Abstract

The use of laser light to selectively remove and/or precisely reduce unwanted layers and encrustations from the surface of cultural heritage (CH) objects and monuments was systematically investigated during the past 30 years bringing about a significant breakthrough in the field. This chapter aims at briefly introducing the reader to the basic concepts of laser cleaning, while highlighting the critical and decisive parameters that determine an efficient and successful laser ablation on stonework. Limitations ensuring a safe process are discussed, and good practice guidelines for laser cleaning interventions are presented, with emphasis to their practical implementation in three laser cleaning projects with different conservation challenges. Finally, ongoing issues related to careful assessment and reliable monitoring of the process are discussed.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

3.1 What Is Laser Cleaning: Principles of Operation

LASER (Light Amplification by Stimulated Emission of Radiation) is a unique illumination source that nowadays holds a vital role in many every-day applications (i.e., material science, communications, medicine, entertainment, etc.). Laser light was born in the laboratories in the early 60s based on Einstein’s studies on the absorption and emission of light. It was progressively established as a valuable diagnostic and material processing tool due to its distinctive features such as monochromaticity (it is emitted in light beams of single or narrow bands of wavelengths), high directionality, and coherence, in addition to its high energy. These unique properties enable laser-material interactions that are characterised by selectivity, spatial confinement, remote action, immediate control, and feedback, and made possible the broad use of lasers for analytical and cleaning purposes in a number of material processing applications, as well as in the cultural heritage (CH) field [1, 2].

Laser-assisted removal is realized with the deposition of light energy in a controlled volume of material (in the range of a few cubic micrometres)Footnote 1 within a short time frame (usually a few nanoseconds).Footnote 2 This rapid energy deposition results, through a series of processes, in material breakdown, generation of a micro-plasma plume, and eventually in material removal. In fact, the interaction of intense laser light with matter is a complex process, also known as laser ablation, to which many parameters play important role.

Physical and chemical properties of the material, such as the absorption coefficientFootnote 3 (a), the thermal conductivityFootnote 4 (k), the heat capacityFootnote 5 (C), etc., are decisive for the quality of the cleaning intervention. For materials that strongly absorb the laser light, laser-ablation is effectively taking place within a well-defined and restricted volume (Fig. 3.1), and thus any thermal or photo-chemical effects to the underlying or surrounding material are minimal. Given that the properties of the material are inherent and cannot be changed, a safe and precise laser cleaning process can be influenced and controlled by the careful selection of the characteristics of the laser light. The wavelength Footnote 6 (λ), the applied energy density or fluenceFootnote 7 and the pulse durationFootnote 8 (τp) have a major role in ensuring efficient and satisfactory cleaning processes. Other important factors are the laser beam quality and profile, the repetition rate and the use of enhancing liquids, e.g. water. Fine-tuning of all these parameters enables the development of an appropriate cleaning methodology and is crucial for successful conservation interventions that will respect and safeguard the original surfaces.

In this respect, another very important condition refers to the “self-limiting” mechanism, i.e., the significant difference that characterizes the onset for ablation (ablation threshold) between the (unwanted) over-layer and the original surface [1, 2]. As a rule of thumb this condition is effective for most of the cases involving dark encrustations (e.g., soiling and pollutants accumulations) on light-coloured stonework (e.g., white marble or limestone ), but it may not apply in all cleaning challenges. Therefore, extensive studies have been carried out with the aim to prove and establish laser cleaning, while, at the same time, significant research is nowadays focused on developing reliable monitoring diagnostics.

3.2 Advantages and Limitations

Lasers offer a number of important advantages in respect to other commonly used cleaning techniques, i.e., chemical (solvent/paste) and mechanical (abrasive/scalpel ) cleaning, as their unique properties allow the effective handling of a number of open and vital issues in CH conservation. Laser light is selectively interacting only with the materials that significantly absorb the specific laser wavelength , resulting in cleaning interventions confined in space and materials. Indeed, for self-limiting conditions, the removal process is restricted only to the highly-absorbing, usually dark-coloured encrustation , and thus, any risks for damages or accidents to the original surface due to over-cleaning, or operator’s fatigue and inattention, are practically minimized. This is particularly important for objects with high surface relief and curved details, or for delicate and damaged original surfaces, as lasers can effectively remove the encrustation , and reveal the substrate intact. Furthermore, they enable contactless and distant operations, as no excessive pressure is exercised onto fragile surfaces, minimizing any harmful results.

In parallel, laser cleaning can offer strictly localized action, while it is spatially confined only to the size of the beam diameter,Footnote 9 without affecting the underlying or adjacent areas. As a result, issues related to precision of intervention, especially in cases of non-homogeneous surface crusts, can be easily overcome, while issues associated with uncontrolled penetration and/or spread of chemicals into the bulk of the treated surfaces and their surrounding areas, as well as difficulties in residues removal, are clearly avoided.

Finally, problems associated with the insufficient visibility of the surface under treatment and the monitoring of the process, as well as repetitive and time-consuming applications, have been significantly restrained due to the immediate control and feedback offered by laser cleaning. Issues related to the health and safety of the operators/conservators and the environment are effectively tackled, by following strict rules upon laser operation, as well as by carefully collecting and disposing the extracted dust waste.

