Abstract

Prokaryotes that can oxidize ammonia and/or nitrite are known as nitrifiers and are common in terrestrial, freshwater and marine environments. Where the temperature is commonly in the range 0–20 °C, psychrophilic strains or species can be isolated or identified using molecular techniques. It is therefore no surprise to also find psychrophilic nitrifiers in engineered systems used, for example, to remove ammonia from raw, used or wastewater or from contaminated air. In temperate regions, we have been using psychrophilic nitrifiers without most people realizing, and this chapter attempts to put their importance into context by comparing and contrasting their presence in natural and engineered systems. It concludes by describing a biofilm-based process technology, the expanded bed biofilm reactor, which the author has improved with several inventions that make this technology cost-effective for wider adoption.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

1 Introduction

Purification of used water tends to be done at municipal wastewater treatment works and, in temperate countries, it normally relies on the activities of psychrophilic microorganisms, as the temperature of the wastewater rarely rises above 20 °C. Because the purification of used water by secondary, biological processes involves the conversion of organic matter to microbial biomass, it represents the largest biotechnology application of cold-adapted microbes. For example, in the European Union (EU), if all wastewater was subjected to secondary treatment, approximately 4 million tonnes of biomass would be produced per year, much of it consisting of psychrophilic, heterotrophic microorganisms such as bacteria, protozoa and rotifers, as well as oligochaete and nematode worms.

In contrast, nitrification is conducted mostly by autotrophic ammonia- and nitrite-oxidizing bacteria (AOB and NOB, respectively), although bacteria capable of carrying out both processes have recently been reported (Daims et al. 2015; van Kessel et al. 2015) and ammonia-oxidizing archaea (AOA) have been found in wastewater plants in the USA by Park et al. (2006). The energy yield from oxidizing ammonia or nitrite is much less than from using organic matter as the electron donor and, for nitrite, it is one third that of ammonia. That is, 100 molecules of nitrite need to be oxidized to harvest enough energy to fix one CO2 molecule, whereas it only requires oxidation of 35 ammonia molecules (Prosser 1986). Therefore, for nitrification, approximately 367 thousand tonnes of AOB and 86 thousand tonnes of NOB would be produced per year in Europe if tertiary treatment was used for nitrification of all domestic wastewater. Nitrification processes have become more common in recent years, for the protection of aquatic organisms and the restoration of good ecological status. An important driver for use of these processes in the EU has been the Urban Wastewater Treatment Directive (European Council 1991), which has been subsumed into the Water Framework Directive (European Council 2000).

Treatment of domestic wastewater consists of up to three stages: primary, secondary and tertiary. Primary treatment consists of physical separation of particulate materials, typically using screens and grit channels. This removes particles larger than a few millimetres or with a significantly higher density than water. The partially clarified wastewater (“settled sewage”) is normally subjected to secondary, biological treatment using one of several process technologies. The oldest established technology is the trickling filter (TF), which was perfected in Salford, UK, in 1893. The second oldest, activated sludge (AS), was developed in Davyhulme, Manchester, UK, in 1914. Despite their age, these processes are still used worldwide. Oxidation ponds (lagoons) date from about the same time, but more recently developed processes include rotating biological contactors (RBC), moving bed biofilm reactors (MBBR) and membrane bioreactors (MBR) (Murdoch University Environmental Technology Centre 2000; Metcalf & Eddy et al. 2014). Essentially, secondary treatment is a process of growing mostly heterotrophic microbes on nutrients in wastewater, thus removing the polluting matter by settling out the biomass as sludge. This sludge is often combined with that from the primary settling tanks and subjected to anaerobic digestion, to reduce the final sludge volume, by about tenfold, and to generate methane-rich biogas as a renewable fuel. Although this process is normally operated at mesophilic or thermophilic temperatures, recent work by O’Flaherty’s group at the National University of Ireland, Galway, has established a method of low-temperature anaerobic digestion based on biomass granules (McKeown et al. 2009).

