Abstract

A combination of transportation modes offers environmentally friendly alternatives to transport high volumes of freight over long distances. In order to reflect the advantages of each transportation mode, it is the challenge to deal with data uncertainty during the transportation planning phase. This chapter investigates the alternative ways of modeling the uncertainty by discussing them and their characteristics in terms of solution times, the quality, and the limitations. Moreover, several real-life case studies are provided to demonstrate potential environmental benefits by considering the principles of green logistics for single-mode and intermodal transportation.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

1 Introduction

The growing demand leads to increased transportation volumes on the limited transportation networks which leads to delays and disruptions due to unexpected events. This is particularly crucial for road transportation which has been traditionally the most preferred transportation mode and still has the major share on the modal split in Europe [43]. Moreover, road transportation is one of the main contributors to carbon dioxide equivalent (CO2e) emissions from transportation that are responsible for severe impacts on climate [20]. Therefore, logistics companies are looking for alternative transportation solutions that would minimize negative impacts of their transportation activities but still offer competitive solutions in a highly saturated market (Table 1).

One of the alternatives is intermodal freight transportation, a specialization of multimodal transportation which consecutively uses multiple transportation modes moving the goods in the same standardized loading unit (e.g., container) [17]. In addition to flexibility offered by multimodal transportation, intermodal transportation offers numerous advantages for shippers with large volumes, such as standard sizes, faster transshipments, and reduced packaging expenses [45]. However, the combination of different transportation modes requires more coordination and accurate transportation planning. Since most of the intermodal services are running according to fixed schedules, the reliability of the transportation plans is an important issue in order to avoid delays and enable on-time delivery of the goods. In this context, improved collection of real-time traffic flow information over the last decade builds the data basis for reliability of transportation plans.

While transportation literature offers extensive methods for (unscheduled) road transportation (see, e.g.,[31, 19]), these approaches are only of limited use for planning transportation activities in intermodal transportation networks, where services such as train, vessel, or flight connections follow a fixed schedule. In such cases, service network design (SND) provides promising alternatives for the reproduction of transportation flows on more than one mode. SND problems deal with the selection of available services for specific transports by offering advantages for the consolidation of transports as well as the consideration of multiple modes. Moreover, it provides methodological possibilities which enable the representation of transshipment as well as the consolidation of containers.

The research on dynamic SND problems is still in its early days, though, which leads to a lack of applications to as well as the development of new methods for service network environments. Most of the limited publications in this domain are dealing with demand uncertainty (e.g., [32, 10]), while only a minority takes travel time uncertainties into account. Input from practitioners, though, suggests that travel time uncertainty is an important source of variability to consider when trying to make accurate transportation plans.

The aim of this chapter is to give an overview about possible approaches for modeling intermodal freight transportation planning under uncertainty. For this, different approaches are at first described and then compared using a case study in order to show their advantages and weaknesses. In order to discuss different aspects of transportation activities, multiple objectives (e.g., costs, time, emissions) are considered in the models which provide managerial insights on interaction between economic and ecological objectives in transportation planning and on the benefits of using alternative transportation modes in comparison to road transportation. In this way the ecological footprint of transportation operations can be improved which contributes to achieving the objectives of the green logistics concept.

The remainder of the chapter is organized as follows. Section 2 introduces the green intermodal service network design problem and discusses important points for considering CO2e emissions in transportation planning. Section 3 describes alternative ways of uncertainty modeling. Section 4 presents case studies to highlight and compare the importance of methodological approaches to intermodal transportation. Conclusions are stated in Sect. 5.

2 The Green Intermodal Service Network Design Problem

The intermodal transportation chain consists of a number of transportation services served by different transportation modes that connect intermodal terminals where transshipment has to be handled. These services need to be coordinated in order to ensure smooth flow of freight in containers through the network from their origin to the destination within time windows specified by the customer. Typically, there exist various alternative routes within the network between the planned origin and destination of a container, and the aim is to find the optimal route that fulfills the criteria set by the decision maker. In this respect, the most important criteria for transportation mode choice are not only transportation costs but also safety, flexibility, and reliability, as shown in a survey performed by [48]. Since customers want to have the goods delivered on time and avoid delays which can cause additional costs or production stoppages, reliability of the system is becoming more crucial. Therefore, it is necessary to include the uncertainties in travel times caused by delays and disruptions of transportation network into the planning algorithms. In this way the created transportation plan becomes robust since it can stay feasible even if a disruption occurs, and therefore goods can be delivered on time [22].

High robustness of transportation plans is of special importance in case of intermodal transportation planning where several vehicles of different transportation modes are connected in one transportation chain. Thereby, every mode has its special characteristics that need to be considered. Whereas some services in intermodal transportation networks (e.g., rail, inland waterway) have fixed departure times according to planned schedules, other services (mostly road) are usually more flexible as they do not have fixed time slots when they can use the available infrastructure. This feature further increases the complexity of the intermodal transportation problem since the fixed departure times have to be considered when coordinating the individual services in a transportation plan. Whereas schedules can be easily incorporated into planning if only deterministic travel times under ideal conditions are considered, they might lead to disruptions of the network when delays occur and the goods are delivered to the terminal only after the next planned service has already left. In that case the goods have to wait for the next train or vessel which might result in a delay of hours or even days depending on the frequency of the connection. Alternatively, a new plan has to be found which might result in higher costs, time, or emissions. Therefore, it is necessary to include buffer times into transportation planning to avoid such situations.

Buffer times should not be too long since this would make the total transportation time longer and therefore further decrease the competitiveness of intermodal transportation in comparison to direct single-mode transportation which does not require any transshipment operations on the route. The length of the buffer times is dependent on the type and frequency of disruptions occurring on a certain route which can be derived from historical data as well as from actual real-life data about the current transportation network state and represented in form of travel time probability distribution as shown in Sect. 3. In reality, the same delay can lead to different results for different connections: e.g., a delay of 30 min can be critical for a truck operating in a just-in-time environment, whereas the same delay might not have any influence in case of an inland waterway vessel sailing 3 days between origin and destination. Besides that, the type of disruption also determines the impact of a certain disruption on the transportation: whereas a truck can usually take a detour if an accident happens on a highway, in case of a low water level on a certain river section, the vessel either has to wait for a couple of days, or goods have to be transshipped to another transportation mode [47]. If all these factors are included in the transportation planning process, the robustness of the resulting plan can be increased so that most of the disruptions are covered by the included buffer time.