3.2.1 Discoloration Side Effects: Darkening of Pigments and Yellowing of Stone

The wide use of lasers in CH conservation has been often restricted and criticized due to side effects associated with undesirable discoloration observed on the treated surfaces. Darkening of paints, as well as yellowing of the cleaned stonework have been reported as unfavourable fallouts of laser cleaning [3, 4] urging for further studies.

Discoloration of pigments was among the first drawbacks reported during one of the earliest laser cleaning interventions at the Portal of Amiens Cathedral in France, 25 years ago [5]. Systematic studies both on pigment powder, as well as on paint mock-ups, have been performed, aiming to investigate the sensitivity of pigments to laser irradiation, taking into account both the material properties (chemical composition of the pigment and the binding media) and the laser parameters (λ, F, τp, etc.) [6,7,8,9,10,11,12,13,14,15,16,17]. These studies indicated that darkening of the pigment particles and the paint (pigment-binder mixtures) appears in most of the studied cases upon direct exposure to laser light and depends closely to the chemistry of the pigment and the binder , as well as the applied irradiation parameters. Light-sensitive pigments, such as red vermilion (HgS, cinnabar), are particularly sensitive also to lasers, either due to phase transition to black meta-cinnabar [9], or chemical reduction of HgS to the darker Hg2S [10, 13]. Lead pigments discolor only temporarily [10, 12], as their darkening appears temporal while its reversal time depends on the composition of the pigments and the applied irradiation parameters. Apparently, the chemical composition of the binding medium and its absorbance to the applied laser beam are important for the appearance of darkening phenomena. It was reported that for highly absorbing binders (i.e., drying seed oils, protein-based compounds, such as eggs and glues), the interaction of the ultraviolet (UV) laser beam with the paint was restricted to a superficial layer, preventing damage to the paint bulk [4, 16, 17]. Nevertheless, as proven by the Acropolis case [31], paint layers or traces hidden behind the encrustation on polychromed stonework can be safeguarded on the condition that the operating parameters are fine-tuned, and the operator has the total control of the intervention (i.e., low pulse repetition rates are employed).

On the other hand, discoloration of irradiated stone surfaces towards yellower hues is mainly associated with infrared (IR) laser ablation of environmental encrustation from marble surfaces and has been under investigation through the past 25 years [18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34]. These studies discuss a number of hypotheses that have been put forward in order to explain its origin and, accordingly, to offer solutions for its prevention and/or remediation. Initially, it was investigated whether discoloration was due to the uncovering and revealing of pre-existing layers or patinas (i.e., scialbaturas [4, 18, 30]). These colored surfaces may have been developed naturally through the years due to the stone’s exposure to the environmental conditions, or they may have been applied intentionally as protective coatings or as a preparation surface for the polychromy . The hypothesis that the color of the cleaned surface is different to what was expected because its original surface has been altered due to its proximity with the encrustation has been also considered. Indeed, it has been reported that migration of water-soluble organic compounds from the encrustation to the underlying stone can be favoured in humid environments, causing significant changes to the original stone color [20, 21]. In any case, no matter whether the colored layers have been developed naturally or they have been applied on purpose, they may keep valuable historical evidence (sculpted details and tooling traces, pigment remnants, etc.), and therefore their protection and safeguarding is considered imperative [22].

Other hypotheses refer to the chemical transformation of iron and other metallic components of the crust and stone, induced by the photo-thermal mechanisms that govern the IR laser ablation. Although the presence of iron in the crust is very low (~0.6%) [23], its chemical transformation from hematite (Fe2O3) into magnetite (Fe3O4), goethite (α-FeO(OH)) or even maghemite (γ-Fe2O3), may result in notably visible discoloration [19, 24,25,26,27].

Finally, attention was focused on insufficient cleaning due to the selective vaporization of the darker components of the crust . Actually, the dark-colored particles, embedded in the gypsum bulk of the pollution crusts, absorb highly the IR radiation and, thus, irradiation at relatively low F values may support their preferential removal, leaving behind remnants of the non-ablated gypsum matrix, which appear yellow [3, 34].

Apparently, given that each distinct cleaning challenge fulfils more than one of the above hypotheses, there is no unique and unambiguous answer to the origin of the yellow discoloration . Therefore, it is imperative that a thorough investigation of the stratigraphy and the components of the encrustation takes place prior to defining the optimum cleaning level, which will eventually influence the degree of the discoloration .

In parallel a series of experiments were undertaken using different laser parameters (λ, tp, F values etc.) [4, 28,29,30,31,32,33,34] with the aim to avoid or rectify the unpleasant yellowing. These experiments employed real fragments, as well as technical mock-ups simulating black crusts, starting from its simplistic approach, i.e., charcoal particulates embedded in gypsum [4], to more sophisticated crust simulations [28]. Comparative tests, using the 1064 nm and 355 nm beams from a QS – Nd:YAG laser, confirmed the IR-induced discoloration on the gypsum-charcoal mock-ups. The presence of the charcoal was found to have a vital contribution to the recorded discoloration , as the intensity of the yellowing was found to be dependant to its quantity. Furthermore, voids, resulting due to preferential removal of charcoal, were reported upon irradiation with lower F values, at least for those ones that lay below the ablation threshold of gypsum and above the one of charcoal. On the contrary, no discoloration was observed to the reference gypsum mock-ups (without charcoal) or upon UV irradiation of the gypsum-charcoal ones. In this latter case, a “layer-by-layer” model of removal was confirmed for higher F values, which put into risk the gypsum crystal, as its damage threshold at 355 nm was found to be rather low. Similarly, IR irradiation on real samples verified the preferential removal of dark particulates at lower F values and the beige-yellow discoloration of the residual gypsum-rich matrix material.

