Abstract

Yeast, and products of yeast, are composed of proteins, carbohydrates and minerals that fruit flies can utilize for development. They are being considered widely as alternative sources of protein for baits used for fruit fly suppression. In this chapter, we describe how we used techniques developed in Australia to developed fruit fly protein baits from waste brewer’s yeast (WBY) from breweries in Kenya, Tanzania and Uganda. In attraction and feeding response studies, protein originating from waste yeasts compared favourably with commercially available protein baits used for fruit fly suppression. In field evaluation trials, the total number of oriental fruit fly, Bactrocera dorsalis, captured in Kenyan (112.1 flies/trap/day [FTD]) and Ugandan (109.8 FTD) WBY was superior to the standard NuLure (56.8 FTD) although Torula yeast gave the highest catch of 132.4 FTD. In field suppression trials, mango fruit infestation by B. dorsalis in treatments receiving protein bait originating from Kenyan WBY in combination with other management methods incurred 6.7–20.0 % fruit damage compared to 65.6 % fruit damage in the untreated control. The results suggest that locally developed protein baits made from WBY offers a suitable alternative to expensive imported food baits for the management of fruit flies in Africa. On the basis of these results, a local commercial protein bait production plant using WBY is being established in Kenya inspired by a similar facility in Mauritius.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The process of yeast-catalyzed chemical conversion of sugars into ethyl alcohol and carbon dioxide has led to the production of alcoholic beverages including wine, beer or cider and other products that are subsequently distilled into brandy, whisky or vodka (Menezes et al. 2016). Associated with the brewing process is the production of large quantities of by-products usually referred to as waste yeast or spent grain (Hernandez-Pinerua and Lewis 1975). In fact, waste brewer’s yeast (WBY) falls within the category of environmental hazard and disposal methods increase the energy costs for the factory (Grieve 1979; Peel 1999; Mirzaei-Aghsaghal and Maheri-Sis 2008). Despite environmental concerns, the use of brewery waste streams, especially WBY for various industrial products has been recognized for decades (Henry 1990; Lloyd and Drew 1997; Fillaudeau et al. 2006; Ferreira et al. 2010). Indeed, there is a continuous and increasing demand for brewer’s grains, spent hops and other waste materials, some of which were previously considered of little or no value. Although dried WBY and spent hops are unsuitable for human consumption, they are known to be valuable as cattle feed (Grieve 1979; Tripathi and Karim 2011), and hops are also be used as a manure when mixed with other materials. WBY is reported to contain: a variety of enzymes, most of them capable of scientific or industrial application; nucleic acids, which are of great therapeutic value; vitamins; and proteins, carbohydrates and minerals that can be used as a food source by animals including fruit flies (Lloyd and Drew 1997; Sookar et al. 2002; Ferreira et al. 2010).

Lloyd and Drew (1997) pioneered the development of autolyzed protein bait from WBY for fruit fly control. The authors used pasteurized waste yeast from a Brisbane brewery in Australia and from the Royal Brewery in Tonga to produce a protein bait that could be used in fruit fly management strategies. Since this report several other studies have assessed the utility of WBY for fruit fly control with varying degrees of success (Seewooruthun et al. 1998, 2000; Chinajariyawong et al. 2003; Sookar et al. 2002, 2006; Umeh and Garcia 2008). In this chapter, we describe our attempt to develop protein baits from three different brewery sources in Kenya, Tanzania and Uganda using the methodology outlined by Lloyd and Drew (1997) with some minor modifications to the procedure. The attraction and feeding responses of the oriental fruit fly Bactrocera dorsalis (Hendel) to protein baits produced from the three sources of waste yeasts were evaluated in the laboratory and in field cages. The most effective yeasts were compared with commercially available protein baits for their attraction to B. dorsalis. Fruit fly suppression trials targeted at B. dorsalis on mango were also undertaken using a formulated protein bait product and are reported in this chapter.

2 Protein Bait Production from Waste Brewer’s Yeast

Waste yeast was obtained from three breweries: Kenya Breweries Limited, Tanzania Breweries Limited and Uganda Breweries Limited. The solid content of the start-up materials ranged from 11 to 16 %, the alcohol content from 5.8 to 6.2 % and the pH from 5.2 to 6.1. Production methodology followed the procedure of Lloyd and Drew (1997) with slight modifications. Briefly, yeast slurry was boiled using aluminum pots in a water bath set at 120 °C with intermittent manual stirring to minimize burning and to remove as much of the alcohol as possible. Boiling continued until the material had reached 40 % solid state. The concentrated yeasts were then digested with 0.4 % papain for 24 h in a water bath held at 70 °C. Following digestion, 0.4 % methyl p-hydrozybenzoate (Nipagin) was added as a preservative and the baits were evaluated directly for attractiveness to fruit flies, feeding response of fruit flies and field suppression, without further formulation.

