Abstract

Collaborative logistics is becoming more important in today’s industry. This is driven by improved economic and environmental efficiency through collaborative planning supporting resources sharing and new business models implementation. This paper presents a survey of contributions to the field of collaborative logistics. It first describes current opportunities in collaborative planning. It then discusses important issues related to building the coalition, sharing resources and benefits, as well as related to information and decisions technologies. Business cases are described and used to support the discussion. Finally, questions are raised, opening new paths for researchers in the field.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

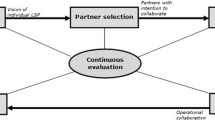

In this paper, we will discuss issues related to collaboration between companies when dealing with logistics and transportation. Logistics and transportation are activities that provide many opportunities for collaboration between companies. This collaboration, either through information or resource sharing, aims to reduce the cost of executing the logistics activities, improve service, gain market shares, enhance capacities as well as protect the environment, and mitigate climate change (Simchi-Levi et al. 1999). Collaboration occurs when two or more entities form a coalition and exchange or share resources (including information), with the goal of making decisions or realizing activities that will generate benefits. As illustrated in Fig. 1, collaboration can range from information exchange, joint planning, joint execution, up to strategic alliance (e.g., co-evolution) (D’Amours et al. 2004). As collaboration becomes more strategic, typically more resources are involved and sensitive information is shared between the collaborating entities.

In this paper, we discuss important aspects when building a coalition of business entities aiming for collaborative logistics. These are of different natures. After introducing opportunities for collaborative logistics, we will discuss which entities should be part of the coalition and who should decide about this. The second aspect raised is how the coalition will share the benefits gained. The third aspect is the need for specific information and decision technologies. Finally, a discussion will bring up problems related to collaborative logistics.

2 Collaborative Logistics Problems

Logistics deal with moving and storing products as they flow through the supply chain. Efficient logistics planning and execution can provide competitive advantages to the different entities of the supply chain. Figure 2 presents the supply chain as being the network of business entities involved in the production and distribution of products from raw material to delivery. In some cases, the supply chain spans even further, including activities like design and engineering as well as return and recovery of products. Collaboration in logistics based on information exchanged has been identified as one means of reducing the negative impacts of the bullwhip effect, known as the amplification of demand variation going upstream the supply chain (Lee et al. 1997; Moyaux et al. 2004). The bullwhip effect results in higher inventory levels and increased backlogs. Collaboration can considerably reduce these negative effects.

The supply chain entities such as carrier, producer, customer, and third party logistics collaborate in different ways. In terms of transportation, they aim to optimize the traveling time and load capacity usage. They share information in such a way that the operative pick-up and delivery routing problems capture the benefit of a denser network. They aim to minimize transportation costs, in particular the backhauling costs. Backhauling represents the possibility of combining two transport orders in such a way that the unloaded distance is minimized. The supply chain entities may also collaborate to increase responsiveness and reduce inventory holding costs. In such cases, they share demand and consumption information in a timely manner and use different approaches to synchronize efficiently their activities. The entities may also face large transportation costs and may aim to deploy new infrastructures that will provide them with a competitive advantage over others. Such shared infrastructure could be pipelines (e.g., crude oil and gas), terminals (e.g., forestry), distribution centers or warehouses (e.g., retailing), or transportation modes (integrating, e.g., train, ship, truck in general transportation organizations). Another common practice in collaborative logistics is to share spare parts between different entities.

Collaboration is related to some forms of interdependency. Frayret et al. (2004) have reviewed these forms. They are listed and briefly described in Table 1.

