Abstract

Simulations of nonlinear mechanical systems have always been a challenge due to their computational cost: even though techniques able to reduce simulations cost have been deeply studied in the last decades, this is still an open field of research. Methods used to reduce model size are known as model order reduction methods.

The approach here proposed is a model order reduction method named Multi-Phi; it is addressed to nonlinear mechanical systems that vary their configuration depending on one or more parameters. This method describes the nonlinear system time evolution through a series of linear ODEs, projecting the nonlinear system in the configurations space. Linear modal analysis is used to reduce separately each linear system, allowing retaining of physical properties, as long as the elasticity hypothesis is respected.

In this paper the method is presented and details about its implementation are provided, specifying how interactions between linear systems are faced. Two simple examples of its application are provided, highlighting the potential of this method to deal with nonlinear systems in a simple and intuitive way and showing its perspectives in terms of computational time reduction. As conclusions, considerations about the capabilities of this method are discussed and future steps are proposed.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

11.1 Introduction

In the last decades, numerical simulations have become a powerful tool to replace physical prototypes and to simulate system behaviour. In order to correctly describe a system or a model, a large number of coordinates, namely Degrees Of Freedoms (DOFs), are required. This leads to large models, which require long simulation time. It is however possible to define a level of accuracy that is good enough for the purpose, with a smaller number of DOFs, reducing the computational cost: this procedure is known as Model Order Reduction (MOR). MOR methods have been largely studied and developed in recent years, in several engineering fields, as summarized by [1, 2]. Examples of MOR applications can be found in structural dynamics [3,4,5,6], systems and control [7, 8] and mathematics [9,10,11].

Two main categories of MOR methods can be identified:

-

Data-based

-

Model-based

Data-based approaches are founded on a database of simulations of the original nonlinear system. The database is used to obtain on-line reliable predictions of conditions that are intermediates with respect to those obtained off-line and stored in the database. For what concern nonlinear systems, an example of data-based method is the Proper Orthogonal Decomposition (POD) [12, 13].

Model-based approaches require no previous simulation of the original nonlinear system. Generically speaking, it is reduced by projecting it into a sub-manifold, whose definition depends on the method considered. The reduced system is then simulated, since it requires a lower computational cost with respect to the original system.

Several methods have been proposed for nonlinear systems, such as methods that reduce the model retaining the nonlinearities [14, 15] or methods that linearise the model around linearisation point. Interesting example of this last category are the Trajectory Piecewise Linear Approximation method (TPWL) [16,17,18] and the Global Modal Parametrization method (GMP) [19, 20]. In other proposed methods [21,22,23] the emphasis is on the selection of the base used to describe the system.

The method here proposed is called Multi-Phi and it is a linearisation method based on the projection of the nonlinear system in the configuration space, followed by a separate reduction of each of the linearised systems. The nonlinear system is therefore described through a subset of the vibrational modes (mode shapes) and the static deformed shapes of each of the linearised systems. Like as in GMP methods, the model is separately reduced around multiple possible configurations, but there is no need of explicit the nonlinear equations of motion. Nonlinearities are implicit in the differences between mode shapes and static deformed shapes of the various configuration, since this approach is based on an existing Finite Elements model, able to describe the nonlinear system through a set of configurations.

In the following, the proposed method is introduced and two simple examples of its application are provided.

11.2 Methodology

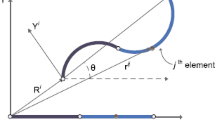

As in the GMP method, Multi-Phi is based on a preprocessing phase in which the model is linearised around multiple configurations. Each linearised system is reduced by means of a subset of its vibrational modes and of a static deformed shape due to non-null boundary condition. This last deformed shape is called asymptotic configuration (x ∞) and it is considered only when boundary conditions force the system to have a non-null state of strain at t → ∞ and with no external forces acting on the system.

At each linearised reduced model is associated a specific value of a parameter α: the monitoring of this parameter will define the interaction between the linearised model during the simulation.

