Abstract

The classification of various faults using a fault simulator and support vector machines (SVMs) has been studied. A database is created for number of faults by measuring vibration signals using seven accelerometers mounted on a machinery fault simulator (MFS). Statistical features are extracted in time domain from the vibration signals. Then, the sensitive features are selected using compensation distance evaluation technique. Multi-class SVMs ensemble algorithm is implemented for classification of the various faults by considering SVMs created by the possible combinations of sensitive features for each class of the fault. The effect of distance evaluation criterion for selection of sensitive features amongst the extracted twelve statistical features has been addressed. By using the developed algorithm, the effective location of accelerometer among seven accelerometers for better classification of the faults has been investigated. Measurements are done at five different rotational speeds. The robustness of the developed algorithm has been tested at different speeds.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Several studies have been carried out for fault detection using Motor current signature analysis (MCSA), vibration and acoustics signal. Now-a-days, soft computing based methods are increasingly being used for fault detection and prediction. Artificial neural networks (ANNs) have been utilized to detect faults in machinery in recent years and also statistical methods to preprocess the vibrating signal as input features. Support vector machine (SVM) is a machine learning method, which employs a small sample based on statistical learning theory and principle of risk minimization. Compared to the ANN, the SVMs are relatively new and their utility in condition monitoring remains unexplored [1]. Based on the idea of performing an excellent and easy maintenance program for machine fault diagnosis, AI systems such as artificial neural network, fuzzy experts system, and condition based reasoning were utilized in several studies but the application of support vector machines is still rare. Use of the SVMs in condition monitoring and fault diagnosis is tending to develop in future [2]. In order to compare these two methods, in an earlier study, time domain vibration signal of a rotating machine with normal and defective bearing were utilized for featured extraction to measure the fault detection [3]. It was noted that the time required to train the SVM was promisingly less than ANN [4]. The SVMs give better classification and high accuracy for detection of healthy and faulty conditions and the classification can be used for other rotating machineries [5]. Genetic algorithm was implemented with the ANN for identifying the required number of good features for more complex systems where some faults cannot be easily distinguished [6]. A novel fault diagnosis method for induction motor was proposed which is based on the classification of independent component analysis and multi-class SVM. Current and vibration data are considered in form of time domain features (mean, rms, shape factor, skewness, kurtosis, crest factor, entropy error, entropy estimation, histogram lower and upper) and frequency domain features [7]. Researchers have reported newer features of SVM that can be used for fault detection and fault classification; and showed their effectiveness compared to the traditional methods [8–10].

So here, in this study fault classification for five speeds in a wide speed range of 1,140–2,580 RPM is presented. Here the classification has been done considering the time domain data only, thus making it easy, to implement for on-line fault classification where a transformation to the frequency domain is not required. Based on the selected features, a multi-class SVMs algorithm has been used and then experimentally validated to classify the fault conditions of bearing and rotor unbalance.

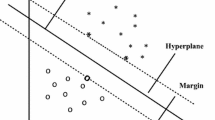

2 Multiclass SVMs

In spite of the fact that SVMs are binary classifiers, multi-classification using one-against-all approach is implemented to classify the fault conditions mentioned in Table 2. In one-against-all approach [11], the N-SVM models are created where N is the number of conditions. For ith SVM, the model is trained by considering all the sample data for the ith condition as positive and the remaining condition’s sample data as negative. Number of samples considered for classification in this approach are calculated as N × M where M is the number of the bins (each bin contains 4,096 samples) for each condition and N is the total number of conditions.

Here, the training data for N conditions is given by \( \left\{ {\left( {\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle\thicksim}$}}{x}_{~1} ,y_{1} } \right),\left( {\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle\thicksim}$}}{x}_{~2} ,y_{2} } \right), \ldots, \left( {\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle\thicksim}$}}{x}_{~N} ,y_{N} } \right)} \right\}, \) where \( \underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle\thicksim}$}}{x}_{~i} \in R^{m} ,i = 1,2, \ldots N \) and \( y_{i} \in \left\{ {1,2, \ldots ,N} \right\} \), the ith SVM model solves the following optimization problem

where C is the penalty term and data \( {\mathbf{x}}_{i} \) is mapped into higher dimensional space using the function \( \phi \). The term \( 1/2\left\| {{\mathbf{w}}^{i} } \right\|^{2} \) minimizes the margin between two conditions and the penalty term \( C\sum\nolimits_{j = 1}^{N} {\xi_{j,j} } \) reduces the training errors when the data is non-separable. The function \( \text{sign} \left( {\left( {{\mathbf{w}}^{i} } \right)^{T} \phi \left( {x_{j} } \right) + b^{i} } \right) \) decides whether \( {\mathbf{x}}_{i} \) is to be in the ith class or not. To select the condition of data \( {\mathbf{x}}_{i} \), here the “Max Wins” strategy is used. This strategy predicts the condition of data \( {\mathbf{x}}_{i} \) on the based largest vote [6].

