mexico can be considered as benchmark of microalgal biotechnology (Borowitzka 1999). Particularly during the past two or three decades, algal biotechnology grew steadily into an important global industry with a diversified field of applications, and more and more new entrepreneurs began to realize the potentiality of microalgae in biotechnological exploitation. Nowadays, about 107 t of microalgae are harvested each year by different industries for various purposes. Today’s commercial algal biotechnology is still a non-transgenic industry that basically produces food, feed, and feed additives, cosmetics, and pigments. Presently active researches are going on for the development of genetically modified algae and for biotechnological exploitation. Due to the marine and aquatic applications, algal biotechnology is sometimes also called blue biotechnology.

Commercial large-scale cultivation of microalgae started in the early 1960s in Japan with the culture of Chlorella by the company Nihon Chlorella (Taipei, Taiwan) (Borowitzka 1999; Iwamoto 2004). It was followed in the early 1970s by the establishment of an Arthrospira culturing and harvesting facility in Lake Texcoco by Sosa Texcoco S.A. (Mexico City, Mexico) (Borowitzka 1999). The first use of algae in aquaculture appeared in the 1970s (Pulz and Scheibenbogen 1998). By 1980, there were 46 large-scale factories in Asia producing more than 1,000 kg of microalgae (mainly Chlorella) per month. The commercial production of Dunaliella salina, as a source of β-carotene, became the third major microalgal industry when production facilities were established by Western Biotechnology (Hutt Lagoon, Australia) and Betatene in 1986 (Whyalla, Australia, now Cognis Nutrition and Health). These were soon followed by other commercial plants in Israel and the USA. Together with these, the large-scale production of cyanobacteria (blue-green algae) began in India at about the same time. More recently, several plants producing Haematococcus pluvialis as a source of astaxanthin have been established in the USA and India (Biotechnological and Environmental Applications of Microalgae [BEAM]). Thus, in a short period of about 30 years, the algal biotechnology industry has grown and diversified significantly. Nowadays, the microalgal biomass market produces about 5,000 t of dry matter/year and generates a turnover of approximately US$ 1.25 × 109/year.

The aim of this review is to focus on the latest status of multidisciplinary research in the area of algal biotechnology mainly related to industrial applications of algae.

2.2 Microalgae in Human and Animal Nutrition

The microalgal market as food is dominated by Chlorella and Spirulina (Becker 2004; Pulz and Gross 2004), mainly because of their high protein content and nutritive value. The biomass of these algae is marketed as tablets, capsules, and liquids (Table 2.1, Fig. 2.1). Microalgae can act as a nutritional supplement or represent a source of natural food colorants (Apt et al. 1996; Borowitzka 1999; Soletto et al. 2005). The commercial applications are dominated by four strains: Arthrospira, Chlorella, Dunaliella salina, and Aphanizomenon flos-aquae. Arthrospira is used in human nutrition because of its high protein content and its excellent nutritive value (Radmer 1996; Rangel-Yagui et al. 2004; Soletto et al. 2005; Desmorieux and Decaen 2005). In addition, this cyanobacterium has various possible health-promoting effects, like alleviation of hyperlipidemia, suppression of hypertension, protection against renal failure, growth promotion of intestinal Lactobacillus, suppression of elevated serum glucose level, etc. (Vílchez et al. 1997; Yamaguchi 1997; Liang et al. 2004).

The world’s largest producer of Arthrospira – the Hainan Simai Enterprising – is located in the Hainan province of China. This company has an annual production of 200 t of algal powder, which accounts for 25 % of the total national output and almost 10 % of the world output. Their Arthrospira-based products (tablets and powder) are distributed in over 20 countries around the world. Many other companies sell a wide variety of nutraceuticals made from this microalga. For example, the Myanmar Spirulina Factory (Yangon, Myanmar) sells tablets, chips, pasta, and liquid extract, and Cyanotech (a plant in Kona, Hawaii, USA) produces products ranging from pure powder to packaged bottles under the name Spirulina Pacifica.

For human consumption, Cognis Nutrition and Health, the world’s largest producer of this strain, offers Dunaliella powder as an ingredient of dietary supplements and functional foods. According to many research studies, used alone or in combination with other nutraceuticals and natural food products, A. flos-aquae promotes overall good health (Jensen et al. 2001; Pugh and Pasco 2001; Benedetti et al. 2004).

Many evaluations have shown the suitability of algal biomass as a feed supplement (Becker 2004). Mainly, the microalgae Spirulina and, to some extent, Chlorella are used in this domain for many types of animals: cats, dogs, aquarium fish, ornamental birds, horses, poultry, cows, and breeding bulls (Spolaore et al. 2006). All these members are able to enhance the nutritional content of conventional feed preparations, and hence, they positively affect the physiology of these animals. Even very small amount of microalgal biomass can positively affect the physiology of animals by improving the immune response, resulting in growth promotion, disease resistance, antiviral and antibacterial action, improved gut function, probiotic colonization stimulation, as well as by improved feed conversion, reproductive performance, and weight control (Harel and Clayton 2004).

The external appearance of the animals may also be improved, resulting in healthy skin and a lustrous coat, for both farming animals (poultry, cows, breeding bulls) and pets (cats, dogs, rabbits, ornamental fishes, and birds) (Certik and Shimizu 1999). Since feed corresponds to the most important exogenous factors influencing animal health and also the major expense in animal production, the use of alternative high-quality protein supplements replacing conventional protein sources is encouraged. In fact, 30 % of the current world algal production is sold for animal feed applications (Becker 2004).

2.3 Aquaculture Feed

From an economic perspective, the importance of using algae in aquaculture has grown over the years as it can be utilized as an unconventional source of protein alternative to the much used fish meal. Since 1940s, microalgae became more and more important as live feed in aquaculture (shellfish or fish farming). Microalgal feeds are currently used mainly for the culture of larvae and juvenile shell and finfish as well as for raising the zooplankton required for feeding of juvenile animals (Fig. 2.2) (Benemann 1992; Chen 2003). They are required for larval nutrition during a brief period, either for direct consumption in the case of mollusks and penaeid shrimp or indirectly as food for the live preys, mainly rotifers, copepods, and Artemia nauplii, which in turn are used for crustaceans and fish larvae feeding (Brown et al. 1997; Duerr et al. 1998; Muller-Feuga 2000). In 1999, the production of microalgae for aquaculture reached up to 1,000 t (62 % for mollusks, 21 % for shrimps, and 16 % for fish) for a global world aquaculture production of 43 × 106 t of plants and animals (Muller-Feuga 2000). The most frequently used microalgae in aquaculture are Chlorella, Tetraselmis, Isochrysis, Pavlova, Phaeodactylum, Chaetoceros, Nanno-chloropsis, Skeletonema, and Thalassiosira (Yamaguchi 1997; Borowitzka 1997; Apt and Behrens 1999; Muller-Feuga 2000). Microalgae contain essential nutrients which determine the quality, survival, growth, and resistance to disease of cultured species. To support a better balanced nutrition for animal growth, it is often advised to use mixed microalgae cultures, in order to have a good protein profile, adequate vitamin content, and high polyunsaturated fatty acids, mainly EPA, AA, and DHA, recognized as essential for survival and growth during the early stages of life of many marine animals (Volkman et al. 1989). One of the beneficial effects attributed to adding algae is an increase in ingestion rates of food by marine fish larvae which enhance growth and survival as well as the quality of the fry (Naas et al. 1992). Aquatic species, such as salmonids (salmon and trout), shrimp, lobster, sea bream, and koi carp, under intensive rearing conditions need a supplementation of carotenoids pigments in their diet to attain their characteristic muscle color. In addition to pigmenting effects, carotenoids, namely, astaxanthin and canthaxanthin, exert benefits on animal health and welfare, promote larval development, and provide growth and performance. A positive metabolic role of carotenoids in the nutrition of larval fish and survival of young fry was also discussed by Reitain et al. (1997), Planas and Cunha (1999), and Lazo et al. (2000).

The present group reported the use of nonconventional algal feed with improved results in growth, carcass composition, and pigmentation of goldfish (Fig. 2.3) (Khatoon et al. 2010a), rohu (Khatoon et al. 2010b), and prawn (Khatoon et al. 2009).