Different cases are reported in the literature. Frisk et al. (2010) discuss collaboration between eight forest companies. These companies wanted to study what the potential savings in tactical monthly planning would be if all companies share all supply and demand. The transportation planning problem can be formulated as a Linear Programming (LP) problem. The potential savings were as much as 14%. About 6% arises from better transportation planning within each company and another 8% comes from the actual cooperation. This is an example of pooled interdependence. Audy et al. (2010) analyses a potential collaboration between four furniture manufacturers. The aim is to optimize collectively the outbound transportation of their products to the US. The case raises interesting issues about benefit sharing. This is another example of pooled interdependence. Lehoux et al. (2009) presents a different context which is an example of a producer–consumer relationship. In their paper, a producer and a distributor evaluate the possibility of collaboration. They can follow different logistics approaches (e.g., VMI – Vendor Managed Inventory, CPFR – collaborative planning forecasting and replenishment). In their case, no equilibrium solution can be found; therefore, the partners need to work out some efficient incentives to make it possible.

Collaborative logistics may involve different levels of resource and information sharing between two or many entities as illustrated in Fig. 1. The impact can be strategic. The collaboration can be a voluntary action or imposed by certain policies. Finally, it can bring together business entities which are competitors or suppliers/customers. In such cases, the coalition is said to be, respectively, horizontal and vertical. In some cases, companies acting in complementary sectors of activities may collaborate to develop an extended value proposition. Such networks are defined as diagonal. They are common in the tourist industry, where packages are built through a collection of offers. These perspectives will now be discussed.

2.1 Strategic Collaboration in Logistics

Collaboration can be strategic and therefore imply the sharing of key infrastructures or highly sensitive information. Examples of such collaborations could be the sharing of costly infrastructure. The location and the investment for such infrastructure are considered strategic for the entities involved. Other strategic collaboration relates to defining industry standards; this is the case when entities of a same industry collaborate to define different business standards to improve the interoperability of their systems (e.g., PapiNet – a standard for information exchange in the forest products industry). Strategic collaboration can also imply a long term business contract and the exchange of demand and capacity information. At the strategic level, it is likely to see entities exchanging a “complete” model of their demand or capacity, permitting the coalition to compute the value of the collaboration and to propose a reasonable sharing strategy (Montreuil et al. 1999; Frisk et al. 2010).

2.2 Operational Collaboration in Logistics

Operational collaboration requires low commitment. An example of such a collaboration could be a web based platform inviting enterprises to share their transportation needs in order to find joint routes that will reduce their transportation costs. Applications can be found in the Swedish and Finnish forest industry. In Eriksson and Rönnqvist (2003), a web-based transportation planning tool is described. Here, a backhauling solution is provided to all transport planners in several regions and companies in order to support manual planning of daily routes.

2.3 Size of the Coalition

Collaboration can bring together two or more entities. In all cases, the need for each entity to improve its logistics is a prerequisite for the collaboration. In a many-to-many context, the design of proper collaboration mechanisms is more difficult, mainly because the exchanges are not bilateral as in a supplier–customer type of collaboration. Externalities play a role in defining when the coalition reaches its optimal size. Some entities may enter with a lot to provide and little to gain, while others will benefit greatly with little to offer.

2.4 Collaboration Driver

Collaboration can emerge from a coalition of voluntary entities that see in the sharing of resource and information ways to improve their logistics (VICS 2004). It can also be imposed by one of the leading entities of the supply chain. For example, WalMart’s move to set RFID systems with all major suppliers was done in order to increase the collaboration, but it was imposed on the different entities. Although they are all free to maintain or not their business with WalMart, we define it as an imposed collaboration scheme. Other imposed schemes can be set by public policies. For example, natural resources can be managed by governmental authorities and the allocation rules may impose collaboration between many entities. This is the case in the forestry industry in Canada. In such a situation, the different entities are asked to find harvesting plans which meet the needs of all members of the coalition (Beaudoin et al. 2007).

2.5 Collaboration in Vertical Network

In a context where a supplier and a customer aims for more efficiency in their logistics, they will evaluate the possibility of exchanging more information, plan jointly their activities, and maybe share in the execution of some of the activities. Some responsibilities can also be shifted from one entity to another, so the global efficiency of the coalition is improved as is the case in Vendor Managed Inventory.

