Abstract

Transforming Foundation Industries Research and Innovation hub (TransFIRe) was developed in response to the UK Government Industrial Strategy Challenge Fund call to transform the Foundation Industries: Chemicals, Cement, Ceramics, Glass, Metals, and Paper. These industries produce 75% of all materials in the UK economy and are vital for the UK’s manufacturing and construction industries. Together, the Foundation Industries are worth £52 Bn to the UK economy and produce 28 Mt of materials per year, accounting for about 10% of the UK’s total CO2 emissions. TransFIRe is a consortium of 20 investigators from 12 institutions, more than 50 companies, and 14 NGO, and government organisations related to the sectors, with expertise across the FIs as well as material flows and energy mapping, life cycle sustainability, circular economy, industrial symbiosis, computer science, AI and digital manufacturing, management, social science, and technology transfer. This paper will introduce the Foundation Industries, present the three work streams through which transformative change will be enabled, and initial plans for including a diversity of stakeholders.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Background

A £166.5 million funding package transforming the Foundation Industries (FIs) was announced by the UK Government on the 24th May 2021 via UK Research and Innovation (UKRI) and will support development of technologies in carbon capture, greenhouse gas removal, and hydrogen, while also helping find solutions to decarbonise the UK’s polluting sectors including manufacturing, metals, energy, and waste. The FIs; Chemicals, Cement, Ceramics, Glass, Metals, and Paper produce 75% of all materials in the UK economy and are valued at £52 Bn p.a. However, they produce at least 10% of the UK CO2 emissions but are vital for the UK’s manufacturing and construction industries.

This investment will help put the UK at the forefront of the green technologies of the future, while supporting British industries to lower costs, remain competitive, and protect jobs as they improve their energy efficiency and transition to a green economy. The investment, awarded to innovators, businesses, academics, and heavy industry right across the UK, will accelerate the delivery of the critical game-changing technologies needed to further drive Britain’s climate change ambitions, with a projected 60,000 new jobs across the UK. This was linked to the publication of the UK Prime Minister’s Ten Point Plan for a Green Industrial Revolution in November 2020 [1].

UKRI has allocated £4.7 M with a further £4.7 M matched funding for a research and innovation hub for three years to work with universities, research organisations and industry, to assist with: technology development and transfer, new business developments, and new opportunities in materials and technologies to help achieve the Net Zero 2050 target. Transforming Foundation Industries Research and Innovation hub (TransFIRe) was developed in response to the UKRI call [1].

TransFIRe is a consortium of 20 researchers from 12 institutions, more than 50 companies, and 14 non-governmental organisations related to the sectors, with expertise across the Foundation Industries as well as material flow and energy mapping, life cycle sustainability, circular economy, industrial symbiosis, computer science, AI and digital manufacturing, management, social science and technology transfer. Led by Cranfield University, the consortium includes investigators from Bangor, Cambridge, Cardiff, Durham, Edinburgh, Exeter, Leeds, Northumbria, Sheffield Hallam, and York universities, and the British Geological Survey.

The research programme will develop a self-sustaining hub of expertise to support the Foundation Industries’ transformation into non-polluting, resource efficient modern competitive manufactories working in harmony with the communities in which they are situated, providing attractive places to be employed with unparalleled Equality, Diversity, and Inclusion (ED&I) performance.

The foundation materials industries are the root of all supply chains providing fundamental products into the industrial sector, often in a vertically-integrated fashion. They are all water, resource and energy-intensive, often requiring high temperature processing; they share processes such as grinding, heating, and cooling; they produce voluminous and often pernicious waste streams and heat; and they have low profit margins, making them vulnerable to foreign competition.