The nonlinear system considered is described in the following form:

It can be noted that all the nonlinearities are taken into account by means of a variation of the matrices and that they are not transformed into pseudo-forces. The aim of this approach is to remain as generic as possible, allowing a common method for all nonlinearities describable through a variation of the system matrices. The matrices of Eq. (11.1) are n x n matrices, with n overall DOFs.

First, each linearised system l is described by means of its modal coordinates:

The symbol ^ is used to identify the matrices and the variables on which no reduction has been applied; the dimensions of the above matrices is v l x v l , except for the modal matrix \( {\widehat{\boldsymbol{\Phi}}}_l^T \), which is a v l x n matrix. It is highlighted that the dimension of the matrices in Eq. (11.2) can vary between the linearised systems, since it is possible to have variable boundary conditions. The number of boundary conditions is in fact equal to (n-v l ).

The selection of the vibrational modes to be considered depends on the specific application, therefore in Eq. (11.3) it is referred to a generic set of r l modes for the linearised system l:

It has to be note that all the matrices involved are all diagonal, except for \( {\boldsymbol{\Phi}}_l^T \). Moreover, obviously, r l < < v l .

The simulation output is the full system state at each time instant; since this method is not aimed to be used for real-time calculation, the state in terms of physical coordinates can be obtained after the simulation itself, by using Eq. (11.4):

In Eq. (11.4) the addition of x ∞ is necessary whenever the set of mode shapes used to simulate the system evolution cannot describe the system state because of non-null boundary conditions. It is considered function of time because it depends on the linearised system considered at each time instant.

The matrix Φ(t) is varying in time as a consequence of the transition between the linearised system: it is composed by the succession in time of the matrices Φ l , with l = 1, …, L if a number of linearised systems equal to L is considered.

In order to clarify how the evolution of the system state in time is obtained, it is necessary to distinguish two cases:

-

1.

Discrete transitions,

-

2.

Continuous transitions.

In the following it will be referred to each linearised system as to a “level”, so that at the level l it is associated the linearised system characterized by α = α l , the set of reduced matrices \( {\left(2\boldsymbol{\upzeta} \boldsymbol{\upomega} \right)}_l,\kern0.36em {\boldsymbol{\upomega}}_l^2 \) and Φ l and the asymptotic configuration x ∞ , l .

11.2.1 Discrete Transitions

In the approach characterized by discrete transitions, it is supposed that the parameter α can assume only discrete values. Therefore, during the simulation only one level at the time is considered, depending on the value of α. The evolution of the full system, during the span of time in which α = α l , depends only by the linearised system l and the transition to another level m occurs whenever α = α m .

The transition is governed by Eq. (11.5), in which the initial conditions of the modal coordinates of the level m are described by means of the final conditions of modal coordinates of the level l:

At the end of the simulation, the system state at each time instant can be obtained through Eq. (11.4), with Φ(t) and x ∞(t) that are piecewise constants. The modal weights η(t) and their derivatives are a single vector, but the mode shapes at which they are referred depend on the punctual value of Φ(t), namely the linearised system considered at each instant of time.

11.2.2 Continuous Transitions

In the approach characterized by discrete transitions, it is supposed that the parameter α can assume continuous values. Therefore, every intermediate configuration should be described by two levels contemporary. Considering α l < α < α m , the two levels l and m are considered, with the corresponding linearised systems. The coordinates replacement described by Eq. (11.6) is considered, increasing the size of the ODE to be numerically integrated, from r l to (r l + r m ):

Equation (11.3) is therefore modified into Eq. (11.7):

The mix between the two linearised systems is obtained by the use of a weighting function w = w(α). The system state at a generic time instant t can be obtained through Eq. (11.8):

Whenever α exits the interval [α l , α m ], two new levels are considered, performing a discrete transition, as described above, with all the following considerations.

11.3 Examples

The examples here presented represent two simple applications of the method. The first one is a very simple lumped system, representing a contact and therefore with discrete transitions. No reduction is performed on this example, of which the only aim is to demonstrate that the system state is correctly described by means of the proposed procedure.