A transportation planning approach which enables the inclusion of uncertainty and includes multiple objectives was first studied by [15] and followed by [24]. In their paper, the authors present a mixed-integer linear program for optimizing the transportation plan within an intermodal network considering uncertain travel times and demands. The approach chosen is called service network design (SND) in which each transportation link between two terminals is modeled as a service characterized by its origin, destination, capacity, route, departure time, planned travel time, transportation costs and emissions as well as the vehicle used for this service. This approach is also the basis for this chapter, where we investigate the transportation plan based on three different objectives which can have different weights according to the user’s preferences. The objectives are transportation costs, time in form of costs for in-transit inventory and penalty costs for late deliveries at the final customer, and CO2e emissions expressed as emission costs. Since a survey by [13] has shown that this combination of objectives and especially consideration of CO2e is not usual in the current transportation management systems (TMS) responsible for planning operations, Sect. 2.1 shortly discusses requirements and possible problems for modeling emissions. After that, the mathematical model used for intermodal transportation planning is presented in Sect. 2.2.

2.1 Air Pollution and GHGs

The environmental impact of transportation can be measured in the form of CO2e emissions which have to be calculated accurately. Using accurate calculation methods and quantifying the emissions might help to identify possibilities for their reductions which together with a proper implementation of green logistics bring more advantages than disadvantages for the logistics service providers or freight forwarders. Therefore, there is an increasing need to highlight these advantages to transportation companies.

Greenhouse gases (GHGs) are the most studied negative externality of freight transportation. These gases cause atmospheric changes and climate disruptions which are harmful to the natural and built environments and pose health risks. The primary transportation-related man-made GHGs in the Earth’s atmosphere are carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), and ozone (O3). As CO2 is the dominant man-made GHG, the impacts of other gases can also be calculated based on carbon dioxide equivalent (CO2e) emissions [27, 6].

Despite the fact that transportation sector is one of the biggest contributors of CO2e emissions, a survey performed by [13] showed that calculation of emissions is only slowly becoming part of TMS. Even when emissions are taken into account in TMS, they are only reported as an additional factor for the resulting routes, and they are not used as an optimization objective. Usually only costs are taken into account for optimization, and in case of multiple objectives, costs are combined with service, distance, time, etc. This development might be caused by multiple reasons which make the calculation of emissions challenging.

Firstly, the amount of emissions is dependent on the energy needed for moving the vehicle coming either from diesel or electricity consumption. Although the energy consumption can be easily measured after the transportation has been conducted, calculation of energy consumption before the start of the transportation is problematic as it is dependent on a number of factors which are not always known. These factors include the characteristics of the vehicle (e.g., weight, air and rolling resistance, engine), route and driving characteristics (e.g., gradient, speed, number of stops, driving behavior), and the amount of goods transported [5, 18, 12]. In order to be able to estimate the emissions, a number of different models requiring detailed inputs have been developed as shown by [12] and [14]. Besides these detailed microscopic models, emission calculators based on real-world measurements and recommended values for a typical vehicle are also available (e.g.,[9, 18, 26]). However, each of these models and calculators is based on certain assumptions which lead to discrepancies between calculated and measured emissions.

Secondly, the scope of emissions has to be determined in order to know which emissions to consider for calculation. According to the GHG protocol, emissions can be divided into three scopes: emissions from resources owned by a company, e.g., emissions from production (Scope 1), indirect emissions from purchased energy (Scope 2), and all other emissions including also other stages of supply chain, e.g., suppliers, transport, and distribution (Scope 3) [46]. Similarly, the emissions from transportation activities can either be calculated as emissions from fuel consumption directly in the vehicle (tank-to-wheel, TTW) or can also include emissions from production of the fuel (well-to-wheel, WTW). Inclusion of emissions from fuel production is especially important in cases where electric vehicles are involved since emissions from electricity consumption are equal to zero [30].

Thirdly, the monetary value of CO2e emissions is unclear. Since the long-term effects of emissions on climate change and the amount of released emissions cannot be easily predicted, the estimation of emission costs is again based on a number of assumptions including different discount rates for future events and risk attitude of the decision makers. As a result, the so-called social costs of carbon emissions are estimated to be between 0 EUR and more than 700 EUR per ton of emissions depending on the model [3, 37, 23]. In the analysis of [16], there are also differences in emission costs ranging between 5 EUR and 135 EUR. Therefore the monetary value of emissions cannot be easily compared to transportation costs.

In the calculation methodology used for the model, the emissions were calculated per TEU transported by a certain service and then converted into emission costs. As the estimation of emission costs is difficult, a fixed price of 70 EUR/ton of CO2e emissions was used for calculations as recommended by the German Federal Environment Agency [39]. Besides that, additional assumptions had to be made regarding the average utilization of the vehicles since the emission functions for trains and vessels are nonlinear. As a result, the utilization was assumed to be 80% for trains [39] and 90% for inland vessels [50]. Despite these additional assumptions, the results show the influence of emissions on the optimal routing decisions.

2.2 Mathematical Model

This part of the chapter provides a linear mixed-integer mathematical formulation of the green intermodal service network design problem (GISND). The presented model can be used to find optimal transportation plans under deterministic conditions, i.e., in situations where no uncertainty is considered. The possibilities for including uncertainty into the model are discussed in Sect. 3. The aim here is to find an optimal plan for orders \(p\in {\mathcal {P}}\) defined by their demand d p, origin i, and destination j nodes as well as earliest release \(\varGamma ^{p}_{\mathrm {release}}\) and due time \(\varGamma ^p_{\mathrm {duetime}}\). Moreover, \(\gamma ^p(i,j)=\{(p \in \mathcal {P}) | i\in {\mathcal {N}} \, \text{and}~ j\in {\mathcal {N}} \}\) is a set of orders with origin i and destination node j. The orders can be routed in a transportation network consisting of services \(s\in {\mathcal {S}}\) (scheduled transports) and nodes \(i,j\in {\mathcal {N}}\) (transshipment locations). Each service, since it is connected to a schedule and vehicle, is unique and connects transshipment locations i and j. Therefore, \(\delta ^s(i,j,v,D^s_m)=\{(s \in \mathcal {S}) | i\in {\mathcal {N}} \, \text{and}~ j\in {\mathcal {N}} \, \text{and}~ v\in {\mathcal {V}} \}\) is a set of services executed by vehicle v between origin i and destination node j within the starting time window bounded by \(T^s_{\mathrm {min}}\) and \(T^s_{\mathrm {max}}\). In addition to that, services are characterized by their scheduled departure time D s and service travel time t s as well as service slot price c s and CO2e emissions per container e s. Services on the road as well as transshipment are assumed to be available when needed. We first present sets, parameters, and decision variables and then provide the mathematical formulation of the model. This model extends the model introduced by [15] by adding in-transit inventory costs to the original time-related cost component of the objective.

