Abstract

An overview is presented of the current state of understanding of the chemical pathways that lead to the formation of crystalline metal soap phases in oil paints, based on recent experimental work by the authors and supported by relevant literature. Improved (quantitative) interpretation of Fourier-transform infrared (FTIR) spectra has revealed that metal ions are bound to carboxylate functionalities of the oil polymer during oil paint aging, a state similar to ionomeric polymers. Tailored ionomer-like systems based on linseed oil were synthesized to study the structure of the mature oil paint binding medium, and such systems were used as the starting point for studies on metal soap crystallization. Additionally, series of differential scanning calorimetry (DSC) studies shed light on the driving forces and kinetics of metal soap crystallization, and electron microscopy studies have been used to image the initial stages of metal soap crystallization. The results have been used to construct a model of the chemical reactions leading to metal soaps from a mixture of pigment and oil. Additionally, the model provides insight into diffusion mechanisms for metal ions and fatty acids and potential physical transitions in the structure of metal soaps. The mechanisms described are helpful in explaining the different morphologies of lead and zinc soaps observed in actual samples from historic paintings and the locations within paint films where these are typically found.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

1 Introduction

Since metal soaps were first identified in large protrusions in oil paint layers, considerable efforts have been made to characterize them and the mechanisms by which they form. We now know that lead and zinc are the most common metal ions to form metal soaps, originating from pigments and/or driers like zinc white ( ) [13, 19, 31], lead white (

) [13, 19, 31], lead white ( ) [20], lead-tin yellow (

) [20], lead-tin yellow ( ) [16], chrome yellow (

) [16], chrome yellow ( ) [30], red lead (

) [30], red lead ( ), litharge (

), litharge ( ), or lead acetate (

), or lead acetate ( ), though copper and calcium soaps have also been found. The fatty acids in these metal soap phases derive from the drying oil binder or paint additives (for instance, stearate salts used as dispersing agents in modern paints). They are almost exclusively the saturated fatty acids palmitic, stearic, or azelaic acid [33], with the occasional presence of oleic acid [10]. In terms of morphology, it has been observed that lead soaps tend to form large metal soap aggregates like in Fig. 3.1. This material seems to be capable of deforming the paint layers under which it grows, and it can undergo remineralization to carbonates, sulfates, chlorides, or oxides [3, 20]. In contrast, zinc soaps tend to remain more dispersed throughout a paint layer [13]. Though not all metal soap formations are detrimental to paint stability, it is unquestionable that both lead and zinc soaps have been associated with paint flaking, protrusions, transparency, brittleness, and delamination, examples of which are well-documented in some of the other contributions to this volume.

), though copper and calcium soaps have also been found. The fatty acids in these metal soap phases derive from the drying oil binder or paint additives (for instance, stearate salts used as dispersing agents in modern paints). They are almost exclusively the saturated fatty acids palmitic, stearic, or azelaic acid [33], with the occasional presence of oleic acid [10]. In terms of morphology, it has been observed that lead soaps tend to form large metal soap aggregates like in Fig. 3.1. This material seems to be capable of deforming the paint layers under which it grows, and it can undergo remineralization to carbonates, sulfates, chlorides, or oxides [3, 20]. In contrast, zinc soaps tend to remain more dispersed throughout a paint layer [13]. Though not all metal soap formations are detrimental to paint stability, it is unquestionable that both lead and zinc soaps have been associated with paint flaking, protrusions, transparency, brittleness, and delamination, examples of which are well-documented in some of the other contributions to this volume.

For the conservation of paintings that are negatively affected by metal soap formation, a comprehensive understanding of the chemical pathways that lead from a fresh oil paint to a degraded painting should be the ultimate goal. When it is possible to characterize all the stages in the metal soap formation pathway and accurately diagnose the state of a specific paint layer, targeted strategies can be developed to slow down degradation at that particular stage. Besides determining a set of chemical reactions occurring in the drying oil medium and at the interface with pigments, it is important to develop an understanding of the reaction rates and transport processes. These rates not only determine how fast degradation takes place under certain circumstances, but they may also affect the size and location of metal soap phases.

In the past 5 years, we have conducted research on the structure of mature oil paint binding media and the crystallization of metal soaps using a combination of Fourier-transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), differential scanning calorimetry (DSC), and electron microscopy. An adaptable experimental model system that mimics mature oil paint binding media was developed to allow the isolation and control of parameters, like metal concentration, extent of polymerization, and degree of oxidation, and study their effect on metal soap formation. This system also offers an alternative to artificially aged reconstructions of oil paints for the study of cleaning or restoration methods.

In this paper, an overview is given of our current level of understanding of the processes that lead to metal soap formation, which is based on experimental evidence gathered by the authors, supported by relevant literature from the oil paint conservation field as well as the wider chemical literature. To structure the discussion, we classify oil paint aging processes in two sets: processes that mostly contribute to the drying and stabilization of an oil paint (Sect. 3.2) and processes that have a tendency to cause paint deterioration (Sect. 3.3). The two classes of processes are not separated in time; in reality, all processes are likely to co-occur on all timescales to some extent, with paint stabilization being dominant only on relatively short time scales. The discussion of mechanisms presented here mostly concerns metal soap formation in mixtures of pigment and drying oil. The presence of lead driers or additives like aluminum stearate may change the order in which processes take place, but many of the individual reaction or transport steps described here should be relevant to most cases of metal soap formation. It should be noted that the systems described in the chapter are simplified with respect to historic artists’ paints (which can have significant formulation differences between lead white and zinc white paints in terms of particle sizes, additives, impurities, and driers), so as to be able to derive widely applicable mechanistic information on paint aging. Finally, we discuss important gaps remaining in our comprehension of metal soap formation and suggest experiments that could reduce their magnitude.