2.4 Chemicals and Pharmaceuticals

A large number of studies have demonstrated the benefits and potential of algae as a source for biologically active (Table 2.2; Fig. 2.4) compounds (Hirayasu et al. 2005; Bansemir et al. 2006) and their antioxidant activity (Yuan et al. 2005).

There are at least 30,000 known species of microalgae among which only a handful is currently of commercial significance (Table 2.3). Algae provide a largely untapped reservoir of novel and valuable compounds. Current exploitation mainly aims to utilize fatty acids, pigments, vitamins, and other bioactive compounds. In the 1980s, the use of microalgae as a source of common and fine chemicals was the beginning of a new trend (de la Noue and de Pauw 1988).

Higher plants and animals lack the requisite enzymes to synthesize polyunsaturated fatty acids (PUFAs) of more than 18 carbons (Lee 2001; Sancho et al. 1999). Thus, they have to get them from their food. Currently, algal docosahexaenoic acid (22:6 ω3, 6, 9, 12, 15, 18) produced from the dinoflagellate member, Cryptheco-dinium cohnii, is the only commercially available ω3-polyunsaturated fatty acid producer (Walker et al. 2005), but others like γ-linolenic acid from Spirulina, arachidonic acid from Porphyridium, and eicosapentaenoic acid from Nannochloropsis, Phaeodactylum, or Nitzschia have already demonstrated as potential for industrial production of their high-value compounds (Spolaore et al. 2006). Other fatty acids or lipids are isolated from Phaeodactylum tricornutum as a food additive; from Odontella aurita for pharmaceuticals, cosmetics, and baby food; and from Isochrysis galbana for animal nutrition (Pulz and Gross 2004).

Polysaccharides are isolated from Chlorella spp. for dietary supplements (Walker et al. 2005) and from Porphyridium cruentum for pharmaceuticals, cosmetics, and nutrition (Pulz and Gross 2004). Extracts from the cyanobacterium Lyngbya majuscula are used as immune modulators in pharmaceuticals and nutrition management (Pulz and Gross 2004). Components of algae are frequently used in cosmetics as thickening agents, water-binding agents, and antioxidants.

Cosmetics companies claim benefits on the skin or health in general from contents like carrageenan, other algal polysaccharides, algal proteins or lipids, vitamin A, vitamin B1, iron, phosphorus, sodium, copper, magnesium, calcium, or other elements; some companies promise that algal extracts inhibit oxidative degeneration of collagen and hyaluronic acid and that they have antiaging properties. From a scientific point of view, many of the promised effects have to be judged as not scientifically proven and unsubstantiated. Typical species that are used for cosmetics are Spirulina platensis, Nannochloropsis oculata, Chlorella vulgaris, and Dunaliella salina.

From a commercial point of view, the carotenoids and the phycobiliproteins seem to be the most important. In addition to their role in coloration, carotenoids act as provitamin A and as biological antioxidants, protecting cells and tissues from the damaging effects of free radicals and singlet oxygen. Therefore, carotenoids are utilized in pharmaceuticals, health food, and dietary supplements, cosmetics, and as a feed additive. The carotenoids including β-carotene are produced in large amounts from the halophilic green microalga Dunaliella salina. To a lesser extent, carotenoids are isolated from Dunaliella bardawil (Walker et al. 2005). The most prominent xanthophyll is astaxanthin, which is extracted in large scale from the green microalga Haematococcus pluvialis (Pulz and Gross 2004). Further utilized xanthophylls are lutein, canthaxanthin, and zeaxanthin. Phycobiliproteins consist of proteins with covalently bound phycobilins, which are tetrapyrrole structures with pyrrole rings that are laid out linearly. For efficient photosynthesis, phycobiliproteins capture light energy at certain wavelengths and pass it on to the chlorophylls. The phycobiliproteins-phycoerythrin and phycocyanin are isolated from Spirulina and Porphyridium and are utilized for health food, pharmaceuticals, and cosmetics (Becker 2004; Pulz and Gross 2004; Spolaore et al. 2006). Phycobiliproteins are not only used as pigments but have also been shown to have health-promoting properties. They are also used in research laboratories as labels for biomolecules (Spolaore et al. 2006). The first and most important application of phycocyanin is as food pigment, replacing current synthetic pigments (Becker 2004). Dainippon Ink & Chemicals (Sakura) has developed a product called “Lina blue” which is used in chewing gum, ice sherberts, popsicles, candies, soft drinks, dairy products, and wasabi. They also sell another form of this pigment for natural cosmetics like lipstick and eyeliners (Yamaguchi 1997; Viskari and Colyer 2003). Their global market was estimated at more than US$50 million in 1997.

2.5 Biofertilizers

Biofertilizer contains microorganisms which promote the adequate supply of nutrients to the host plants, ensure their proper development of growth and regulation in their physiology, and protect plants from soil-borne diseases to a certain degree. The need for the use of biofertilizer has arisen, primarily for two reasons: first, because increase in the use of fertilizers leads to increased crop productivity, and second, because increased usage of chemical fertilizer leads to damage in soil texture and raises other environmental problems. Therefore, the use of biofertilizer is both economical and environment friendly. Among the microalgae, cyanobacteria have drawn much attention as prospective and rich sources of biologically active constituents that can be used as biofertilizers (Fish and Codd 1994; Schlegel et al. 1999). In early times, several authors like De (1939) and Gupta and Shukla (1967) studied the algal influence on growth, yield, and protein content of rice plants and showed that presoaking rice seeds with BGA cultures or extracts enhances germination, promotes the growth of roots and shoots, and increases the weight and protein content of the grain. Beneficial effects of cyanobacterial inoculation were reported, not only for rice but for other crops as well such as wheat, soybean, oat, tomato, radish, cotton, sugarcane, maize, chili, bean, muskmelon, and lettuce (Venkataraman 1972; Rodgers et al. 1979; Arif et al. 1995; Thajuddin and Subramanian 2005; Saadatnia and Riahi 2009; Maqubela et al. 2008; Karthikeyan et al. 2007). Efficient nitrogen-fixing blue green algal strains are utilized for rice production. Several reasons have been proposed for beneficial effects of cyanobacteria on the growth of different plants. The capacity for enhanced biosynthesis of growth-promoting substances such as auxins, amino acids, sugars, and vitamins (vitamin B12, folic acid, nicotinic acid, and pantothenic acid) by algalization was reported by Misra and Kaushik (1989b) that can enhance the growth of plant. Cyanobacteria play an important role in fixing atmospheric nitrogen due to the presence of heterocysts and buildup of soil fertility, consequently increasing rice growth and yield as a natural biofertilizer (Song et al. 2005). Additionally, cyanobacteria excrete complex organic carbon compounds that bind to the soil particles and improve soil aggregation, hence improve soil structure, soil permeability, and water-holding capacity of soil (Kaushik 2007). Cyanobacteria are capable of abating various kinds of pollutants and have advantages as potential biodegrading organisms (Subramanian and Uma 1996). Blue-green algal inoculation with composite cultures was found to be more effective than single culture inoculation. Both free-living andas well as symbiotic cyanobacteria (blue-green algae) have been harnessed in rice cultivation in India. A composite culture of BGA having heterocystous Nostoc, Anabaena, Aulosira, etc. is given as primary inoculum in trays, polythene-lined pots, and later mass multiplied in the field for application as soil-based flakes to the rice-growing field at the rate of 10 kg/ha. At many sites where algal inoculation was used for three to four consecutive cropping seasons, the inoculated algae establish well and the effect persisted over subsequent rice crop. The blue-green algal inoculum may be produced by several methods, viz., in tubs, galvanized trays, and small pits and also in field conditions.

However, the large-scale production is advisable under field condition which is easily adopted by farmers. Nowadays, liquid fertilizers are in use. There are many advantages of liquid biofertilizer over the conventional carrier-based biofertilizers. As they have greater potentials to fight with native population; cost saving on carrier material, pulverization, neutralization, sterilization, packing, and transport; easy and quick quality control protocols; better survival on seeds and soil; and very much easy to use by the farmer. The increasing demand for the biofertilizers and the awareness among farmers and planters in the use of biofertilizers have paved way for the fertilizer manufactures and new entrepreneurs to get into biofertilizer production. A number of biofertilizer production units have been started recently particularly in the southern states of our country (Fig. 2.5).

The application of BGA biofertilizer in rice popularly known as “algalization” helps in creating an environment-friendly agroecosystem that ensures economic viability in paddy cultivation while saving energy-intensive inputs. The technology can be easily adopted by farmers for multiplication at their own level.