Following the Industrial Revolution and the growth of crowded cities, biological wastewater treatment was developed as a means of protecting human health, by breaking the cycle of waterborne disease. It also gave some basic protection to the aquatic environment. This work continues, with increasing protection of the aquatic environment driven by ever-tighter standards on effluent quality. One of the main pollutants remaining after secondary treatment, in terms of mass, is ammonia, and those eating a Western-style omnivorous diet produce about 8 g of ammoniacal nitrogen waste per day, approximately half of which is removed during secondary treatment. Therefore, to protect sensitive organisms from the damaging effects of ammonia in water bodies receiving treated effluent, a tertiary process is required for nitrification. Such processes are designed to reduce the residual ammoniacal nitrogen concentration so that the works’ effluent is suitable for discharge into the aquatic environment.

2 Nitrification in the Natural Environment

Nitrification is a common microbiological process that occurs in terrestrial and aquatic environments, both freshwater and marine. Ammonia is oxidized to nitrite (nitritation) by one group of specialist bacteria or archaea and nitrite oxidized to nitrate (nitritation) by another group of specialist bacteria, phylogenetically unrelated to the AOB (Costa et al. 2006) but bacteria capable of carrying out both processes have recently been reported (Daims et al. 2015; van Kessel et al. 2015). No nitrite-oxidizing archaea have yet been identified. Ammonia and nitrite are electron donors and, therefore, the energy source for these prokaryotes. In recent years, ammonia-oxidizing archaea (AOA) have been isolated, with the discovery by Konneke et al. (2005) of a new species, from the rocky substratum of a tropical marine tank at the Seattle Aquarium (USA). Thus, AOA join the ammonia-oxidizing bacteria (AOB) and nitrite-oxidizing bacteria (NOB) as important prokaryotes in global nitrogen cycling.

Although ammonia and nitrite oxidation was always thought to occur in different species (Costa et al. 2006), several new candidate species of bacteria from the genus Nitrospira have been discovered that are capable of complete ammonia oxidation, comammox, i.e. the sequential oxidation of ammonia to nitrite and nitrite to nitrate by a single species. However, as one species was isolated by Daims et al. (2015) from microbial biofilm growing on the walls of a hot water pipe (56 °C) at an oil exploration well in Aushiger (North Caucasus, Russia), it would not have been psychrophilic. However, the other was isolated by van Kessel et al. (2015) from a trickling filter system for carp (Cyprinus carpio) aquaculture, following enrichment at 23 ± 1 °C, which is closer to psychrophilic conditions. More recently, Chao et al. (2016) provided metagenomic evidence for Nitrospira-like amoA genes in activated sludge (AS) and biofilm samples from an aerobic suspended carrier biofilm reactor (otherwise known as a moving bed biofilm reactor, MBBR) at the Stanley WWTP in Hong Kong. This plant had a design temperature of 18 °C and an operational water temperature of about 22 °C for the Hybas™ nitrification process (Lau 2011) that was probably the source of the material for metagenomic analysis, so these comammox Nitrospira may not have been true psychrophiles either.

Nevertheless, there is growing evidence of significant nitrification at low temperatures, suggesting that psychrophilic nitrifiers are ubiquitous in cold environments. For example, Clark et al. (2009) provided evidence that nitrification proceeds in frozen soils (−6 °C for clay and −2 °C for loam) collected 5 km south of Québec City (Canada). This observation has been confirmed by Jusselme et al. (2016) for soils in the French Alps, where evidence for nitrification activity was obtained at soil surface temperatures in the range −0.6 to +0.8 °C. Furthermore, chemical evidence has been presented by Telling et al. (2014) for nitrification in ice-entombed cryoconite holes in the surface of glaciers in the McMurdo Dry Valley (Antarctica), where air temperatures rarely exceed 0 °C. Therefore, from an ecological perspective, nitrification by psychrophiles should occur in wastewater treatment processes whenever the wastewater is in the range 0–20 °C.