2 Oil Paint Drying: The Formation of Ionomer Networks

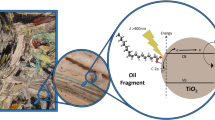

As soon as a pigment is mixed with a drying oil (typically linseed oil), reactions will start to take place that persist well after the paint has dried to the touch, some of which ultimately lead to the formation of metal soaps. In what follows, it is very important to make the distinction between metal soaps (complexes of metal ions and fatty acids, in oil paints usually saturated mono- or dicarboxylic fatty acids) and the much broader class of metal carboxylates, which may have any sort of molecular functionality or structure behind the carbon atom in the carboxylic headgroup. The main reaction steps believed to be contributing to the stability of the polymer medium are illustrated in Fig. 3.2 and will be discussed in detail below.

Illustration of the processes near the pigment/medium interface occurring during drying in oil paints containing pigments prone to develop metal soaps. The drying oil binding medium (a) acquires carboxylate groups during autoxidative drying (b), after which diffusion of metal ions from the pigment surface (c) leads to the formation of an ionomeric system (d). Dashed red arrows illustrate the diffusion of metal ions from the pigment surface into the polymerized binding medium mediated by negatively charged carboxylate moieties

2.1 Carboxylate Formation During Oil Paint Drying

The early stages of oil paint drying are described extensively in the literature. Upon exposure to oxygen, drying oils such as linseed oil form a densely cross-linked polymer network mostly through radical polymerization reactions [25,26,27,28,29]. In this polymerization process, one reaction pathway leads to scission of fatty acid chains containing a peroxyl radical to yield aldehydes. FTIR spectroscopy has revealed that these aldehydes are at least partially oxidized to carboxylic acid groups [25]. Carboxylic acids can also be generated by hydrolysis of the ester bond in the triacyl glyceride molecules that make up the oil, as discussed in detail in Sect. 3.3.1. Polymers containing carboxylic acid functionalities have been shown to adsorb on metallic zinc, especially when that zinc surface was treated with base to increase the concentration of hydroxyl groups on the oxidized zinc surface [36]. Fatty acids are also routinely used to coat ZnO nanoparticles [1, 34]. The ability of carboxylate groups to adsorb on metal oxide surfaces makes fatty acids and carboxylic polymers common stabilizers for colloidal dispersions [5, 23, 35]. These carboxylic-metal surface interactions are expected to be a common phenomenon as well for many pigments in polymerized linseed oil, as the coordination of metal ions on the pigment surface by carboxylate groups could help lower the interfacial energy between pigment and binding medium (Fig. 3.2b).

2.2 Migration of Metal Ions Throughout the Polymeric Medium

In cross-sections of oil paintings that contain metal soaps, it has often been observed that the metal soap aggregates are separated from pigment particles by stretches of binding medium. This important observation implies that either metal soaps have formed near the pigment-oil interface and migrated as complex or that metal ions have diffused through the binding medium (assuming that free saturated fatty acids can be found throughout the binding medium). Considering the mass, the bulkiness, and, as we shall discuss in detail later, the very low solubility of metal soap complexes [15], the latter case is highly likely to be the dominant process. As experimental support of this idea, we observed that characteristic zinc carboxylate vibration bands can be found in equal intensity in transparent areas of a ZnO model paint film and in areas containing pigment, indicating that zinc ions must have migrated through the binding medium, as shown in Fig. 3.3. We propose that metal ions such as zinc and lead are able to diffuse through the binding medium by “hopping” from one carboxylate group to the next, as illustrated in Fig. 3.2c. Such a transport mechanism has been studied both experimentally and through molecular dynamics simulations for several synthetic polymers [4, 9, 22, 38]. Before the transfer of a metal ion from one carboxylic group to a second can occur, the bound and unbound carboxylic groups need to come in close proximity, which requires mobility of the polymer segments. The rate at which metal ion migration through the medium can occur is therefore strongly increased by conditions that increase polymer dynamics. The swelling of paint films by solvent, for instance, plasticizes the polymeric binding medium and is likely to have a strong effect on metal ion diffusion rates. Like all polymers, oil paint binding media also have a glass transition temperature (T g), the temperature range at which a polymer changes from a rigid glass-like state to a softer rubbery state. There is still some uncertainty about typical T g values for oil paint binding media or the influence of pigments on T g. However, an interesting study by Phenix [2009] reported broad glass transitions between −2 ∘C and 45 ∘C for a variety of fully dried pigmented paint films, with some zinc white paint films only showing gradual thermal softening.

(a) Detail of a thin model “paint” film consisting of a low concentration of ZnO in linseed oil, with a band of transparent polymerized medium on the outer perimeter. The film was dried at room temperature for 7 weeks. (b) FTIR spectra corresponding to sections of the film with and without ZnO, both showing a broad zinc carboxylate band centered around 1580 cm−1, indicating that zinc ions have migrated through the binding medium

2.3 Formation of Ionomer-Like Binding Medium

When dissociation of metal ions from the pigment surface and subsequent metal ion migration through the polymerized binding medium are spontaneous processes, they are likely to continue until many of the free carboxylate groups in the binding medium are bound to metal ions. Such a binding medium filled with metal ions can be classified as an ionomeric polymer network (Fig. 3.2d). We consider this stage in oil paint curing as part of the drying process, because despite the necessary loss of pigment during the formation of an ionomeric system, the metal ions can in fact contribute to the stability of a polymerized oil network. Divalent ions such as Zn2+ and Pb2+ need to coordinate to two carboxylate groups to balance their charge, so they effectively form additional cross-links between sections of polymer chain. Though these bonds are more easily dissociated than covalent cross-links, at room temperature, these strong metal carboxylate links will increase the stiffness of the binding medium. The formation of ionomer-like structures in oil paint binding media has been suggested before as an interpretation of broad metal carboxylate bands shifted toward higher wavenumbers compared to pure metal soap references often observed in FTIR spectra of mature oil paints. Ionomers have also been offered as an explanation for the somewhat surprising remaining structural stability of oil paints that have suffered extensive breakdown of the polymer network through aging [3, 39, 40, 42].