We now provide the sets, parameters, and decision variables used for the formulation of the mathematical model in Tables 2 and 3.

Subject to:

The objective function (1) of the mathematical model minimizes a weighted sum of the total costs. The weights enable the reflection of individual preferences regarding direct transportation (ω 1), time-related (ω 2), and CO2e emissions-related (ω 3) costs. The direct transportation costs consist of transportation costs per container and service c s, which include the fixed transportation costs per service allocated to one container as well as the direct transportation costs per container and transshipment costs per container (c j ). The time-related costs (\(c_t^p\)) are represented by in-transit inventory costs for the total time spent since the release of goods at the origin until the arrival of the order to the destination. In addition to that, charges for delayed deliveries (\(c_{\mathrm {pen}}^p\)) are also included in time-related costs. As the third objective, the CO2e emissions-related costs per kg (c emi) for the emissions consumed per container serviced (e s) and transshipped (e j ) are also included.

Constraints (2), (3), and (4) handle the movement of containers. While constraints (2) and (3) focus on the origin and destination nodes, constraint (4) manages the transshipment. Demand, in that regard, is positive if more containers are planned to originate from a specific node than are destined for that node. Constraint (5) ensures that capacity limits of services are adhered to. Constraints (6), (7), and (8) make sure that a service is only allowed to process any amount of containers when it is selected. While (9) tracks the transshipment necessary, constraints (10) and (11) ensure the timely sequencing of the services within the network. As seen in (10), each service has interrelated departure, service, and arrival times. In addition to the synchronization at nodes in terms of loading units (2), (3), and (4), constraint (11) takes care of the timely synchronization. It ensures the relation of sequential services at a transshipment location. This is necessary due to more or less fixed schedules of services, which permit services with earlier departure times than possible preceding services from following up on them. Constraint (12) ensures that only containers which have to change the vehicle are considered when calculating transshipment times, costs, and CO2e-emissions. Constraints (13) and (14) provide the time frame for each order to plan within. The lower limit (earliest pick-up time) is fixed, while the upper limit (due date) can be bent, with penalties – if desired – allocated to late deliveries (\(a^{p}_{\mathrm {delay}}\)). Constraint (15) defines the arrival time of the order to the destination which is dependent on the arrival of the last service which the order is carried on. Constraint (16) gives the time window within which services can depart with \(T^s_{\mathrm {min}} = T^s_{\mathrm {max}}\) being valid for scheduled services. Constraints (17) and (18) ensure that the feasibility of two consecutive services is only checked if these services are designated to be used within the same routing plan. The domain of the decision variables is given in constraints (19) and (20).

3 Dealing with Travel Time Uncertainty

Whereas the presented mathematical model can easily calculate transportation plans in a deterministic environment, it has only limited possibilities to handle the increased complexity of the problem if stochastic factors are included. The reason for this is that considering uncertainty for different variables results in a high number of possible scenarios which cannot be handled by conventional methods, such as dynamic programming and multistage stochastic programming for realistic instance sizes. As an example, in a network with three services that can have three possible travel time realizations each, in total 27 different travel time combinations are possible, and the number of combinations is exponentially increasing with the increasing number of services and scenarios. Therefore, two possible approaches which can handle such complexity and evaluate the reliability of transportation plans under uncertainty are presented in this chapter, namely, sample average approximation and simulation-optimization. The focus here is on travel time uncertainty, but these approaches can be easily applied to other uncertain factors, such as demand or customer.

3.1 Sample Average Approximation

The sample average approximation (SAA) method is used to reduce the complexity of a stochastic problem by approximating a distribution or an expected value of an uncertain variable. The approximation of a distribution is obtained by replacing the actual distribution with an empirical distribution by Monte Carlo sampling. In cases where the objective function corresponds to an expected value, it is approximated by its sample average estimate. The resulting problem is then solved by deterministic optimization methods.

The SAA method has been widely applied in the context of transportation planning and routing. Kenyon and Morton [28] use SAA to solve a stochastic vehicle routing problem (VRP) under two different objective functions: minimizing the expected completion time and maximizing the probability of completion time being below a target level. Luedtke and Ahmed [33] provide an application of SAA to a chance-constrained transportation problem with a convex feasible region where the dimension of the random vector presents a computational challenge. Wang and Meng [52] apply SAA for a schedule design problem for liner shipping services to minimize expected costs, and [53] apply it to chance-constrained liner ship fleet deployment problem. Verweij et al. [49] provide an introduction to the application of SAA to stochastic routing problems with expected value objectives.

The SND formulation presented in Sect. 2 extended by travel time uncertainty can be classified as a chance-constrained problem where a chance constraint measuring the number of successful realizations of a transportation plan under different travel time scenarios decides about the reliability of the plan. In this context, SAA method is used to approximate the true probability of the constrained event by its frequency of occurrence within the sample. In general, SAA is applied to chance-constrained stochastic problems because of two reasons: the feasible region defined by the chance constraint can be non-convex, and the probability of the constrained event may be difficult to evaluate [33, 38]. It has been shown that the optimal solution of the sampled problem converges exponentially fast to the optimal solution of the original problem as the number of scenarios increases.

