Abstract

The commercialization of miniaturized systems for bioanalytical applications demands fabrication methods which allow the generation of disposable devices which on the one hand fulfill requirements with respect to high geometrical precision and compatibility with the chemistries involved and, on the other hand, offer manufacturing cost which allows these devices to become low-cost disposables. We present a technology chain for the realization of such devices using polymer replication methods and subsequent back-end processing steps. Due to the usual complex set of requirements faced during the development of a bioanalytical system utilizing microfluidic functionality, development strategies for their implementation will be discussed. Practical examples of devices for the use in biotechnological applications will be presented.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Just like the microelectronic revolution changed the way how electronic components and circuits were manufactured 50 years ago, which led to an explosive growth in the applications of integrated circuits and a birth of new industries, a similar development can be seen with the introduction of miniaturization in the Life Sciences with the initial concept of the so-called miniaturized total analysis system (μ-TAS), also often called “Lab-on-a-Chip” technology, which deals with the handling and manipulation of miniature amounts of liquid in the Life Sciences and was introduced about 20 years ago [1]. The functional key elements for this technology are microstructures which have typical dimensions in the range of some 10 to some 100 μm [2]. The large and economically successful areas like microfluidics for inkjet printing, automotive applications like fuel injection, and microelectronic applications like chip cooling will not be discussed here. Recent years have seen an explosive growth of scientific activities in the Lab-on-a-Chip technology which now finally also make their way into an increasing number of commercial devices and instruments [3]. There are many drivers behind this development: first, the fundamental method of mass transport by diffusion which governs many processes in chemistry and biology scales with length−2. This scaling allows to develop systems, e.g., for clinical diagnostics or analytical chemistry, where the overall time from the input of a sample to the analytical result can be decreased to the time frame of minutes rather than current hours or even days. Similar scaling advantages can be found for other physical parameters, e.g., heat transport which is important for processes like polymerase chain reaction (PCR). Second, the cost and the overall available volume of reagents in the Life Sciences is often a critical factor, e.g., in protein crystallization or drug discovery. By reducing these volumes, not only a cost reduction can be achieved but often this represents the only way of handling and processing scarce material. Third, many functional elements of biology, e.g., cells, blood vessels, bacteria, etc. have a size which lies exactly in the range of microtechnological methods, i.e., from 0.5 μm to about 100 μm, making it an ideal fit between available manufacturing technologies and applications. Fourth, the very high geometrical accuracies of miniaturized systems together with the high surface-to-volume ratio (which also scales favorably with length−1) makes the environment in which the fluids are contained extremely well controlled, allowing, e.g., chemical reactions to be performed on a microfluidic device with a substantially higher yield than in conventional systems. Due to the small lateral dimensions, flows in such microstructures are practically always laminar (low Reynolds number) which makes the flow extremely well controllable. Last but not least, miniaturization offers the potential to automate many laborious laboratory processes which often include many manual steps like pipetting, sample transfer, etc., again reducing the cost and time of the complete analytical process and reducing the risk of procedural error. These advantages have proven to be very attractive, first spurning a very large scientific activity in the field and increasingly also in form of commercial products.

The next section explains the typical process steps in the analytical or diagnostic process performed on a microfluidic device and describes strategies for functional integration of these steps, followed by a section on the use of optical technologies. In Sect. 4, the fabrication chain for the manufacturing of polymer-based microfluidic devices will be discussed. The subsequent section contains an example for the development and realization process of an integrated microfluidic device.

2 Development and Integration Strategies

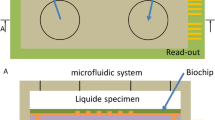

One of the crucial success factors for microfluidics on the way to a broadly used enabling technology is the ability to integrate the complete (bio-)analytical process with its numerous process steps which are shown schematically in Fig. 1 onto a single device, keeping issues like manufacturability and fabrication cost in mind.