3 Attraction and Feeding Responses of Bactrocera dorsalis to Commercial Protein Baits Compared with Protein Baits Made from Waste Brewer’s Yeast: Field Cage Studies

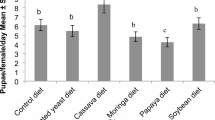

A field cage trial were done at icipe’s Thomas Odhiambo Centre, Mbita, Kenya, which is located on the shores of Lake Victoria. Four field cages (5 m tall and 5 m dia.) made of nylon screen were set up under a shaded tree and experimental procedures were similar to that described by Vargas et al. (2002; Vargas and Prokopy 2006), one for each WBY bait (Kenyan, Ugandan and Tanzanian) and one for the water control. Briefly, 2–4 potted mango trees were placed in each cage to provide roosting sites and a shady canopy for the insects. To ensure insects were not attracted to bait because they were thirsty, the cages and trees were sprayed with water before initiation of the trials. After 30 min, 250 males and 250 females were released in to each cage. Test bait substances (20 droplets, ca 10 μl) were applied to mango leaf strips cut to fit into Petri dishes and covered with a screened lid. The dishes with the bait (or water in the control) were hung randomly around the perimeter of the tree canopy. Every 5 min, an observer walked around the canopy and recorded the number of male and female flies that had landed on the top of the screened Petri dishes. Both sexes of B. dorsalis were attracted to the different food baits although significantly more females were attracted than males (Fig. 14.1). Amongst the protein baits from the different waste yeast sources, the Kenyan and Ugandan WBY attracted more females compared with the Tanzanian WBY (Fig. 14.1). The lowest fly counts were observed in the water control. In a subsequent similar trials comparing the WBY baits from Kenya and Uganda with commercial food attractants our results showed that both the WBY baits were as effective at attracting female B. dorsalis as corn steep liquor, GF-120, Mazoferm and Buminal (Fig. 14.2). However, B. dorsalis females responded more to NuLure and Torula yeast than either the WBY baits from Kenya and Uganda. Overall, the WBY baits were as good as the commercially available protein baits tested in our studies. In a laboratory experiment, Lloyd and Drew (1997) showed that the relative attractiveness of WBY baits to the Queensland fruit fly, Bactrocera tryoni (Froggatt), ranged from ~0.6–0.9 compared with Mauri’s bait, the commercial standard. The relative attractiveness of different dilutions of WBY baits (available commercially as Tongalure®) to Bactrocera facialis (Coquillett) were also high (0.66–1.97) at dilutions ranging from 1:5–1:50. Vargas et al. (2002) reported that the type of protein used influenced the attraction of the Mediterranean fruit fly (medfly), Ceratitis capitata (Wiedemann), to baits. The authors showed that C. capitata responded more to Provesta protein than the standard NuLure. Similar observations have also been reported for the melon fly, Zeugodacus cucurbitae (Coquillett) (= B. cucurbitae), and B. dorsalis (Vargas and Prokopy 2006).

Attraction and feeding response of Bactrocera dorsalis to protein baits made from waste brewer’s yeast (WBY) in comparison with commercially available food attractants. For each parameter and sex, bars and lines bearing the same letter do not differ significantly from each other using Tukey’s (HSD) test. Bars denote SE

Feeding assays were done using only female B. dorsalis. Mango leaf disks (5 cm × 5 cm) were placed in glass Petri dishes and treated with one drop of bait placed at the middle of the leaf. Each leaf disk was then transferred to a Perspex cage (30 cm × 30 cm × 30 cm). Female B. dorsalis (14 d old) were released individually on to the leaf surface and observed; the experiment ended after 600 s if the insect remained on the leaf all the time, or when the insect flew away or crawled off from the leaf disk. The time spent feeding was recorded and the total feeding time calculated. Results showed that the total feeding time varied significantly depending on the bait (Fig. 14.1). Female B. dorsalis fed for longer on the Kenyan and Ugandan WBY baits compared with the Tanzanian WBY bait. Female B. dorsalis spent the shortest time feeding in the water control. When we compared our WBY baits with commercial food attractants, feeding time was longest on NuLure and Kenyan WBY compared with the Ugandan WBY and other commercial baits (Fig. 14.2). Feeding times were similar on Corn steep liquor, GF-120, Torula yeast, Mazoferm and Ugandan WBY (Fig. 14.2). The shortest feeding times were observed for HymLure and Solbait. Clearly, the type of protein in the bait also influences feeding and food attractants must be examined in the context of both attraction and feeding response (Vargas et al. 2002; Vargas and Prokopy 2006).