To investigate the validity of the metal migration processes just described experimentally, we have compared oil paint binding media to a synthetic ionomer based on linseed oil with controllable metal ion concentrations. The most successful method was to synthesize complexes of either lead or zinc with sorbic acid (2,4-hexadienoic acid), mix this insoluble powder with linseed oil, and cure a thin layer of the resulting paste in an air-circulated oven at 150 ∘C. Transparent homogeneous orange/brown films were obtained that showed no remaining metal sorbate bands in FTIR spectra or crystalline peaks of the metal sorbate complex in X-ray diffractograms [13]. Instead, a broad metal carboxylate IR band appeared with a maximum around 1585 and 1530 cm−1 for zinc and lead ionomers, respectively (see Fig. 3.4). The position and shape of these bands are very similar to those observed in many samples from naturally aged oil paints containing ZnO or lead-containing pigments [16, 31, 37, 42]. Small-angle X-ray scattering (SAXS) revealed that these linseed oil-based ionomers, similar to commercial less cross-linked ionomer systems, show characteristic peaks at d = 70–90 Å caused by the formation of clusters of ionic metal carboxylate groups within the polymerized binding medium [14]. The properties and concentration of these ionic clusters in oil paint binding media could have an important effect on metal ion migration rates and the mechanical properties of the paint.

Several hypotheses have been put forward to account for the broad metal carboxylate band in FTIR spectra of oil paint samples, such as the top spectra in Fig. 3.4a, b. Besides the ionomer hypothesis, it has been suggested that carboxylate groups could be adsorbed on the surface of pigments with a variation of binding geometries and bond lengths, causing the metal carboxylate band to broaden [6, 31]. Alternatively, the band could be associated with metal soaps that have not yet crystallized. In molten (i.e., amorphous) form, the metal soaps are known to show a shift in the metal carboxylate bands [17]. In order to distinguish between these three hypotheses, we can consider the potential maximum number of metal carboxylate bonds in each of them [14]. The number of noncrystalline metal soap complexes that can be formed in a fully cured binding medium is limited by the fraction of the total fatty acid content (present as esters) in linseed oil that is saturated. These saturated fatty acids are stearic and palmitic acid naturally present in linseed oil, and diacids such as azelaic acid formed through oxidation. The fraction of saturated fatty acids in linseed oil is usually around 7–13% [41]. In the case of adsorption of carboxylates on pigments, on the other hand, the maximum number of metal carboxylate bonds is limited by the available pigment surface area, which in turn depends on the pigment-to-oil weight ratio and the average particle size of the pigments.

Using the linseed oil ionomer model system, we prepared a calibration series varying in metal content that allows calculation of the molar ratio of metal carboxylate groups to ester groups (COOM/COOR) in any real oil paint sample or model paint. A determination of the absolute concentration of metal carboxylates is not (yet) possible, because the concentration of ester bonds is difficult to determine in insoluble solid polymer films. Typical oil paint films showing a broad and shifted metal carboxylate band had a COOM/COOR ratio around 0.5 or higher [14]. This concentration of metal carboxylate groups is too high to be explained completely by either amorphous metal soaps or the adsorption of carboxylates on pigment surfaces or a combination of the two. In each of these cases, the COOM/COOR ratio would never increase beyond 0.15 for a realistic paint formulation [14]. We may conclude, therefore, that the broad metal carboxylate bands observed in FTIR spectra of oil paint films are largely caused by metal ions bound to the linseed oil polymer network. In those cases, the binding medium has become an ionomer-like system.

The classification of the oil paint binding medium as an ionomer-like system has a big impact on our understanding of metal soap-related degradation pathways and paint stability. If the ionomer model for aged oil paints is appropriate, it means that metal ions are distributed throughout the binding medium as carboxylate complexes, where they may act as a catalyst or reactant in subsequent reactions. Therefore, in theory, the formation of metal soaps could occur anywhere where there are free saturated fatty acids available to form a complex with. These free acids can be located either within the paint layer or on the interface with, for instance, a medium-rich layer. In the next section, we will discuss potential molecular mechanisms for forming large crystalline metal soap phases from ionomeric binding media.

3 Oil Paint Deterioration: Metal Soap Formation in Ionomer Networks

Ionomer networks are potentially stable for long periods of time. When there are no other significant concentrations of negatively charged ions and the number of carboxylic groups in the system reaches a constant value in a fully dried paint film, there is no net movement of metal ions through the system once all carboxylate functionalities are bound to metal ions. If crystalline metal soaps are to form in an ionomeric system, a significant fraction of the ester bonds in the triacylglycerides that make up the drying oil polymer need to be hydrolyzed (or the system needs to be exposed to an external source of fatty acids, e.g., beeswax), as the concentration of free saturated fatty acids (SFAs) in liquid drying oil is rather low. The processes leading to metal soap formation in ionomeric oil paint media are illustrated in Fig. 3.5.

Illustration of metal soap-related degradation processes in ionomeric binding media (a), triggered by the presence of free SFAs (b) and resulting in the formation of large crystalline metal soap phases (c). Dashed arrows illustrate the diffusion of metal ions (red) and free SFAs (blue) toward the growing crystalline metal soap aggregate