However, there is little transfer of knowledge horizontally; why would a paper mill researcher talk to a steel maker? There have been some traditional uses of waste materials/by-products as raw materials in other sectors, but little cross-fertilisation of technologies. In the nineteenth century, blast furnace slag was used in road building for kerbs, and more recently, Ground Granulated Blast Furnace Slag (GGBFS) has been used to improve concrete, originally by improving its resistance to sulphates and chlorides. More recently, still it is used as a low-carbon partial replacement for cement and as a value-added raw material in glass manufacture—whilst the paper industry pays the agricultural industry to spread its waste sludge on fields as a soil improver. But could this material be used as a raw material for other products with further processing? In the past, flaring of oil refinery gas was seen as part of the process. Now, it is avoided to reduce carbon emissions. How might this waste heat, from oil refineries or from cooling molten metals, glass, fired ceramics, or cement clinker, be put to good use in communities of businesses?

Partners

A list of co-investigators is given in Table 1. The Universities of Bangor, Cardiff, Exeter, Leeds, Northumbria, and Sheffield Hallam are key in the fundamental materials understanding of the specific FI sectors, and six of the PDRAs funded by the programme will have specific materials expertise. These PDRAs will spend extended periods of time on secondment at partner universities and companies, applying their expertise to support the site-based materials expert teams as they work on the analysis of a particular process unit operation. The PDRAs will also spend time working with their peers in the other sectors specifically working on cross-sector case studies. This will help maximise knowledge transfer between the industrial sectors, as well as being an efficient way of providing the multidisciplinary capability needed to ensure success in attaining project targets in each processing sector.

The other collaborating research institutions, Cranfield University, British Geological Survey, and the Universities of Cambridge, Durham, Edinburgh, Leeds, and York, will focus on the cross-sector challenges of circular economy, materials and energy mapping, AI and data, life cycle analysis, management and governance, and environment and social aspects. The remaining PDRAs will develop or have existing expertise in the supporting topics of the hub and will spend significant periods of time across both the hub universities and commercial partners, as appropriate. This approach will be comparable to the EU Marie Sklodowska-Curie academic mobility programmes. Each PDRA will be allocated a mentor from industry as well as a line manager from one of the university partners. Developing a cohort approach to the development of the PDRAs is key to the success of the hub and to the knowledge transfer to the FIs.

Research Plan

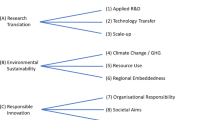

TransFIRe will focus on three major work streams (Fig. 1), the direction of which will remain flexible as projects and case studies start to produce results with the effort being targeted in the direction with the consortium Stakeholder Steering Group sees as bringing the best return for the government investment.

WS1: Transferring Best Practice—Applying “Gentani”

The Foundation Industries share many common processes (i.e. comminution, granulation, drying, cooling, heat exchange, and materials handling) and equipment (i.e. steam systems, furnaces, mechanical drives). Most of these are energy, material, and water intensive. Using the Gentani philosophy, “the minimum resource needed to carry out a process”, this research will explore best practice for common processes and equipment and identify the theoretical and practical limits for resource use (energy, materials, and water) and minimum environmental impacts (dust, emissions, and waste) across sectors. This unique approach will identify cross-sector opportunities for improving plant performance. The research will be underpinned by the mapping material streams along the UK Foundation Industry supply chains, including raw materials inputs, products, by-products, waste streams, and trade flows. The British Geological Survey Centre for Sustainable Mineral Development, which is the global leader in the compilation, provision, and analysis of mineral statistics, will provide spatial and statistical minerals information on the UK raw materials used by the FIs. This will be used to identify common cross-sector processes and equipment and explore resource efficiency options and environmental impact reduction. Evidence suggests that most industrial processes use energy at levels well beyond the theoretical minimum process energy requirements. For example, the production of steel from iron requires a minimum energy of 6.7 GJ/t, with an additional 1.2 GJ/t [2] for melting, yet average global energy use is 22.6 GJ/t [3]. Cement requires only 1.8 GJ/t but typically uses 4.6 GJ/t, while flat glass requires a minimum 3 GJ/t [4], which is well below the current energy use of 7 GJ/t. Studies exploring the reduction of energy are typically focused only in one sector and often overlook material efficiency strategies such as improving process yields, reducing waste material, and utilising by-products. The analysis in this work stream will take a different approach, exploring material and energy efficiency opportunities in processes and equipment which are common across Foundation Industries. This will facilitate knowledge transfer and allow the learning of best practice resource use and waste minimisation to be shared across the sectors. In the first year, WS1 will hold workshop sessions across the hub to identify modelling approaches (e.g. material flow analysis (MFA), value stream mapping (VSM), life cycle assessment (LCA), exergy analysis, agent-based modelling and discrete event simulation) and focuses (e.g. energy, material, reaction energy, phase changes, utilities, water use and emissions) used to analyse processes and equipment in the Foundation Industries. Technical Working Groups (TWGs) will be set up for each material, comprised of researchers with specific materials, energy and processing expertise, industry experts, and representatives from trade associations, policymakers and non-profits, to identify the hot spots of resource usage within each sector and to locate “Gentani” to drive improvements. Finally, the material streams for UK Foundation Industries will be mapped, from raw materials to final products and including trade flows.