2.6 Biofuel

Algae, particularly green unicellular microalgae, have been proposed for a long time as a potential renewable fuel source (Benemann and Oswald 1996; Oswald and Golueke 1960; Brennan and Owende 2010). Microalgae have long been recognized as potentially good sources for biofuel production because of their high oil content and rapid biomass production (Table 2.4). In recent years, the use of microalgae as an alternative biodiesel feedstock has gained renewed interest from researchers, entrepreneurs, and the general public. As with plant-derived feedstocks (Table 2.5), algal feedstocks can be utilized directly or processed into liquid fuels and gas by a variety of biochemical conversion or thermochemical conversion processes (Amin 2009; Brennan et al. 2010). Dried algal biomass may be used to generate energy by direct combustion (Kadam 2002), but this is probably the least attractive use for algal biomass. In addition, hydrogen can be produced from algae by bio-photolysis (Melis 2002). One of the attractions of microalgae as a biofuel feedstock is that they can be effectively grown in conditions which require minimal freshwater input unlike many plant-based biofuel crops and utilize land which is otherwise nonproductive to plant crops, thus making the process potentially sustainable with regard to preserving freshwater resources. There has therefore been significant interest in the growth of microalgae for biofuels under saline conditions (Rodolfi et al. 2009; de la Noue et al. 1992).

The rise in world oil prices led to a sharp increase in biofuel production around the world. High oil species of microalgae cultured in growth-optimized conditions of photobioreactors have the potential to yield 5,000–15,000 gal of microalgal oil per acre per year. The most significant distinguishing characteristic of algal oil is its yield and hence its biodiesel yield. According to some estimates, the yield (per acre) of oil from algae is over 200 times the yield from the best-performing plant/vegetable oils (Becker 1994). They can complete an entire growing cycle every few days. Microalgae are very efficient solar energy converters, and they can produce a great variety of metabolites (Chaumont 2005). A major current problem for the commercial viability of biodiesel production from microalgae is the low selling price of biodiesel. Biodiesel from microalgal oil is similar in properties to the standard biodiesel (Huang et al. 2010). The algae that are used in biodiesel production are usually aquatic unicellular green algae. These types of algae are a photosynthetic eukaryote characterized by high growth rates and high population densities. Under good conditions, green algae can double its biomass in less than 24 h. Additionally, green algae can have huge lipid contents, frequently over 50 %. This high yield, high density biomass is ideal for intensive agriculture and may be an excellent source for biodiesel production (Fig. 2.6).

Algal oil contains saturated and monounsaturated fatty acids. The fatty acids were determined in the algal oil in the following proportions: 36 % oleic (18:1), 15 % palmitic (16:0), 11 % stearic (18:0), 8.4 % iso-linoleic (17:0), and 7.4 % linoleic (18:2). The high proportion of saturated and monounsaturated fatty acids in this alga is considered optimal from a fuel quality standpoint, in that fuel polymerization during combustion would be substantially less than what would occur with polyunsaturated fatty acid-derived fuel (Chaumont 2005; Gao et al. 2010). After oil extraction from algae, the remaining biomass fraction can be used as a high-protein feed for livestock (Schneider 2006). This gives further value to the process and reduces waste. Algae biomass can play an important role in solving the problem between the production of food and that of biofuels in the near future (Chisti 2007).

2.7 Bioremediation

Organic pollutants and heavy metals are considered to be a serious environmental problem for human health. Lead, cadmium, and mercury are the most frequent water- and soil-polluting heavy metals. Industrial processes, including plastic manufacturing, electroplating, Ni-Cd battery production, mining, and smelting industries, continuously release substantial amounts of heavy metals into the environment. The contamination of soils and aquatic systems by toxic metals and organic pollutants has recently increased due to anthropogenic activity. Phycoremediation is the use of microalgae for the removal or biotransformation of pollutants, including nutrients and xenobiotics from wastewater and CO2 from waste air with concomitant biomass propagation (Olguín et al. 2003, 2004; Mulbry et al. 2008; Moreno-Garrido 2008). Phytoremediation technologies are becoming recognized as cost-effective methods for remediating sites contaminated with toxic metals at a fraction of the cost of conventional technologies, such as soil replacement, solidification, and washing strategies (Chaney et al. 1997; Flathman and Lanza 1998; Munoz and Guieysse 2008). Recent studies have shown that microalgae can indeed support the aerobic degradation of various hazardous contaminants (Munoz et al. 2008; Safonova et al. 2004). Since few decades the potential of microalgae in metal biosorption process has been studied extensively due to their ubiquitous occurrence in nature (Gekeler et al. 1998). Many algal genera are found to have capabilities to accumulate heavy metals, thereby reducing their toxic effects (Huang et al. 1990; Kuyucak and Volesky 1990; Schiewer and Volesky 2000; Satıroğlu et al. 2002; Arica et al. 2004; Selatnia et al. 2004). There has been a growing interest in using algae for biomonitoring eutrophication, organic pollutants, and inorganic pollutants. There are numerous processes of treating water, industrial effluents, and solid wastes using microalgae aerobically as well as anaerobically. Many algae synthesize phytochelatins and metallothioneins that can form complexes with heavy metals and translocate them into vacuoles (Oswald and Golueke 1960). The growth of microalgae is indicative of water pollution since they respond typically to many ions and toxins. Blue-green algae are ideally suited to play a dual role of treating wastewater in the process of effective utilization of different constituents essential for growth leading to enhanced biomass production. Secondly, the role of microalgae is the accumulation and conversion of wastewater nutrients to biomass and lipids. Microalgae are efficient in the removal of nutrients from wastewater. Unicellular algae have shown great efficiency in the uptake of nutrients and have been found to show dominance in oxidation ponds (Pittman et al. 2010). Chlorella, Ankistrodesmus, and Scenedesmus species have been already successfully used for the treatment of olive oil, mill wastewaters, and paper industry wastewaters (Abeliovich 1986; Narro 1987; Tilzer 1983). The algae have many features that make them ideal candidates for the selective removal and concentration of heavy metals, which include high tolerance to heavy metals, ability to grow both autotrophically and heterotrophically, large surface area/volume ratios, phototaxy, phytochelatin expression, and potential for genetic manipulation (Cai et al. 1995). Mei et al. (2006) suggested that Platymonas subcordiformis, a marine green microalgae, had a very strontium uptake capacity, although high concentrations of strontium cause oxidative damage, as evidenced by the increase in lipid peroxidation in the algal cell samples and the decrease in growth rate and chlorophyll contents. Caulerpa racemosa var. cylindracea as a low-cost biomaterial could be used for the removal of boron species from aqueous solution (Bursali et al. 2009). Dunaliella salina, a green microalgae, have high tendency for zinc accumulation followed by copper and cobalt, the lowest tendency was for cadmium, and this may be due to the importance of zinc as hydrogen transferring in photosynthesis (Liu et al. 2002). The present group also reported several algae like Oscillatoria, Anabaena, Rhizoclonium, and Chara that accumulated lead, cadmium, and chromium from wastewater (Chakraborty et al. 2011). Arsenic-resistant genera recorded from the contaminated area were Oscillatoria princeps, Oscillatoria limosa, Anabaena sp., and Phormidium laminosum (Bhattacharya 2011).

The biomass resulting from the treatment of wastewaters can be applied for different aims, including the use as additives for animal feed, the extraction of added value products like carotenoids or other biomolecules, or the production of biofuel. The accumulation of heavy metals by algae provides an advantage for phytoremediation over other methods which are more costly and not environmental friendly. Therefore, there is a need to improve the possibilities of accumulation of heavy metals in algae.

2.8 Phyconanotechnology

Nanotechnology and biotechnology are the two most fascinating technologies of the twenty-first century, and unification of these two results in the development of nanobiotechnology which deals with the synthesis of nanostructures using biological organisms. Reliable and eco-friendly synthesis of metallic nanoparticles is an important goal of nanotechnology. Nanomaterials are gaining so much of interest due to their unique optical, chemical, photoelectrochemical, and electronic properties which are absent in the bulk material because of the quantum-size confinement imposed by nano-size (Kumar et al. 2003).