The application of SAA to the GISND problem has been studied by [15]. In their approach, a number of different independent samples are created where each sample consists of M scenarios representing different travel time realizations based on their probability distributions. Then, the model is solved for each of the samples which results in a number of candidate solutions. These candidate solutions are then tested on another test sample with a large number of scenarios in order to evaluate the probability that a plan is not feasible under a certain travel time combination, and therefore replanning is required. If this probability is higher than a certain value 1 − α which has to be chosen arbitrarily before the start of the process, then the plan is not considered as a feasible solution. From all feasible candidate solutions, the solution with minimal total costs is chosen at the end as an optimal solution. In order to apply the SAA method to the GISND, the mathematical model presented in Sect. 2 has to be extended by a set of travel time scenarios M and the following constraints checking the reliability of the plan:

where \(f_m^{\mathrm {qrp}}\) is a binary variable checking whether an order p can catch the planned ensuing service after arriving to a transshipment terminal (\(f_m^{\mathrm {qrp}}=1\)) or not (\(f_m^{\mathrm {qrp}}=0\)), depending on the delay of the order determined by constraint (11). Based on the constraints (21), (22), and (23), the binary variable \(f^p_m\) then shows whether a certain transportation plan for order p is feasible (\(f^p_m=1\)) or not (\(f^p_m=0\)). Constraint (24) is then the chance constraint measuring the number of feasible scenarios which has to be higher than the factor α (e.g., 95%) in order to classify a plan as reliable.

3.2 Simulation-Optimization Approach

Another possibility for including uncertainty into the green intermodal transportation problem is a two-step hybrid approach combining the presented deterministic optimization model in Sect. 2 with a simulation model which is able to create and evaluate a high number of scenarios for the stochastic elements. This approach is getting more attention in the last years when it has been used for solving complex dynamic problems in supply chain management (see, e.g.,[2, 1, 35]). As an example, [40] combines simulation and optimization models in order to optimize a supply chain by combining transportation planning and production decisions including stochastic and nonlinear elements. In case of [44], a simulation-based approach is used for sustainable transportation optimization by searching for strategies that minimize the generalized costs of multimodal planning. In addition to that, [7] and [42] apply a hybrid approach combining simulation and optimization for coordinating production and distribution decisions, and [11] uses a similar method for the perishable goods industry. Whereas these contributions cover the production processes and their combination with distribution, the application of the simulation-optimization approach to the transportation planning area is very limited. Besides that, the main purpose of combining the two methods is usually the estimation of uncertain parameters by simulation which are then used for the optimization. This differs from our approach where the simulation model with stochastic travel times is used to evaluate the reliability of deterministic transportation plans created by the optimization model.

The solution procedure has been described in detail in [24] and is presented in Fig. 1. The authors considered a system which consists of an optimization model and a simulation model run in different software that are connected through a database including the relevant transportation network represented by terminals and services as well as orders that need to be shipped. All of the data has to be available at the beginning of the process and is the input for the optimization model which computes the optimal transportation plan considering deterministic travel times in ideal situation where no congestion or delay occurs. In this way the optimal plan is obtained relatively quickly, and additional constraints connected to travel time uncertainty which might limit the size of the instances that can be solved to optimality can be avoided.

An overview of the simulation-optimization approach presented by [24]

The transportation plans calculated by the optimization model serve as a basis for the simulation model which in the second step of the solution procedure evaluates their reliability under stochastic circumstances. In this step, the travel time is uncertain and can take different values depending on the underlying probability distribution that has to be determined in advance. During the simulation, multiple runs of the simulation model are executed in order to consider different possible travel time combinations for all services in the transportation network. Within each run, the optimal deterministic route for each order is simulated in order to see whether the plan is still feasible under the chosen travel time realizations. In this way, in addition to calculating the number of scenarios in which a plan becomes infeasible, also the problematic service or sequence of services which might lead to delay and infeasibility of the plan can be identified. The plan becomes infeasible if the containers arrive too late to an intermediate terminal, and therefore the planned subsequent service is missed. In this case the transportation process cannot be continued according to the original plan, and therefore an alternative solution has to be found. The simulation model enables to define some simple solutions in advance (e.g., using an additional truck to transport the containers directly to the destination) which can be used and simulated in case of infeasibility. In this way not only the reliability of the plan but also the additional costs in case of infeasibility can be estimated.

At the end of the simulation phase, the reliability of the plans is evaluated based on two criteria: the number of runs in which the plan was infeasible and the average additional costs of this infeasibility in comparison to the optimal deterministic solution. The thresholds for these criteria have to be set at the beginning of the optimization process, and they are decisive for classifying a transportation plan as reliable or not reliable. Transportation plans which are reliable leave the optimization process and are fixed for execution which means that the service capacity used by these plans has to be blocked and the free capacity of the services has to be updated in the database. Transportation plans which are not reliable are sent back to the optimization model together with the updated service capacities, and the whole optimization process starts from the beginning. In order to prevent the repeated choice of the unreliable plan by the optimization model, the service sequence of the plan is also used as input for the optimization model and is handled in an additional constraint so that an alternative plan has to be chosen. This process is repeated until a reliable plan is found for all orders. If there is no feasible and reliable route for an order in the considered network, a direct transportation by truck is used as a default option.

3.3 A Comparison of the Methods

Both presented methods can be used to get reliable transportation plans; however, the decision about which method to use and also the quality of the solution for each method might be dependent on the complexity of the problem which has to be solved. The division of the solution procedure into two steps in the simulation-optimization approach decreases the complexity for the mathematical optimization model which only has to deal with deterministic times. Therefore, larger instances can be solved than in the case of the SAA approach since the scenarios are included in the mathematical model which limits the size of the problem a solver can handle. In terms of computational time, the integration of scenarios into the model leads to faster solutions for SAA for smaller instances since the simulation model needs some time to run all scenarios and the time further increases if solutions are infeasible and further runs of the optimization and simulation model are necessary. However, whereas the computational times for SAA tend to increase exponentially with the increasing complexity of the instances, the time needed for one simulation run is rather stable. Moreover, with regard to the quality of the solution, the simulation-optimization approach evaluates the reliability based on two criteria so that some plans which are unreliable according to SAA can be accepted by simulation since the infeasibility might cause only very small cost increase that might be negligible in comparison to the higher costs of an alternative plan. Furthermore, the simulation model shows where the disruption occurs which is not reported by SAA where only a solution is chosen based on the chance constraint. The simulation model also gives possibilities to increase the number of considered scenarios and replications in order to increase the statistical significance of the solution, and the travel time can be modeled by using different probability distributions. The described differences are also illustrated by a computational comparison in Sect. 4.2.

4 Case Studies

The combination of different objectives and the consideration of travel time uncertainty in the optimization process often lead to trade-offs and conflicting solutions which are dependent on the priorities that the transportation planner sets before the solution process is started. In order to illustrate these trade-offs, this section consists of two case studies that show the influence of the individual objectives and the travel time uncertainty on the optimal solution. Comparing results for different objectives is not only important in the intermodal transportation, which is described in Case study B (Sect. 4.2), but can also help to improve the reliability of single-mode transportation, as it is illustrated in Case study A (Sect. 4.1).