WS2: Where There’s Muck There’s Brass—Creating New Materials and Process Opportunities [5]

Fundamental to the transformation of our FIs will be the development of new and novel materials and processes that enable cheaper, lower-energy, lower-carbon, and at the same or even exceeding quality products. For example, in the ceramic and glass fields, chemistries to enable lower processing temperatures and advanced materials for enhanced processing (e.g. new glass refining materials, ceramic sintering aids, and enhanced particle morphologies including consolidation, to provide improved heat transfer and longer furnace lifetimes, with lower-energy demand and CO2 emissions) will be investigated. Another example will be drawing together experience from the chemicals and paper sectors to share knowledge to develop biopolymer alternatives across both FIs exemplifying the use of sustainable sourcing and atom economical chemistries. Comparable research approaches to this, for each of the represented FIs, will be taken. The research will also investigate relationships between the new materials chemistries and their underlying physics (thermodynamics) via lab-based experiments to establish the practical viability of each approach by comparison versus benchmarks representing current best practice with consideration of new technologies in the context of industrial capability requirements. The use of hydrogen for thermally-driven processes across the Foundation Industries will also be explored, collaborating initially with research entities that have investigated hydrogen power in their sector (e.g. Project Partners Glass Futures and Pilkington-NSG for glass [6], the SUSTAIN Manufacturing Hub [7] for steel and the Low Carbon Hydrogen (HyPER) project led by Cranfield [8]) and transferring this knowledge across all FI sectors—working in partnership with these and other UK entities.

Wastes arising from the FIs and their associated supply chains, from mineral waste from primary extraction which is one of the largest UK waste flows (80 Mt pa), to back-end wastes generated by FI manufacturing operations and post-user wastes, represent a vast, and only partially-tapped UK resource. The challenges associated with finding applications for these wastes are the lack of data on their properties (physical, mineralogical and chemical), the absence of production statistics, inconsistent quality, and its occurrence in multiple locations, sometimes distant from the potential consuming FIs. Data on resource stocks and flows obtained in WS1 and WS2.1 will be combined with e.g. spatial information about waste sources and locations, mineral workings (active, inactive), availability, impacts, and supply constraints to identify opportunities minimisation and valorisation of these wastes. Much of the UK supply is vertically integrated and co-located with the FIs, for example, clay pits supplying brick works, limestone quarries supplying lime, glass, and cement factories providing a useful starting point. In WS2 through a combination of fundamental research and focussed technology development, the hub will directly address these needs. Raw material waste streams will be mapped and those that could potentially be used as raw materials for other sectors in the industrial landscape with little or no further processing (i.e. industrial symbiosis) will be identified. Streams will be identified where there is potential to add value by “upcycling” waste through further processes (e.g. by application of separation technologies), and multiple approaches from simple sizing to magnetic, wind sifting, and advanced separation technologies available through multiple project partners will be applied to new wastes and in new FI sectors to develop new materials, new potential applications/end-users and alternative by-products from innovative processing technologies with less environmental impact. This will require novel industrial symbioses and relationships, new processing technologies, sustainable and circular business models and governance arrangements. Our holistic approach (i) is essential for success and (ii) has never previously been undertaken from a UK Foundation Industry perspective before, emphasising the breadth, depth, and quality of our proposed research.