3 Nitrification in Engineered Environments

As well as AOB, AOA have been found in granular activated carbon filters for nitrification of raw water. The number of AOA was stable all year, even though the raw water temperature ranged from 17.7 to 28.6 °C in summer and 4.6 to 5.5 °C in winter, whereas AOB numbers were lower in winter (Niu et al. 2016). These observations indicate that psychrophilic AOA and AOB were present, with the AOA community being more resilient at low temperature. In contrast, during an investigation of the ammonia-oxidizing prokaryotes in a horizontal flow biofilm reactor (HFBR) for the treatment of ammonia-contaminated air at 10 °C, Gerrity et al. (2016) found that AOB were significantly more abundant than AOA. Nevertheless, both types of microbe were presumably psychrophilic. In a study of the relative abundance of AOB and AOA in biofilms of sequential discs in an RBC at Guelph Wastewater Treatment Plant (Ontario, Canada), Sauder et al. (2012) demonstrated that AOA became more dominant as the ammonia concentration was reduced along the reactor. This indicates that these AOA are k-strategists (Wett et al. 2011; Wu et al. 2016), as they had a higher affinity for ammonia than the AOB. Therefore, operating conditions to encourage the growth of AOA or k-strategist AOB are likely to result in a higher-quality effluent, i.e. one with a lower concentration of ammonia. Furthermore, as the average temperature in Guelph ranges from about −6 °C in winter to 20 °C in summer (http://en.climate-data.org/location/881/), both the AOB and AOA were most likely psychrophilic.

Biofilm reactors are especially useful when slow-growing process microbes have to be used, such as nitrifiers in a wastewater treatment process. Chao et al. (2016) found that the abundance and diversity of nitrogen cycle genes (both for nitrification and denitrification) were significantly higher in biofilm than that in AS. They considered that this difference indicated that the nitrogen-removing bacteria growing as biofilm contained more abundant or diverse functional genes, revealing that the increased nitrogen removal ability of biofilm processes might be mainly attributed to enhancement of removal, rather than the accumulation of nitrogen removal bacteria. Presumably, there was enhancement through physiological changes in the bacteria when growing as a biofilm, rather than a mere increase in biomass. It is widely reported that AMO and NOB cell clusters are found close to each other in biofilms (Maixner et al. 2006; Akhidime 2009), which is assumed to be the result of a selection pressure for the NOB to more readily access the nitrite produced by the AOB. Although this clustering was observed by Maixner et al. (2006) for Nitrospira sublineage I, it was not for sublineage II, which might be evidence that the latter were comammox bacteria and, therefore, clustering with AOB (or AOA) conferred no growth advantage.

The nitrification rate in biofilm has been calculated to decrease by about 4.5% per °C fall, compared to 10% in conventional AS systems (Boller et al. 1987, as reported by Bodık et al. 2003). This differential reduction in rate is likely to have been a consequence of the nitrifiers being washed out of the AS process faster than they can grow, owing to their low growth yield. This effect is not a problem for biofilm systems, where the microbes can be retained irrespective of growth rate.

A similar phenomenon was observed during pilot-scale trials of an expanded bed biofilm reactor (EBBR) designed for nitrification of secondary effluent. This trial was conducted at the United Utilities Davyhulme Wastewater Treatment Works (Manchester, UK), and during a particularly wet summer when it rained every day for 3 weeks, an increase in the AS plant effluent nitrite concentration was observed, increasing from about 1 to 10 mg L−1 NO2 −-N (unpublished observation). This was assumed to have been caused by the NOB being washed out of the AS process but not the ammonia oxidizers, owing to their higher growth yield. In contrast, the EBBR, which treated the AS settled effluent, continued to produce a treated effluent low in both ammonia and nitrite, indicating that the NOB were retained in this system, presumably as a result of immobilization in attached biofilm.

A similar effect is predicted when suspended cell and biofilm processes are operated during cold weather, when the AOB, AOA and NOB growth rates may be depressed. If the growth rate is less than the hydraulic residence time (HRT) of suspended cell reactors, cells will be washed out faster than they can reproduce, whereas in fixed biofilm systems, cells are retained because the reproduction rate is decoupled from HRT.