These studies inspired the combined use of the two laser ablation regimes in order to exploit their advantages, and early experiments were focused on the sequential employment of the UV laser beam to rectify the IR-induced discoloration [30]. However, their result was inhomogeneous, almost at the borderline of damage, while colour rectification was not satisfactory. Further experimentation was focused to their synchronous use in partial and temporal overlapping, while the contribution of each individual ablation mechanism was regulated by adjusting the energy density ratio of the two beams (FIR/FUV) [4, 30,31,32,33,34]. Systematic studies on mock-ups and fragments with different crusts and careful assessment of the cleaned surfaces resulted in the optimization and fine-tuning of this 2-λ methodology, which was then adapted for the cleaning challenges of the Athens Acropolis sculptures described in paragraph 3.5.1.

3.3 Historical Review & Main Research Highlights

The first laser assisted removal of unwanted material on CH surface took place 50 years ago in Venice [35,36,37,38]. In the course of a project related to the holographic recording of the famous Venetian monuments, John Asmus and his collaborators experimented on the use of a ruby laser to clean black pollution crust from stonework. Several cleaning tests were performed, but it took another two decades before the scientific community considered laser ablation for conservation interventions, mainly due to restrictions posed from the laser technology itself.

In the early 90s, systematic investigation for establishing laser cleaning on stonework was reported mainly in Europe. In the UK, Loughborough University and the National Galleries on Merseyside in Liverpool collaborated towards a methodical description of the mechanisms ruling Nd:YAG laser ablation of encrusted stonework, and the definition of the first systematic methodology for cleaning interventions, with emphasis on black pollution crusts on limestones [1, 39,40,41,42]. In parallel, in France, the Laboratoire de Recherche de Μonuments Historiques in Paris [18, 22, 24,25,26,27] undertook a detailed comparison of laser assisted crust removal to mechanical and chemical means and applied the technique in situ at Portail de la Mère Dieu in Amiens Cathedral [5]. The issue of laser-induced discoloration was reported for the first time. In parallel, St. Stephen’s Cathedral in Vienna [43, 44] and Maddalena church in Venice [45] were laser cleaned in situ, while a very active research team was formed in Florence at Consiglio Nazionale delle Ricerche (CNR) investigating different laser ablation regimes and challenges [45,46,47,48,49,50,51,52,53,54]. Meanwhile, in Greece, the Foundation of Research and Technology-Hellas (FORTH) performed the first experiments for removing aged varnish layers from wooden icons and paintings, as well as biological stains from paper substrates using UV laser radiation (at 248 nm and 193 nm) emitted from excimer laser sources [2, 55]. Concurrently, the Greek research team, in close collaboration with the Acropolis Restoration Service, initiated a thorough research for investigating the appropriate cleaning methodology and, most importantly, the laser-diagnostic techniques for the removal of pollution crusts from the sculptures of the Acropolis in Athens [56,57,58,59,60,61,62]. Thereafter, significant research effort has been dedicated worldwide for the broad application of lasers in the conservation, as well as the analysis and diagnosis, of CH objects and monuments.

In 1995, validating the pioneer role of this research, the first LACONA (LAsers in the COnservation of Artworks) conference was organised by FORTH in Crete, Greece. Twelve LACONA conferencesFootnote 10 were subsequently organised and the multidisciplinary research community was vigorously dedicated to the wide establishment of laser technology in the field, while showing the way to new tools and applications. Within the past three decades, several national and EU funded projects allowed the flourishing of this pioneer research, and several supporting measures, for example, the G7 COST action on “Lasers and Optical Methods in Artwork Restoration”, set the basis for facilitating the communication and collaboration between the various disciplines. Finally, a number of training activities were established in order to enable the conservation professionals to become acquainted with the laser technology.

In the meantime, there was also a significant development in laser technology, resulting in a considerable number of laser cleaning systems available for use in various applications. The early experiments employed the 1064 nm beam of a QS Nd:YAG system with tp in the range of 10–25 ns. The harmonic wavelengths of this laser (mainly the 2nd (532 nm) and 3rd (355 nm) and to a lesser extent the 4th (266 nm) and the 5th (213 nm)) have also been employed for a number of applications with promising results, while the combination of 1064 nm and 355 nm was proposed as a solution to prevent unwanted side effects related to discoloration of stonework. Longer laser pulses emitted from SFRFootnote 11 and LQS11 Nd:YAG systems are also broadly used especially for applications related to removal of pollution crusts from stonework. In these cleaning regimes, photo-thermal mechanisms are important, and the presence of a moistening agent is imperative. Material is removed through vaporisation as a result of water steam formation, while the ablation depth can be controlled, allowing discrimination of the various layers. Plenty of world-known monuments and objects with complex and demanding stratigraphy and cleaning challenges have been treated successfully with these types of lasers (e.g. the Santi Quattro Coronati [50] and the Porta della Mandorla [51] in Florence). On the other hand, shorter laser pulses (of picoFootnote 12- and femto12-second duration) have been also considered as they can practically minimise thermal phenomena. Irradiation using ultra-short laser pulses is associated with shorter thermal diffusion lengths, resulting into more effective material removal, which is particularly important in case of hard encrustations. The disadvantage, in this case, is the fact that the operative fluence window may be smaller than in other laser cleaning regimes, necessitating the presence of monitoring approaches, especially for multi-layered encrustations [28].