WS3: Working With Communities—Co-Development of New Business

FIs have great potential for community socio-economic benefit. Large volumes of warm air and water are produced across the sectors providing opportunities for low-grade energy capture. The 46 UK paper mills produce over 12 Mt of product per annum. Specific energy per tonne is 12.5 GJ, leading to the potential recoverable energy up to 150 PJ. For every tonne of metal melted, 1 GJ of energy is released when it cools to room temperature. In the UK, about 8 Mt of metal is melted p.a. [9, 10] giving about 8 PJ of energy into the atmosphere. A Volvo cast iron foundry in Skövde, Sweden, has developed a new process and innovative building in which excess heat from all processes is captured and used for office heating or shared with the local community. Energy is used from renewable electrical resources and is half that of equivalent factories across Europe: 2.1 GJ/t (590 kWh/t) compared to upwards of 3.6 GJ/t (1000 kWh/t) [11, 12]. There are also no carbon emissions. Potential synergies with waste hydrogen from future hydrogen-fuelled FIs will also be investigated, linking with work in WS2 and with other UK hydrogen studies.

In WS3, the focus will be on four key areas: (1) the promotion and dissemination of innovative co-development business practices, (2) community co-design approaches, (3) place-based new business opportunities, and (4) holistic impact-assessment metrics.

The research in (1) Business practices drives later activities as well as draws from them. At a transactional level, good practice is shared. At a research level, it is asked “how do we foster a culture of sharing and collaboration”, akin to how small breweries readily share knowledge, resources, and capital. We want to learn “how” to share as well as influence “who” shares. We want to know how EDI advance impacts this. We will work with regional agencies (e.g. Local Enterprise Partnerships (LEP)), initiatives (e.g. Circular Yorkshire [12]) and support organisations (e.g. Make UK [13]) for routes to wider business to investigate local opportunities. We will examine new ways to disseminate innovative practice across sectors and not only through firms and researchers, but through communities and employees’ organisations, leading to community-to-community learning.

For (2) Working with communities and companies, we will identify the potential for co-located businesses, social enterprises and community benefits in eight specific locales selected in the first 6 months. We ask “how does stakeholder co-design impact on value creation” by adapting co-design and co-investigation methods used in AHRC “connected communities” research, engaging communities in devising ideas and investigating proposals. Examples range from the use of waste heat (for community buildings and food production) to other resources (materials, water) to education (sharing STEM knowledge), noting the scope for positive ED&I community impacts.

Progressing from this, we engage in (3) Business opportunities by working across the FI sector, wider industry, and solution providers from concept to experimentation. We ask “How can ‘place’ foster value creation”. Using participatory mapping the potential co-located businesses, social enterprises and community benefits can be studied spatially, and considered from societal, environmental, gender-impact, technical, business, and governance perspectives. Place opportunities could include resources (e.g. waste heat and CO2 for horticulture and the move to biomass as a starting point for new industrial scale processing), valorising wastes (akin to AB Sugar fostering new resource exploitation partnerships) and knowledge (akin to Sony, Wales co-locating innovative businesses). We work beyond the incumbent supply chain to seek opportunities for new actors, apply value-creation tools, devise circular business models, and identify funding sources for prototypes and demonstrators. Demonstrators will also be online to promote concepts widely.