3.1 Free Fatty Acid Generation Through Ester Bond Hydrolysis

There are two distinct ways in which ester hydrolysis can occur, both of which require the presence of water molecules. Firstly, spontaneous hydrolysis, the reaction of an ester group with a water molecule, would lead to the formation of a carboxylic acid group and an alcohol. When the specific fatty acid chain is completely saturated, this reaction would lead to the generation of a carboxylic acid that may diffuse through the polymerized binding medium, a free SFA. However, we need to consider that, in the case of an ionomeric binding medium, there are lead or zinc ions dispersed throughout the system and these ions may act as Lewis acids. The ions are coordinated to carboxylic groups, but the fact that they are capable of diffusing through the binding medium means that it is a rather dynamic type of coordination. The width of the metal carboxylate band in FTIR spectra of ionomers also suggests that metal coordination is not very well-defined in these systems. Given this situation, it is reasonable to suppose that ester carbonyl moieties can transiently bind to the metal ion as well. Lewis acids such as lead and zinc ions draw away electron density from the ester carbonyl bond, destabilizing the  bond that links the fatty acid to the glycerol backbone. This destabilization makes the ester more prone toward hydrolysis. Cases have been reported in the literature where a zinc carboxylate complex catalyzes transesterification of a wide variety of methyl esters [18]. MacDonald and co-workers found that ethyl linoleate is quickly hydrolyzed to form ethanol and metal linoleate complexes in the solutions of either zinc or lead acetate in methanol, while ethyl linoleate seemed to remain intact when potassium acetate was used [24]. This experimental result supports the idea that, given the presence of metal ions in the polymerized binding medium, these ions themselves play a role in liberating fatty acids through hydrolysis, a proportion of which will be saturated.

bond that links the fatty acid to the glycerol backbone. This destabilization makes the ester more prone toward hydrolysis. Cases have been reported in the literature where a zinc carboxylate complex catalyzes transesterification of a wide variety of methyl esters [18]. MacDonald and co-workers found that ethyl linoleate is quickly hydrolyzed to form ethanol and metal linoleate complexes in the solutions of either zinc or lead acetate in methanol, while ethyl linoleate seemed to remain intact when potassium acetate was used [24]. This experimental result supports the idea that, given the presence of metal ions in the polymerized binding medium, these ions themselves play a role in liberating fatty acids through hydrolysis, a proportion of which will be saturated.

In light of these findings, the common addition of aluminum stearate (either as AlSt(OH)2 or AlSt2OH, with St = stearate) to commercial titanium white and zinc white oil paint formulations could prove doubly problematic [2, 8, 31]. Besides adding a source of saturated fatty acids to the system that could crystallize with zinc ions to form zinc soaps, Al3+ is a relatively strong Lewis acid. If the carboxylate or hydroxyl ion coordination to aluminum is temporarily disrupted, the aluminum ion may well have a strong influence on ester hydrolysis reactions.

Even if ester hydrolysis occurs mostly near metal ions, diffusion of metal ions and fatty acids can still happen. In fact, the diffusion rates of metal ions and/or fatty acids may play an important role in determining how fast crystalline metal soap phases grow in oil paint layers, as is discussed below.

3.2 The Crystallization of Metal Soaps

When the transition has occurred from an ionomer to a binding medium that contains a concentration of free SFAs as well as metal ions, a state is reached where all the necessary ingredients for metal soap formation are present (Fig. 3.5b). To investigate whether the availability of these components is really a sufficient condition for the formation of crystalline metal soaps, i.e., whether free SFAs are causing the formation of metals soaps, we carried out experiments in which lead and zinc ionomers based on linseed oil were exposed to a solution of palmitic acid in ethanol. Figure 3.6 shows a typical time series of ATR-FTIR spectra of a lead ionomer that shows the immediate increase of IR bands associated with crystalline lead palmitate, the lead carboxylate band at 1510 cm−1, and the alkyl chain progression bands in the 1200–1350 cm−1 range being the most prominent. XRD analysis confirmed that the metal soaps were indeed crystalline. The same experiment was carried out with zinc ionomers, which showed crystalline zinc palmitate formation on a similar timescale. The metal soap formation reactions are very quick in these experiments, with metal palmitate bands appearing just seconds after starting exposure. This high reaction rate suggests that, in the reaction pathway toward crystalline metal soap phases in oil paint layers, the reaction between metal ions and fatty acids to form crystalline metal soaps is not rate limiting.

Time series of ATR-FTIR spectra of a lead ionomer of linseed oil (16 mg lead sorbate with 200 mg linseed oil) exposed to a solution of palmitic acid in ethanol (143 mM). All spectra were normalized to the ester carbonyl band at 1740 cm−1. Arrows indicate characteristic crystalline lead palmitate bands that increase in intensity over time

To help understand why metal soaps would crystallize and form aggregates in oil paint binding media, we studied the melting and crystallization temperatures of lead and zinc palmitate in both liquid and partially polymerized linseed oil with differential scanning calorimetry (DSC) [15]. The resulting phase diagrams for these two metal soaps are shown in Fig. 3.7a, b. It is immediately clear that the solubility of both lead and zinc soaps is very low in linseed oil at room temperature, in the order of 10−3–10−4 mol%, and that this solubility only starts to increase significantly around 80 ∘C for lead palmitate and around 90 ∘C for zinc palmitate. It was also found that the melting temperatures of both metal soaps did not change much as the linseed oil started to polymerize due to heat treatment, as shown in Fig. 3.7c, d. This means that the solubility of metal soaps is not greatly affected by oil polymerization [15]. Therefore, soon after a part of the ester bonds are hydrolyzed and the resultant free carboxylates have bound to metal ions (which will not be difficult if hydrolysis is truly catalyzed by metal ions), the binding medium has become supersaturated with metal soaps. In other words, the system has become metastable. Though a metastable state of uncrystallized metal soaps in an ionomer is potentially long-lived under some conditions, the system will tend to show spontaneous crystallization of metal soaps. Whether and at what rate that crystallization does actually occur depends partially on the energy barrier that needs to be overcome for the first metal soap “units” to come together and form a crystalline nucleus. In the case of long-chain metal soap formation in ionomeric oil paint media, the largest driving force for crystallization is probably the alignment of the alkyl chain to maximize Van der Waals interactions, because the metal ions are already coordinated by carboxylate groups (though this coordination might not be ideal).