In the first step, the sample has to be brought onto the device through some interface. As the type of sample can be very different (e.g., biopsy, swab, sputum, and blood), this interface has to be adapted to the type of sample to, on the one hand, safeguard a most efficient sample transfer to the device and, on the other hand, ensure the absence of any contamination of the sample or infection risk of the operator. These “world-to-chip” interfaces still are often an overlooked but important item during the development of microfluidic systems; more and more use of existing standards from the targeted application area (e.g., Luer-Lok compatible interfaces in clinical diagnostics) is established, however, with disadvantages mainly in terms of size. For this reason, we have developed a similar press-fit interface with a reduced footprint (called “Mini-Luer”), allowing up to 32 fluidic ports on a device the size of a microscopy slide. Figure 2 shows in comparison microfluidic chips with (from left to right) tube connectors, Mini-Luer, and full-size Luer connectors.

The next step, the various sample preparation processes like liquefaction of the sample, the lysis of cells, extraction of DNA/RNA, the sample concentration, etc., have so far been typically carried out off-chip due to their complexity and the different nature of the various samples. Moving these steps onto the device represents the biggest challenge mainly due to the fact that usually several media (wash buffer, carrier buffer, beads, lysing agents, etc.) have to be handled sequentially as well as in parallel, all of which require interfaces and plumbing in very restricted device areas. Furthermore, many of these steps have to be carried out with a high precision in terms of volume, times, or sequence, which in specialized (and often costly) laboratory equipment is much less difficult to achieve. It is therefore a specific requirement in the development of miniaturized assays that the assay should be as robust as possible in terms of, e.g., process steps, volumetry, and timing in order to be carried out on-chip. As an example, a volumetric precision of ±5% of e.g., a 1-μl volume requires a manufacturing precision of a microchannel with a dimension of 100 × 100 μm of ±2% in each dimension, a factor which is directly related to the manufacturing cost of the device. Thus a more robust assay with reduced process precision requirements also helps keeping the fabrication cost of the devices in bay. In recent years, several groups have demonstrated the integration of such sample preparation steps on-chip, see e.g., [4, 5]. For the development of such an integrated device, a two-prong approach has proven to be advisable. On the one hand, a holistic top–down approach from the system level is necessary in order to ensure the inclusion of all necessary functions as well as the definition of all interfaces (fluidic, mechanic, optic, etc.). A flow diagram of all process steps performed on the device can then be translated into individual functional modules. The second line of approach is then a development (e.g., by simulation and subsequent prototyping) of the individual module (e.g., a DNA extraction chamber, a mixing structure for the lysis buffer, etc.) where the individual functions can be validated before integration. One significant difference to other engineering disciplines, especially mechanical or electrical engineering, however, exists in the realm of microfluidics. In these fields, the development of individual modules tends to be simpler due to the fact that the mutual interactions of the individual modules are more limited and often calculable with simple restraints, allowing the assembly of module libraries which can simply be transferred from one development case to another. In microelectronics, an operation amplifier or a storage capacitor will behave (almost) identical regardless of the overall system layout. In microfluidics, however, the performance of a single module is often to a large extent dependent on the overall system layout. A typical example would be the parameter of flow speed in a microfluidic module, e.g., a simple T-shaped microchannel. This flow speed can be easily calculated given the dimension of the various arms of the channel. However, as the flow speed depends (amongst others) on the back pressure the different arms of the T are experiencing, the flow distribution changes depending on the back pressure generated by preceding or succeeding modules. If this happens in a time series, already the functional description of such a simple module can become quite difficult. It is therefore emerging as best practice in the development to combine the theoretical (or modeling) approach (see e.g., Fig. 3 as example) with some experimental data from module prototypes.

The next process step usually in devices using molecular biology methods involves an amplification of target molecules, using methods like conventional or isothermal PCR and rolling circle amplification (RCA) in order to increase the number of target molecules to achieve better detection selectivity and sensitivity. This amplification step is then frequently followed by a separation step like electrophoresis, chromatography (up to now not well developed on-chip), the use of capture probes (e.g., DNA arrays), or other filtration mechanisms in order to isolate the desired component spatiotemporally or remove unwanted components from the mixture.