Nanoparticles are synthesized by a number of chemical and physical procedures. Several manufacturing techniques are in use that employs atomistic, molecular, chemical, and particulate processing in a vacuum or a liquid medium (Daniel and Astruc 2004). But most of these techniques are costly, as well as inefficient in materials and energy use. Therefore, second-generation nanotechnology is focused toward clean technologies that minimize possible environmental and human health risks associated with manufacture and fabrication; there is an ever-growing demand for the development of clean, nontoxic, and environmentally benign synthesis procedures. Green synthesis of nanoparticles is a significant process for the production of precious metals such as gold, silver, platinum, and palladium due to their various applications in material sciences. A number of microorganisms and higher plants have already been found to be competent to serve as eco-friendly nanofactories for the synthesis of gold nanoparticles (GNP) and silver nanoparticles (SNP). Cyanobacteria and microalgae having the reducing power are already designated as potential bioreagents for nontoxic nanoparticle synthesis. They are effective in nanoparticle synthesis, as they grow rapidly in eco-friendly atmosphere producing large amount of biomass in a very short time and can accumulate high quantity of metals followed by subsequent reduction. Their production costs are also negligible (Nair and Pradeep 2002; Lin et al. 2005; Lengke et al. 2006a, b). The properties of nanogold change with varying sizes and shapes of the particles and are suitable for applying in diverse fields, starting from decorative coating paints to different fields of science like electronics, catalysis, pollution control, cancer therapy, drug delivery, biomedical assay, biosensor, bioimaging, etc. (Xu et al. 2004; Huang et al. 2006; Hauck et al. 2008). The “green” route for nanoparticle (NP) synthesis is therefore of great interest for economic prospects and applications. The green chemistry synthetic route can be employed for both GNP and SNP syntheses. Moreover, nanoproducts, synthesized from algae, are expected to be biocompatible, therefore minimize environment and human health risks. The use of SNPs and GNPs in drug delivery systems might be the future thrust in the field of medicine. Further research is needed to screen the most suitable algal taxa for large-scale controlled synthesis of gold and silver nanoparticles.

The synthesis of nanogold was first reported in 1995 in Chlorella vulgaris (Ting et al. 1995) and afterwards, Lengke et al. (2006a, b) reported it in Plectonema boryanum. In the same year, the present group reported cyanobacteria- and algae-based systemic process of gold and silver nanoparticle synthesis and published a series of papers on biosynthesis of gold nanoparticle by cyanobacteria (such as Lyngbya majuscula and Spirulina subsalsa), green algae (Rhizoclonium hieroglyphicum and R. riparium), Spirogyra and diatoms (Nitzschia obtusa and Navicula minima) (Chakraborty et al. 2006, 2009; Nayak et al. 2006a; Roychoudhury and Pal 2014). Screening for different algae as bioreagent of GNP production and biosynthesis of gold nanorods by Nostoc ellipsosporum was done by Parial et al. (2012); Parial and Pal (2014) and of silver nanoparticles by Roychoudhury et al. (2014) (Fig. 2.7).

2.9 Genetic Engineering and GM Algae

Algal genome research is needed to get a new level of efficiency in biotechnological applications. Algal species are targets of genetic engineering to improve productivity, broaden environmental tolerance limits, or increase pest or pathogen resistance. DNA sequences are introduced into the algal cells with the goal of modifying biochemical pathways. Among the biotechnologically important biomolecules, some are with high value but required in small quantity like medicinal compounds, but some are low-value product and are required in large amount like algal biodiesel. Therefore, the aim of the algal biotechnologists is always to reduce the cost of the required products. Sometimes the cost of microalgal biomass production becomes so high that ultimately the production cost of the required compound becomes exorbitant therefore unusable. For this reason, biotechnologists tried to manipulate genetically many commercially viable microalgae to get suitable combinations of genes in the required strain for successful low-cost production or to get the required compounds – called as molecular farming. But till date, most of the results related to GM algae production are laboratory confined. The propagation of GM algae is in question as algae are the lower group of plants which frequently propagate through vegetative propagation like binary fission resulting in the uncertain distribution of the altered genetic combination.

There are several microalgal genome projects (Table 2.6), of which the most advanced projects are those for the red alga Cyanidioschyzon merolae, the diatom Thalassiosira pseudonana, and the three green algae Chlamydomonas reinhardtii, Volvox carteri, and Ostreococcus tauri. Cyanobacteria are preferable source materials in plant genetic engineering studies due to genetic homology of chloroplasts in eukaryotic plants, prokaryotic genome organization, short generation time, and fast growth rate. Most studies have therefore been made on commonly called as ‘green yeast’. Chlamydomonas reinhardtii. Apart from Chlamydomonas, cyanobacterial strains of Synechocystis sp., Synechococcus sp., and Anabaena variabilis. Synechocystis sp. and Synechococcus sp. are naturally transformable with exogenous DNA. The green alga Haematococcus pluvialis naturally accumulates large amounts of astaxanthin when exposed to unfavorable growth conditions. The gene coding for the enzyme that converts ß-carotene into astaxanthin has been identified from H. pluvialis and cloned into Synechococcus. After the transformation, both zeaxanthin and the attractive compound astaxanthin were produced (Sahu et al. 2012). Tremendous success has been achieved in establishing functional association between plant seedling/calli/protoplast cultures and N2-fixing cyanobacterial filaments through the application of basic tissue culture technique. Nostoc, Anabaena, and Plectonema are among the few N2-fixing cyanobacterial species successfully practiced in these studies. The use of transgenic cyanobacterium to control insect is a new technology. Various combinations of genes were introduced in Anabaena which showed toxicity against mosquito larvae. Further studies of genetic engineered algae and bioremediation have been performed on the green algae on Chlamydomonas reinhardtii. In the last few years, successful genetic transformations of ~25 algal species have been demonstrated; most of these were achieved by nuclear transformation. Ten species of green algae have been transformed; stable transformation have been shown for seven of them, one of which was the unicellular model organism Chlamydomonas reinhardtii (Debuchy et al. 1989; Kindle et al. 1989); and transient transformation was demonstrated in the other three. All of these green algae are unicellular species except for Volvox carteri, for which stable transformation has been shown (Schiedlmeier et al. 1994). Many species of cyanobacteria, e.g., Spirulina, Anabaena, or Synechocystis, can be transformed by electroporation or conjugation (Koksharova and Wolk 2002). Algae have also demonstrated suitability for synthesizing vaccines. In this regard, stable expression of the hepatitis B surface antigen gene has been shown in Dunaliella salina (Sayre et al. 2001; Geng et al. 2003; Sun et al. 2003). A further project aims at the application of antigen producing algae in the fish industry. It is intended to use an alga-produced antigen to vaccinate fish against the infectious hematopoietic necrosis virus (IHNV) which causes an infectious disease that kills 30 % of the US trout population each year; vaccination is realized simply by feeding the fish with the algae (Banicki 2004).

For further biotechnological exploitation of algae, several researchers are screening extracts from a multiplicity of algal species in order to find effective organic components like secondary metabolites (Kopecky et al. 2000; Lubián et al. 2000), antifungal or antibacterial biomolecules (Piccardi et al. 2000), algal toxins (Piccardi et al. 2000), or active pharmaceutical ingredients as drug candidates (Skulberg 2000).

2.10 Cultivation

Algae have an important role to play in the current world economy with an approximate turnover of US$5 billion per year. The biotechnological basis for the most efficient production of microalgal biomass is a key issue for the future impact of these organisms. The large-scale cultivation of microalgae and the practical use of its biomass as a source of certain constituents were probably first considered seriously in Germany during World War II. This initial research was taken up by a group of scientists at the Carnegie Institution of Washington, who summarized their experiences in the classic report Algal culture: from laboratory to pilot plant (Burlew 1953). In the course of time, the continuous cultivation of algae under partially or fully controlled conditions has become an important development, with various economic possibilities. Techniques for the cultivation of algae on a large scale and processes for their utilization have been successfully developed in several countries (Table 2.7), and an attempt in this direction is worthwhile in some of the developing countries (Benemann and Oswald 1996; Venkataraman and Becker 1985).

Most algal species are obligate phototrophs and thus require light for their growth. The requirement for light, coupled with the high extinction coefficient of chlorophyll in these organisms, has necessitated the design and development of novel systems for large-scale growth. A few algal species are capable of heterotrophic growth, and for these organisms, conventional fermentation technology can be used for large-scale cultivation (Fig. 2.8).