By starting up a process to remove ammonia from used water at temperatures in the psychrophilic range, there will be a selection pressure for species and strains that are cold adapted. These bacteria will therefore have higher growth rates at lower temperatures than if a process is established under mesophilic conditions and then operated under psychrophilic conditions. This is a problem with some research work on the effect of temperature shifts on nitrification (and other processes), where processes are established in the lab in the mesophilic range and then process performance is also evaluated in the psychrophilic range. It is likely that warm-adapted species dominate the microbial community that develops under mesophilic conditions, which then perform badly when the temperature is lowered into the psychrophilic range. Whereas, if the bioreactor is seeded with material from a psychrophilic environment and operated in the psychrophilic range, then good performance should be achieved under psychrophilic conditions but not necessarily if the temperature is increased into the mesophilic range. It is all a question of understanding microbial physiology and ecology, and applying it in an industrial context!

The local seasonal temperature range determines which species are available for seeding a bioreactor, and the temperature under which the process is started up and operated largely determines which will become established. Psychrophiles have an optimum temperature for growth at or below 15 °C; a maximum temperature of about 20 °C, above which they die; and a minimum temperature at or below 0 °C, below which they cannot grow. For example, a newly identified, psychrophilic nitrite-oxidizing bacterium, “Candidatus Nitrotoga arctica”, has been reported from permafrost soil in the Siberian arctic (Alawi et al. 2007). This candidate species grows in the temperature range 4–17 °C, and bacteria with similar 16S rDNA sequences have now been isolated by cultivating at 10 °C or 17 °C activated sludge from the Hamburg (Germany) plant, which typically operates in the range 7–16 °C (Alawi et al. 2009).

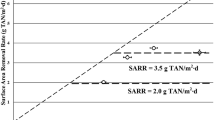

Generally, a wastewater treatment process will develop a psychrophilic population if one is available locally and the process is operated in the relevant temperature range. During pilot-plant trials of the EBBR referred to above (Dempsey et al. 2006), good nitrification was observed down to 8 °C (Fig. 26.1), which was the lowest influent wastewater temperature seen in 5 years of operation, as normally it never fell below 11 °C. The fact that this process was able to reduce the ammonia-nitrogen concentration below 1 mg L−1 in the temperature range 8–20 °C indicates that the active nitrifiers were psychrophilic. Currently, DNA sequencing is being conducted to determine which species of nitrifiers this process contained.

Relationship between process temperature and effluent ammonia concentration during operation of an expanded bed biofilm reactor pilot plant (0.5 m diameter, 3 m bed depth) to achieve an effluent ammonia-nitrogen concentration below 1 mg L−1 when treating the activated sludge plant settled effluent at the United Utilities Davyhulme Wastewater Treatment Works (Manchester, UK)

4 Expanded Bed Biofilm Reactor Technology

Advanced Bioprocess Development (ABD) has developed an expanded bed biofilm reactor (EBBR), which is a fixed-film, submerged-bed technology (BS-EN-12255-7 2002) where biofilms grow on small particles (0.7–1.0 mm) of porous carbon (ABDite®, Fig. 26.2; Dempsey 2001). Calculated on the basis of solid geometry, 1 mm spheres (assuming 60% packing) have a specific surface area (SSA) of 3600 m2 m−3. Therefore, ABDite® particles have a similar SSA if we ignore the material’s porosity. This large SSA is almost four times greater than any other biomass support medium (Fig. 26.3). Once colonized by biofilm, the term bioparticles or particulate biofilms is used (Fig. 26.1). When expanded by 50%, the biofilm SSA is up to 2400 m2 m−3 and the biomass concentration is up to 42,000 mg L−1 (VSS equivalent).

Biomass support media particles (0.7-1.0 mm porous carbon, ABDite®). (a) Scanning electron micrograph (SEM), showing porous nature of these media particles (magnification ×60, pore size approx. 50 μm wide); (b) SEM of ABDite® colonized with thin nitrifying biofilm (bioparticle size approx. 1 mm); (c) light micrograph of bioparticle, showing relatively smooth nature once colonized with thick biofilm (bioparticle size 1.0–1.5 mm)

Specific surface area of media particles used for different types of wastewater treatment technology: Suez Environment’s Biofor®, Veolia Water Technologies’ Biostyr®, Veolia Water Technologies’ Kaldnes® moving bed biofilm reactor (MBBR), submerged aerated filter (non-proprietary), rotating biological contactor (non-proprietary) and Advanced Bioprocess Development’s expanded bed biofilm reactor (EBBR)