The final analytical step comprises the detection of the analyte of interest. While for many larger, lab-based systems, optical detection methods like laser-induced fluorescence (LIF) still act as a benchmark with respect to sensitivity, for portable systems, electrochemical analysis methods, or various other sensor methods (e.g., surface acoustic waves (SAW), quartz crystal microbalance (QCM), thermal measurements) are becoming increasingly of interest. It should be noted that all the preceding process steps have to be matched to the selected detection method in order to generate the best results.

A minor but nevertheless important design step of an integrated device in diagnostics is the layout of a waste container system in order to retain all liquids used in the process on-chip. This is often necessary to avoid the contamination risk of the instrument and to prevent carryover from one measurement to the next. Critical can be the required volume of such waste reservoirs, frequently stressing the limited real estate on the chip.

As a method to develop microfluidic systems which contain the above listed analytical steps, a stepwise approach has proven to be advisable. Functional modules for specific functions are defined (e.g., DNA extraction) and realized in order to validate their performance.

Once these functions have been verified, a stepwise integration into a single device then can take place. This stepwise approach also simplifies the search for and correction of possible errors observed in the performance of the device.

3 The Importance of Optical Technologies in Microfluidics

Optical technologies have always played an important role in conjunction with microfluidic systems in the Life Sciences, primarily for detection means [6, 7]. For many applications, the most sensitive and selective method for detection and/or imaging is fluorescence detection, usually induced by one or several lasers, where the respective target is labeled with a fluorescent dye. LIF has been the primary method for the detection of biomolecules in miniaturized CE systems, for PCR products (see example in Sect. 5) as well as for practically all cell-based methods. Optical components can also be directly integrated in microfluidic chips. Optical waveguides for the coupling of the excitation light into a microchannel as well as the collection of the fluorescent light have been generated on microfluidic chips using femtosecond laser machining [8]. Photonics has furthermore been used in many other microfluidic applications such as the actuation and manipulation of droplets using intense light fields [9, 10] or even complex “optofluidic” circuits [11], where the variability of physical parameters of liquid media in a microfluidic device is utilized. Even microfluidic dye lasers have been realized [12].

4 Manufacturing Technologies

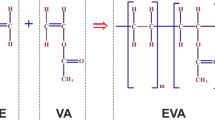

The progress made in polymer microfabrication technologies [13] has greatly contributed to the onset of the commercial applicability of microfluidic devices. The possibility to generate devices at a cost which makes them usable as disposable is one of the important breakthroughs for this technology. The necessary technology chain for the manufacturing of such devices is shown in Fig. 4. It starts with the design of the device. At this point, it is important to notice that in the device design beyond the application-driven aspects, input from the complete manufacturing chain is necessary to achieve what is called design-to-manufacture, i.e., a device design which allows the manufacturing at a given cost. As for polymer disposables, replication methods like injection molding and hot embossing are the preferred manufacturing methods, the device design has to be translated into a replication master (often also with some verbal unspecificity referred to as “replication tool,” “mold,” or “mold insert”). Although the requirements for such a master structure differ with respect to the physical parameters of the chosen replication method (e.g., force, temperature), four basic statements can be made: (a) the geometrical replication result can only be as good (or as bad) as the geometrical accuracy of the master, (b) for the ability to separate mold and molded part (demolding step), no undercuts in the structure itself can be allowed, (c) the surface roughness of the master should be as low as possible (ideally peak-valley values of below 100 nm), and (d) a suitable interface chemistry between master and substrate has to be chosen. In order to generate the master structure, principally all microfabrication methods are suited. The proper selection of the master fabrication technology is one of the crucial steps in the product development of commercial microfluidic devices, especially as there is no generic recipe for this selection. Table 1 lists the most common master fabrication methods with their properties. For commercial applications, the most suitable methods are precision-machined masters made out of steel for structural dimensions down to about 30–50 μm or, for smaller structures, nickel masters which are generated by electroplating of photoresist or silicon. For larger structures, micro electrode discharge machining (μ-EDM), which is among the most common methods for stainless steel tooling in the macroworld, becomes possible. Both methods combine long master lifetimes with good geometrical definition at reasonable cost and availability. The LIGA process generates the masters with the highest precision and best surface roughness available; however, the manufacturing process is complex, expensive, and time-consuming. On the opposite side, masters consisting of silicon can be made quickly at low cost; due to the brittleness of the material, they can mainly be used for casting and hot embossing. A recent development is the use of polymers (e.g., fully cured SU-8 photoresist) as a material for replication masters. The master lifetime in this case is limited typically to a few 10–100 replications at moderately complex designs and low aspect ratios. For more complex geometries, namely when comparatively large structural dimensions (mm-sized features) have to be combined with small features, hybrid tooling such as the combination of precision machining for the larger features and lithography or laser ablation for the finer features can offer a solution. Figure 5 shows as an example a precision-machined stainless steel master structure.