2.11 Phototrophic Systems

Commercial growth of photosynthetic algae has been achieved in different ways: (1) open cultivation using natural sunlight (Oswald and Golueke 1960), (2) closed cultivation using natural sunlight, and (3) closed cultivation using artificial illumination. Each system has advantages and disadvantages, and the choice of system depends on the degree of parameter control needed to produce the desired product and on the value of the product. A common limitation to all these systems is the need to supply light to the culture, making it advantageous to maximize the surface-to-volume ratio of the culture. Many configurations of open cultures using natural sunlight have been proposed and constructed (Oswald 1988; Chaumont 1993; Pushparaj et al. 1997). These systems are generally large, open ponds or raceways, and the principle advantage of these configurations is that the light energy is free (Pulz and Scheibenbogen 1998). However, this advantage is more than offset by several significant disadvantages. In open systems, it is very difficult to prevent contamination of the algal culture by other organism (i.e., algae and other microorganisms). This problem has been addressed by culturing algae that require or tolerate unique growth conditions that would exclude contaminating organisms. Open cultures attain cell densities leading to the need to process large quantities of water to harvest the algae. Outdoor phototrophic growth systems are also subject to daily and seasonal variations in light intensity and temperature, making it difficult to control or reproduce specific culture conditions. Nevertheless, for specific algal products, this technology has proven very successful, producing many thousands of tons of dried biomass per year (Lee 1997). This is especially true for Spirulina, which is extensively cultured in the USA, Mexico, Thailand, and China (Metting 1996; Li and Qi 1997; Vonshak 1997). Several different closed systems using natural sunlight have been described (Richmond et al. 1993; Qiang and Richmond 1994; Molina Grima et al. 1995; Spektorova et al. 1997). In these systems, the algae are enclosed in a transparent material (either glass or plastic) and the vessels placed outdoors for illumination. The closure of the vessels minimizes contamination by other algal species. Closed, outdoor systems are still subject to variations in light intensity and temperature that make cultivation reproducibility problematic. In addition, a major problem with closed systems is the removal of oxygen from the culture and the provision of adequate temperature control. Although both of these issues can be resolved, the cost of doing so can more than offset the cost advantage of using natural sunlight. As with the outdoor systems, numerous designs have been constructed for the indoor, closed culture of algae using electric lights for illumination (Ratchford and Fallowfield 1992; Wohlgeschaffen et al. 1992; Iqbal et al. 1993; Lee and Palsson 1994). These vessels are often referred to as photobioreactors, and in principle, they are similar to conventional fermentor, the major difference being that they are driven by light rather than by an organic carbon source. These vessels provide the ability to control and optimize culture parameters, and, coupled with the closure that they provide, photobioreactors are suitable for culturing many different types of algae (Ratchford and Fallowfield 1992).

2.12 Heterotrophic Systems

The most significant advance in closed culture systems is the adaptation of fermentation technology that allows for the heterotrophic growth of microalgae and eliminates the problem of light limitation (Barclay et al. 1994; Kyle 1996; Chen 1997). A significant number of microalgae are capable of heterotrophic growth and potentially suitable for growth in fermentors (Droop 1974; Gladue and Maxey 1994). The basic principle of fermentor growth is to provide highly controlled optimal growth conditions to maximize productivity. In these, the biomass levels are at least tenfold higher than those achieved by photosynthesis-based culture systems (Radmer and Parker 1994). The high biomass levels also greatly decrease the volume of water that must be processed during harvesting. The effectiveness of large-scale cultures and the production of high biomass levels can make the cost of fermentative growth an order of magnitude less expensive than photobioreactors (Radmer and Parker 1994). Larger-scale production of the dinoflagellate Crypthecodinium by fermentative growth for the production of the polyunsaturated fatty acid DHA has been under way for several years (Kyle 1996). Production of Crypthecodinium begins with a certified seed stock that was cryopreserved under liquid nitrogen conditions to maintain genetic stability. Crypthecodinium has been reported to produce approximately 30 % of their dry weight as the total fatty acid (Kyle et al. 1992), with DHA making up close to 50 % of the total fatty acid (Behrens and Kyle 1996). Chlorella is also extensively grown in large quantities by fermentation techniques. Production levels in Japan are estimated to exceed 500 T per year, accounting for 50 % of the country’s total production (Lee 1997). Plans have also been announced in Korea to begin the production of heterotrophically grown Chlorella at a level exceeding 1,000 T per year (Lee 1997). Milking of microalgae is the most advanced technique for biotechnologically important compounds (Hejazi and Wijffels 2004).

These systems have to be evaluated in their various configuration concepts regarding their potential productivity and economic feasibility. The most important and most obvious differences in microalgal production systems are the exposure of the microalgal culture to the environment.

2.13 Conclusions

More basic research needs to be performed before algal biotechnology would reach a capacity to compete with other systems. But since many physiological, morphological, biochemical, or molecular characteristics of algae are quite different from higher plants or animals, algae can meet several requirements that other systems cannot sufficiently accomplish. This is one reason why algal systems gain more and more influence in the production of substances of economic, industrial, and pharmaceutical importance. However, microalgae are still not a well-studied group from a biotechnological point of view. The genetic improvement of algal strains is also a present challenge. The use of transgenic microalgae for commercial applications has not yet been reported but holds a significant promise. Among the algal species that are believed to exist, only a few thousand strains are kept in collections, a few hundred are investigated for chemical content, and just a handful are cultivated in industrial quantities (i.e., in tons per year). The combination of the exceptional nutritional value of microalgae with coloring and therapeutical properties, associated with an increase demand of natural products, makes microalgae worth exploring for utilization in the future in feed, food, cosmetic, and pharmaceutical industries, with recognized advantages comparing with the traditional ingredients.

References

Abeliovich A (1986) Algae in wastewater oxidation ponds. In: Richmond A (ed) Handbook of microalgal mass culture. CRC Press, Boca Raton, pp 331–338

Amin S (2009) Review on biofuel oil and gas production processes from microalgae. Energy Convers Manag 50:1834–1840

Apt KE, Kroth- Pancic PG, Crossman AR (1996) Stable nuclear transformation of the diatom Phaeodactylum iricornutum. Mol Gen Genet 252:572–579

Apt KE, Behrens PW (1999) Commercial developments in microalgal biotechnology. J Phycol 35:215–226

Arica MY, Bayramoglu G, Yılmaz M, Genc O, Bektas S (2004) Biosorption of Hg2+, Cd2+ and Zn2+ by Ca-alginate and immobilized wood rotting fungus Funalia trogii. J Hazard Mater 109:191–199

Arif M, Gupta R, Joshi MC (1995) Studies on the use of cyanobacteria as biofertilizer for vegetable cultivation in hydroponic system, in Schirmacher oasis region, East Antarctica Eleventh Indian expedition to Antarctica scientific rep Department of ocean development. Tech Publ 9:243–246

Banicki JJ (2004) An alga a day keeps the doctor away. Engineered algae as a new means to vaccinate fish. Twine Line 26:1–5

Bansemir A, Blume M, Schröder S, Lindequist U (2006) Screening of cultivated seaweeds for antibacterial activity against fish pathogenic bacteria. Aquaculture 252:79–84

Barclay WR, Meager KM, Abril JR (1994) Heterotrophic production of long chain omega-3 fatty acids utilizing algae and algae-like microorganisms. J Appl Phycol 6:123–129

Becker EW (1994) In: Baddiley J et al (eds) Microalgae: biotechnology and microbiology. Cambridge University Press, Cambridge, NY

Becker W (2004) Microalgae in human and animal nutrition. In: Richmond A (ed) Handbook of microalgal culture. Blackwell, Oxford, pp 312–351

Behrens PW, Kyle DJ (1996) Microalgae as a source of fatty acids. J Food Lipids 3:259–272

Benedetti S, Benvenuti F, Pagliarani S, Francogli S, Scoglio S, Canestrari F (2004) Antioxidant properties of a novel phycocyanin extract from the blue-green alga Aphanizomenon flos-aquae. Life Sci 75:2353–2362

Benemann JR (1992) Microalgae aquaculture feeds. J Appl Phycol 4:233–245

Benemann JR, Oswald WJ (1996) Systems and economic analysis of microalgae ponds for conversion of CO2 to biomass. Final report, U.S. Department of Energy.http://www.osti.gov”www.osti.govbridge”servlets”purl”493389”FXQyZ2”webviewable”493389.pdf