Phase diagrams of (a) lead palmitate and (b) zinc palmitate in liquid linseed oil. Closed and open symbols represent melting and crystallization temperatures, respectively. Dashed lines indicate the approximate phase boundary as determined by fitting the ideal relation between the saturation concentration of a solute and temperature to the data. Bottom figures show the melting (red) and crystallization (blue) temperature (left axis), as well as the crystallization enthalpies (open symbols, right axis) for (c) lead palmitate and (d) zinc palmitate in linseed oil as a function of heating time at 150 ∘C (concentration of metal soaps is at a mol fraction of 0.11). See Hermans et al. [15] for further details

The degree of supercooling (i.e., the difference between the crystallization and melting temperature) needed for the formation of a critical crystal nucleus and the start of crystallization is a qualitative measure for the crystallization rate. It was found that lead and zinc palmitate are very different in this respect, with zinc palmitate in linseed oil starting crystallization approximately 50 ∘C below its melting point, while this value was around 6–9 ∘C for lead palmitate in linseed oil (Fig. 3.7a, b). Furthermore, this difference between melting and crystallization temperatures increased steadily as the linseed oil medium became more polymerized, as shown in Fig. 3.7c, d. These observations could mean that in the case of a fully polymerized binding medium, zinc soaps may be kinetically trapped in an amorphous state, while lead soaps would crystallize relatively fast, which can be a partial explanation for the difference in morphology observed for lead and zinc soaps formed in oil paint layers.

Once the crystallization process has started by the formation of crystallization nuclei, the further growth of crystalline metal soap phases in polymeric binding media is likely to be diffusion-limited. When the local concentrations of metal ions and fatty acids close to crystalline metal soaps drop, a concentration gradient arises which causes a net diffusion of those components toward the crystalline phase (illustrated in Fig. 3.5c). At this point, an oil paint can become subject to dramatic changes, because the accumulation of SFAs and metal ions into the crystalline metal soap phases enhances the equilibrium reactions that liberate the fatty acids from the polymerized medium and metal ions from pigments, causing a breakdown of both binding medium and pigment. However, it is unclear which factors control the rate of growth of metal soap crystals. Ostwald ripening may take place, causing the growth of larger metal soap phases at the expense of smaller ones, as is suggested by the frequent observation of very large crystalline lead soap protrusions in samples from oil paintings, such as the one depicted in Fig. 3.1.

The location of metal soap crystallization is also interesting to consider. Crystalline zinc soaps have often been detected especially in the lower parts of zinc white paint layers [13, 31], and lead soap aggregates have been often found close to the interface between paint layers. These preferential locations for crystalline metal soap aggregates could be due to a variety of factors that affect either the nucleation or growth of crystals. For instance, if paint layers do not polymerize homogeneously but have a lower cross-link density in the deeper sections of the paint layer, nucleation of crystal phases could be easier in those areas of the paint. Such an effect is perhaps more relevant for paints based on zinc pigments than for lead-rich paint, as lead pigments may act as a through drier in oil paints. Alternatively, a gradient in polymer properties could affect the rate of diffusion of metal ions and/or free SFAs toward crystal nuclei. In multilayer systems, the growth of metal soap phases could also be dependent on the supply of either metal ions or SFAs from a neighboring paint layer, causing metal soap phases to appear near the interface between two paint layers.

In an attempt to gain some insight into the early stages of the formation of crystalline zinc soaps, a combination of scanning electron microscopy (SEM) and transmission electron microscopy (TEM) was used to study a model paint film after a few weeks of aging at room temperature. The film consisted of ZnO in linseed oil pretreated with water to promote the formation of metal carboxylates (Fig. 3.8). In the images, the contrast is reversed from the usual convention, with the regions of higher electron density appearing darker. The concentration of ZnO was deliberately kept very low to ensure an excess of saturated fatty acids and to allow an easy distinction between ZnO particles (black), polymeric binding medium (light gray), and (semi-)crystalline metal soaps (dark gray) in the electron microscopy images.

(a) Backscatter electron SEM image (Zeiss, 12 keV) of the surface of a model ZnO paint. The surface was prepared by cutting the sample with a microtome blade inside the microscope chamber. Darker colors represent higher electron density. The inset shows a gray value histogram with frequencies of black, dark gray, light gray, and white pixel regions. The black spots are remaining ZnO particles, light gray is the polymer medium, and dark gray areas are zinc soaps. The white lines are artifacts as a result from microtoming. (b) ATR-FTIR spectrum of the model ZnO paint, showing a strong broad zinc carboxylate band that is associated with an ionomer-like linseed oil network. (c) Detailed TEM image (FEI Tecnai F30 FEG-TEM, 300 kV) of an aggregated zinc soap in a 300 nm thick microtomed slice of a different section of the same model paint film, showing the layer structure of the crystalline zinc soap phase. Arrows indicate very small zinc soap fragments

Figure 3.8a shows that there is a large number of dark gray zinc soap aggregates. Interestingly, there seems to be no correlation between the location of remaining ZnO particles and the zinc soaps; crystallization obviously does not happen near the surface of pigment particles. This observation suggests that the zinc ions are in fact dispersed throughout and that crystallization may take place anywhere in the polymer, which is consistent with the ionomer model discussed previously. A TEM image of one of the zinc soap accumulations in Fig. 3.8c shows the internal structure of the aggregate zinc soap phase in greater detail. The accumulation is composed of many small (semi-)crystalline domains, each clearly showing the layered structure of zinc soaps. The spacing between the layers was calculated by taking the average of many measurements of the interlayer distance within one domain oriented roughly perpendicular to the plane of the image, and was found to be 45 ± 4 Å, which is similar to the interlayer spacings reported for zinc palmitate (38.5 Å) and zinc stearate (42.8 Å) [12]. The relatively wide range of measured spacings and the abundance of rough edges, breaks, and curvature in the zinc-containing planes suggest that there is still significant disorder in the packing of alkyl chains and/or metal ion coordination.