For the high-volume manufacturing of disposable microfluidic devices, high-precision injection molding has established itself as the method of choice. As it is by far the most widespread fabrication process for polymers in the macroworld, it is not surprising that the first application of this production technology for microfluidic components was already published more than 10 years ago [14]. Due to the comparatively high demands in equipment and process, it is seldom used in academics compared to industrial use. For the commercial success of microfluidics, it will nevertheless play a crucial role.

One of the constraining factors for the use of injection molding is the high requirements for the so-called injection molding tool. It has to perform very precise mechanical motions under high temperature variations and forces. In Fig. 6, an example of such an injection molding tool for microtiter plate-sized devices is shown. The mechanical complexity of such an injection molding tool becomes apparent. One of the strategies to reduce the development cost of microfluidic devices is the use of so-called family tools, which use exchangeable mold inserts and can thus be used for molding different device designs. The molding process itself consists of the following steps: The polymer material is fed as pre-dried granules into the hopper. In the heated barrel, a screw transports the material toward the injection port of the molding tool. During this transport, the polymer melts and reaches the tool in liquid form with a melt temperature of the order of 200–350°C depending on the polymer. It is now injected under high pressure (typically between 600 and 1,000 bars) into the mold which contains the microstructured mold insert. For microstructure replication, it has to be evacuated to achieve a good filling of the mold and to prevent the formation of air pockets. Depending on the surface-to-volume ratio of the structure, the mold can be kept at temperatures below the solidification temperature of the polymer (typically between 60 and 120°C, so-called cold cavity process) or, in case of small injection volumes and high aspect ratio structures, has to be kept at temperatures above the so-called glass-transition temperature T g and cooled together with the melt. The need for this so-called variotherm process drastically increases the cycle time; therefore in commercial applications the development of the microstructure has as a goal the moldability with a cold cavity process. Typical cycle times for a cold-cavity process are of the order of 30 s–2 min, a variotherm process can take up to 5 min. After opening of the mold, the molded part will be ejected from the mold. Normally, remains of the material from the injection port (so-called sprue) will still be connected to the part which has to be removed, either mechanically by cutting, sawing, and breaking off or using a laser.

Figure 7 shows an example of a multilevel structure injection molded from a mechanically machined mold insert. The big advantages of injection molding are the ability to form three-dimensional objects, which, in case of microfluidic devices, means e.g., the integration of fluidic interconnects [15] (see Fig. 3) or through-holes. Furthermore, the ejected part does not normally need additional mechanical process steps, thus reducing the need for mechanical back-end processes (see below).

At this point in manufacturing, one has a microstructured polymer part. While for prototyping or low-volume manufacturing, most of the cost is concentrated in this part [16], for higher volumes, the majority of production cost lies in the subsequent back-end processing steps. These can be roughly divided into two groups:

-

1.

Physical processes: In this category, steps like bonding of a cover lid, e.g., with adhesives, laser or ultrasonic welding, thermal or solvent-assisted bonding (for a recent review see, e.g. [17]) in order to close the channels, the assembly of the device in case of the integration of sensors, gaskets, membranes, septa, or other components and mechanical processes like dicing or drilling are used. A special process is the integration of electrodes onto the polymer device. This can be realized using thin-film processes like thermal evaporation or sputtering or thick-film processes like screen-printing. Recently, inkjet printing of conductive inks has received increasing attention due to its cost structure and ease of integration of this process in the overall production line [18].