In the present study, MATLAB SVM solver has been used for binary classification. The effectiveness of 2-norm soft margin SVM classification technique based on quadratic programming [QP] and least square based SVM [LS] has been investigated. Gaussian radial basis function (RBF) is considered as a kernel function to transfer the input data space to higher dimensional feature space.

The RBF kernel functions are very popular and are regarded as the best kernel functions for classifications. Insight regarding the RBF functions can be found elsewhere [12]. There are two parameters which are associated with these kernel function; C and \( \sigma \). The upper bound parameter, C for penalty term and the kernel parameter, σ play important role in classification performance of SVMs. Improper selection of these parameters leads to under fitting and over fitting problems. The objective of cross-validation is to identify the optimum values of C and σ for which the SVM classifier is able to classify with the highest classification rate. In v-fold cross validation, the training set is divided into v subsets where v – 1 subsets are used to train the classifier and the remaining subsets are used for testing. This process is repeated for v times by considering that each of the subset is being used to test the classifier once. The cross validation accuracy is defined as the percentage of data correctly classified amongst the entire training data.

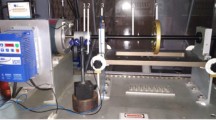

3 Experimental Setup

Experiments were conducted on the machine fault simulator (MFS) as shown in Fig. 1a. The transducers and their corresponding mount locations are represented in Fig. 1b. Vibrations of the drive end (DE) bearing and non-drive end bearing (NDE) were measured in three directions (x, y, z) with B&K 4,370 accelerometers and B&K 4,526 accelerometer was mounted on top of the motor to measure vibration in the vertical direction. Thus a total of seven channels of vibration data were acquired. All seven channels of data from the respective transducers were acquired and recorded simultaneously using B&K Pulse Time Data Recorder at 4,096 samples/s and a span of 1.6 kHz for duration of 5 min [13, 14].

4 Results and Discussions

In this paper, for combined fault condition classification having both bearing and unbalance defects, a total of 8 conditions (4 bearing, 3 unbalance and 1 normal) have been considered. In the first part of the parameter selection, a preliminary analysis has been carried out using the measured vibration signals. Further, feature extraction, feature selection and fault classification using multi-class SVMs has been discussed. Also, the effect of several parameters related to fault classification has been investigated in order to appropriately select them for the SVM process.

4.1 Preliminary Analysis

Each data set has been divided into 50 bins for a total time of 1 s per bin consisting of 4,096 sampled data points. The vibration signals of a bin for all bearing and unbalance defect conditions in the rotor rig measured by the 1st transducer at 1,740 RPM are shown in Fig. 2. It is difficult to study these time signals for fault classification because of its high dimensionality. The dimensionality of these data has been reduced by extracting the twelve time domain features. So in all for 7 transducers there were a total of 84 features. The features are in group of seven as per the sequence given in the first column of Table 1. For example feature number 48 is [6 × 7] + 6 corresponding to the RMS of the signal and so on. One set of such time domain features for all conditions, for an operating speed of 1,740 RPM of the rotor-bearing rig for the vibration signal measured by 1st transducer is shown in Table 1. The normalized time features for all the conditions as measured by the vibration transducer at location 1 while operating at 1,740 RPM are shown in Fig. 3. It can be observed from Fig. 3 that the time domain features are significantly affected by the fault conditions. It is also difficult to classify the faults based on these features alone, since there is no noticeable pattern or effect of the defects on these features. Additionally, some of these features consist of irrelevant and redundant features. The feature selection using compensation distance evaluation technique has thus been used and distance evaluation criterion has been shown for bearing and unbalance cases in Fig. 4. The feature which has the distance evaluation criterion value as 1 is considered as the most sensitive parameter for the classification of faults. From Fig. 4, it is seen that the 11th time feature (crest factor) is the most sensitive feature for bearing defect case and 10th feature (skewness) is the most sensitive feature for unbalance based on the vibration signal measured by 1st transducer at 1,740 RPM. Distribution of the most two sensitive parameters have been shown for all conditions of bearing and unbalance defects in Fig. 5. A similar analysis was done for all the other transducers and operating speeds.