We discuss here three types of supplier–customer collaboration models: Vendor Managed Inventory (VMI) and Continuous replenishment and collaborative Planning Forecasting and Replenishment (CPFR).

Under a VMI agreement, the producer is responsible for managing the inventory of its customer. The customer provides the daily consumption to the producer so it can build a production–distribution plan that meets the fixed service level as well as optimizes the usage of its production–distribution resources. The VMI approach showed that a certain amount of collaboration between the supplier and the customer is possible. VMI has contributed positively to enhancing the logistics performance. Danese (2006) reported the benefits gained by the pharmaceutical giant GlaxoSmithKline. Since then, companies have explored new approaches such as Continuous Replenishment models based on carrier capacity or production capacity. The replenishment is structured around a pre-scheduled reservation of capacity. For example, the collaboration may set a one truck per day delivery to the customer. Then, the customer is responsible for setting the mix of products to be on the truck every day. This approach satisfies the needs of the customer over time and reduces the pressure on the producer. The same approach applies with capacity reservation. Finally, the Collaborative Planning, Forecasting and Replenishment (CPFR) business model aims to balance demand and production–distribution capacity up-front in order to define a win-win unique plan for both parties. Cederlund et al. (2007) reported a reduction of 50% of transportation costs and 30% of inventory holding costs at Motorola. Although these collaboration approaches seem to perform well, overcoming many hurdles limits their implementation (Lehoux et al. 2008).

Bilateral collaboration may not reach an equilibrium meaning that no solution is the best for both parties and therefore unless an incentive can be provided, one of the parties will not participate under the defined model. Often, one needs to share the benefits to motivate the others to participate in the collaboration. The design of these incentives is critical for the collaboration (Chen 2003, Cachon 2003).

2.6 Research Questions

Collaborative logistics raises the need for specific methods to support decision-making. The main questions are related to how to build the coalition, sharing policies and information and decision systems.

When dealing with how to build the coalition, the following questions are raised. How will the coalition be built? Which entity or entities will lead the coalition and therefore set its goals? Which entities should be invited to join or leave the coalition?

When dealing with defining the sharing policies, the following questions need to be addressed. How will the value of the collaboration for the whole coalition and for each entity be set? Which sharing method will provide a sustainable solution for the coalition? What should be shared: costs or savings?

Finally, when designing the information and decision technology needed to support the coalition different questions need to be answered. What are the coalition decisions support systems? Which type of electronic platform should be used? Are there any security issues? How to make the systems of the entities work together to transfer information in a timely manner?

The following sections will review current methods and knowledge used to solve these problems.

3 Building Coalitions

We denote by coalition a set of stakeholders (e.g., producer, customer, carrier, third party logistics), disposed to share information or resources in order to better realize logistics activities including planning. We denote by entities each of these stakeholders and consequently, a coalition must include at least two entities. To implement collaborative logistics between these players, we need to build a coalition. From a business point of view, one or a set of the entities will lead in the creation of the coalition. Audy et al. (2007a) have identified six different forms of leadership currently used in coalition building for the specific problem of log supply to mills. We generalize the proposed type of leadership and identify five different models. They are presented in Table 2. In these models, the leader is either one entity which aims to optimize its own objective through some sharing or by a coalition of many that aim to optimize a collective objective.

These models have different objectives and therefore require different methods to support the building of the coalition. The objectives often depend on the leader’s attitude. It may behave altruistically, aiming for a fair sharing of the benefits between the coalition members. It can also behave in a more opportunistic way, arguing that it is assuming most of the risk and the effort to build the coalition. In such a case, it can propose bilateral offers for each new entity entering the coalition. Depending on the behavior of the leader, the sequence in which the entities are invited into the coalition may have an impact on its benefit. For example, a coalition aims to reduce procurement costs through collaborative routing and supply allocation. The leader is opportunistic and shares costs or savings with one entity at a time, as they enter the coalition. The benefits are shared following a volume ratio. If the costs are shared, then the leader wants to bring in the bigger entities first and then the smaller ones. If the savings are shared, then the inverse logic would be pursued (Audy et al. 2007b).