The second example regards a cantilever beam, with a lumped nonlinear spring that has non-symmetric cubic stiffness, so that continuous transitions are used. Moreover, several level of model reduction are considered, leading to consideration about the computational time saved and the error introduced with the approximation.

11.3.1 Lumped Masses

In the first example the system shown in Fig. 11.1 is considered. It is a lumped system, with 8 masses, 7 springs and 7 dampers. The first and the last masses are fixed and a rigid wall is placed at c = 0.2 mm with respect to the equilibrium position of the 5th mass; because of the position of the wall, the undeformed configuration is obtained with the mass not in contact with the wall. All the masses are considered free to move only along the x coordinate. No modal truncation will be performed: in this example, the interest lies in being able to correctly describe the evolution of this nonlinear system by means of modal coordinates with the appropriate use of the asymptotic configurations.

The values of masses and springs are summarized in Table 11.1.

Two levels are considered:

-

1.

No contact between mass and rigid wall: if x 5 > 0.2 mm, then R 5 = 0 N;

-

2.

Contact between mass and rigid wall: if x 5 = 0.2 mm, then R 5 > 0 N.

In the contact condition, an additional boundary condition is considered, beside the ones applied to the first and the last masses. It has to be noted that both natural frequencies and mode shapes vary depending on the level considered. Table 11.2 reports the natural frequencies.

A proportional damping is considered, as C = α M + β K, with α = 1 s−1 and β = 1 × 10−2s; the initial condition of the system is defined so that the first and the last masses have zero relative displacement, while the relative displacements of the others increase linearly, between x2 = 0 mm and x7 = 8 mm.

Figure 11.2a shows simulation results for all DOFs, highlighting the position of the wall. An absolute reference system is used to better identify masses displacements. In order to validate the obtained results, the same system has been simulated by means of the physical coordinates only, using the nonlinear equation of motion. Figure 11.2b shows a comparison between the Direct Integration and the Multi-Phi approach about contact point and reaction force. No meaningful differences are observable between the two methods. The change of coordinates, from physical to modal coordinates, does not introduce any significant error.

11.3.2 Beam with Nonlinear Spring

In the second example the system shown in Fig. 11.3a is considered. It is a cantilever beam, with a nonlinear spring and subjected to a sinusoidal excitation. The nonlinear characteristic, together with the linearisation points used, is shown in Fig. 11.3b. It is worth noting that there is an error introduced by the linearization, which will affect the simulations performed. This error can be reduced by increasing the number of linearization points, leading however to an increased computational effort.

Model parameters are summarized in Table 11.3.

The spring characteristic has been modeled according to Eq. (11.9):

Proportional damping has been used, with α = 1 × 10−6 s−1 and β = 1 × 10−7s.

The model has been described through 301 nodes, leading to an overall problem size of n = 903 unknowns, becoming v = 901 applying boundary conditions. The beam model has been linearised according to 51 equally spaced points, so that L = 51 levels are considered. It is important to know that the discretisation error introduced in this passage, will not be compensated during the model reduction. The larger the number of linearisation points, the smaller the discretisation error, but the computational cost increases with the number of discretisation points.

The results, obtained by using the proposed reduction method, are compared with a direct integration (DI) of the nonlinear original beam.

Figure 11.4 shows the displacement of the node at which the spring is attached, obtained through DI and with several level of modal truncation (Modal Truncation Level, MTL), expressed in percentage.