Er:YAG laser systems have also been used for cleaning applications in the CH field (initially in paintings conservation and later in other materials), in parallel to their broad implementation in medical and dental applications. IR pulses at 2940 nm emitted from Er:YAG laser systems rely on the selective excitation of molecules containing OH-groups (i.e., water and other solutions) which are the main absorbers at this wavelength. Their presence favours the thermal dissipation of the laser energy into the outer surface of the unwanted material, increasing its temperature and pressure, stimulating its removal through steam formation and gas expansion. Thus, ablation in this regime is photo-thermally dominated. A significant number of studies have been dedicated to the investigation of the potential heating effects, also aimed at defining the most suitable moistening agents and the appropriate laser parameters in order to confine the absorption of the 2940 nm radiation to the outer surface layers, and effectively control the cleaning interventions in this regime [63,64,65,66,67,68].

3.4 A Methodological approach for Laser Cleaning of Stonework

Laser cleaning, similar to any other irreversible intervention, must be approached with high level of responsibility and attention. Although it is established as a safe, controllable, and effective cleaning tool, care should be taken to determine the optimum parameters for each individual cleaning case, in order to avoid any damaging and/or irreparable situations. Along these lines, a protocol that can ensure careful and effective conservation processes is briefly presented (Fig. 3.2), aiming to indicate the main steps that must be followed, keeping in mind that every single conservation challenge, although appearing similar to previously studied ones, may vary significantly, and, thus, necessitates its own consideration.

3.4.1 Phase A: Definition of the Conservation Challenge

With the aim to define the cleaning level and ensure safeguarding of the original surface, a systematic study is essential prior to any cleaning intervention. This is well-practised in CH conservation and refers to careful analytical investigation of the involved materials and layers with emphasis to the determination of their chemical composition, their morphology, thickness, and stratigraphy, taking into account historical data and past conservation treatments. In laser cleaning, specifically, it is crucial to additionally determine the physico-chemical characteristics of the unwanted materials and the original substrate, including their absorptivity profile, as they are critical for the selection of the operational characteristics of the laser system. Other important details that characterise each unique conservation challenge refer to the presence of organic materials (due to past conservation treatments) and paint traces, the state of cohesion and adhesion of the involved materials and surfaces, their ageing condition (fresh or aged polymeric coatings), and any variations in thickness and/or stratigraphy across the surface.

3.4.2 Phase B: Feasibility Study

The ablation threshold values for the involved materials (i.e., the onset for removal of encrustation material, Fcrust, and the onset for damage to the substrate, Fsubstrate) are particularly important when it comes to the decision of the appropriate laser cleaning approach. Their relative difference may ensure a self-limiting process (Fcrust < <Fsubstrate) or may call for extra monitoring processes. To this end, it is advisable to perform “etch-rate” studies for the encrustation and substrate in order to determine how much material is removed for different F values. Practically, this can be achieved on the basis of series of irradiation trials involving spot tests of single (1), as well as multiple (2, 5, 10 etc.) pulses at increasing F values. The resulting craters are significant for the determination of the cleaning methodology. This phase may necessitate the use of model mock-ups of the same or very similar physicochemical properties, thickness, surface morphology, and ageing condition to the actual cleaning challenge. Alternatively, real fragments (unidentified or of lower historical importance) of the same monument or site may be also utilised.

In this stage, it is also important to investigate whether the presence of a wetting agent may enhance the cleaning efficiency [1, 4, 52] and, thus, irradiation tests on pre-wetted surfaces should be also implemented. Moistening must take place in a standard way (i.e., by means of a spray or by a clean and slightly wet cotton-swab, sponge , or brush), while care must be taken in order to avoid excessive wetting of the surface which may cause staining or other undesired surface alterations to the surrounding areas, including uncontrolled ablation.

A first indication of the ablation thresholds of the involved materials is usually based on visual and spectral imaging of the irradiated spots supported by microscopic (optical, stereo-, and scanning electron microscopy) evaluation. When applicable, determination of the depth of the laser induced craters using mechanical profilometers or optical diagnostics can be also employed in order to fully study the etching rate of the unwanted crusts.

Once the ablation thresholds of the involved materials are determined, further tests on larger areas (e.g., 1 cm2) are advisable in order to further evaluate the result [69, 70]. Their assessment must be multi-analytical and responsibly address the cleaning result in regard to:

-

(a)

Surface morphology: undesirable effects due to excessive or insufficient irradiation conditions may be observable as surface alteration (i.e., disrupted marble crystals, darkened ceramics, or damaged biotite grains within the granite [69]), micro-cracking, selective vaporisation of individual (darker) components of the crust leaving behind usually bleached or discoloured crust remains, melting, and other thermally induced phenomena.