If we disregard external business considerations, the basic rule of adding an entity p to a coalition c is if the entity p increases the benefit of the current coalition c. The benefit of a coalition c is defined as the difference between the value of the collaborative plan including all entities in the coalition c, V c, compared to the sum of the values of the individual plan of each player p in the coalition c, ∑ p ∈ S V p where S is the set of players in coalition c. In a minimization objective context, the benefit refers generally to the savings whereas in a maximization context they refer to a profit.

A coalition c’ will be created if more benefit can be generated by adding entity p’ to coalition c. On the other hand, any entity p already in a coalition c who does not contribute to the benefit of this coalition c should be removed.

Although the addition of an entity to a coalition can provide a benefit, it seems that the entities’ willingness for the collaboration is tightly linked to the business model of the coalition that is driven by one or several leading players. These leading entities aim at building the coalition in such a way that they will maximize their returns while providing enough incentives to the others to keep them in the coalition.

Evaluating the value of the collaboration for the coalition as well as the entities is fundamental in building the coalition. In logistics, this evaluation is mainly conducted using operational research planning and transportation models, which are sequentially used to solve the entity problem and the different coalitions’ problems. Examples can be found in recent papers by Frisk et al. (2010), Audy et al. (2010), and Lehoux et al. (2008).

4 Sharing Principles

4.1 Game Theoretic Background

We will discuss a number of sharing principles once the coalition has been formed and agreed. These have been applied in various industrial settings. Before we describe each of the principles we start by introducing some basic notation used in game theory. We will discuss sharing principles based on cost allocation methods. The motivation is that logistics is more often concerning costs than revenues.

-

We have a set of business entities N.

-

A coalition S is a subset of business entities, i.e., S ⊂ N.

-

The grand coalition is the set of all entities, i.e., N.

-

The cost of a coalition is denoted c(S).

A cost allocation method distributes (or allocates) the total cost of the grand coalition to the entities. This aspect is important as it often is needed to evaluate individual contributions when coalitions are formed, see e.g., Sprumont (1990). Each entity j will be allocated the cost y j . Since the total cost is to be distributed among the entities, we have

A cost allocation which satisfies the above constraint is said to be efficient. There are other properties that can be associated with a cost allocation. One property which requires that the entity be not allocated a higher cost than its own cost is called individual rationality. This is simply expressed as

Another important concept is to ensure that there are no incitements for a coalition to break out and work independently. This implies that the cost allocated to a particular coalition of entities cannot exceed the actual cost of the coalition. There are many potential coalitions and this means that we have one constraint for each possible coalition. This can be expressed as

Constraint set (1) and (3) define what is called the core. Any solution which is feasible with respect to the core is called stable. In general, there is no guarantee that there exists a feasible solution to the core. The game is said to be monotone if

This means that if one new entity is included in a coalition, the cost never decreases. The game is said to be proper if

This implies that it always profitable (or at least not unprofitable) to form larger coalitions. The properties discussed above are not satisfied for all classes of games. Some may be guaranteed and others not.

For each coalition, S, and a cost allocation, y, we can compute the excess

which expresses the difference between the total cost of a coalition and the sum of the costs allocated to its members. For a given cost allocation, the vector of all excesses can be thought of as a measure of how far the cost allocation is from the core. If a cost allocation is not in the core, at least one excess is negative.

4.2 Quantitative Allocation Methods

There exist many allocation rules and we will discuss some that have been used in different applications. We will discuss a limited number of such allocations in this section.

4.2.1 Weighted Costs

A simple and straightforward allocation is to distribute the total cost of the grand coalition among the participants according to a volume or a cost weighted measure. This is expressed by the formula

It is intuitive but can often lead to an allocation that does not satisfy, for example, the core conditions.