An ATR-FTIR spectrum of a bulk sample of this system is shown in Fig. 3.8b. Though the SEM and TEM images suggest that the system contains a mixture of (semi-)crystalline zinc soaps and ionomer-like polymer medium, the IR spectrum only contains a broad zinc carboxylate band associated with amorphous zinc carboxylates. The lack of any crystalline metal soap features could mean that the zinc soap accumulations are still too disordered to exhibit sharp IR bands and actually contribute to the broad band in Fig. 3.8b. This interpretation is supported by the work of MacDonald and co-workers, who found very similar (semi-)crystalline metal carboxylate domains in ethyl linoleate reacted with lead or zinc acetate [24]. In that system, XRD of an isolated metal carboxylate accumulation showed some crystalline features, while an FTIR spectrum of the same sample exhibited only a broad band associated with amorphous metal carboxylates. Alternatively, it could be the case that, despite the apparent abundance of zinc soaps in Fig. 3.8a, the zinc soap only constitutes a very small fraction of the total population of zinc carboxylate species, meaning that the FTIR spectrum is still dominated by ionomeric zinc carboxylates. Extended research on zinc- and lead-containing systems combining SEM and TEM with high-resolution FTIR microscopy or nanoIR (AFM-IR) would be able to further characterize this early stage of metal soap crystallization in oil paint layers.

4 Outlook

The experiments on metal soaps and ionomers described in the literature and those carried out by the authors have contributed to an understanding of the chemical processes occurring in oil paints that lead to the formation of large crystalline metal soap aggregates [11]. There is increasing evidence that oil paint binding media go through an ionomer-like state before metal soap crystallization takes place and that the hydrolysis of ester bonds by various mechanisms is a critical process. However, there are parts in the reaction pathway where we are still mostly limited to speculation. Moreover, the kinetics of nearly the entire pathway to the formation of metal soaps are uncertain. The reaction or diffusion rates can be strongly dependent on environmental conditions or paint composition, and these rates may make the difference between fast degradation and degradation that is too slow to be observed. Even when it is possible to measure directly the rate of a reaction or diffusion in a tightly controlled model system, this rate needs to be “translated” to more accurate systems that resemble mature oil paints. Finally, in order to develop improved conservation strategies, it is crucial that the more fundamental knowledge on the aging processes in oil paint is applied to the context of the practice of cleaning, restoring, and storage of oil paintings.

One of the important gaps in our current knowledge about the behavior of oil paints is the interactions between the liquid or polymerized oil medium and the surface of pigment particles. While it is almost certain that polar molecular groups like carboxylates and alcohols adsorb onto the surface of metal salt pigments, it is unclear exactly how this binding leads to the dissociation of metal ions from the surface into the binding medium. The stability of the pigment structure and its surface properties both play an important role, and they could be one of the reasons why metal soap formation is only regularly observed in paints with a limited selection of pigments. There have been interesting studies on the coordination of carboxylates on the surface of treated zinc surfaces [36], but more detailed experiments are needed that focus on the rate of metal ion release in relation to the concentration of carboxylates or other charged groups in the surrounding medium. The role of water in these processes should be considered as well, since humidity is consistently found to influence the degree of metal soap-related degradation and we have observed that pretreating model oil paints with a little water leads to a fast generation of broad metal carboxylate bands in FTIR spectra. Water could have an effect on the pigment surface charge or polarity, or it could directly affect the concentration of carboxylate groups or other polar groups in the polymer medium that make the polymer medium a more hospitable environment for metal ions.

While we have shown that the appearance of intense broad metal carboxylate bands in FTIR spectra of oil paints signifies a linseed oil polymer network that contains metal ions in its structure [14], it is at present not certain whether a full ionomer-like state is absolutely necessary to form crystalline metal soap phases. If the release of metal ions from certain pigments is much slower than the generation of free saturated fatty acids (either within the paint layer or in an adjacent one), it could be the case that metal ions do migrate through the binding medium by an ion-hopping mechanism but that they react with free SFAs quick enough to prevent the buildup of a concentration of metal carboxylates bound to the polymeric binding medium high enough to be detected with FTIR spectroscopy. In this scenario, especially likely for the more stable lead-containing pigments, one would expect only to detect crystalline metal soaps.

An interesting set of experiments to start investigating the questions raised above would be to prepare mixtures of zinc white or various lead pigments with linseed oil, with and without water pretreatment, and to track the appearance of both broad and sharp types of metal carboxylate band with FTIR as the mixtures polymerize to dry paints. Using calibration methods similar to those in Hermans et al. [14], it is possible to quantify the concentration of reaction products and find potential mechanistic differences for the formation of metal soaps with different pigments.

Another important point to be investigated is the hydrolysis of esters in drying oils. If hydrolysis is really the key process that triggers the crystallization of metal soaps, we need to verify whether metal carboxylates or other metal species present in paints have an active role in catalyzing this reaction, how strongly humidity affects the reaction, and what measures can be taken to minimize the rate of hydrolysis. A good starting point would be to test the potential catalytic effect of insoluble lead and zinc carboxylates on the hydrolysis of esters with model compounds in various solvents with different concentrations of water.

The rate at which an ionomer state is reached in oil paint binding media will be affected by the diffusion rate of metal ions through the system. The mobility of metal ions in ionomers can be studied by measuring the conductivity of the polymer system [7, 21, 38]. In a pilot experiment, we have found that the ionomer model system based on linseed oil has a low conductivity that seems to be a function of metal ion concentration. It will be very interesting to see how the mobility of metal ions is affected by an increase in temperature or a humid environment.

The same environmental conditions could also have a strong effect on the probability of forming a critical nucleus for metal soap crystallization and the rate with which this nucleus can grow into a large crystalline metal soap phase. The relation between all these rates, diffusion rates on the one hand and reaction rates on the other, will ultimately determine the location and size of crystalline metal soap phases in oil paint layers. For example, when diffusion is slow and crystallization fast in an ionomeric system, one expects a large number of small metal soap crystals to form that will only gradually increase in size through Ostwald ripening. However, when the situation is reversed (fast diffusion and slow crystallization) while keeping the concentration of reactants the same, one expects to find only few metal soap crystals that grow to a large size once they are formed. If conditions like humidity, temperature, or exposure to solvents have a strong effect on the relative rates of diffusion and crystallization in oil paint binding media, one can even imagine that mechanisms of metal soap formation are altered due to external influences. Detailed time-resolved FTIR studies on reaction-diffusion systems of linseed oil-based ionomers exposed to palmitic acid solutions are currently underway.