-

(b)

Colour: the cleaned surface must show similar coloration to the surface selected as reference. Discoloration can usually be detected easily, due to the high sensitivity of human eye, nevertheless, its quantitative measurement, e.g., by using a colorimeter, can be a demanding process and must be evaluated with caution.

-

(c)

Physicochemical changes to the inorganic and/or organic components or layers of the original surface: their effects may be directly visible (i.e., darkening of pigments) or they may affect the surface in the long-term (i.e., dehydration of inorganic or polymerisation of organic molecules). Different analytical and diagnostic tools may be employed for the detection of such potential alterations, including X-ray diffraction [23, 24, 70], Raman spectroscopy [13, 34], IR spectroscopy [11, 23, 64, 94], X-ray photoelectron spectroscopy [10], fluorescence spectroscopy [11, 23], and mass spectrometric techniques [11, 30, 71], while issues of sensitivity of the analytical technique, sampling restrictions, and reliability of results, due to point or superficial analysis, are currently under discussion by researchers.

3.4.3 Phase C: Development of the Cleaning Methodology

This phase is rather technical and refers to the fine-tuning of the laser cleaning parameters to ensure a homogeneous and satisfying result. The number of applied pulses according to the thickness and the morphology of the encrustation , their repetition rate (in Hz), the spot size of the light beam, the scanning protocol (either manually or computer-driven) and the optimization of its conditions (i.e., overlapping, repetitions etc.), the most suitable moistening scheme, the archiving protocol, etc. are among the parameters that must be decided for an optimum laser-assisted encrustation removal. It is also important to clearly differentiate this optimal cleaning level compared to under-cleaned and/or damaged surfaces [80].

3.4.4 Phase D: Monitoring of the Process

Finally, to ensure a responsible and safe laser cleaning intervention, reliable and careful control of the removal process, in situ and, if possible, in real time with the actual process, is imperative. A key issue in this respect is to find out the appropriate controlling tool and, accordingly, to determine the critical point that denotes when the cleaning limit is about to be reached and, thus, the process must be timely terminated or continued to an adjacent point or area, ensuring that the original surface is safeguarded from any mistakes or irreversible damage. This is not an easy and straightforward procedure, as in most of the cleaning cases, the treated objects involve multifaceted layers and materials of possibly different weathering or ageing states, with heterogeneous structures and thicknesses that may significantly vary across the object. Therefore, total automation of laser-cleaning processes, as well as cleaning at high repetition rates, are not advisable, as they risk preventing the end-user to react timely to any unpredicted situation. On the contrary, it is recommended to continuously and carefully observe the treated area and employ the suitable monitoring device.

Early studies were focused on imaging approaches [72, 73], and were based on digital processing of the acquired images to quantitatively identify the differences between an optimum, under-cleaned, and damaged surface. In parallel, laser spectroscopies (LIBS , laser induced breakdown spectroscopy and LIF, laser induced fluorescence) were also considered, as they were easily adopted using the same laser beam [56,57,58, 74, 75]. In this case, the monitoring relies on the observation of the optical emission of the ablation plume and the recording of the intensity of specific spectral lines for successive laser pulses upon the cleaning process. Any significant changes to these spectral lines are expected to delineate the encrustation-substrate interface, on the condition that the emission spectra of the removed material and the underlying substrate are different. Another critical point is that the laser ablation plasma is associated with high F values that most of the times are close to the Fsubstrate and thus, call for particular attention. Optical coherence techniques have also been investigated for their potential to control cleaning, either by determining the thickness of remaining organic coatings (optical coherence tomography [76, 77]), or by detecting structural changes (holographic interferometry [78, 79]). Recently, photoacoustic signals generated upon laser ablation have been also considered for on-line control with encouraging results [80,81,82].

3.5 Case Studies and Ongoing Issues

Within the past 30 years the laser ablation mechanisms have been carefully studied and different cleaning challenges and side issues have been satisfactorily tackled. The interested reader may find in various scientific journals and conference proceedings (e.g., the LACONA conference proceedings) plenty of relevant information on multifaceted laser cleaning queries, reflecting careful investigations to determine and fine-tune the appropriate ablation parameters and methodologies. In this section, selected examples of laser cleaning on stonework are briefly presented with emphasis on the dedicated cleaning approaches that have been developed for different encrustation materials on three unique Greek heritage objects and monuments.

3.5.1 Gypsum–rich Dark Pollution Encrustation on Marble – The Athens Acropolis Sculptures

A unique example of laser-assisted removal of pollution encrustation using the 2-λ methodology is the cleaning intervention at the sculptures of the Athens Acropolis [33]. This unique complex of monuments, located on a hill in the centre of Athens in Greece, has been exposed to the environmental conditions and weathering for more than two and a half millennia. Nevertheless, the main cause for its weathering is considered the rapid industrialisation of the Greek capital within the past 70 years, favouring the intense deposition of pollution particulates on these fine-sculpted objects made of exquisite white Pentelic marble. The cleaning challenge involved the controlled removal of various overlayers in order to reveal the original substrate.