This large surface area of biofilm and high concentration of biomass are maintained in an active state by control of biofilm thickness, ideally in the range 100–400 μm (Akhidime and Dempsey 2009), via recycling of particles from the top of the bed to the bottom (Fig. 26.4). Bioparticles with the thickest biofilm are the least active, owing to increasing diffusional limitation as the biofilm depth increases. Fortunately, these bioparticles migrate to the top of the bed, owing to their lower fluidization velocity. Thereby, the least active biofilm is removed via attrition during passage through regions of high turbulence, including within an injection device (Dempsey 2011), and the moving bed distributor (Dempsey 2004) at the base of the expanded bed.

The influent wastewater enters the top of the aeration column (Fig. 26.4), at flow rate q, and flows downwards. In contrast, the process air (depleted of nitrogen for highly aerobic processes, such as nitrification) flows upwards. Separation of this countercurrent flow from the immobilized biomass is unique to this technology and allows a high degree of turbulence for achieving highly efficient oxygen transfer from the gas to the liquid phase, without risking detachment of biofilm from the media particles. Aerated wastewater is pumped into the base of the expanded bed, at flow rate Q, causing particle fluidization and bed expansion. Ammonia is oxidized to nitrite by ammonia-oxidizing bacteria and the nitrite oxidized to nitrate by nitrite-oxidizing bacteria as the wastewater passes up through the bed. Treated effluent leaves at the same flow rate (q) as the influent enters, thus causing a variable recycle of partially treated wastewater back to the top of the aeration column, dependent on the works flow. Thus, diurnal variations in the flow to the works, as well as variations caused by rainfall or other precipitation, are automatically adjusted for. Bioparticles with the thickest biofilm are recycled from the top to the bottom of the bed by another automatic system, which relies on an injector driven by the flow of wastewater induced by the fluidizing pump.

By virtue of their immobilization in the biofilm that grows on the biomass support media particles (ABDite®) and the fact that these particles are retained in the reactor, process microbes are retained despite the relatively high upflow velocity (36 m h−1) of the process liquid (wastewater in this case). In contrast, planktonic cells will be washed out with the treated effluent. Thus, irrespective of their growth rate, process microbes will be available at all times, despite the fact that they will normally be reproducing more slowly than the hydraulic residence time (approx. 30–60 min for a tertiary nitrification process). This process has now been developed to Technology Readiness Level 7, with the development of a prototype package plant in collaboration with J. K. Fabrications, Newry, Northern Ireland (Fig. 26.5).

Full-scale, expanded bed biofilm reactor (EBBR) prototype package plant (Technology Readiness Level 7) constructed in stainless steel by J. K. Fabrications, Newry, Northern Ireland. The expanded bed column is 1.5 m diameter and the expanded bed depth is 5 m. This size of EBBR is able to nitrify at least 8.8 kg NH3-N per day, which is equivalent to purifying the secondary effluent from a population of about 2200 people

5 Conclusions

It is clear that nitrifying prokaryotes adapted to psychrophilic conditions (0–20 °C) are widespread in cold environments and are also found in bioprocesses operated under psychrophilic conditions. In order to establish a bioprocess, such as nitrification of raw, used or waste water, for treatment under psychrophilic conditions, it is necessary to maintain the temperature in the correct range and, ideally, to seed it with material likely to contain the psychrophilic microbes necessary for the process. In the case of nitrification, these will include ammonia-oxidizing bacteria and archaea, as well as nitrite-oxidizing bacteria and comammox bacteria; and nitrite-oxidizing archaea, should they be discovered.

Furthermore, where there is a requirement for effluent ammonia concentrations below 1 mg/L, as is becoming more frequent in Europe, the USA and other highly developed countries, it is also necessary to operate the process with nitrifiers that have a high affinity for ammonia. These nitrifiers can be enriched quite simply, by always operating the process with a low effluent ammonia concentration, which will create the conditions where k-strategists have a selective advantage over r-strategists.