4.2.2 Separable and Non-Separable Costs

A more advanced method is based on dividing the allocation into two parts. One is associated with a separable cost and the other a non-separable cost. The separable cost or the marginal cost (8) of entity j and the non-separable cost (9) as can be expressed as

Methods based on separable and non-separable costs allocate the costs according to

Depending on which weights are chosen, there are different versions of the method; the two most straightforward methods are the Equal Charge Method that distributes the non-separable cost equally and the Alternative Cost Avoided Method that uses the weights \({w}_{j} = c(\{j\}) - {m}_{j}\), expressing savings that are made for each participant by joining the grand coalition instead of operating alone. These allocations satisfy the efficiency and symmetry properties. However, they are not necessarily in the core. These and other additional versions are discussed in Tijs and Driessen (1986).

4.2.3 Shapley Value

The Shapley value (Shapley 1953) is a solution concept that provides us with a unique solution to the cost allocation problem. The underlying idea is based on the assumption that the grand coalition is formed by entering the entities into this coalition one at a time. As each entity enters the coalition, it is allocated the marginal cost, and this means that its entry increases the total cost of the coalition it enters. The amount an entity receives by this scheme depends on the order in which the entities are entered. The Shapley value is just the average marginal cost of the entity, if the entities are entered in completely random order. The cost allocated to entity j is equal to

Here, |. | denotes the number of entities in the considered coalition. The quantity, c(S ∪{ i}) − c(S), is the amount by which the cost of coalition S increases when entity j joins it, here denoted by the marginal cost of entityj with respect to the coalition S. The Shapley value satisfies the efficiency property but does not necessarily satisfy the stability or the individual rationality properties.

4.2.4 Equal Profit Method

In many applications, the entities compute the relative savings and there is a desire to have an equal relative savings. One such approach, called Equal Profit Method (EPM), is suggested in Frisk et al. (2010). In this approach a Linear Programming (LP) model is solved where the model can be formulated as

The first constraint set is to measure the pair-wise difference between the profits of the entities. The variable f is used in the objective to minimize the largest difference. The two other constraint sets define all stable allocations. In cases where the objective is not 0 (no difference between the entities), the reason is that there is a coalition that has an incentive to break out, i.e., the core constraints must be satisfied.

The EPM is related to a weighted version of the Constrained Egalitarian Allocation (CEA) method (Dutta and Ray 1991). The CEA method seeks to pick a point in the core that is as egalitarian as possible, i.e., where the allocated amounts are as equal as possible. We can also define a weighted version of the CEA method (Koster 1999). In order to relate the weighted CEA method to the method of Frisk et al. (2010), we set the weight of player i equal to 1/c({i}).

5 Technology

Building a coalition and managing it, require that quality information is shared between the collaborating entities. In all supply chains, information flows both upstream and downstream. For example, orders, sales forecasts, point of sales data or customer surveys, are sent top-down within the chain. In the opposite direction, information such as delivery plans, offers, catalogue, promotion, and availability (e.g., capacity or inventory) are sent from the suppliers to the customers.

The same principles also apply to financial flows. The payment will go from a customer to a supplier, whereas the credits, returns, or guarantees will go from the supplier to the customer. Financial flows involve financial institutions. All product and financial flows are supported by information flows. Typically, the flows link business entities two by two within the chain. However, collaborative logistics raise the need for higher connectivity as flows may be used by more entities.

This challenge has motivated great efforts to standardize the information flows. Different standards such as RosettaNet (www.rosettanet.org) provide shared guidelines in order to support timeless and effective interoperability within the supply chain. The aim is to eliminate the need for negotiating and agreeing on data definitions and formats with each trading entity, each time a possible transaction occurs. A common messaging interface enables the entities to exchange rapidly with many different entities by means of electronic data exchange technology and to reduce errors in data treatment and exchange.

Large corporations have started to use such standards to streamline their supply chain with their main customers (see PapiNet.org for examples). Although many standards exist, still many software enterprises develop their own model. In such cases, they typically use XML files to support the integration of the different technologies.