Bhattacharya P, Pal R (2011) Response of cyanobacteria to arsenic toxicity. J Appl Phycol 23:293–299

Borowitzka MA (1997) Microalgae for aquaculture: opportunities and constraints. J Appl Phycol 9:393–401

Borowitzka MA (1999) Commercial production of microalgae: ponds, tanks, tubes and fermenters. J Biotechnol 70:313–321

Brennan L, Owende P (2010) Biofuels from microalgae – a review of technologies for production, processing, and extractions of biofuels and co-products. Renew Sust Energy Rev 14:557–577

Brown MR, Jeffrey SW, Volkman JK, Dunstan GA (1997) Nutritional properties of microalgae for mariculture. Aquaculture 151:315–331

Burlew JS (1953) Algal culture from laboratory to pilot plant. Carnegie Institution of Washington, Washington, DC, 357

Bursali EA, Cavas L, Seki Y, Bozkurt SS, Yurdakoc M (2009) Sorption of boron by invasive marine seaweed: Caulerpa racemosa var. cylindracea. Chem Eng J 150:385

Cai XH, Logan T, Gustafson T, Traina S, Sayre RT (1995) Application of eukaryotic algae for removal of heavy metal from water. Mol Mar Biol Biotechnol 4:338

Certik M, Shimizu S (1999) Biosynthesis and regulation of microbial polyunsaturated fatty acid production. J Biosci Bioeng 87:1–14

Chakraborty N, Pal R, Ramaswami A, Nayak D, Lahiri S (2006) Diatom: a potential bio-accumulator of gold. J Radioanal Nucl Ch 270:645–649

Chakraborty N, Banerjee A, Lahiri S, Panda A, Ghosh AN, Pal R (2009) Biorecovery of gold using cyanobacteria and an eukaryotic alga with special reference to nanogold formation – a novel phenomenon. J Appl Phycol 21:145–152

Chakraborty N, Banerjee A, Pal R (2011) Biomonitoring of lead, cadmium and chromium in environmental water from Kolkata, North and South 24-Parganas using algae as bioreagent. J Algal Biomass Utln 2(3):27–41

Chaney R, Malik M, Li YM, Brown SL, Brewer EP, Angle JS, Baker AJM (1997) Phytoremediation of soil metals. Curr Opin Biotechnol 8:279–284

Chaumont D (1993) Biotechnology of algal biomass production: a review of systems for outdoor mass culture. J Appl Phycol 5:593–604

Chaumont D (2005) Biotechnology of algal biomass production: a review of systems for outdoor mass culture. J Appl Phycol 5:593–604

Chen F (1997) High cell density culture of microalgae in heterotrophic growth. Trends Biotech 14:421–426

Chen YC (2003) Immobilized Isochrysis galbana (Haptophyta) for long-term storage and applications for feed and water quality control in clam (Meretrix lusoria) cultures. J Appl Phyco 15:439–444

Chisti Y (2007) Biodiesel from microalgae. Biotechnol Adv 25:294–306

Daniel MC, Astruc D (2004) Gold nanoparticles: assembly, supramolecular chemistry, quantum-size-related properties, and applications toward biology, catalysis, and nanotechnology. Chem Rev 104:293–346

De PK (1939) The role of blue-green algae in nitrogen fixation in rice fields. Proc R Soc Lond 127:121–139

De la Noue J, de Pauw N (1988) The potential of microalgal biotechnology – a review of production and uses of microalgae. Biotechnol Adv 6:725–770

De la Noue J, Laliberte G, Proulx D (1992) Algae and waste water. J Appl Phycol 4:247–254

Debuchy R, Purton S, Rochaix JD (1989) The argininosuccinate lyase gene of Chlamydomonas reinhardtii: an important tool for nuclear transformation and for correlating the genetic and molecular maps of the ARG7 locus. EMBO J 8:2803–2809

Desmorieux H, Decaen N (2005) Convective drying of Spirulina in thin layer. J Food Eng 66:497–503

Droop MR (1974) Heterotrophy of carbon. In: Steward WDP (ed) Algal physiology and biochemistry. University of California Press, Berkeley, pp 530–559

Duerr EO, Molnar A, Sato V (1998) Cultured microalgae as aquaculture feeds. J Mar Biotechnol 75:65–70

Fish SA, Codd GA (1994) Bioactive compound production by thermophilic and thermotolerant cyanobacteria (blue green algae). World J Microb Biotechnol 10:338–341

Flathman PE, Lanza GR (1998) Phytoremediation: current views on an emerging green technology. J Soil Contam 7:415–432

Gao C, Zhai Y, Ding Y, Wu Q (2010) Application of sweet sorghum for biodiesel production by heterotrophic microalga Chlorella protothecoides. Appl Energy 87:756–761

Gekeler W, Grill E, Winnnacker EL, Zenk MH (1988) Algae sequester heavy metals via synthesis of phytochelatin complexes. Arch Microbiol 150:197–202

Geng D, Wang Y, Wang P, Li W, Sun Y (2003) Stable expression of hepatitis B surface antigen gene in Dunaliella salina (Chlorophyta). J Appl Phycol 15:451–456

Gladue RM, Maxey JE (1994) Microalgal feeds for aquaculture. J Appl Phycol 6:131–141

Gupta AB, Shukla AC (1967) Studies on the nature of algal growth promoting substances and their influence on growth, yield, and protein content of rice plants. J Sci Technol 5:162–163

Hallmann A (2007) Algal transgenics and biotechnology. Transgenic Plant J 1:81–98

Harel M, Clayton D (2004) Feed formulation for terrestrial and aquatic animals. US Patent 20070082008 (WO/2004/080196)

Hauck TS, Jennings TL, Yatsenko T, Kumaradas JC, Chan WCW (2008) Enhancing the toxicity of cancer chemotherapeutics with gold nanorod hyperthermia. Adv Mater 20:3832–3838

Hawksworth DI, Mound LA (1991) Diversity data-bases: the crucial significance of collections. In: Hawksworth DL (ed) The biodiversity of microorganisms and insects. CAB International, Wallingford, pp 17–29

Hejazi MA, Wijffels RH (2004) Milking of microalgae. Trends Biotechnol 22:189–194

Hirayasu H, Yoshikawa Y, Tsuzuki S (2005) Sulfated polysaccharides derived from dietary seaweeds increase the esterase activity of a lymphocyte tryptase, granzyme A. J Nutr Sci Vitaminol (Tokyo) 51:475–477

Huang CP, Huang CP, Morehart AL (1990) The removal of Cu (II) from dilute aqueous solutions by Saccharomyces cerevisiae. Water Res 24:433–439

Huang X, EL-sayed IH, Qian W, EL-sayed MA (2006) Cancer cell imaging and photothermal therapy in the near-infrared region by using gold nanorods. J Am Chem Soc 128:2115–2120

Huang G, Chen F, Wei D, Zhang X, Chen G (2010) Biodiesel production by microalgal biotechnology. Appl Energy 87:38–46

Iqbal M, Grey D, Stepan-Sarkissian F, Fowler MW (1993) A flat sided photobioreactor for culturing microalgae. Aquacult Eng 12:183–190

Iwamoto H (2004) Industrial production of microalgal cell-mass and secondary products—major industrial species—Chlorella. In: Richmond A (ed) Handbook of microalgal culture. Blackwell, Oxford, pp 255–263

Jensen GS, Ginsberg DI, Drapeau MS (2001) Blue green algae as an immuno-enhancer and biomodulator. J Am Nutraceutical Assoc 3:24–30

Kadam KL (2002) Environmental implications of power generation via coal microalgae cofiring. Energy 27:905–922

Karthikeyan N, Prasanna R, Nain L, Kaushik BD (2007) Evaluating the potential of plant growth promoting cyanobacteria as inoculants for wheat. Eur J Soil Biol 43:23–30

Kaushik BD (2007) Cyanobacterial biofertilizer technology. In: Kannaiyan S, Kumar K, Govindarajan K (eds) Biofertilizers technology. Scientific Publishers, Jodhpur, pp 53–59

Khatoon N, Chattopadhyay P, Mukhopadhyay A, Mukhopadhyay M, Pal R (2009) Algal diet in prawn aquaculture. Fishing Chimes 28:44–47