In Fig. 11.4a it is clear the error due to the modal truncation, while in Fig. 11.4b it is highlighted the error due to the linearisation. In order to properly estimate the error due to the two approximations, an indicator has been used. The formulas to obtain it are reported in Eq. (11.10):

The indicator used is a global weighted normalized mean square error (gwMSE), that follows from the definition of MSE [24, 25]. The subscript s is referred to the simulation taken into account, M is the total number of time instant considered and τ is the single time instant. The subscript j identifies each of the N degrees of freedom (DOFs) analysed. The value of MSE obtained for each simulation s is therefore a vector with N components and it is summarized by means of a weighted sum. Since MSE values are percentage errors, summing all of them would be meaningless: it is therefore defined a weight that takes into account the importance of each DOF. In fact, the variance (\( {\sigma}_{ref,j}^2 \)) of each DOF (j) represents its amplitude of motion, and the weighting function is obtained by dividing each variance by the mean variance of all DOFs (\( {\overline{\sigma}}_{ref}^2 \)). Finally, x j is the displacement of the j-th DOF, over time simulation.

The overall error committed with several levels of modal truncation is shown in Fig. 11.5, together with the calculation time required, as a percentage of the one required by the DI. All the DOFs along the direction z have been considered.

On one hand, the error remains constant and low (below 0.005%) with MTL up to 98%: only for severe levels of modal truncation the error becomes large, up to 0.8%. It has to be noted that 100% error means a solution of the reduced model that gives no displacements at all.

On the other and, the calculation time shows advantages only for very large level of modal truncation. Effective advantages can be obtained with MTL close to 97%, with still a small error and a computation time of approximately 10% with respect to direct integration of the nonlinear system.

The reasons of the large computational time required for the proposed method with low level of modal truncation can be found with the following considerations:

-

The contemporary evolution of two reduced linear systems is necessary to reduce the linearisation error, but it double the number of coordinates. It is pointless to use MTL < 50%. Moreover, being a MOR method, it is pointless to use reduction that does not reduce substantially the number of DOFs. Low reduction examples were simulated only to address future works;

-

The calculation of the weight between the two reduced linear systems needs to be performed on-line, increasing the computational time;

-

Switches between couples of reduced linear systems require additional computational time;

-

All numerical integrations have been performed by using Matlab and not a specifically developed environment.

11.4 Conclusions

A model order reduction method, based on the linear modal analysis and targeted at mechanical nonlinear systems was introduced. Two different categories of problems were considered, with two simple example. An analysis of the results obtained was proposed, with an a posteriori estimation of the error. The proposal seems to be suitable for different kind of nonlinearities, according to a good compromise between precision of results and calculation time.

Future works will be focused in optimizing the reduction criteria, switching from a simple modal truncation to a more effective modal selection. Moreover, an optimization of the simulation environment could lead to increase the performances in terms of simulation time.

References

Besselink, B., Tabak, U., Lutowska, A., van de Wouw, N., Nijmeijer, H., Rixen, D.J., Hochstenbach, M.E., Schilders, W.H.A.: A comparison of model reduction techniques from structural dynamics, numerical mathematics and systems and control. J. Sound Vib. 332, 4403–4422 (2013)

Aizad, T., Maganga, O., Sumislawska, M., Burnham, K.J.: A comparative study of model-based and data-based model order reduction techniques for nonlinear systems. Prog. Syst. Eng. 330, 83–88 (2014)

Géradin M., Rixen D.: Mechanical Vibrations: Theory and Application to Structural Dynamics, 2nd ed., John Wiley & Sons, Hoboken, NJ (1997)

Rixen D.J.: High order static correction modes for component mode synthesis. In: Proceedings of the 5th World Congress on Computational Mechanics, Vienna, Austria (2002)

Hurty, W.C.: Dynamic analysis of structural systems using component modes. AIAA J. 3(4), 678–685 (1965)

Craig Jr., R.R., Bampton, M.C.C.: Coupling of substructures for dynamic analyses. AIAA J. 6(7), 1313–1319 (1968)

Moore, B.C.: Principal component analysis in linear systems -controllability, observability and model reduction. IEEE Trans. Autom. Control. 26(1), 17–32 (1981)

Glover, K.: All optimal Hankel-norm approximations of linear multivariable systems and their L∞-error bounds. Int. J. Control. 39(6), 1115–1193 (1984)