4 Attraction of Bactrocera dorsalis to Commercial Protein Baits Compared with Protein Baits made from Waste Brewer’s Yeast: Open Field Studies

Larger scale protein bait evaluations were done at Nguruman, Kenya in an orchard that had a mixture of different mango varieties (Boribo, Tommy Atkins, Kent, Apple and Ngowe). Seven protein baits were evaluated between October 8, 2012 and November 28, 2012: (1) Protein bait from Kenyan WBY at a rate of 9 %, (2) Protein bait from Ugandan WBY at a rate of 9 %, (3) Torula yeast (ISCA Technologies, Riverside, CA, USA) at the rate of three pellets (4.78 g/pellet) per 1000 ml of water, (4) GF-120® (Dow AgroSciences, Indianapolis, IN, USA) at the on-the-label rate of 18.2 %, (5) Hymlure® (Savoury Food Industries Ltd, Johannesburg, South Africa) at the on-the-label rate of 4 %, (6) Biolure®, a three-component synthetic lure containing ammonium acetate, trimethylamine and putrescine (Suttera LLC, Bend, OR, USA) as a wet trap also containing 0.01 % Triton X-100 and (7) Nulure® (Miller Chemical & Fertilizer Corporation, Hanover, PA, USA) at a rate of 9 %. Each bait was placed in a Multi-lure trap® (Better World Manufacturing, Fresno, CA, USA) for evaluation. In all the traps, 3 % borax was added to preserve trapped flies. Traps were placed on randomly selected trees of the various cultivars in the orchard and their position within each block was rotated sequentially every week, at the time they were checked for the presence of B. dorsalis. Apart from Biolure®, all baits were replaced weekly at the time of trap checking. Biolure® was replaced every 4 weeks. At each weekly check, flies were removed from the trap and the number and sex of B. dorsalis captured was recorded and a daily catch rate estimated. Results showed that the total number of B. dorsalis captured was greatest in traps baited with Torula yeast (132.4 flies/trap/day [FTD]) followed by the Kenyan WBY bait (112.1 FTD) and the Ugandan WBY bait (109.8 FTD) (Fig. 14.3). Fly catches in the standard NuLure-baited traps were 56.8 FTD. The percentage of female catches in all the food attractants ranged from 50.4 % in HymLure-baited traps to 72.1 % in NuLure-baited traps. Although Torula yeast was the best attractant, the use of this food bait in fruit fly management has been restricted to detection and monitoring, largely because its high pH may lead to phytotoxicity problems when applied directly to plants as part of field suppression strategies. Sookar et al. (2006) evaluated the catches of the peach fruit fly, Bactrocera zonata (Saunders), the Natal fruit fly, Ceratitis rosa Karsch and C. capitata using various combinations of Biolure (ammonium acetate [AA], putrescine [PT] and trimethylalamine [TMA]) and WBY and reported that traps baited with AA + PT + TMA with water/Triton as a retention device in multilure traps and the WBY treatment captured significantly more female flies compared with other treatments and that females accounted for more than 75 % of the catches. In Nigeria, Umeh and Garcia (2008) compared the performance of WBY with commercial protein hydrolyate for monitoring Ceratitis spp. on citrus and reported that average catches of fruit flies ranged from 8.3 to 10.4 flies/trap in WBY-baited traps compared with 6.2–12.2 flies/trap in protein hydrolysate-baited traps. Our observations in Kenya are in agreement with the previous studies and suggest that the two protein sources from Kenyan and Ugandan WBY offer excellent option for fruit fly monitoring and management in Africa.

5 Field Suppression of Bactrocera dorsalis Using Protein Baits Developed from Kenyan Waste Brewer’s Yeast

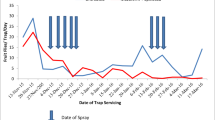

Suppression trials were done in Meru county, Kenya (Fig. 14.4) between December 7, 2013 and April 4, 2014. Four sub-Counties in the major mango production areas of the County were selected as study sites and a census of mango growers in the sub-Counties was made with the assistance of County agricultural extension workers and an agribusiness NGO promoter (TechnoServe). Three of the four sub-Counties (Central Imenti, North Imenti and South Imenti) were assigned as fruit fly management areas and the remaining sub-County (Tigania West) served as a control area; this division was largely based on the farmers’ methods of fruit fly management at the time which ranged from smoking the trees to drive away fruit flies to broad-spectrum cover sprays of different pesticides.