In logistics, application deals with different flows. Table 3 summarizes briefly the main information being exchanged when dealing with logistics.

Information can also be exchanged to inform on the status or characteristics of the main element of the value chain, as given in Table 4.

To support the information flows, platforms are needed. Building and sharing this type of infrastructure represent a challenging problem related to collaborative planning. Internet based technologies are providing many ways to connect the different entities and support their collaboration.

More specifically, agent-based technologies are rising as a new body of approaches building on distributed computing techniques. They intend to tackle the need for reactive, reliable, and (re)configurable operation management systems. An agent-based system may be defined as a system made of interdependent software agents designed to (a) individually handle a part of a problem such as planning an order or dispatching a task to a carrier and (b) collectively carry out specific higher functions such as planning a shared warehouse. Software agents generally exhibit characteristics that allow them to individually behave and interact with each other in order to fulfill the purpose of the entire system.

In such systems, information flows are supported by conversation protocols and messages. A conversation protocol links messages to form a conversation. As for messages, they have their own purposes and move from one sender to one or many receivers. The platform to support the flows of messages can vary greatly going from a blackboard where messages are posted to a real collaborative logistics eHub.

Application of an agent-based platform for collaborative logistics is described in Audy et al. (2007b). It illustrates the Virtual Transportation Manager which is a web-based application permitting entities to post their transportation needs on a platform which thereafter optimizes the multiple pick-up and delivery transportation planning problem. The optimized routes, once accepted by the entities, are proposed to carriers.

6 Discussion

This paper sought to review some critical issues in building and planning a coalition with the aim of conducting collaborative logistics. As shown throughout the paper, the interest for this domain is rising both in the academic community as well as in industry. Even though new ideas and methods are provided to support the different decisions, many problems are still very difficult to deal with. These problems often call for interdisciplinary solutions. For example, in the process of building a coalition, some entities may be strong competitors. This type of relation has been called “co-opetition”. In such a case, trust may play an important role in the decision process.

Legal issues are also very important. Many countries are concerned with potential collusive activities and therefore legislate to avoid them (e.g., antitrust law). Collaborative logistics projects need to address upfront the legislative limitation. Therefore, legal competencies may be needed. The sharing scheme may be analyzed in detail.

The sharing of the benefit in practice can be difficult, in particular when these benefits are intangible. For example, suppose there is a collaborative logistics project which permits an entity to access high value markets more easily, more rapidly and therefore develop them at low costs. What is the value of the increased geographical coverage or the faster deliveries?

Finally, the collaboration is rarely fixed in time. The environment changes constantly as well as the parameters considered when designing the collaboration. How should this dynamic be considered upfront? How often should the terms of the collaboration be reviewed?

References

Audy, J. F., D’Amours, S., & Rönnqvist, M. (2007a). Business models for collaborative planning in transportation: an application to wood products. In L. Camarinha-Matos, H. Afsarmanesh, P. Novais, & C. Analide (Eds.), In IFIP international federation for information processing, establishing the foundation of collaborative networks (Vol. 243, pp. 667–676). Boston: Springer. 10–12 septembre, Guimarães, Portugal.

Audy, J. F., D’Amours, S., & Rousseau, L. M. (2007b). Collaborative planning in a log truck pickup and delivery problem. 6th Triennial Symposium on Transportation Analysis (p. 6), June 10–15, Phuket Island, Thailand.

Audy, J. F., D’Amours, S., & Rousseau, L. M. (2010). Cost allocation in the establishment of a collaborative transportation agreement-an application in the furniture industry. Journal of the Operational Research Society, (26 May 2010) doi:10.1057/jors.2010.53.

Beaudoin, D., LeBel, L., & Frayret, J. M. (2007). Tactical supply chain planning in the forest products industry through optimization and scenario-based analysis. Canadian Journal of Forest Research, 37(1), 128–140.

Cachon, G. P. (2003). Supply chain coordination with contracts. In Handbooks in operations research and management science (vol. 11, pp. 229–339). Elsevier.