4.1 Case Study A: Choosing the Optimal Route for Road Transportation

Road transportation is a very popular transportation mode with the highest share on the modal split within the EU (74.9% in 2014) [21]. The reason for this is a high flexibility of this transportation mode since most of the customers can be reached without problems via the dense road network so that a truck can be used either for the pick-up and last-mile delivery of goods within intermodal transportation chains but also for direct connections between origin and destination. However, the high volume of road freight transportation is responsible for a significant amount of emissions from transportation, and the limited infrastructure capacity in combination with dense individual passenger traffic might cause unexpected congestions or delays that might influence the reliability of this transportation mode and cause late deliveries of goods to the customer. Since the dense road network usually offers a number of alternative routes between two terminals, a comparison of the possible routes according to transportation costs, travel time, and CO2e emissions can lead to transportation plans that might cause slightly higher costs but improve the environmental impact and reliability of travel times so that buffer times accounting for possible delays might be reduced. In order to be able to compare the routes according to travel time uncertainty, historical data about past trips has to be available.

The importance of travel time reliability can be illustrated on regular truck transportation of air freight between major European airports which is necessary due to consolidation of goods or due to changes in available plane capacities that are used for further transportation of the goods. As the changes in capacities are announced at very short notice, the planning process has to be fast and use very accurate data. In order to achieve this, a detailed analysis of travel times for truck transportation between the airports in Amsterdam and Frankfurt (AMS-FRA) and Amsterdam and Brussels (AMS-BRU) was conducted. The distance for AMS-FRA is approximately 450 km, whereas for AMS-BRU trucks are traveling slightly more than 200 km. The available data covered 3 weeks of transports in spring and summer 2014 in which around 300 trips were conducted for each origin-destination pair. The collected data included travel times, speed, direction, breaks, delays, departure times, and GPS coordinates of the trips [4]. As a result, three different routes could be identified for AMS-FRA and two different routes for AMS-BRU. They are displayed in Fig. 2 (routes 1–3 for AMS-FRA and 4–5 for AMS-BRU). Whereas the number of trips was almost equal for routes 4 and 5, route 1 was clearly preferred for the relation AMS-FRA.

Since the distance of the routes for each origin-destination pair is very similar, the differences in total costs and emissions between the routes are less than 2%. However, the analysis of travel times revealed important differences in travel time distributions that might have influence on the reliability of transportation. Although most of the trips were conducted during evening or night hours due to flight schedules, there were enough trips during the day and rush hours for which typical delays could be observed. Therefore, the travel times were divided into three categories: uncongested travel time accounting for minimal travel time without any disruptions, congested travel time representing travel times with small delays caused by usual (recurring) congestion, and disrupted travel time which was observed for trips with major delays. The resulting travel times with their correspondent probability of occurrence for each route are summarized in Table 4.

As shown in Table 4, route 1, which is preferred by the truck drivers, is the route with the lowest uncongested travel time for FRA-AMS and therefore the fastest route if no disruption occurs. However, this happens only in about 75% of the cases, and the risk of delay of 1 h is about 20%, caused mainly by the fact that there are regular congestions on the route which is passing important German cities (Cologne, Düsseldorf, Dortmund). In addition to that, there is even a risk of major disruptions adding another 4 h to the transportation time. In contrast to that, route 3 has a slightly higher uncongested travel time, but the probability of congestion is lower, and also the average delay is lower which reduces the fluctuation in arrival times. Therefore, it might be more convenient to choose route 3 when trying to avoid driving on congested highways which leads to delays and, especially in a stop-and-go traffic, to higher fuel consumption and CO2e emissions.

In the case of AMS-BRU, average travel times are the same for both routes, and route 4 has a higher probability of congestion with longer average delay. However, when taking into account disrupted travel times, route 4 might be better since the probability and also average delay for this travel time category is lower.

Although the historical data cannot certainly predict the exact travel time for the next trip, the distribution of past travel times can at least help to avoid routes which might be critical when a disruption occurs. In this way the efficiency of transportation can be increased minimizing the costs, delays, and emissions. Whereas the current study was only based on a limited number of trips, recording and analyzing historical data continuously can further improve the accuracy of travel time distributions and predictions.

4.2 Case Study B: Intermodal Transportation Planning Under Travel Time Uncertainty

The second case study investigates an intermodal transportation planning problem on which the differences between the methods presented in Sects. 2 and 3 and the influence of the individual optimization objectives can be presented. For this, an intermodal transportation network consisting of intermodal terminals connected by services on road, rail, and inland waterway has been created. This network is based on real-world connections where [34] and [29] were used for railway schedules, [51] was the basis for modeling inland waterway services, and road connections were designed based on [41]. In total, the network consists of 20 terminals located in Austria, Slovakia, Czech Republic, Germany, Slovenia, and Italy which are used either as ports or as collection terminals for feeder services to Western European harbors. For each terminal and service, the estimated transshipment and transportation costs, times, and emissions have been assigned. The transportation network, which was firstly defined in [15], is depicted in Fig. 3. Due to the high complexity of the network, only rail and inland waterway connections are included in the figure. These connections are extended by road services. The travel time distribution for each service was modeled as a three-point distribution with uncongested, congested, and disrupted travel time as already described in Sect. 4.1.

The analysis was conducted on an Intel(R) Core(TM) i5-5300U CPU with 2.3 GHz and 8 GB of memory. The deterministic optimization model and the SAA model were solved using CPLEX 12.6 [25], and the simulation was run in Anylogic University 7.2.0 [8]. For the inventory costs, 1 EUR/h was assumed for each order, and the penalty costs are different for each order varying between 1 and 10 EUR/h. The emission costs were estimated to be 70 EUR/t of CO2e emissions as recommended by [39].The thresholds for evaluating the reliability of the plans were set to 5% for the share of infeasible scenarios and also 5% for the additional costs of unreliability. In the simulation-optimization model, an extraordinary truck which transports the goods directly to the destination is chosen as an alternative plan in case of infeasibility. This truck is usually the fastest option if the original plan does not work; however, since it has to be organized in a short time, an increase of 25% for the transportation costs in comparison to a planned truck on the same route is assumed.