Seven treatments with varying combinations of tools from the fruit fly management package were applied to a total of 1071 mango orchards (153 farms per treatment) and the control treatment was assigned to 152 farms totaling 1223 farms used in total. The treatments included: [1] releases of two parasitoids Fopius arisanus (Sonan) and Diachasmimorpha longicaudata (Ashmead) (P), orchard sanitation (OS) and male annihilation technique (MAT); [2] P, OS and application of the Kenyan WBY bait laced with spinosad (= DuduLure®) (FB); [3] P, OS and soil application of a biopesticide based on Metarhizium anisopliae (Metchnikoff) Sorokin (= Met 69®) (BIOP); [4] P, OS, MAT and FB; [5] P, OS, FB and BIOP; (6) P, OS, MAT and BIOP; (7) P, OS, MAT, FB and BIOP; and [8] control. The socio-economic impact of these interventions have been recently reported by Muriithi et al. (2016) and details of how each treatment was applied can be found in this publication.

A sub-set of 40 orchards (five farms per treatment) were randomly selected from the 1223 farms (eight treatments) for monitoring of fruit fly populations. Also at harvest 50 fruits were sampled from each orchard at colour break and transported to the laboratory. Fruit samples from each treatment were incubated separately in plastic containers with sterile sand to facilitate pupation. The number of infested fruits, pupae recovered and adult emergence per treatment were recorded. The bulk of the insects that emerged from infested mango fruits were B. dorsalis, perhaps not surprising given that the native Ceratitis species have been displaced (Ekesi et al. 2009). After 8–12 weeks of treatment (depending on the mango variety), results showed that average post-treatment catches of B. dorsalis ranged from 84.9 flies/trap/week in orchards where FB had been applied in combination with P, OS, MAT and BIOP to 337.3 flies/trap/week in orchards assigned to P, OS and MAT (Fig. 14.5). The highest fruit fly catches (796.1 flies/trap/week) was observed in the control orchards. In locations where the fruit fly IPM toolbox was implemented, mango fruit infestation by fruit flies ranged from 7 % in the treatment using all the tools in the package (P, OS, MAT, BIOP and FB) to 30 % in orchards assigned to P, OS and BIOP (Fig. 14.6). Fruit infestation by fruit flies in treatments incorporating FB did not exceed 23 %. In the control orchards, mango fruit damage reached 66 % (Fig. 14.6). In Tonga, weekly treatment of chilli with protein baits developed from WBY reduced fruit damage due to B. facialis from 90 to 7 % while damage in untreated control plots increased from 27 to 100 % (Heimoana et al. 1997). Following the success story in the Pacific Islands, locally produced neutralized WBY was used as a source of protein bait for the eradication of B. dorsalis in Mauritius (Seewooruthun et al. 1998). Although good results were obtained with the bait based on the success of the eradication campaign (Seewooruthun et al. 2000), the neutralized WBY was observed to clog and damage the nozzles of knapsack sprayers and the product was also phytotoxic to young leaves of pawpaw and cucurbits. Sookar et al. (2002) modified the WBY product by digesting the yeast slurry with papain (0.8 %), raw pawpaw or pineapple juice (4 % v/v) and tested the new products for the control of Z. cucurbitae on ridged gourd, Luffa acutangulata (L.) Roxb. After 12 weeks of bait application, fruit infestation by Z. cucurbitae was reported to be 1 % in treatment using WBY autolysed with papain, 2 % in the treatment using WBY autolysed with pawpaw, 6 % in treatment using WBY autolysed with pineapple, 7 % in the boiled/unautolysed treatment, 2 % in the standard protein hydrolysate treatment and 100 % infestation in the untreated control plots. No bait exhibited phytotoxicity effects on the plants. In Tanzania, Mwatawala et al. (2015) formulated WBY in molasses, water and an extract of Derris elliptica Benth. (insecticidal plant) and reported that mango fruit infestation in orchards treated with the WBY ranged from 0.004 to 1.7 % compared with 0.58–2.52 % in orchards treated with Success® bait spray and 0.4–2.03 in the treatment receiving a cover spray of dimethoate/Karate. Generally, the results obtained from the suppression trials in Kenya are in agreement with other studies and demonstrate that protein baits from WBY offer cheap readily available alternatives to expensive imported protein hydrolysate for the management of fruit flies in Africa.