Cederlund, J. P., Kohli, R., Sherer, S. A., & Yao, Y. (2007). How Motorola put CPFR into action. Supply chain management review, October 2007, 28–35.

Chen, F. (2003). Information sharing and supply chain coordination. In Handbooks in operations research and management science (vol. 11, 341–421). Elsevier.

D’Amours, F., D’Amours, S., & Frayret, J. M. (2004). Collaboration et outils collaboratifs pour la PME Manufacturière. Technical report, CEFRIO, http://www.cefrio.qc.ca/upload/ 1412_ RapportfinalCollaborationetoutilscollaboratifs.pdf

Danese, P. (2006). The extended VMI for coordinating the whole supply network. Journal of Manufacturing Technology Management, 17(7), 888–907.

Dutta, B., & Ray, D. (1991). Constrained egalitarian allocations. Games and Economic Behavior, 3(4), 403–422.

Eriksson, J., & Rönnqvist, M. (2003). Decision support system/tools: Transportation and route planning: Åkarweb – a web based planning system. Proceedings of the 2nd forest engineering conference, Växjö, pp. 48–57, May 12–15.

Frayret, J. M., D’Amours, S., & Montreuil, B. (2004). Co-ordination and control in distributed and agent-based manufacturing systems. Production Planning and Control, 15(1), 1–13.

Frisk, M., Göthe-Lundgren, M., Jörnsten, K. & Rönnqvist, M. (2010) Cost allocation in collaborative forest transportation, European Journal of Operational Research, 205, 448–458.

Montreuil, B., Frayret, J. M., & D’Amours, S. (1999). A Strategic framework for networked manufacturing. Computers in Industry, 42(2–3), 299–317.

Moyaux, T., Chaib-draa, B., & D’Amours, S. (2007). The impact of information sharing on the efficiency of an ordering approach in reducing the bullwhip effect. IEEE Transactions on Systems, Man, and Cybernetics, Part C (SMC-C), vol. 37(3).

Koster, M. (1999). Weighted constrained egalitarianism in tu-games, Center for Economic Research. Discussion Paper 107, Tilburg University.

Lee, H. L., Padmanabhan, V., & Whang, S. (1997). Information distortion in supply chain: the bullwhip effect. Management Science, 43(4), 546–558.

Lehoux, N., D’Amours, S., & Langevin, A. (2008) Dynamique des relations interentreprises: Mécanismes, barrières et cas pratique. Revue Française de Gestion Industrielle 27(4), 1–25.

Lehoux, N., D’Amours, S., & Langevin, A. (2009) Collaboration and decision models for a two-echelon supply chain: a case study in the pulp and paper industry. Journal of Operations and Logistics, 2(4), 1–17.

Simchi-Levi, D., Kaminsky, P., & Simchi-Levi, E. (1999). Designing and Managing the Supply Chain: Concepts, Strategies, and Cases (p. 321). McGraw-Hill/Irwin.

VICS, (2004). CPFR Guidelines. http://www.vics.org/home

Shapley, L. S. (1953). A value for n-person Games. Annals of Mathematics Studies, 28, 307–317.

Sprumont, Y. (1990). Population monotonic allocation schemes for cooperative games with transferable utility. Games and Economic Behavior, 2(4), 378–394.

Tijs, S. H., & Driessen, T. S. H. (1986). Game theory and cost allocation problems. Management Science, 32(8), 1015–1028.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2010 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

D’Amours, S., Rönnqvist, M. (2010). Issues in Collaborative Logistics. In: Bjørndal, E., Bjørndal, M., Pardalos, P., Rönnqvist, M. (eds) Energy, Natural Resources and Environmental Economics. Energy Systems. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-12067-1_22

Download citation

DOI: https://doi.org/10.1007/978-3-642-12067-1_22

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-12066-4

Online ISBN: 978-3-642-12067-1

eBook Packages: EngineeringEngineering (R0)