References

Akhidime ID (2009) Aspects of expanded bed nitrification including treatment of oil refinery wastewaters. PhD, Manchester Metropolitan University, Manchester. http://ethos.bl.uk/OrderDetails.do?uin=uk.bl.ethos.509884

Akhidime ID, Dempsey MJ (2009) Influence of biofilm thickness on ammonia oxidation rate of bioparticles from expanded bed process for tertiary nitrification. Paper presented at the 2nd IWA Specialized Conference on Nutrient Management in Wastewater Treatment Processes, Krakow, Poland, 2009

Alawi M, Lipski A, Sanders T, Eva Maria P, Spieck E (2007) Cultivation of a novel cold-adapted nitrite oxidizing betaproteobacterium from the siberian arctic. ISME J 1(3):256–264. doi:10.1038/ismej.2007.34

Alawi M, Off S, Kaya M, Spieck E (2009) Temperature influences the population structure of nitrite-oxidizing bacteria in activated sludge. Environ Microbiol Rep 1(3):184–190. doi:10.1111/j.1758-2229.2009.00029.x

Bodık I, Kratochvıl K, Gašpariková E, Hutňan M (2003) Nitrogen removal in an anaerobic baffled filter reactor with aerobic post-treatment. Bioresour Technol 86(1):79–84. doi:10.1016/S0960-8524(02)00109-8

Boller M, Eugster J, Weber A, Gujer W (1987) Nitrification in nachgeschalteten rotierenden Tauchkörpern. Bericht über 2 Jahre Pilotuntersuchungen. EAWAG report no. 28–601, Dübendorf, Switzerland

BS-EN-12255-7 (2002) Wastewater treatment plants. Biological fixed-film reactors. British Standards Institution, London

Chao Y, Mao Y, Yu K, Zhang T (2016) Novel nitrifiers and comammox in a full-scale hybrid biofilm and activated sludge reactor revealed by metagenomic approach. Appl Microbiol Biotechnol 100(18):8225–8237. doi:10.1007/s00253-016-7655-9

Clark K, Chantigny MH, Angers DA, Rochette P, Parent L-E (2009) Nitrogen transformations in cold and frozen agricultural soils following organic amendments. Soil Biol Biochem 41(2):348–356. doi:10.1016/j.soilbio.2008.11.009

Costa E, Perez J, Kreft JU (2006) Why is metabolic labour divided in nitrification? Trends Microbiol 14(5):213–219. doi:10.1016/j.tim.2006.03.006

Daims H, Lebedeva EV, Pjevac P, Han P, Herbold C, Albertsen M, Wagner M (2015) Complete nitrification by nitrospira bacteria. Nature 528(7583):504–509. http://www.nature.com/nature/journal/v528/n7583/abs/nature16461.html#supplementary-information. doi:10.1038/nature16461

Dempsey MJ (2001) Nitrification process. EU Patent EP 1,129,037

Dempsey MJ (2004) EU Patent No. EP 1,444,167

Dempsey MJ (2011) Improvements in and relating to fluid bed expansion and fluidisation. US Patent US 7,309,433

Dempsey MJ, Porto I, Mustafa M, Rowan AK, Brown A, Head IM (2006) The expanded bed biofilter: combined nitrification, solids destruction, and removal of bacteria. Water Sci Technol 54(8):37–46

European Council (1991) Urban wastewater treatment directive. Council Directive 91/271/EEC, L135, May 30, 1991

European Council (2000) Directive 2000/60/ec of the European parliament and of the council establishing a framework for the community action in the field of water policy, December 22, 2000

Gerrity S, Clifford E, Kennelly C, Collins G (2016) Ammonia oxidizing bacteria and archaea in horizontal flow biofilm reactors treating ammonia-contaminated air at 10°C. J Ind Microbiol Biotechnol 43(5):651–661. doi:10.1007/s10295-016-1740-z

Jusselme M-D, Saccone P, Zinger L, Faure M, Le Roux X, Guillaumaud N, Poly F (2016) Variations in snow depth modify n-related soil microbial abundances and functioning during winter in subalpine grassland. Soil Biol Biochem 92:27–37. doi:10.1016/j.soilbio.2015.09.013