Radial basis function is considered as the kernel function for SVMs classifier. Firstly; preliminary analysis for fault classification using multi-class SVMs has been carried out to choose appropriate SVMs parameters for better fault classification. During this analysis, effect of grid search for C and σ; the type of SVM solver; effect fivefold and 10-fold cross validation; repeatability and effect of distance evaluation criterion, ψ have been carried out.

4.2 Fault Classification of Combined Defects

To test the robustness of the fault classification algorithm, after the individual classifications for bearing and unbalance defects were done separately, then the data set for all the 8 conditions were considered together for classification by SVM. Table 2 summarizes the classification results for the combined defects at all speeds. The most two sensitive features for each of the operating speed are selected based on the CDET criterion [15] as is shown in Fig. 4. A high classification rate is obtained in all the cases.

For a typical case, the most two sensitive feature distribution at 2,580 RPM for all the conditions is shown in Fig. 6. This is further validated by the fact that 100 % classification is obtained at 2,580 RPM as shown in Table 2.

5 Conclusion

In this paper a methodology for fault classification of bearings and unbalance in a machine fault simulator has been developed. The classification technique was based on the compensation distance evaluation technique for feature selection. Support vector machines with a grid search approach were used to optimize the hyper-parameters for the fault classification process. The standard deviation of the classification rate is less than 1.5 % for all the cases. This methodology can be implemented for on-line condition monitoring of rotating machines.

References

Jack LB, Nandi AK (2002) Fault detection using support vector machines and artificial neural networks, augmented by genetic algorithms. Mech Syst Signal Process 16(2–3):373–390

Widodo A, Yang B (2007) Support vector machine in machine condition monitoring and fault diagnosis. Mech Syst Signal Process 21:2560–2574

Samanta B, Al-Balushi KR, Al-Araimi SA (2003) Artificial neural network and support vector machines with genetic algorithms for bearing fault detection. Eng Appl Artif Intell 16:657–665

Samanta B (2004) Gear fault detection using artificial neural networks and support vector machines with genetic algorithms. Mech Syst Signal Process 18:625–644

Yang B, Hwang W, Kim D, Tan AC (2005) Condition classification of small reciprocating compressor for refrigerators using artificial neural networks and support vector machines. Mech Syst Signal Process 19:371–390

Saxena A, Saad A (2007) Evolving an artificial neural network classifier for condition monitoring of rotating mechanical systems. Appl Soft Comput 7:441–454

Widodo A, Yang B, Han T (2007) Combination of independent component analysis and support vector machines for intelligent faults diagnosis of induction motors. Experts Syst Appl 32:299–312

Sugumaran V, Sabareesh GR, Ramachandran KI (2008) Fault diagnosis of roller bearing using kernel based neighborhood score multi-class support vector machine. Experts Syst Appl 34:3090–3098

Widodo A, Yang BS (2007) Support vector machine in machine condition monitoring and fault diagnosis. Mech Syst Signal Process 21:2560–2574

Lei Y, He Z, Yanyang Z, Chen X (2008) New clustering algorithm based fault diagnosis using compensation distance evaluation technique. Mech Syst Signal Process 22(2):419–435

Bottou L, Cortes C, Denker JS, Drucker H, Guyon I, Jackel LD, Cun YL, Muller UA, Sackinger E, Simard P, Vapnik, V (1994) Comparison of classifier methods: a case study in handwritten digit recognition. In: Proceedings of the 12th International Conference on Pattern Recognition and Neural Networks, IEEE, Jerusalem pp 77–82

Vapnik VN (1995) The nature of statistical learning theory. Springer, New York

Fatima S, Mohanty AR, Naikan VNA (2013) Most effective transducer locations for permanent health monitoring of a rotating machine. In: Proceedings of the 20th International Congress on Sound and Vibration Bangkok, Thailand

Fatima S, Mohanty AR, Dastidar SG, Naikan VNA (2013) Technique for optical placement of transducers for fault detection in rotating machines. J Risk Reliab 227(2):119–131

Lei Y, He Z, Yanyang Z, Chen X (2008) New clustering algorithm-based fault diagnosis using compensation distance evaluation technique. Mech Syst Signal Process 22(2):419–435

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Fatima, S., Mohanty, A.R., Naikan, V.N.A. (2015). Multiple Fault Classification Using Support Vector Machine in a Machinery Fault Simulator. In: Sinha, J. (eds) Vibration Engineering and Technology of Machinery. Mechanisms and Machine Science, vol 23. Springer, Cham. https://doi.org/10.1007/978-3-319-09918-7_90

Download citation

DOI: https://doi.org/10.1007/978-3-319-09918-7_90

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-09917-0

Online ISBN: 978-3-319-09918-7

eBook Packages: EngineeringEngineering (R0)