Finally, in (4) Impact assessment, we examine the range of impact-assessment tools currently available (including assessing equality, gender, wellbeing). Our focus is on “performance measurement and lifecycle theories”; we will validate metrics through engagement with community groups. We ask “which tools are best suited to provide a holistic set of metrics that capture social (including ED&I), environmental, technical, and economic performance” across the FIs; these metrics will allow us to devise and measure our responsible research and innovation (RRI) strategies.

Equality, Diversity, and Inclusion (ED&I)

Equality, Diversity, and Inclusion is at the heart of the hub and is critical in establishing and maintaining a good working environment within it. We have an award-winning, experienced lead in this area in Professor Sue Black at the University of Durham. Building ED&I experience and capability from the inside of the project, we will also work with external organisations that have key expertise in specific areas to supplement and deepen our knowledge of ED&I issues within Science, Technology, Engineering, and Maths in general and the Foundation Industries in particular. A number of the partner companies (e.g. Encirc360 [14]) already have proactive strategies for gender diversity in place from which we will take best practice and disseminate across the sectors.

It is now becoming increasingly apparent and widely accepted that ED&I are of paramount importance in the success of any organisation or project. The Foundation Industries in general are behind the curve in this respect. As part of this project, we will design and implement a cutting-edge ED&I plan with the aim not only of informing the participating organisations but also to inform best practice within UK Foundation Industries and beyond. We will review the current best practice, both within and without the Foundation Industries in the UK and overseas, using these findings to inform our strategy. As this project brings together highly skilled individuals from the many areas of expertise within the Foundation Industries, it provides a unique opportunity to formulate a comprehensive plan meeting the needs of all in the sector.

This project aims to make a distinct and tangible difference in the Foundation Industries and their perception from an ED&I perspective. Alongside working hard within the project as a whole to champion and support ED&I, our successes will be shared through social and traditional media. Highlighting key role models identified within the lifetime of the project with the aim of changing the public perception of the suitability of a career in the Foundation Industries for women, BAME, and all minority groups and people of diverse socio-economic backgrounds.

Stakeholder Engagement

Transformative change in the Foundation Industries requires the adoption of far-reaching changes in practices from a variety of stakeholders across the UK. Developing an effective strategy for stakeholder engagement and impact delivery, integrated with the research programme, is hence of vital importance. TransFIRe’s engagement and impact strategy will be based on participation process management, building on best practice in previously funded UKRI research programmes [15].

Stakeholders can be engaged at increasing participation levels from informing to listening, consulting, co-producing, co-deciding, and complete self-determination. There is an ethical motivation for stakeholder participation, given that transformative change will have a major impact on companies and their communities. Participation processes can offer stakeholders equal opportunity to contribute to the changes that will affect them. Moreover, higher participation levels have been associated with greater commitment to solutions, and they can also hold essential ingredients for change such as information, experience, access to facilities, contacts, finance, networks, and influence.

In a participation process, stakeholders can be brought together to explore, share, and negotiate perceptions with regard to, in the case of TransFIRe, the transformation of Foundation Industries. During this process, stakeholder views start to overlap, allowing for the identification of shared solution spaces within which transformative changes can take shape. Participation processes are geared towards increasing the quality, legitimacy, and speed of transformative change.

TransFIRe aims to engage the full stakeholder community involved in transforming the Foundation Industries in interdisciplinary research for solutions that can be rapidly deployed within these industries. The TransFIRe proposal was co-produced with stakeholders who signed up as project partners. After securing the funding, these project partners were involved in the development of a detailed engagement and impact strategy, while new stakeholders were also identified and invited to join TransFIRe. The following steps were taken to inform the strategy (based on [15, 16]):

-

Clarified the exact challenges that were to be solved, targets to be achieved, and for whom and why. This happened through the Technical Working Groups, ED&I Advisory Committee, Stakeholder Steering Group, International Advisory Committee, Foundation Industries Forum, and open events.