5 Conclusions

The processes in the pathway by which metal soaps are formed in oil paint systems have been reviewed, based on experiments on synthetic linseed oil-based ionomer systems conducted by the authors and supported by literature. Improved interpretation of metal carboxylate bands in FTIR spectra has shown that many oil paints containing pigments prone to metal soap formation go through a state in which the metal ions are bound to carboxylate groups attached to the polymer network. This characterization of oil paint media as an ionomer-like system is very helpful, because it allows us to make use of the existing literature on the structure and diffusion mechanisms in ionomers to understand molecular and macroscopic degradation phenomena in oil paintings.

When oil binding media are in an ionomer-like state, the presence of free fatty acids like palmitic and stearic acid (generated through ester hydrolysis) may cause a fast crystallization of metal soaps, as these complexes are practically insoluble in linseed oil. The location, size, and number of crystalline metal soap phases are determined in part by the relative rates of metal ion and fatty acid diffusion and the rate of metal soap crystallization. Therefore, kinetic studies on these processes are very important to improve our understanding of oil paint degradation phenomena related to metal soaps, and they are a logical starting point to investigate the effect of cleaning, restoration, and storage on the condition of oil paints.

References

Badre C, Dubot P, Lincot D, Pauporte T, Turmine M (2007) Effects of nanorod structure and conformation of fatty acid self-assembled layers on superhydrophobicity of zinc oxide surface. J Colloid Interface Sci 316(2):233–237

Boon JJ, Hoogland FG (2014) Investigating fluidizing dripping pink commercial paint on van Hemert’s seven-series works from 1990–1995. In: van den Berg KJ, Burnstock A, de Keijzer M, Krueger J, Learner T, Tagle A de, Heydenreich G (eds) Issues in contemporary oil paint. Springer, Cham, pp 227–246

Boon JJ, Hoogland F, Keune K (2006) Chemical processes in aged oil paints affecting metal soap migration and aggregation. In: AIC annual meeting, Providence, pp 18–25

Castagna AM, Wang W, Winey KI, Runt J (2011) Structure and dynamics of zinc-neutralized sulfonated polystyrene ionomers. Macromolecules 44:2791–2798

Cesarano J, Aksay IA (1988) Processing of highly concentrated aqueous α-alumina suspensions stabilized with polyelectrolytes. J Am Ceram Soc 71(12):1062–1067

Clementi C, Rosi F, Romani A, Vivani R, Brunetti BG, Miliani C (2012) Photoluminescence properties of zinc oxide in paints: a study of the effect of self-absorption and passivation. Appl Spectrosc 66(10):1233–1241

Fragiadakis D, Dou S, Colby RH, Runt J (2008) Molecular mobility, ion mobility, and mobile ion concentration in poly(ethylene oxide)-based polyurethane ionomers. Macromolecules 41:5723–5728

Gabrieli F, Rosi F, Vichi A, Cartechini L, Pensabene Buemi L, Kazarian SG, Miliani C (2017) Revealing the nature and distribution of metal carboxylates in Jackson Pollock’s Alchemy (1947) by micro-attenuated total reflection FT-IR spectroscopic imaging. Anal Chem 89(2):1283–1289

Hall LM, Stevens MJ, Frischknecht AL (2012) Dynamics of model ionomer melts of various architectures. Macromolecules 45:8097–8108

Helwig K, Poulin J, Corbeil MC, Moffatt E, Duguay D (2014) Conservation issues in several twentieth-century Canadian oil paintings: the role of zinc carboxylate reaction products. In: van den Berg KJ (ed) Issues in contemporary oil paint. Springer, Cham, pp 167–184

Hermans JJ (2017) Metal soaps in oil paint: structure, mechanisms and dynamics. Ph.D. thesis, University of Amsterdam

Hermans JJ, Keune K, van Loon A, Corkery RW, Iedema PD (2014) The molecular structure of three types of long-chain zinc(II) alkanoates for the study of oil paint degradation. Polyhedron 81:335–340

Hermans JJ, Keune K, van Loon A, Iedema PD (2015) An infrared spectroscopic study of the nature of zinc carboxylates in oil paintings. J Anal At Spectrom 30:1600–1608

Hermans JJ, Keune K, van Loon A, Iedema PD (2016a) Ionomer-like structure in mature oil paint binding media. RSC Adv 6:93,363–93,369

Hermans JJ, Keune K, van Loon A, Iedema PD (2016b) The crystallization of metal soaps and fatty acids in oil paint model systems. Phys Chem Chem Phys 18:10896–10905

Higgitt CL, Spring M, Saunders DR (2003) Pigment-medium interactions in oil paint films containing red lead or lead-tin yellow. Nat Gallery Tech Bull 24:75–95

Ishioka T, Maeda K, Watanabe I, Kawauchi S, Harada M (2000) Infrared and XAFS study on structure and transition behavior of zinc stearate. Spectrochim Acta A 56:1731–1737

Iwasaki T, Maegawa Y, Hayashi Y, Ohshima T, Mashima K (2008) Transesterification of various methyl esters under mild conditions catalyzed by tetranuclear zinc cluster. J Org Chem 73:5147–5150

Keune K, Boevé-Jones G (2014) It’s surreal: zinc oxide degradation and misperceptions in Salvador Dalí’s couple with clouds in their heads, 1936. In: van den Berg K (ed) Issues in contemporary oil paint. Springer, Cham, pp 283–294

Keune K, van Loon A, Boon JJ (2011) SEM backscattered-electron images of paint cross sections as information source for the presence of the lead white pigment and lead-related degradation and migration phenomena in oil paintings. Microsc Microanal 17:696–701