Studies of the stratigraphy of the encrusted sculptures indicated a complex situation calling for careful treatment . Three main types of encrustations on the sculptures were encountered: (a) loose gypsum-rich deposits of soot and dirt forming a uniform thin veil that obscures surface details; (b) homogeneous compact crusts of well-adhered deposits that hide any surface traces and details; and (c) thicker dendritic crusts of re-crystallised and re-precipitated calcium carbonate bonded together with gypsum and dark atmospheric particles that significantly alter the surface condition. The substrate is comprised mainly of weathered marble , while two monochromatic layers of ancient origin are recorded on well preserved marble surfaces, indicating important historical details. These two layers are identified as the “epidermis”, an orange-brown thin (30–100 μm) lower layer rich in calcium oxalates, calcium phosphates, and iron oxides [23, 33, 83], and the “coating ”, a thicker (80–120 μm) outer beige layer of calcium carbonate. They are a distinctive indication of the original surface, as they retain tool-marks and pigment traces, and they must be preserved.

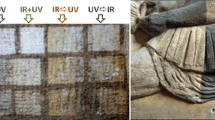

To deal with this particularly challenging cleaning problem, the conservators and researchers of the Acropolis Restoration Service (ΥΣΜΑ) investigated several conservation methodologies. Laser radiation was found superior over the conventional cleaning methods due to its selectivity, effectiveness, and controllability, but scepticism regarding yellowing triggered the research related to the combination of two ablative mechanisms to reach an optimum cleaning result. Figure 3.3 shows a series of laser irradiation tests using different laser parameters (details in [33]) on a newer marble corner-complement of the Parthenon West Frieze with a thick pollution crust . The critical evaluation of these tests on the basis of the potential chemical alterations or colour changes induced to the substrate allowed fine-tuning of the method, and the development of a prototype hybrid portable laser cleaning instrument dedicated to the specific cleaning challenge. Ranges for F values that would ensure effective and safe cleaning result were determined [33, 84].

Laser cleaning tests using different laser parameters (λ and F values, as well as F ratios upon simultaneous irradiation) on a newer marble corner-complement of the Parthenon West Frieze with pollution encrustation . Snapshot during the laser cleaning on marble substrate. Area (1) was irradiated at 1064 nm, area (2) at 355 nm and areas (3)–(10) at various combinations of the two beams. Detailed info can be found in [33]. © Hellenic Ministry of Culture and Sports, Hellenic Organization of Cultural Resources Development, Acropolis Restoration Service (YSMA) and Ephorate of Antiquities of Athens

The first assemblage from the Acropolis to benefit from the laser cleaning methodology was the West Frieze of the Parthenon (2002–2005). Figure 3.4 shows an area on block N. 6 during the laser cleaning. Dendritic crusts (on the horse-rider’s cloth), compact crust (on the background), as well as loose deposits (on the horse body) were removed in an effective and controlled way, ensuring the safeguarding of the ancient surface layers and the weathered marble surface. Employment of the 2-λ laser cleaning approach has been, since then, followed for the surface treatment of these unique sculptures, either on site (i.e., for the cleaning of the coffered ceiling of the Erechtheion prostasis at the Caryatids porch, Fig. 3.5), or inside the Acropolis conservation laboratories (for a number of sculptures such as the Northern and Eastern Parthenon metopes and the Frieze of the Temple of Athena Nike).

Parthenon West Frieze, Block N. 6 (VI). (a) Snapshot during the laser cleaning on marble substrate, (b) general view, and (c) detail of Block N. 6 (VI) before cleaning. © Hellenic Ministry of Culture and Sports, Hellenic Organization of Cultural Resources Development, Acropolis Restoration Service (YSMA) and Ephorate of Antiquities of Athens, photos by S. Mavrommatis

(a) The porch at the Erechtheion prostasis with the Caryatids casts, and (b) laser cleaning of its coffered ceiling. © Hellenic Ministry of Culture and Sports, Hellenic Organization of Cultural Resources Development, Acropolis Restoration Service (YSMA) and Ephorate of Antiquities of Athens, photo 3.5a by P. Pouli and photo 3.5b by D. Garbis

The inauguration of the new Acropolis Museum in 2009 also signalled a new era in the laser cleaning practice, as a temporal, but at the same time, advanced laser laboratory has been set-up inside the exhibition area to enable preservation activities in situ and open to the public. The specially designed platform, developed by the Acropolis Museum, is surrounded by protective curtains, in agreement with laser safety measures, and “embraces” and isolates one sculpture at a time, while it is moving in different heights to offer optimum access along the working area (Fig. 3.6). The original Caryatids, the female figures holding the Erectheion porch, were initially treated, while the visitors were able to follow the interventions in real time in a symbolic connection between ancient and modern Greece [31].

3.5.2 Insoluble Aluminosilicate Encrustations on Excavated Marble – The Hermes of Ancient Messene

The removal of inorganic encrustations from excavated objects is a controversial yet essential intervention. Such crusts are carbonatic, rich in aluminosilicates and metallic components, that may be abundant in the surrounding soil during the burial period. In most of the cases, no gypsum compounds can be detected, while the presence of surface patination layers (protective treatments or polychromy preparation layers) is uncommon. Thick layers of crust well-adhered to the substrate can be found on sound surfaces (usually on the parts of the sculptures and fragments which were buried face-down), while thinner layers occupying inter-crystalline space, due to the stone’s disaggregation, are present on the parts that were buried face-up. Although burial crusts cannot be considered harmful to the object, they may undermine aesthetic, artistic, and archaeological value, as they can obscure significant details, expressions, and textures, and therefore, their removal is recommended.