-

Evaluated resource availability. While initial funds and person-time were secured via UK Research and Innovation and project partner contributions, the required expertise and contacts evolved with the clarification of the challenges.

-

Analysed the context using the “PESTEL” approach covering the political-economic system, markets, societal trends (e.g. public narrative, community perceptions, others aiming for change), technological potential for change, environment (e.g. climate change, biodiversity), and legislation.

-

Revisited the stakeholder analysis and built up relations to get to know them and gain insights into their perspectives, motivations, interests, concerns, wishes, relations, and learning and innovation behaviour with the aim to understand how TransFIRe could help them.

-

Developed a tacit understanding of the “space for change” and where there might be areas of overlapping perceptions that could function as a springboard for change.

-

Developed a public identity that is being communicated consistently.

-

Involved the TransFIRe team in the coproduction of plans for engagement and impact, and identify how the team needs to be supported in the delivery of the stakeholder engagement and activities that are likely to make a real difference in practice.

Based on an initial understanding of stakeholder perceptions, a targeted programme for research and innovation was detailed using a Participatory Situational Analysis (PSA) [17]. PSA is a structured approach to bring a diverse group of stakeholders with widely differing and sometimes conflicting perspectives into a controlled environment to co-produce a shared vision for transformative change, identify drivers and barriers for realising the vision, identify stakeholders who are in control of making the most of drivers and/or helping to overcome barriers, agree upon potential actions for the stakeholders who are in control of unlocking transformative change, and identify any gaps in expertise that may constrain the actions from being taken.

During the delivery of the engagement and impact strategy and technical programme, stakeholders continue to be involved via the Technical Working Groups and the delivery of case studies, i.e. tranches of research projects, as well as the governance bodies of TransFIRe. Knowledge transfer is enhanced by secondments of researchers to project partners in industry, the co-mentoring of researchers by industry and academic advisors, and supporting the career progression of researchers into industry.

Progress towards delivery of the vision and objectives of TransFIRe is monitored and regularly evaluated based upon a set of Key Performance Indicators, and the Engagement and Impact Strategy and Technical Programme are adapted when needed.

The hub will act as a springboard for Early-Career Researchers (ECR). The key investigators have extensive track records of supporting ECRs into fellowships and permanent posts, and mentoring support will be given to help develop fellowship proposals that are consistent with our strategy. The alignment of the hub with the strategic plans of the parent universities and our project partners will ensure that our researchers are in prime place to apply for the posts in both academia and industry that are certain to emerge as the CE agenda gathers pace.

Summary

The Transforming Foundation Industries Research and Innovation hub was developed in response to the UK Government Industrial Strategy Challenge Fund call to transform the Foundation Industries: Chemicals, Cement, Ceramics, Glass, Metals, and Paper. TransFIRe is a consortium of 20 investigators from 12 institutions, 49 companies, and 14 NGO and government organisations related to the sectors, with expertise across the FIs as well as energy mapping, life cycle and sustainability, industrial symbiosis, computer science, AI and digital manufacturing, management, social science, and technology transfer.

Our vision is to build a proactive, multidisciplinary research, and practice driven research and innovation hub that optimises the flows of all resources within and between the FIs. The hub will work with communities where the industries are located to assist the UK in achieving its Net Zero 2050 targets and transform these industries into modern manufactories which are non-polluting, resource efficient and attractive places to be employed. TransFIRe will initially focus on three major challenges: (1) Transferring best practice—using the philosophy Gentani (minimum resource needed to carry out a process). (2) Creating new materials and process opportunities that enable cheaper, lower-energy and lower-carbon products. (3) Working with communities—co-development of new business and social enterprises. This research will highlight issues of equality, diversity and inclusiveness, investigating the potential from societal, environmental, technical, business, and governance perspectives.