Pillage, L.T., Rohrer, R.A.: Asymptotic waveform evaluation for timing analysis. IEEE Trans. Comput. Aided Des. Integr. Circuits Syst. 9(4), 352–366 (1990)

Feldmann, P., Freund, R.W.: Efficient linear circuit analysis by Padé approximation via the Lanczos process. IEEE Trans. Compu. Aided Des. Integr. Circuits Syst. 14(5), 639–649 (1995)

Grimme E.: Krylov projection methods for model reduction. PhD. thesis, University of Illinois at Urbana-Champaign, USA (1997)

Kerschen, G., Golinval, J.C., Vakakis, A.F., Bergman, L.A.: The method of proper orthogonal decomposition for dynamical characterization and order reduction of mechanical systems: an overview. Nonlinear Dyn. 41(1), 147–169 (2005)

Liang, Y.C., Lee, H.P., Lim, S.P., Lin, W.Z., Lee, K.H., Wu, C.G.: Proper orthogonal decomposition and its applications—part I: theory. J. Sound Vib. 252(3), 527–544 (2002)

Kerschen, G., Peeters, M., Golinval, J.C., Vakakis, A.F.: Nonlinear normal modes, part I: A useful framework for the structural dynamicist. Mech. Syst. Signal Process. 23, 170–194 (2009)

Amabili, M.: Reduced-order models for nonlinear vibrations, based on natural modes: the case of the circular cylindrical shell. Philos. Trans. R. Soc. A. 371(1993), (2013)

Bond, B.N., Daniel, L.: A piecewise-linear moment-matching approach to parameterized model-order reduction for highly nonlinear systems. IEEE Trans. Comput. Aided Des. Integr. Circuits Syst. 26(12), 2116–2129 (2007)

Rewieński, M., White, J.: A trajectory piecewise-linear approach to model order reduction and fast simulation of nonlinear circuits and micro-machined devices. IEEE Trans. Comput. Aided Des. Integr. Circuits Syst. 22(2), 155–170 (2003)

Rewieński, M., White, J.: Model order reduction for nonlinear dynamical systems based on trajectory piecewise-linear approximations. Linear Algebra Appl. 415, 426–454 (2006)

Brüls, O., Duysinx, P., Golinval, J.C.: The global parametrization for non-linear model-order reduction in flexible multibody dynamics. Int. J. Numer. Methods Eng. 69, 948–977 (2007)

Naets, F., Tamarozzi, T., Heirman, G.H.K., Desmet, W.: Real-time flexible multibody simulation with global modal parametrization. Multibody Syst. Dyn. 27, 267–284 (2012)

Géradin, M., Rixen, D.J.: A nodeless dual superelement formulation for structural and multibody dynamics application to reduction of contact problems. Int. J. Numer. Methods Eng. 106, 773–798 (2016)

Witteveen, W., Pichler, F.: Efficient model order reduction for the dynamics of nonlinear multilayer sheet structures with trial vector derivatives. Shock Vib. 2, 1–16 (2014)

Witteveen W., Pichler F.: Efficient model order reduction for the nonlinear dynamics of jointed structures by the use of trial vector derivatives, IMAC (2014)

Lehmann, E.L., Casella, G.: Theory of Point Estimation. Wadsworth & Brooks/Cole Advanced Books & Software, Monterey, CA (1991)

Loève, M.: Probability Theory. Springer, New York, NY (1977)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 The Society for Experimental Mechanics, Inc.

About this paper

Cite this paper

Bonisoli, E., Scapolan, M. (2017). A Proposal of Multi-Dimensional Modal Reduction for Nonlinear Dynamic Simulations. In: Kerschen, G. (eds) Nonlinear Dynamics, Volume 1. Conference Proceedings of the Society for Experimental Mechanics Series. Springer, Cham. https://doi.org/10.1007/978-3-319-54404-5_11

Download citation

DOI: https://doi.org/10.1007/978-3-319-54404-5_11

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-54403-8

Online ISBN: 978-3-319-54404-5

eBook Packages: EngineeringEngineering (R0)