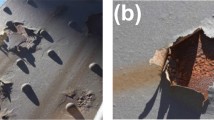

Hermes is a life-size Roman (first century AD) marble statue, excavated in 37 fragments in Ancient Messene in the Peloponnese, Greece. Its appearance after conservation undermined legibility and appearance, so cleaning of the inorganic encrustations was proposed. Prior to being the first statue to be laser-cleaned in situ in Greece, cleaning trials were undertaken in order to compare the result of most common conventional techniques (ultrasound pick and micro-air abrasive) on a marble fragment from the same excavation, characterised by a thick dark brown crust, similar in texture and composition to the one on the Hermes statue. The cleaning results were evaluated by means of optical microscopy and spectral imaging, for different types of crust and substrate condition, as well as their performance efficiency, the degree of control, and their complexity in handling [85]. The sculpture, which is currently exhibited in the Archaeological Museum of ancient Messene, was laser cleaned on February 2001 in situ by “Lithou Sintirissis Conservation Associates”, using a QS Nd:YAG system (Lynton Lasers) on damp surfaces. F range was 0.8–1.6 J/cm2 (Fig. 3.7).

3.5.3 Cement on Selenite – The Peripheral Monuments of the Minoan Palace of Knossos (Crete, Greece)

Another cleaning challenge refers to the removal of hard and often insoluble encrustation (i.e., cement) from stonework. The task gets more demanding in case of sensitive surfaces (i.e., weathered marble ) or other softer substrates (i.e., mineral gypsum), as the removal threshold of the overlayer can be significantly higher compared to the damage threshold of the authentic surface. Therefore, the determination of the operative laser parameters requires extra caution.

Selenite (mineral gypsum, CaSO4∙2H2O) is extensively used in the Minoan Palatial architecture both as an ornamental and building element due to its exceptional iridescence properties, but it is particularly soft (2/10 on the Mohs scale of mineral hardness) and fragile (due to its susceptibility to weathering and humidity). During the reconstruction of the archaeological site of Knossos, in Heraklion, Crete, at the beginning of the twentieth century AD, dark-coloured cement was used extensively, mainly to attach the gypsum elements on their original position, but also as a “coating ” covering the Minoan selenite walls. Such types of cement coatings disturb the appearance of the Knossean monuments, and endanger the longevity of the selenite surfaces, mainly due to the different mechanical properties (hardness, elasticity, etc.) of the materials, resulting in structural and surface failure. Therefore, their removal was deemed necessary. Although a significant part of the cement crust can be removed by mechanical means, attempts to remove thinner remains resulted in partial detachment of the original gypsum, due to the loss of cohesion between the surface layers of selenite crystal aggregates. Laser cleaning was considered, and feasibility tests were focused on investigating the cleaning parameters that will ensure: (a) cement removal without any change (physical or chemical) to the selenite crystalline phase (due to the de-hydration of gypsum to hemihydrate and/or anhydrous calcium sulphate), and (b) preservation of the “colored surface patination layers” (rich in calcium oxalates, calcium phosphates, calcite, and clay minerals).

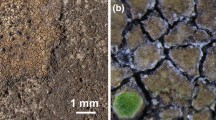

Following systematic studies [70] on technical mock-ups (1 mm thin cement layer on 1–1.5 mm of tabular translucent selenite crystal layer parallelepipeds) and real fragments (collected from a stone-pile located nearby the Royal Villa, at the east of the Minoan Palace), it was shown that a short-pulse IR laser beam at 1064 nm effectively removes such thick and hard insoluble cement crusts without affecting the gypsum surface morphology, the colour, and the chemistry of the authentic selenite surface, as it was confirmed through a number of imaging (optical microscopy, spectral imaging) and analytical (Raman spectroscopy, X-ray diffraction) techniques. Through these studies, the removal threshold of cement (Fcement = 1.5 J/cm2) and the damage threshold of selenite (Fselenite = 6.5 J/cm2) were determined, and, accordingly, the range of cleaning F (2–5 ± 0.3 J/cm2) was chosen (Fig. 3.8). Tests with the UV beam of the same QS Nd:YAG laser at 355 nm indicated that the damage threshold of selenite in this regime was significantly lower, and the removal efficiency of the cement was appreciably effected compared to the IR. Therefore, this cleaning regime was rejected for the purposes of this study.

Close magnifications of IR laser irradiation tests at 1064 nm to remove cement from selenite: (a) 10 pulses at F = 6.5 J/cm2 on selenite reference “monolayers”; (b) 5 and 30 pulses at 3 J/cm2 on cement covered selenite “monolayers”; and (c) removal of light-coloured thick cement layer from a real fragment using 30–50 pulses at 1064 nm. All irradiations were performed on wet surfaces

3.5.4 Other Materials

Further to the above-mentioned cases, other challenging encrustations disturb CH stonework and urge for careful solutions. Biological formations, quite common in archaeological sites with high humidity, call for particular attention, as they may penetrate within the stone bulk, causing further irreversible damage. Therefore, their removal is considered a particularly demanding intervention [54, 65, 86,87,88,89]. Usually these types of crusts can be removed using the 532 nm beam of a Q-Switched Nd:YAG laser [54, 87,88,89], although successful approaches have been reported with the 2940 nm of an Er:YAG laser [65].