Konneke M, Bernhard AE, de la Torre JR, Walker CB, Waterbury JB, Stahl DA (2005) Isolation of an autotrophic ammonia-oxidizing marine archaeon. Nature 437(7058):543–546. http://www.nature.com/nature/journal/v437/n7058/suppinfo/nature03911_S1.html

Lau FTK (2011) Application of hybrid reactor to maximize treatment capacity and nitrification with short sludge-age operation. http://www.dsd.gov.hk/EN/Files/Technical_Manual/RnD_reports/RD2038.pdf

Maixner F, Noguera DR, Anneser B, Stoecker K, Wegl G, Wagner M, Daims H (2006) Nitrite concentration influences the population structure of nitrospira-like bacteria. Environ Microbiol 8(8):1487–1495. doi:10.1111/j.1462-2920.2006.01033.x

McKeown RM, Scully C, Enright AM, Chinalia FA, Lee C, Mahony T, O’Flaherty V (2009) Psychrophilic methanogenic community development during long-term cultivation of anaerobic granular biofilms. ISME J 3(11):1231–1242. doi:10.1038/ismej.2009.67

Metcalf & Eddy Inc, Tchobanoglous G, Stensel HD, Tsuchihashi R, Burton F (2014) Wastewater engineering: treatment and resource recovery, 5th edn. WCB/McGraw-Hill, New York, NY

Murdoch University Environmental Technology Centre (2000) Environmentally sound technologies in wastewater treatment for the implementation of the unep global programme of action (gpa) “guidance on municipal wastewater”. http://www.unep.or.jp/ietc/publications/freshwater/sb_summary/index.asp

Niu J, Kasuga I, Kurisu F, Furumai H, Shigeeda T, Takahashi K (2016) Abundance and diversity of ammonia-oxidizing archaea and bacteria on granular activated carbon and their fates during drinking water purification process. Appl Microbiol Biotechnol 100(2):729–742. doi:10.1007/s00253-015-6969-3

Park HD, Wells GF, Bae H, Criddle CS, Francis CA (2006) Occurrence of ammonia-oxidizing archaea in wastewater treatment plant bioreactors. Appl Microbiol Biotechnol 72(8):5643–5647. doi:10.1128/aem.00402-06

Prosser JI (ed) (1986) Nitrification, vol 20. Published for the Society for General Microbiology by IRL, Oxford

Sauder LA, Peterse F, Schouten S, Neufeld JD (2012) Low-ammonia niche of ammonia-oxidizing archaea in rotating biological contactors of a municipal wastewater treatment plant. Environ Microbiol 14(9):2589–2600. doi:10.1111/j.1462-2920.2012.02786.x

Telling J, Anesio AM, Tranter M, Fountain AG, Nylen T, Hawkings J, Wadham JL (2014) Spring thaw ionic pulses boost nutrient availability and microbial growth in entombed antarctic dry valley cryoconite holes. Front Microbiol 5:694. doi:10.3389/fmicb.2014.00694

van Kessel MAHJ, Speth DR, Albertsen M, Nielsen PH, Op den Camp HJM, Kartal B, Lücker S (2015) Complete nitrification by a single microorganism. Nature 528(7583):555–559. doi:10.1038/nature16459

Wett B, Jimenez JA, Takacs I, Murthy S, Bratby JR, Holm NC, Ronner-Holm SGE (2011) Models for nitrification process design: one or two aob populations? Water Sci Technol 64(3):568–578. doi:10.2166/wst.2011.499

Wu J, He CD, van Loosdrecht MCM, Perez J (2016) Selection of ammonium oxidizing bacteria, (aob) over nitrite oxidizing bacteria (nob) based on conversion rates. Chem Eng J 304:953–961. doi:10.1016/j.cej.2016.07.019

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

Dempsey, M.J. (2017). Nitrification at Low Temperature for Purification of Used Water. In: Margesin, R. (eds) Psychrophiles: From Biodiversity to Biotechnology. Springer, Cham. https://doi.org/10.1007/978-3-319-57057-0_26

Download citation

DOI: https://doi.org/10.1007/978-3-319-57057-0_26

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-57056-3

Online ISBN: 978-3-319-57057-0

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)