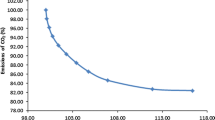

In the first step, the solutions of the deterministic optimization model, SAA, and simulation-optimization were compared with regard to computational times, quality, and limitations. For this, the number of services in the network with 20 terminals was stepwise increased from 50 to 500, and the number of orders considered varied between 1 and 20. In this setting, the deterministic model could find an optimal solution for all instances with up to 250 services; bigger instances could not be solved due to memory problems of the solver. For SAA it could be observed that the approach is limited by the number of scenarios M used where more than ten scenarios for choosing candidate solutions significantly reduce the network size that can be handled by the model. Besides that, the number of orders also has a negative influence on computational time since the computational time tends to grow exponentially with the increasing number of orders. The SAA approach could find optimal solutions for all instances with up to 250 services and 5 orders. The best results with regard to size limitations were obtained by the simulation model used in simulation-optimization where it can be seen that the model can handle all of the tested instances and the computational times are relatively stable. This means that it is more convenient to use the simulation-optimization model especially for bigger instances where the computational time using ten simulation runs is lower than in the case of SAA. In addition to that, the simulation model can also handle increased number of scenarios which improves the statistical significance of the results. This is also illustrated in Fig. 4, where computational times for deterministic model, SAA, and simulation model with 10 and 100 runs are summarized.

When looking at the quality of the results, it could be observed that both SAA and simulation-optimization are able to identify the same unreliable plans based on the number of scenarios where the plan becomes infeasible. This is mainly the case in small network with 50 services where usually very limited number of possible connections exist. However, there is a difference in the estimated total costs of the reliable solution since SAA only estimates the increase in costs due to unreliability, whereas the simulation model can also calculate the costs of the extraordinary truck. Therefore, it might happen that the estimated costs after simulation are lower than the costs from the deterministic optimization model. This might indicate that using a direct truck for a part of the route or the whole route might be a more convenient option when considering the economic factors and reliability. However, this has usually a negative impact on CO2e emissions.

In order to analyze the influence of different objectives on the optimal route, 50 orders were created randomly, and their optimal route was calculated for different combinations of objectives using the deterministic mathematical model in the first step. The underlying network consisted of 100 services, and the results showed that for 25 orders there was only one optimal route independent of the objective weights. For the remaining 25 orders, where a change in plans was recorded, the dominance of solutions minimizing the transportation costs is clearly visible since this cost category has the highest share on the total costs. However, there is also a visible influence of other objectives as it is shown in Fig. 5 where in each of the three graphs, a trade-off between two objectives is shown, whereas the third objective is not considered in the optimization process.

In the first graph, the trade-off between transportation costs and CO2e emissions is shown where the transportation cost-minimizing solution clearly dominates the emission minimization. A change occurs only when the emission objective has a weight of 0.8 or higher. In this case the transportation plans for some of the orders change toward more environmentally friendly transportation modes which results in about 4% saving in CO2e emissions, whereas the increase in transportation costs is only 2.4%. A similar picture can be seen when the trade-off between transportation costs and time is analyzed; however, in this case the increase in total costs due to time-optimizing solutions is much higher. Due to the increased use of direct and fast truck services, the time costs can be minimized by 53%. However, this is only possible when the transportation costs are increased by 53% in comparison to the transportation cost-minimizing solution. Moreover, an increase in emissions by 103% also has to be accepted. The negative impact of time optimization on total costs is even more visible in the third graph where the trade-off between time and CO2e emissions is depicted. Here the total costs are continuously increasing from the minimum when only emissions are minimized until the maximum for the time-minimizing scenario. Similar to the previous case, also here the transportation costs increase in total by 49%, whereas 53% of time costs can be saved. The increase in total emissions is with 111% even higher. The comparison of the individual cost components for optimal deterministic plans according to every single objective is displayed in Table 5.

The reliability of the calculated plans for all 50 orders was tested by the simulation model. Since the travel time uncertainty can be modeled in different ways, three different travel time distributions were used in order to compare the influence of travel times on the reliability of the plans. Besides the discrete three-point distribution, which was already used in Sect. 4.1, two continuous distributions were also applied: a shifted exponential distribution, as suggested by [36], and the uniform distribution, which is usually used if no or insufficient information about the distribution of the uncertain variable is available. The exponential distribution is shifted to the right starting at the uncongested travel time from the discrete distribution, and its shape was obtained by fitting it to three intervals (uncongested, congested, and disrupted) which were also created from the discrete distribution and have borders located in the middle between the discrete travel times for each state and probabilities corresponding to the discrete ones [24]. The borders of uniform distribution are located at the uncongested and disrupted travel time for each service. All three travel time distributions are illustrated in Fig. 6.

The output of the simulation model shows that many of the deterministic plans in the studied instance are not reliable and require replanning. This is especially true for the time optimization where the created deterministic plans often combine various truck services which might be faster than waiting for a direct train that departs only in a couple of days. However, since the truck services are shared by many orders, the truck service has to wait until all orders are available which might result in delay for another order if the truck arrives too late to the destination. This is not such a big problem for trains and vessels where the departure time is given by the schedule and the vehicle is not waiting for a delayed order. Since the network is limited by 100 services, it is often the case that there is only one available route in the intermodal network for a certain order, and if this route is evaluated as unreliable, the only alternative is to use a direct truck, which is then suggested by the simulation model. This is especially true for orders which have to travel for very long distances and have to combine a lot of services (up to eight in the studied instance). In these cases avoiding the unreliable intermodal connection and using direct truck might be more beneficial. In this way the model can increase the motivation of transportation planners to consider intermodal planning as an alternative since it offers them only routes which are reliable. The use of direct truck, which is not available in the original network, might be sometimes cheaper but can have negative impacts on the environment. This can be also seen in Table 6, where the costs after simulation are lower than the deterministic costs especially due to the use of direct truck connections as an alternative to the limited intermodal network.

When comparing the results for the three travel time distributions displayed in Table 6, it can be noticed that the costs in case of continuous distributions are higher than for the discrete distribution. The reason for that might be that the uncongested travel time is the most important travel time for the discrete distribution, whereas it is only the lower border for the continuous distribution, and therefore the travel times for continuous distributions are higher on average. However, since for continuous distributions any time within the specified interval can be chosen, the results give a better picture about the reliability of the plans. Especially in the case of the exponential distribution, the number of infeasible scenarios in cases where these are caused only by very small delays at the destination is decreasing, and the number of infeasible scenarios for plans where the time causing infeasibility is located between uncongested and congested time is increasing. Also it can be seen that due to the equal distribution of travel times in case of uniform distribution, some of the plans that are reliable under exponential distribution become unreliable due to higher number of scenarios with longer travel times. Due to this more conservative evaluation of the plans, the uniform distribution can be used especially in situations where the information about the real distribution of travel times is not available.