-

2.

Chemical processes: These processes are related to the surface chemistry of the device. Frequently, this surface chemistry, especially the hydrophilicity/hydrophobicity of the device, has to be tuned for a specific device [19–21]. As most thermoplastic polymers have a fairly hydrophobic surface (contact angle typically 80–90°), the contact angle has to be decreased in order to get devices which fill by capillary action. This can be realized using a plasma treatment [22], UV light [23], or by flush-coating the enclosed microchannel [20]. Other surface-modification steps include the local binding of (bio-) molecules to the surface (e.g., for array-based assays) or a local deposition of reagents, e.g., lyophilized or in biostabilized form. This form of chemical patterning usually is realized using a spotting tool or inkjet-like printing.

In an industrial setting, the manufacturing chain is finished by a quality control process, usually a combination of optical inspection with a functional test of a subsample which is selected by statistical process control (SPC) methods and the subsequent packaging of the device in a suitable form, e.g., pouches or sealed foil packs.

It is important to notice at this point that by a clever device design the biggest potential for cost-saving lies in reducing or simplifying the back-end processing steps [16].

5 Application Example

In order to elucidate the development and manufacturing processes described above, the stepwise realization of an integrated device for the simultaneous detection of eight different pathogens is described. It starts with the selection and development of individual functional modules and culminates in the complete device integration.

5.1 Functional Modules

The first example of such a functional module is a chip which contains magnetic beads for DNA extraction. The chip (with the size of a microscopy slide) contains two rhombic chambers with a volume of 120 μl each. These chambers are either preloaded with coated magnetic beads or can be loaded after assembly, as shown in Fig. 8. The sample is introduced into the chamber together with lysis buffer and incubated for 5 min. This is followed by three subsequent washing steps with wash buffer; after each washing step, the magnetic beads are held at one end of the chamber using a magnet to concentrate the beads at the desired location. After the final wash step, the buffer is replaced by an elution buffer in which the DNA bound on the magnetic beads is released. After collecting the eluate DNA, it can be then transferred to an amplification module. Figure 9 shows the amplification results in a 36-cycle PCR chip (see next paragraph) of a dilution series of Salmonella as a model organism for the pathogens. The lanes contain from left to right: Lane 1: Mass ruler. Lane 2: 200,000 bacteria. Lane 3: 20,000 bacteria. Lane 4: 2,000 bacteria. Lane 5: 200 bacteria. Lane 6: positive control for 200 bacteria in a conventional PCR cycler. Lane 7: negative control. The specific fragment size of the PCR product was 263 bp.

PCR results of a dilution series of Salmonella from 200,000 to 200 bacteria from DNA extracted with the chip shown in Fig. 8

The next module is an amplification module utilizing the principle of continuous-flow PCR [24, 25]. This principle is especially suited for long-term, decentralized monitoring purposes as it operates with stationary temperature zones instead of conventional thermocycling, thus greatly reducing the energy requirements for an instrument. At the same time, the analysis speed is improved while at the same time very low sample volumes are required. Furthermore, this principle lends itself for continuous monitoring, e.g., in the case of air-borne pathogen monitoring with the sample being continuously taken from an air sampler. Figure 10 shows the principle layout of such a continuous-flow PCR chip with the three temperature zones required to perform the PCR process; Fig. 11 shows the actual chip with 36 PCR cycles as used above, injection molded in polycarbonate (PC) [26].

The final step in the analytical process is the detection of the relevant sample. Up to now in most cases, optical detection methods, namely fluorescence, are used due to their high sensitivity as well as due to the large number of protocols and dyes available.