Kutsumizu S, Hashimoto Y, Hirasawal E, Yanot S (1994) dc conduction properties of a model ethylene-methacrylic acid ionomer. Macromolecules 27:1781–1787

Lin KJ, Maranas JK (2012) Cation coordination and motion in a poly(ethylene oxide)-based single ion conductor. Macromolecules 45:6230–6240

Lin CL, Lee CF, Chiu WY (2005) Preparation and properties of poly(acrylic acid) oligomer stabilized superparamagnetic ferrofluid. J Colloid Interface Sci 291(2):411–420

MacDonald MG, Palmer MR, Suchomel MR, Berrie BH (2016) Reaction of Pb(II) and Zn(II) with ethyl linoleate to form structured hybrid inorganic-organic complexes: a model for degradation in historic paint films. ACS Omega 1(3):344–350

Mallégol J, Gardette JL, Lemaire J (1999) Long-term behavior of oil-based varnishes and paints I. Spectroscopic analysis of curing drying oils. J Am Oil Chem Soc 76(8):967–976

Mallégol J, Gardette JL, Lemaire J (2000a) Long-term behavior of oil-based varnishes and paints. Fate of hydroperoxides in drying oils. J Am Oil Chem Soc 77(3):249–255

Mallégol J, Gardette JL, Lemaire J (2000b) Long-term behavior of oil-based varnishes and paints. Photo- and thermooxidation of cured linseed oil. J Am Oil Chem Soc 77:257–263

Mallégol J, Lemaire J, Gardette JL (2000c) Drier influence on the curing of linseed oil. Prog Org Coat 39(2–4):107–113

Mallégol J, Gonon L, Lemaire J, Gardette JL (2001) Long-term behaviour of oil-based varnishes and paints 4. Influence of film thickness on the photooxidation. Polym Degrad Stab 72:191–197

Monico L, Janssens K, Cotte M, Sorace L, Vanmeert F, Brunetti BG, Miliani C (2016) Chromium speciation methods and infrared spectroscopy for studying the chemical reactivity of lead chromate-based pigments in oil medium. Microchem J 124:272–282

Osmond G, Boon JJ, Puskar L, Drennan J (2012) Metal stearate disributions in modern artists’ oil paints: surface and cross-sectional investigation of reference paint films using conventional and synchrotron infrared microspectroscopy. Appl Spectrosc 66(10):1136–1144

Phenix A (2009) Thermal mechanical transitions in artists’ oil paints and selected conservation materials: a study by dynamic mechanical analysis (DMA). In: AIC paintings specialty group postprints, vol 22, pp 72–89

Plater M, De Silva B, Gelbrich T, Hursthouse MB, Higgitt CL, Saunders DR (2003) The characterisation of lead fatty acid soaps in ‘protrusions’ in aged traditional oil paint. Polyhedron 22:3171–3179

Sehmi SK, Noimark S, Pike SD, Bear JC, Peveler WJ, Williams CK, Shaffer MSP, Allan E, Parkin IP, MacRobert AJ (2016) Enhancing the antibacterial activity of light-activated surfaces containing crystal violet and ZnO nanoparticles: investigation of nanoparticle size, capping ligand, and dopants. ACS Omega 1(3):334–343

Shen L, Laibinis PE, Hatton TA (1999) Bilayer surfactant stabilized magnetic fluids: synthesis and interactions at interfaces. Langmuir 15(2):447–453

Taheri P, Ghaffari M, Flores JR, Hannour F, De Wit JHW, Mol JMC, Terryn H (2013) Bonding mechanisms at buried interfaces between carboxylic polymers and treated zinc surfaces. J Phys Chem C 117:2780–2792

Thoury M, van Loon A, Keune K, Réfrégiers M, Hermans JJ, Berrie BH (2017, in preparation) Visualization of different phases in the development of metal soaps using synchrotron photoluminescence micro-imaging. In: Metal soaps in art. Springer

Tudryn GJ, O’Reilly MV, Dou S, King DR, Winey KI, Runt J, Colby RH (2012) Molecular mobility and cation conduction in polyether-ester-sulfonate copolymer ionomers. Macromolecules 45:3962–3973

Tumosa CS, Erhardt D, Mecklenburg MF, Su X (2005) Linseed oil paint as ionomer: synthesis and characterization. In: Materials research society symposium proceedings, vol 852, pp 25–31

van den Berg JDJ, van den Berg KJ, Boon JJ (2001) Determination of the degree of hydrolysis of oil paint samples using a two-step derivatisation method and on-column GC/MS. Prog Org Coat 41:143–155

van den Berg JDJ, Vermist ND, Carlyle L, Holčapek M, Boon JJ (2004) Effects of traditional processing methods of linseed oil on the composition of its triacylglycerols. J Sep Sci 27:181–199

van der Weerd J, van Loon A, Boon JJ (2005) FTIR studies of the effects of pigments on the aging of oil. Stud Conserv 50(1):3–22

Acknowledgements

The authors are indebted to Dr. John Drennan and his co-workers at the Australian Microscopy and Microanalysis Research Facility (AMMRF) for the collaborative effort to visualize the early stages of zinc soap crystallization. Lambert Baij, Robert Corkery, Ties Korstanje, and Silvia Centeno are thanked for sharing their knowledge and inspiring discussions.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Crown

About this chapter

Cite this chapter

Hermans, J.J., Keune, K., Van Loon, A., Iedema, P.D. (2019). Toward a Complete Molecular Model for the Formation of Metal Soaps in Oil Paints. In: Casadio, F., et al. Metal Soaps in Art. Cultural Heritage Science. Springer, Cham. https://doi.org/10.1007/978-3-319-90617-1_3

Download citation

DOI: https://doi.org/10.1007/978-3-319-90617-1_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-90616-4

Online ISBN: 978-3-319-90617-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)