Khatoon N, Chaudhuri A, Sen Roy S, Kundu N, Mukherjee S, Majumdar D, Homechaudhuri S, Pal R (2010a) Algae as feed supplement in fish nutrition. J Bot Soc 64(2):85–93

Khatoon N, Sengupta P, Homechaudhuri S, Pal R (2010b) Evaluation of algae based feed in goldfish (Carassius auratus) nutrition. Proc Zool Soc 63(2):109–114

Kindle KL, Schnell RA, Fernandez E, Lefebvre PA (1989) Stable nuclear transformation of Chlamydomonas using the Chlamydomonas gene for nitrate reductase. J Cell Sci 109:2589–2601

Koksharova OA, Wolk CP (2002) Genetic tools for cyanobacteria. Appl Microbiol Biotechnol 58:123–137

Kopecky J, Schoefs B, Loest K, Stys D, Pulz O (2000) Microalgae as a source for secondary carotenoid production: a screening study. Arch Hydrobiol Suppl 133:153–168

Kumar A, Mandal S, Selvakannan PR, Parischa R, Mandale AB, Sastry M (2003) Investigation into the interaction between surface-bound alkylamines and gold nanoparticles. Langmuir 19:6277–6282

Kuyucak N, Volesky B (1990) Biosorption by algal biomass. In: Volesky B (ed) Biosorption of heavy metals. CRC Press, Boca Raton, pp 173–198

Kyle (1996) Production and use of a single cell oil which is highly enriched in docosahexaenoic acid. Lipid Technol 2:106–112

Kyle DJ, Sicotte VJ, Singer JJ, Reeb SE (1992) Bioproduction of docosahexaenoic acid DHA by microalgae. In: Kyle DJ, Ratledge C (eds) Industrial applications of single cell oils. American Oil Chemists Society, Champaign, pp 287–300

Lazo P, Dinis MT, Holt J, Faulk C, Arnold C (2000) Co-feeding microparticulate diets with algae: toward eliminating the need of zooplankton at first feeding in larval red drum (Sciaenops ocellatus). Aquaculture 188:339–351

Lee YK (1997) Commercial production of microalgae in the Asia-Pacific rim. J Appl Phycol 9:403–411

Lee YK (2001) Microalgal mass culture systems and methods: their limitation and potential. J Appl Phycol 13:307–315

Lee CG, Palsson BO (1994) High-density algal photobioreactors using light-emitting diodes. Biotechnol Bioeng 44:1161–1167

Lengke M, Fleet ME, Southam G (2006a) Morphology of gold nanoparticles synthesized by filamentous cyanobacteria from gold(I)-thiosulfate and gold(III)-chloride complexes. Langmuir 22:2780–2787

Lengke MF, Ravel B, Fleet ME, Wanger G, Gordon RA, Southam G (2006b) Mechanisms of gold bioaccumulation by filamentous cyanobacteria from gold (III)- chloride complex. Environ Sci Technol 40:6304–6309

Li DM, Qi YZ (1997) Spirulina industry in China: present status and future prospects. J Appl Phycol 9:25–28

Liang S, Xueming L, Chen F, Chen Z (2004) Current microalgal health food R&D activities in China. Hydrobiologia 512:45–48

Lin Z, Wu J, Xue R, Yang Y (2005) Spectroscopic characterization of Au3þbiosorption by waste biomass of Saccharomyces cerevisiae. Spectrochim Acta A 61:761–765

Liu Y, Yang S, Tan S, Lin Y, Tay J (2002) Aerobic granules: a novel zinc biosorbent. Lett Appl Microbiol 35:548–551

Lubián LM, Montero O, Moreno-Garrido I, Huertas IE, Sobrino C, González del Valle M, Parés G (2000) Nannochloropsis (Eustigmatophyceae) as source of commercially valuable pigments. J Appl Phycol 12:249–255

Maqubela MP, Mnkeni PNS, Malamissa O, Pardo MT, Acqui LPD (2008) Nostoc cyanobacterial inoculation in South African agricultural soils enhances soil structure, fertility and maize growth. Plant Soil 315:79–92

Mei L, Xitao X, Renhao X, Zhili L (2006) Chin J Oceanol Limnol 24:154

Melis A (2002) Green alga hydrogen production: progress, challenges and prospects. Int J Hydrogen Energy 27:1217–1228

Metting FB (1996) Biodiversity and application of microalgae. J Indust Microbiol 17:477–489

Misra S, Kaushik BD (1989) Growth promoting substances of cyanobacteria II detection of amino acids, sugars and auxins. Proc Indian Sci Acad B55:499–504

Moreno-Garrido I (2008) Microalgae immobilization: current techniques and uses – review. Biores Technol 99:3949–3964

Molina Grima E, Sanchez Perez JA, Garcia Camacho F, Fernandez Sevilla JM, Acien Fernandez FG, Urda Cardona J (1995) Biomass and icosapentaenoic acid productivities from an outdoor batch culture of Phaeodactylum tricornutum UTEX 640 in an airlift tubular photobioreactor. Appl Microbiol Biotechnol 42:658–663

Mulbry W, Kondrad S, Buyer J (2008) Treatment of dairy and swine manure effluents using freshwater algae: fatty acid content and composition of algal biomass at different manure loading rates. J Appl Phycol 20:1079–1085

Muller-Feuga A (2000) The role of microalgae in aquaculture: situation and trends. J

Munoz R, Guieysse B (2008) Algal–bacterial processes for the treatment of hazardous contaminants: a review. Water Res 40:2799–2815

Naas KE, Naess T, Harboe T (1992) Enhanced 1st feeding of Halibut Larvae (Hippoglossus hippoglossus L) in green water. Aquaculture 105:143–156

Nair B, Pradeep T (2002) Coalescence of nanoclusters and formation of submicron crystallites assisted by Lactobacillus strains. Cryst Growth Des 2:293–298

Narro ML (1987) Petrolium toxicity and oxidation of the aromatic hydrocarbons. In: Fay P, Van Baalen C (eds) The cyanobacteria. Elsevier, Amsterdam, pp 491–511

Nayak D, Nag M, Banerjee S, Pal R, Laskar S, Lahiri S (2006) Preconcentration of 198Au in a green alga, Rhizoclonium. J Radioanal Nucl Ch 268:337–340

Olguín EJ, Mercado G, Perez T (2003) Annual productivity of Spirulina (Arthrospira) and nutrient removal in a pig wastewater recycle process under tropical conditions. J Appl Phycol 15:249–257

Oswald WJ (1988) Large scale algal culture systems (engineering aspects). In: Borowitzka MA, Borowitzka LJ (eds) Microalgal biotechnology. Cambridge University Press, Cambridge, pp 357–410

Oswald WJ, Golueke C (1960) Biological transformation of solar energy. Adv Appl Microbiol 2:223–262

Parial D, Pal R (2014) Green synthesis of gold nanoparticles using cyanobacteria and their characterization. Indian J Appl Res 4:69–72

Parial D, Patra HK, Roychoudhury P, Dasgupta AK, Pal R (2012) Gold nanorod production by cyanobacteria – a green chemistry approach. J Appl Phycol 24:55–60

Piccardi R, Frosini A, Tredici MR, Margheri MC (2000) Bioactivity in free-living and symbiotic cyanobacteria of the genus Nostoc. J Appl Phycol 12:543–547

Planas M, Cunha I (1999) Larviculture of marine fish: problems and perspectives. Aquaculture 177:171–190

Pugh N, Pasco DS (2001) Characterization of human monocyte activation by a water soluble preparation of Aphanizomenon flos-aquae. Phytomedicine 8:445–453

Pulz O, Gross W (2004) Valuable products from biotechnology of microalgae. Appl Microbiol Biotechnol 65:635–648

Pulz O, Scheibenbogen K (1998) Photobioreactors: design and performance with respect to light energy input. Adv Biochem Eng Biotechnol 59:123–151

Pushparaj B, Pelosi E, Tredici M, Pinzani E, Materassi R (1997) An integrated system for outdoor production of microalgae and cyanobacteria. J Appl Phycol 9:113–119

Qiang H, Richmond A (1994) Optimizing the population density in Isochrysis galbana grown outdoors in a glass column photobioreactor. J Appl Phycol 6:391–396

Radmer RJ (1996) Algal diversity and commercial algal products. Bioscience 46:263–270