An example of a chip module made for the fluorescence end-point detection of a qPCR process is shown in Fig. 12a, a subsequent fluorescence image of the detection area in Fig. 12b, and the measurement of qPCR products in Fig. 12c. The channels contain from top to bottom (equivalent to the peaks from left to right in Fig. 12c): negative control Coxiella burnetii from conventional thermocycler; positive control C. burnetii from conventional thermocycler; negative control C. burnetii from chip PCR; positive control C. burnetii from chip PCR; negative control Brucella melitensis from conventional thermocycler; positive control B. melitensis from conventional thermocycler; negative control B. melitensis from chip PCR; positive control B. melitensis from chip PCR. As in the final device, an 8-plex detection was targeted, the spacing of the microchannels after qPCR had to be very narrow in order to have all channels within the field of vision of the detection system in order to avoid the need for optical scanning. This led to 200-μm wide, 300-μm deep microchannels with a spacing of only 150 μm which poses a significant challenge in the leak-tight bonding of the device with a thin cover foil. As can be seen from the fluorescence image, no cross-talk due to incomplete bonding is visible.

5.2 Integrated Device

After validating the modules above, an integrated device for the detection of eight different pathogens from a single sample was developed. The chip with the footprint of an SBS titerplate is shown in Fig. 13 which is made by injection molding and which contains microfluidic structures on the top as well as on the bottom side. The sample is introduced in the upper right hand corner through a Luer connector. Then, a bead-based DNA extraction and concentration takes place. The sample is subsequently divided into eight aliquots which flow through the storage area where the lyophilized PCR master mixes are stored. After liquefaction of the PCR mixes through the sample, the continuous-flow PCR takes place. The sample is then transported through microchannels on the top side of the chip to the detection area, where the fluorescence detection takes place before the samples are carried off to waste.

With this device, experiments for the simultaneous detection of B. melitensis, Burkholderia mallei, B. pseudomallei, C. burnetii, Francisella tularensis, Yersinia pestis, and orthopox virus are currently under way to determine the performance of the device. An overall analysis time including all sample preparation steps as well as PCR of 40–45 min is targeted, which is comparable to the fastest commercially available but significantly more complex and expensive systems like the Genexpert from Cepheid [27].

6 Conclusions

By now microfluidics has reached a stage where it has gained widespread attention in many scientific disciplines. A significant development in the field of microfluidics can be noted in recent years, leading to a maturing of the technology and the subsequent growth in applications and products. The example described above gives a good indication of the ability to develop and manufacture complex microfluidic devices. Although no single “killer application” so far has captured the headlines, it is the long list of widely accepted advantages which nowadays makes microfluidics an essential tool in product development in almost any field of the Life Sciences. The availability of suitable fabrication methods for high-volume manufacturing of disposable microfluidic devices plays an important role to bring this technology to commercial success which will have a significant impact on the whole Life Science industry [28].

References

Manz A, Graber N, Widmer M (1990) Miniaturized total chemical analysis systems: a novel concept for chemical sensing. Sens Actuators B1:244–248

Whitesides GM (2006) The origins and the future of microfluidics. Nature 442:368–373

Becker H (2009) Hype, hope and hubris: the quest for the killer application in microfluidics. Lab Chip 9:2119–2122

Legendre LA, Morris CJ, Bienvenue JM, Barron A, McClure R, Landers JP (2008) Toward a simplified microfluidic device for ultra-fast genetic analysis with sample-in/answer-out capability: application to T-cell lymphoma diagnosis. JALA 13(6):351–360

Yager P, Edwards T, Fu E, Helton K, Nelson K, Tam M, Weigl B (2006) Microfluidic diagnostic technologies for global public health. Nature 442(7101):412–418

Götz S, Karst U (2007) Recent developments in optical detection methods for microchip separations. Anal Bioanal Chem 387:183–192

Baker CA, Duong CT, Grimley A, Roper MG (2009) Recent advances in microfluidic detection systems. Bioanalysis 1(5):967–975

Martinez Vazquez R, Osellame R, Nolli D et al (2009) Waveguide integration in a lab-on-a-chip for fluorescence detection. Lab Chip 9:91–96

Delville JP, de Saint Vincent MR, Schroll RD et al (2009) Laser microfluidics: fluid actuation by light. J Opt A Pure Appl Opt 11:034015, 15 pp

Kotz KT, Noble KA, Faris GW (2004) Optical microfluidics. Appl Phys Lett 85:2658–2661

Psaltis D, Quake SR, Yang SD (2006) Developing optofluidic technology through the fusion of microfluidics and optics. Nature 442:381–386