At the end of the funding, we will expect to have created a “core” cross-sector team of researchers and industrial stakeholders, a body of fundamental research, and a set of governance and mechanisms enabling us to work together across the UK Foundation Industries for the next 15 to 20 years.

References

HMG (18 November 2020) The ten point plan for a green industrial revolution. https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/936567/10_POINT_PLAN_BOOKLET.pdf

Fruehan RJ, Fortini O, Paxton HW, Brindle R (2020) Theoretical minimum energies to produce steel for selected conditions. Carnegie Mellon University, Pittsburgh, PA

Hernandez AG, Paoli L, Cullen JM (2018) How resource-efficient is the global steel industry? Resour Conserv Recycl 133:132–145

Rue DM, Servaites J, Wolf W (2007) Inbdustrial glass bandwidth analysis. Gas Technology Institute, Des Plaines, IL

Lombardi RD, Laybourn P (2012) Redefining industrial symbiosis: crossing academic-practitioner boundaries. J Ind Ecol 16(1):28–37

Glass Futures (2021) https://www.glass-futures.org/. Accessed 6 September 2021

SUSTAIN (2021) Sustain, Future steel manufacturing hub. https://www.sustainsteel.ac.uk/. Accessed 6 September 2021

HyPER (2021) The HyPER project leading the development of a low carbon hydrogen production process in the UK, https://hyperh2.co.uk/. Accessed 6 September 2021

American Foundry Society (December 2019) Modern casting, vol 109, no 12. https://www.qgdigitalpublishing.com/publication/?m=55001&i=637245&p=6&ver=html5. Accessed 10 November 2020

Statista Research Development (17 June 2020) Steel production in the UK-Statistics & Facts. https://www.statista.com/topics/4939/steel-production-in-the-uk/. Accessed November 2020

Jolly M, Salonitis K (April 2017) Primary manufacturing, engine production and on-the-road CO2: how can the automotive industry best contribute to environmental sustainability? In: 38th international Vienna motor symposium, Vienna, Austria

York & North Yorkshire Local Enterprise Partnership (2021) Circular Yorkshire. https://www.businessinspiredgrowth.com/circular-yorkshire/. Accessed 6 September 2021

Make UK (2021) Make UK, The Manufacturer's Organisation. https://www.makeuk.org/. Accessed 6 September 2021

Women with Bottle, Women in Manufacturing Forum, Encirc360

Velenturf APM, Jopson J, Marshall R (June 2019) Delivering knowledge exchange and impact: a case study of the Resource Recovery from Waste programme-invited presentation at UK Research and Innovation. UKRI, Swindon, UK

Breman B, Pleijte M, Ouboter S, Buijs A (2008) Participatie in Waterbeheer: Een vak Apart (Participation in water management: a specialist subject). In: Alterra Wageningen UR, Wageningen, The Netherlands

Velenturf APM, Marshall R, Suarez-Suarez A, Christensen H, Yu E, Falagan C, Sapsford DH, Gomes HI, Mayes W (2018) Participatory situational analysis: how can policy and regulation support resource recovery? Synthesis report. Resource Recovery from Waste, University of Leeds, Leeds

Acknowledgements

The Transforming the Foundation Industries Research and Innovation hub (TransFIRe (EP/V054627/1)) is funded by UKRI (https://gow.epsrc.ukri.org/NGBOViewGrant.aspx?GrantRef=EP/V054627/1).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Jolly, M., Velenturf, A.P.M., Salonitis, K., Paddea, S. (2022). The UK Transforming the Foundation Industries Research and Innovation Hub (TransFIRe). In: Lazou, A., Daehn, K., Fleuriault, C., Gökelma, M., Olivetti, E., Meskers, C. (eds) REWAS 2022: Developing Tomorrow’s Technical Cycles (Volume I). The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-92563-5_35

Download citation

DOI: https://doi.org/10.1007/978-3-030-92563-5_35

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-92562-8

Online ISBN: 978-3-030-92563-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)