Radmer RJ, Parker BC (1994) Commercial applications of algae: opportunities and constraints. J Appl Phycol 6:93–98

Rangel-Yagui CO, Godoy Danesi ED, Carvalho JCM, Sato S (2004) Chlorophyll production from Spirulina platensis: cultivation with urea addition by fed-batch process. Biores Technol 92:133–141

Ratchford IAJ, Fallowfield HJ (1992) Performance of a flat figure, air-lift reactor for the growth of high biomass algal cultures. J Appl Phycol 4:1–9

Ratledge C (2004) Fatty acid biosynthesis in microorganisms being used for single cell oil production. Biochimie 86:807–815

Reitain K, Rainuzzo JR, Oie G, Olsen Y (1997) A review of the nutritional effects of algae in marine fish larvae. Aquaculture 155:207–221

Richmond A, Boussiba S, Vonshak A, Kopel R (1993) A new tubular reactor for mass production of microalgae outdoors. J Appl Phycol 5:327–332

Rodgers GA, Bergman B, Henriksson E, Urdis M (1979) Utilization of blue-green as biofertilizers. Plant Soil 52:99–107

Rodolfi L, Zittelli GC, Bassi N, Padovani G, Biondi N, Bonini G, Tredici MR (2009) Microalgae for oil: strain selection, induction of lipid synthesis and outdoor mass cultivation in a low cost photobioreactor. Biotechnol Bioeng 102:100–112

Roychoudhury P, Pal R (2014) Spirogyra submaxima-a green alga for nanogold production. J Algal Biomass Utln 5(1):15–19

Saadatnia H, Riahi H (2009) Cyanobacteria from paddy-fields in Iran as a biofertilizer in rice plants. Plant Soil Environ 55(5):207–212

Safonova E, Kvitko KV, Ienkevitch MI, Surgko LF, Afti IA, Reisser W (2004) Biotreatment of industrial waste water by selected algae – bacterial consortia. Eng Life Sci 4:347–353

Sahu D, Priyadarshani I, Rath B (2012) Cyanobacteria – as potential biofertilizer CIBTech. J Microbio 1:20–26

Sancho MEM, Castillo JMJ, El Yousfi F (1999) Photoautotrophic consumption of phosphorus by Scenedesmus obliquus in a continuous culture influence of light intensity. Process Biochem 34(8):811–818

Satıroğlu N, Yalcınkaya Y, Denizli A, Arica MY, Bektas S, Genc O (2002) Application of NaOH treated Polyporus versicolor for removal of divalent ions of Group IIB elements from synthetic wastewater. Process Biochem 38:65–72

Sayre RT, Wagner RE, Sirporanadulsil S, Farias C (2001) Transgenic algae for delivery antigens to animals. Int. Patent Number W.O. 01/98335 A2

Schiedlmeier B, Schmitt R, Müller W, Kirk MM, Gruber H, Mages W, Kirk DL (1994) Nuclear transformation of Volvox carteri. Proc Natl Acad Sci U S A 91:5080–5084

Schiewer S, Volesky B (2000) In: Lovley DR (ed) Environmental microbe–metal interactions. ASM Press, Washington, DC, pp 329–362

Schlegel I, Doan NT, de Chazal N, Smith GD (1999) Antibiotic activity of new cyanobacterial isolates from Australia and Asia against green algae and cyanobacteria. J Appl Phycol 10:471–479

Schneider D (2006) Grow your own: would the wide spread adoption of biomass-derived transportation fuels really help the environment. Am Sci 94:408–409

Selatnia A, Boukazoula A, Kechid N, Bakhti MZ, Chergui A, Kerchich Y (2004) Biosorption of lead (II) from aqueous solution by a bacterial dead Streptomyces rimosus biomass. Biochem Eng J 19:127–135

Skulberg OM (2000) Microalgae as a source of bioactive molecules – experience from cyanophyte research. J Appl Phyco 12:341–348

Soletto D, Binaghi L, Lodi A, Carvalho JCM, Converti A (2005) Batch and fed-batch cultivations of Spirulina platensis using ammonium sulphate and urea as nitrogen sources. Aquaculture 243:217–224

Song T, Martensson L, Eriksson T, Zheng W, Rasmussen U (2005) Biodiversity and seasonal variation of the cyanobacterial assemblage in a rice paddy field in Fujian China. Fed Eur Mat Soc Microbiol Ecol 54:131–140

Spektorova L, Creswell RL, Vaughan D (1997) Closed tubular cultivators: an innovative system for commercial culture of microalgae. World Aquacult 28:39–43

Spolaore P, Joannis-Cassan C, Duran E, Isambert A (2006) Commercial applications of microalgae. J Biosci Bioeng 101:87–96

Subramanaian G, Uma L (1996) Cyanobacteria in pollution control. J Sci Ind Res 55:685–692

Sun M, Qian K, Su N, Chang H, Liu J, Shen G (2003) Foot-and-mouth disease virus VP1 protein fused with cholera toxin B subunit expressed in Chlamydomonas reinhardtii chloroplast. Biotechnol Lett 25:1087–1092

Sydney EB, Sturm W, de Carvalho JC, Thomaz-Soccol V, Larroche C, Pandey A, Soccol CR (2010) Potential carbon dioxide fixation by industrially important microalgae. Bioresour Technol 101:5892–5896

Teresa MM, Anto’nio AM, Nidia SC (2010) A review: microalgae for biodiesel production and other applications. Renew Sust Energ Rev 14:217–232

Thajuddin N, Subramanian G (2005) Cyanobacterial biodiversity and potential applications in biotechnology. Curr Sci 89:47–57

Tilzer M (1983) The importance of fractional light absorbance by photosynthetic pigments for phytoplankton productivity in lake constance. Limnol Oceanogr 28:833–846

Ting YP, Teo WK, Soh CY (1995) Gold uptake by Chlorella vulgaris. J Appl Phycol 7:97–100

Um BH, Kim YS (2009) Review: a chance for Korea to advance algal-biodiesel technology. J Ind Eng Chem 15:1–7

Venkataraman GS (1972) Algal biofertilizers and rice cultivation. Today & Tomorrow Printers & Publishers, New Delhi

Venkataraman LV, Becker EW (1985) Biotechnology and utilization of algae- the India experience. CFTRI, Mysore, 25

Vílchez C, Garbayo I, Lobato MV, Vega JM (1997) Microalgae-mediated chemicals production and wastes removal. Enzyme Microb Technol 20:562–572

Viskari PJ, Colyer CL (2003) Rapid extraction of phycobiliproteins from cultured cyanobacteria samples. Anal Biochem 319:263–271

Volkman JK, Jeffery SW, Nichols PD, Rogers GI, Garland CD (1989) Fatty acid and lipid composition of 10 species of microalgae used in mariculture. J Exp Mar Biol Ecol 128:219–240

Vonshak A (1997) Spirulina platensis (Arthrospira): physiology, cell-biology and biotechnology. Taylor & Francis Ltd, London, p 233

Walker TL, Purton S, Becker DK, Collet C (2005) Microalgae as bioreactors. Plant Cell Rep 24:629–641

Wohlgeschaffen GD, Subba Rao DV, Mann KH (1992) Vat incubator with immersion core illumination—a new, inexpensive setup for mass phytoplankton culture. J Appl Phycol 4:25–29

Xu X, Stevens M, Cortie MB (2004) In situ precipitation of gold nanoparticles onto glass for potential architectural applications. J Mater Chem 16:2259–2266

Yamaguchi K (1997) Recent advances in microalgal bioscience in Japan, with special reference to utilization of biomass and metabolites: a review. J Appl Phycol 8:487–502

Yuan YV, Carrington MF, Walsh NA (2005) Extracts from dulse (Palmaria palmata) is effective antioxidants and inhibitors of cell proliferation in vitro. Food Chem Toxicol 43:1073–1081

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer India

About this chapter

Cite this chapter

Khatoon, N., Pal, R. (2015). Microalgae in Biotechnological Application: A Commercial Approach. In: Bahadur, B., Venkat Rajam, M., Sahijram, L., Krishnamurthy, K. (eds) Plant Biology and Biotechnology. Springer, New Delhi. https://doi.org/10.1007/978-81-322-2283-5_2

Download citation

DOI: https://doi.org/10.1007/978-81-322-2283-5_2

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-2282-8

Online ISBN: 978-81-322-2283-5

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)