6 Conclusions and Recommendations for Future Research

Organic waste that originates from the brewing process including excess yeast, spent hops and grains have been the subject of various investigations for their potential use as industrial byproducts. Because WBY is a rich source of protein, carbohydrates, vitamins and minerals, and since these nutrient are essential for the development of fruit flies, it is being widely exploited as a source of protein for use as baits in the management of fruit flies. In most Sub-Saharan African (SSA) countries, the majority of the protein baits used for fruit fly management have to be imported from Europe or North America at a very high price. The cost of the imported protein baits also limits their use, especially for smallholder growers. The ability of various African countries to produce bait from locally available raw materials such as WBY could make a difference in reducing the cost and enhancing the sustainability of fruit fly monitoring and management programmes. Although inconsistent and inadequate performance of brewery wastes has been cited as one of the drawbacks of using WBY in fruit fly suppression, the results presented here show that the use of protein baits made from WBY holds great promise in ameliorating fruit fly problems in Africa. The technology, adapted from Australia (Lloyd and Drew 1997), is gradually gaining importance as a real-time solution to the cost of baiting techniques for fruit fly suppression. Based on this knowledge, the government of Mauritius has recently funded the establishment of a 1000 l capacity facility in Réduit (Fig. 14.7.) providing affordable protein baits based on WBY to over 15,000 fruit and vegetable growers across the country. Under the icipe-led project on ‘Establishment of a Pilot Commercial Processing Plant for Food Bait Production for the Management of Fruit Flies in Kenya’ funded by GIZ/BMZ, a similar bait production plant is being established in Kenya in collaboration with Kenya Biologic Ltd (http://www.worldagroforestry.org/itaacc/projects/food-bait). Currently, bulk waste yeast materials from various lager beers have been used by researchers for the production of protein bait. However, it is unknown how the raw materials, yeast types and various other substrates that are combined in the brewing process influence the quality of the proteins that are autolyzed for fruit fly management and these are potential areas of research that require attention. Research should also focus on appropriate formulation of the baits, addressing shelf life and training of entrepreneurs that are willing to take up business ventures in the production of food baits for fruit fly management on the African continent.

References

Chinajariyawong A, Kritsaneepaiboon S, Drew RAI (2003) Efficacy of protein bait sprays in controlling fruit flies (Diptera: Tephritidae) infesting angled luffa and bitter gourd in Thailand. Raffles Bull Zool 51:7–15

Ekesi S, Billah MK, Nderitu PW, Lux SA, Rwomushana I (2009) Evidence for competitive displacement of the mango fruit fly, Ceratitis cosyra by the invasive fruit fly, Bactrocera invadens (Diptera: Tephritidae) on mango and mechanisms contributing to the displacement. J Econ Entomol 102:981–991

Ferreira I, Pinho O, Viera E, Tavarela J (2010) Brewer’s Saccharomyces yeast biomass: characteristics and potential applications. Trends Food Sci Technol 21:77–84

Fillaudeau L, Blanpain-Avet P, Daugin G (2006) Water, wastewater, and waste management in brewing industries. J Clean Prod 14:463–471

Grieve DG (1979) Feed intake and growth of cattle fed liquid brewer’s yeast. Can J Anim Sci 59:89–94

Heimoana V, Nemeye P, Drew RAI (1997) Assessment of protein bait sprays for the control of fruit flies in chilli and capsicum crops in Tonga. In: Allood AJ, Drew RAI (eds) Management of fruit flies in the Pacific. Nadi, Fuji. 28–31 October 1996. ACIAR Proceedings No.76, pp 179–182

Henry WA (1990) Dried distillery grains compared with oats. Feeds and feeding, 2nd edn. Morrison Publishing Co., Ithaca, 421 pp

Hernandez-Pinerua JR, Lewis MJ (1975) Disposal of excess brewer’s yeast by recycling to the brewerhouse. J Inst Brew 81:476–483

Lloyd A, Drew RAI (1997) Modification and testing of brewery waste yeast as a protein source for fruit fly bait. In: Allwood AJ, Drew RAI (eds) Fruit fly management in the Pacific. ACIAR Proceedings No. 76, pp 192–198

Menezes AGT, Menenzes EGT, Alves JGLF, Rodrigues LF, Cardoso M (2016) Vodka production from potato (Solanum tuberosum L.) using three Saccharomyces cerevisiae isolates. J Inst Brew 122:76–83