5 Conclusions

This chapter provided an overview of current studies aiming at intermodal transportation planning with travel time uncertainty. Even though this area is quite new and there is only limited research, very recent research has been summarized and highlighted to bring more attention on data uncertainty from both the academia and the practice.

Two possible approaches which can handle such complexity and evaluate the reliability of intermodal transportation plans under uncertainty are discussed and compared in terms of solution times, the quality, and the limitations. The methodological approaches presented in this chapter are sample average approximation and simulation-optimization, which both can easily handle travel time complexity. The focus of this chapter was on travel time uncertainty, but these approaches can be easily applied to other uncertain factors (i.e., demand and customer uncertainties).

Moreover, we investigate the transportation plan based on three different objectives which can have different weights according to the transport user’s preferences. The objectives are transportation costs, time in form of inventory costs and penalty costs for late deliveries at the final customer, and CO2e emissions expressed as emission costs.

Computational experiments confirm that both methods can be used to get reliable transportation plans. With regard to the quality of the solution, the simulation-optimization approach evaluates the reliability based on two criteria so that some plans which are unreliable according to SAA can be accepted by simulation since the infeasibility might cause only very small cost increase that might be negligible in comparison to the higher costs of the alternative plan. Furthermore, the simulation model shows where the disruption occurs which is not reported by SAA where only a solution is chosen based on the chance constraint. The simulation model also gives possibilities to increase the number of considered scenarios and replications in order to increase the statistical significance of the solution and the travel time can be modeled by using different probability distributions.

References

Acar, Y., Kadipasaoglu, S., Schipperijn, P.: A decision support framework for global supply chain modelling: an assessment of the impact of demand, supply and lead-time uncertainties on performance. Int. J. Prod. Res. 48(11), 3245–3268 (2010)

Almeder, C., Preusser, M., Hartl, R.F.: Simulation and optimization of supply chains: alternative or complementary approaches? OR Spectr. 31(1), 95–119 (2009)

Anthoff, D., Tol, R.S.J.: On international equity weights and national decision making on climate change. Working Paper (2007)

Arikan, E., Burgholzer, W., Czapla, N., Hrusovsky, M., Jammernegg, W., Demir, E., Van Woensel, T.: Aggregated planning algorithms. Technical report, GET Service Project Deliverable 5.2 (2014)

Barth, M., Boriboonsomsin, K.: Real-world CO2 impacts of traffic congestion. Transp. Res. Rec. 2058, 163–171 (2008)

Bektaş, T., Demir, E., Laporte, G.: Green vehicle routing. In: Psaraftis, H.N. (ed.) Green Transportation Logistics, pp. 243–265. Springer, Cham (2016)

Bilgen, B., Çelebi, Y.: Integrated production scheduling and distribution planning in dairy supply chain by hybrid modelling. Ann. Oper. Res. 211(1), 55–82 (2013)

Borshchev, A.: The Big Book of Simulation Modeling: Multimethod Modeling with AnyLogic 6. AnyLogic North America, Chicago (2013)

Boulter, P., McCrae, I.: Assessment and reliability of transport emission models and inventory systems – final report. Technical report, TRL (2007)

Crainic, T., Fu, X., Gendreau, M., Rei, W., Wallace, S.W.: Progressive hedging-based metaheuristics for stochastic network design. Netw.: Int. J. 58(2), 114–124 (2011)

de Keizer, M., Haijema, R., Bloemhof, J.M., van der Vorst, J.G.: Hybrid optimization and simulation to design a logistics network for distributing perishable products. Comput. Ind. Eng. 88, 26–38 (2015)

Demir, E., Bektas, T., Laporte, G.: A comparative analysis of several vehicle emission models for road freight transportation. Transp. Res. Part D 16, 347–357 (2011)

Demir, E., Van Woensel, T., Bharatheesha, S., Burgholzer, W., Burkart, C., Jammernegg, W., Schygulla, M., Ernst, A.: A review of transportation planning tools. Technical report, Deliverable D5.1, GET Service, Service Platform for Green European Transportation (2013)

Demir, E., Bektas, T., Laporte, G.: A review of recent research on green road freight transportation. Eur. J. Oper. Res. 237, 775–793 (2014)

Demir, E., Burgholzer, W., Hrušovskỳ, M., Arıkan, E., Jammernegg, W., Van Woensel, T.: A green intermodal service network design problem with travel time uncertainty. Transp. Res. Part B: Methodol. 93, 789–807 (2016)

Denisis, A.: An economic feasibility study of short sea shipping including the estimation of externatilities with fuzzy logic. PhD thesis, University of Michigan (2009)

ECMT: European Conference of Ministers of Transport: Terminology on Combined Transport (1993)

Eichlseder, H., Hausberger, S., Rexeis, M., Zallinger, M., Luz, R.: Emission factors from the model phem for the HBEFA version 3. Technical report, TU Graz – Institute for Internal Combustion Engines and Thermodynamics (2009)

Eksioglu, B., Vural, A.V., Reisman, A.: The vehicle routing problem: a taxonomic review. Comput. Ind. Eng. 57(4), 1472–1483 (2009)

European Commission: Road transport: reducing co2 emissions from vehicles (2014). Available at: http://ec.europa.eu/clima/policies/transport/vehicles/index_en.htm. 1 Jan 2017

Eurostat: Freight transport statistics (2016). Available at: http://ec.europa.eu/eurostat/statistics-explained/index.php/Freight_transport_statistics_-_modal_split. 1 Jan 2017

Eustace, D., Russell, E., Landman, E.D.: Incorporating robustness analysis into urban transportation planning process. In: Levinson, D.M, Liu, H.X., Bell, M.G.H. (eds.) Network Reliability in Practice, pp. 79–97. Springer, London (2012)

Hope, C.: Discount rates, equity weights and the social cost of carbon. Energy Econ. 30, 1011–1019 (2008)