Cheng Y, Sugioka K, Midorikawa K (2004) Microfluidic laser embedded in glass by three-dimensional femtosecond laser microprocessing. Opt Lett 29(17):2007–2009

Becker H, Gärtner C (2008) Polymer microfabrication technologies for microfluidic systems. Anal Bioanal Chem 390:89–111

McCormick RM, Nelson RJ, Alonso-Amigo MG, Benvegnu DJ, Hooper HH (1997) Microchannel electrophoretic separations of DNA in injection-molded plastic substrates. Anal Chem 69:2626–2630

Gärtner C, Becker H, Anton B, Rötting O (2003) Microfluidic toolbox: tools and standardization solutions for microfluidic devices for life sciences applications. In: Proceedings of SPIE microfluidics, BioMEMS, and medical microsystems II, San Jose, vol 5345, pp 159–162

Becker H (2009) It’s the economy. Lab Chip 9:2759–2762

Tsao CW, DeVoe DL (2009) Bonding of thermoplastic polymer microfluidics. Microfluid Nanofluid 6:1–16

Pabst O, Perelaer J, Beckert E, et al. (2010) Inkjet printing and argon plasma sintering of an electrode pattern on polymer substrates using silver nanoparticle ink. In: Proceedings of NIP26: international conference on digital printing technologies and digital fabrication, Austin, pp 146–149

Soper SA, Henry AC, Vaidya B, Galloway M, Wabuyele M, McCarley RL (2002) Surface modification of polymer-based microfluidic devices. Anal Chim Acta 470:87–99

Locascio LE, Henry AC, Johnson TJ, Ross D (2003) Surface chemistry in polymer microfluidic systems. In: Oosterbroeck RE, van den Berg A (eds) Lab-on-a-chip. Elsevier, Amsterdam, pp 65–82

Belder D, Ludwig M (2003) Surface modification in microchip electrophoresis. Electrophoresis 24:3595–3606

Nitschk M (2008) Plasma modification of polymer surfaces and plasma polymerization. In: Stamm M (ed) Polymer surfaces and interfaces: characterization, modification and applications. Springer, Berlin, pp 203–214

Lin R, Burns MA (2005) Surface-modified polyolefin microfluidic devices for liquid handling. J Micromech Microeng 15:2156–2162

Köhler JM, Dillner U, Mokansky A, Poser S, Schulz T (1998) Micro channel reactors for fast thermocycling. In: Proceedings of 2nd international conference on microreaction technology, New Orleans, 241–247. German Patent DE000004435107, 30 Sept 1994

Kopp MU, De Mello AJ, Manz A (1998) Chemical amplification: continuous-flow PCR on a chip. Science 280:1046–1048

Gärtner C, Klemm R, Becker H (2007) Methods and instruments for continuous-flow PCR on a chip. In: Proceedings of SPIE microfluidics, BioMEMS and medical microsystems V, San Jose, vol 6465, pp 6465502–1 – 6465502–8

Ulrich MP, Christensen DR, Coyne SR et al (2006) Evaluation of the cepheid GeneXpert system for detecting Bacillus anthracis. J Appl Microbiol 100:1011–1016

Becker H (2008) Microfluidics: a technology coming of age. Med Device Technol 19(3):21–24

Acknowledgments

Parts of this work were funded by the German Federal Ministry of Education and Research (BMBF) (grant no. 13N9556) and managed by the Projektträger VDI-Technologiezentrum Physikalische Technologien. We would like to acknowledge the kind support by all partners of the joint project

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2012 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Becker, H., Gärtner, C. (2012). Polymeric Microfluidic Devices for High Performance Optical Imaging and Detection Methods in Bioanalytics. In: Fritzsche, W., Popp, J. (eds) Optical Nano- and Microsystems for Bioanalytics. Springer Series on Chemical Sensors and Biosensors, vol 10. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-25498-7_10

Download citation

DOI: https://doi.org/10.1007/978-3-642-25498-7_10

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-25497-0

Online ISBN: 978-3-642-25498-7

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)