Mirzaei-Aghsaghal A, Maheri-Sis N (2008) Nutritive value of some agro-industrial by-products for ruminants. World J Zool 3:40–46

Muriithi B, Affognon HD, Diiro GM, Kingori SW, Tanga CM, Nderitu PW, Mohamed SA, Ekesi S (2016) Impact assessment of Integrated Pest Management (IPM) strategy for suppression of mango-infesting fruit flies in Kenya. Crop Prot 81:20–29

Mwatawala MW, Mziray H, Malebo H, De Meyer M (2015) Guiding farmers’ choice for an integrated pest management program against the invasive Bactrocera dorsalis Hendel (Diptera: Tephritidae) in mango orchards in Tanzania. Crop Prot 76:103–107

Peel R (1999) Ecological sustainability in the brewing industry. J Inst Brew 105:14–22

Seewooruthun SI, Sookar P, Permalloo S, Joomaye A, Alleck A, Gungah B, Soonnoo AR (1998) An attempt at the eradication of the oriental fruit fly, Bactrocera dorsalis (Hendel) from Mauritius. In: Lalouette JA, Bachraz DY, Sukurdeep N, Seebaluck BD (eds) Proceedings of the 2nd annual meeting of agricultural scientists. Food and Agricultural Research Council, Réduit Mauritius, pp 135–144

Seewooruthun SI, Permalloo S, Sookar P, Soonnoo AR (2000) The oriental fruit fly, Bactrocera dorsalis eradicated from Mauritius. In: Price NS, Seewooruthun I (eds) Proceedings of the Indian Ocean Commission, Regional fruit fly symposium, Flic en Flac, Mauritius, 5th–9th June 2000. Quatre Bornes. Indian Ocean Commission, pp 207–210

Sookar P, Facknath S, Permalloo S, Seewoorothum SI (2002) Evaluation of modified waste brewer’s yeast as a protein source for the control of the melon fly, Bactrocera cucurbitae (Coquillet). In: Barnes BN (ed) Proceedings of 6th international fruit fly symposium, 6–10 May 2002, Stellenbosch, South Africa, pp 295–299

Sookar P, Permalloo S, Alleck M, Seewooruthun SI (2006) Development of improved attractants and their integration into fruit fly management programmes. Fruit flies of economic importance: from basic to applied knowledge, pp 71–79. In: Proceedings of the 7th international symposium on fruit flies of economic importance. 10–15 September 2006, Salvador, Brazil

Tripathi M, Karim S (2011) Effect of yeast cultures supplementation on live weight change, rumen fermentation, ciliate protozoa population, microbial hydrolytic enzymes status and slaughtering performance of growing lamb. Livest Sci 135:17–25

Umeh VC, Garcia LE (2008) Monitoring and managing Ceratitis spp. complex of sweet orange varieties using locally made protein bait of brewery waste. Fruits 63:209–217

Vargas RI, Miller NW, Prokopy RJ (2002) Attraction and feeding responses of Mediterranean fruit fly and a natural enemy to protein laced with novel toxinx, Phloxine B and spinosad. Entomol Exp Appl 102:273–282

Vargas RI, Prokopy R (2006) Attraction and feeding responses of melon flies and oriental fruit flies (Diptera: Tephritidae) to various protein baits with and without toxicants. Proc Hawaiian Entomol Soc 38:49–60

Acknowledgements

The German Federal Ministry for Economic Cooperation and Development (BMZ) provided funding for research on the Mango IPM and Fruit Fly Food Bait projects at icipe. We thank the mango growers at Nguruman and Meru, Kenya for providing the experimental orchards for all the trials. We also greatly appreciate the efforts by Mr P. Agola and Mr E.F. Mlato for bait production, data collection and processing.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer International Publishing Switzerland

About this chapter

Cite this chapter

Ekesi, S., Tanga, C.M. (2016). Waste Brewer’s Yeast as an Alternative Source of Protein for Use as a Bait in the Management of Tephritid Fruit Flies. In: Ekesi, S., Mohamed, S., De Meyer, M. (eds) Fruit Fly Research and Development in Africa - Towards a Sustainable Management Strategy to Improve Horticulture. Springer, Cham. https://doi.org/10.1007/978-3-319-43226-7_14

Download citation

DOI: https://doi.org/10.1007/978-3-319-43226-7_14

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-43224-3

Online ISBN: 978-3-319-43226-7

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)