Hrušovský, M., Demir, E., Jammernegg, W., Van Woensel, T.: Hybrid simulation and optimization approach for green intermodal transportation problem with travel time uncertainty. Flex. Serv. Manuf. J. (2016, Forthcoming)

IBM ILOG: Copyright ⒸInternational Business Machines Corporation 1987 (2015)

IFEU: Ecological transport information tool for worldwide transports -methodology and data update. Technical report, UIC (2011). Available at: http://www.oeko.de/en/publications/p-details/ecotransit-world-ecological-transport-information-tool-for-worldwide-transports/. 1 Jan 2017

IPCC: Climate change 2007. Synthesis report. Technical report, Intergovernmental Panel on Climate Change, Geneva (2007). Available at: https://www.ipcc.ch/pdf/assessment-report/ar4/syr/ar4_syr.pdf. 1 July 2015

Kenyon, A.S., Morton, D.P.: Stochastic vehicle routing with random travel times. Transp. Sci. 37(1), 69–82 (2003)

Kombiverkehr: Fahrplanauskunft (2014). Available at: http://www.kombiverkehr.de/web/Deutsch/Startseite/. 1 Dec 2014

Kranke, A., Schmied, M., Schön, A.D.: CO2-Berechnung in der Logistik. Verlag Heinrich Vogel (2011). Available at: https://www.heinrich-vogel-shop.de/img/asset/978-3-574-26095-7.pdf. 1 Jan 2017

Laporte, G., Louveaux, F.V., Mercure, H.: A priori optimization of the probabilistic traveling salesman problem. Oper. Res. 42(3), 543–549 (1994)

Lium, A.G., Crainic, T.G., Wallace, S.W.: A study of demand stochasticity in service network design. Transp. Sci. 43(2), 144–157 (2009)

Luedtke, J., Ahmed, S.: A sample approximation approach for optimization with probabilistic constraints. SIAM J. Optim. 19(2), 674–699 (2008)

Metrans: Intermodal services – train schedule, July 2014. Available at: http://www.metrans.eu/intermodal-services/train-schedule-1/. 1 Jan 2017

Nikolopoulou, A., Ierapetritou, M.G.: Hybrid simulation based optimization approach for supply chain management. Comput. Chem. Eng. 47, 183–193 (2012)

Noland, R.B., Small, K.A.: Travel-time uncertainty, departure time choice, and the cost of the morning commute. Technical report, Institute of Transportation Studies, University of California, Irvine (1995) http://www.its.uci.edu/its/publications/papers/ITS/UCI-ITS-WP-95-1.pdf. 1 Jan 2017

Nordhaus, W.D.: Integrated economic and climate modelling (2011). http://papers.ssrn.com/sol3/papers.cfm?abstract_id=1970295

Pagnoncelli, B., Ahmed, S., Shapiro, A.: Sample average approximation method for chance constrained programming: theory and applications. J. Optim. Theory Appl. 142(2), 399–416 (2009)

PLANCO: Verkehrswirtschaftlicher und ökologischer vergleich der verkehrsträger straße, schiene und wasserstraße. Technical report, PLANCO (2007)

Preusser, M.: A combined approach of simulation and optimization in supply chain management. PhD thesis, University of Vienna, Vienna (2008)

PTV: PTV Map &Guide (2014). Available at: http://www.mapandguide.com/de/home/. 1 Jan 2017

Safaei, A., Moattar Husseini, S., Z-Farahani, R., Jolai, F., Ghodsypour, S.: Integrated multi-site production-distribution planning in supply chain by hybrid modelling. Int. J. Prod. Res. 48(14), 4043–4069 (2010)

Sanchez Vicente, A.: A Closer Look at Urban Transport. TERM 2013: Transport Indicators Tracking Progress Towards Environmental Targets in Europe. European Environment Agency, Copenhagen (2013)

Song, M., Yin, M., Chen, X.M., Zhang, L., Li, M.: A simulation-based approach for sustainable transportation systems evaluation and optimization: theory, systematic framework and applications. Proc.-Soc. Behav. Sci. 96, 2274–2286 (2013)

SteadieSeifi, M., Dellaert, N., Nuijten, W., Van Woensel, T., Raoufi, R.: Multimodal freight transportation planning: a literature review. Eur. J. Oper. Res. 233, 1–15 (2014)

Toffel, M.W., Van Sice, S.: Carbon Footprints: Methods and Calculations. Harvard Business Case Study, Boston (2011)

Treitl, S., Rogetzer, P., Hrusovsky, M., Burkart, C., Bellovoda, B., Jammernegg, W., Mendling, J., Demir, E., Van Woensel, T., Dijkman, R., Van der Velde, M., Ernst, A.C.: Use cases, success criteria and usage scenarios. Technical report, GET Service Project Deliverable 1.1 (2013)

Vannieuwenhuyse, B., Gelders, L., Pintelon, L.: An online decision support system for transportation mode choice. Logist. Inf. Manag. 16, 125–133 (2003)

Verweij, B., Ahmed, S., Kleywegt, A.J., Nemhauser, G., Shapiro, A.: The sample average approximation method applied to stochastic routing problems: a computational study. Comput. Optim. Appl. 24(2–3), 289–333 (2003)

via donau: Cold – container liniendienst donau – eine einschätzung der chancen und risiken von containertransporten auf der donau zwischen Österreich und dem schwarzen meer. Technical report, via donau (2006)

via donau: Manual on Danube Navigation, via donau (2007)

Wang, S., Meng, Q.: Robust schedule design for liner shipping services. Transp. Res. Part E: Logist. Transp. Rev. 48(6), 1093–1106 (2012)

Wang, T., Meng, Q., Wang, S., Tan, Z.: Risk management in liner ship fleet deployment: a joint chance constrained programming model. Transp. Res. Part E: Logist. Transp. Rev. 60, 1–12 (2013)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

Demir, E., Hrušovský, M., Jammernegg, W., Van Woensel, T. (2017). Methodological Approaches to Reliable and Green Intermodal Transportation. In: Cinar, D., Gakis, K., Pardalos, P. (eds) Sustainable Logistics and Transportation. Springer Optimization and Its Applications, vol 129. Springer, Cham. https://doi.org/10.1007/978-3-319-69215-9_7

Download citation

DOI: https://doi.org/10.1007/978-3-319-69215-9_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-69214-2

Online ISBN: 978-3-319-69215-9

eBook Packages: Mathematics and StatisticsMathematics and Statistics (R0)