Another difficult cleaning case is the removal of graffiti from stonework, due to their diversity in pigments and binding media, and the inevitable penetration of the paints into the stone bulk. Their complete removal, especially for the paint that occupies inter-crystalline space, is challenging and was approached using mainly Nd:YAG lasers [69, 90,91,92,93,94]. Nevertheless, an important issue in this respect is their practical implementation, as their diversity and wide-scale use necessitates automated cleaning processes.

Other demanding cases involve removal of various crusts from plaster [31, 95], brickwork [96], and granite , to mention a few. Plaster substrates appear to get intensely discoloured upon IR irradiation, and the yellowing is being avoided using a 532 nm beam [95] of the Nd:YAG laser or an appropriate combination of the 1064 and 355 nm beams [31]. Instead, brickwork gets darkened [96] upon 1064 nm irradiation. Likewise, an ongoing issue in laser cleaning of stonework refers to the removal of overlayers (black crusts and graffiti) from granite . Granite is a rather complex substrate which, due to its polymineralic grained texture [69, 94, 97, 98], appears highly sensitive to laser cleaning. Indeed, biotite, potassium feldspar, and plagioclase grains, main constituents of the granitic stone, can be easily damaged (melted, extracted) upon non-optimised laser irradiation conditions, and, thus, careful cleaning approaches must be employed. Another important issue, posing further difficulties as regards the determination of the optimum laser cleaning parameters for granitic substrates, is the fact that gypsum rich crusts must be totally eliminated, as their calcium component does not originate from the stone itself but from external sources (i.e., from the dissolution of joint mortars). For this reason, surface layers of gypsum show different physical and mechanical behaviour with respect to granite , which may lead to detachments and surface losses. Regarding this issue, dual wavelength cleaning approaches have been considered with promising results [69, 98].

3.6 Conclusions and Future Trends

The role of lasers as reliable, safe, and controlled cleaning tools is well established in the CH conservation practice. However, given the irreversibility of the intervention, careful optimisation of the cleaning methodologies (following cautious feasibility studies and best practice protocols) and thorough assessment of the result, combined with in situ and real-time monitoring of the laser-ablation process, must be followed. In this respect, non-invasive and non-destructive analytical and diagnostic sensors must be adopted and carefully chosen on the basis of the requirements posed from each individual cleaning challenge. Their integration into agile suites of surface, optical, and chemical sensors is expected to establish the reliability, controllability, and applicability of laser cleaning, and to highly advance the conservation process. Along these lines the development of portable cleaning and analytical instrumentation, augmented with user-friendly control interfaces, is imperative. Also, the recording, handling, using, and re-using of the acquired data related to laser operational parameters, evaluation, and monitoring information [99] in a FAIR (findability, accessibility, interoperability, and reusability) perspective is expected to play an important role in the field, as this knowledge will become more reachable and comprehensive to heritage scientists and conservators.

Notes

- 1.

1 cubic micrometer (μm3) is a SI measurement unit of volume with sides equal to one micrometer (1 μm = 1 10−6 meter = 1 millionth of a meter).

- 2.

1 nanosecond (ns) = 1 10−9 second = 1 billionth of a second.

- 3.

The absorption coefficient (a) defines how much light of a given wavelength/color (λ) is absorbed by a material of a given thickness.

- 4.

The thermal conductivity (k) of a material is a measure of its ability to conduct/transfer heat.

- 5.

The heat capacity (C) denotes the the amount of thermal energy required to raise the temperature of a substance by one degree.

- 6.

λ = The length of one complete light wave. Wavelength is a key characteristic of the laser light, usually fixed for any given laser system, and characterizes the “colour” of its monochromatic dimension (measured in nm).

- 7.

F = the energy (E) delivered per unit area. In practice this is measured as F = E/S (measured in J/cm2), where E is the output energy of the system for a single laser pulse and S the surface of the irradiated area.

- 8.

τp = The duration of a single laser pulse (τp ranging from several microseconds (μs, 10−6 s) to picoseconds (ps, 10−12 s) are commonly used in laser cleaning applications).

- 9.

Transportable pulsed laser cleaning systems emit beams with circular diameter, usually in the range of 5–9 mm. Using appropriate focusing optics the size of the beam diameter can be regulated and eventually focused to as small as 1 mm.

- 10.

Heraklion, GR (1995), Liverpool, UK (1997), Florence, IT (1999), Paris, FR (2001), Osnabrück, DE (2003), Vienna, AU (2005), Madrid, ES (2007), Sibiu, RO (2009), London, UK (2011), Sharjah, UAE (2014), Kraków, PO (2016), Paris, FR (2018) and forthcoming Florence, IT (2022).

- 11.

SFR: Short free running 50–120 μs and LQS: Long Q-switched 120–950 ns.

- 12.

1 ps = 10−12 s = 1 /1000 ns and 1 fs = 10−15 s = 1/1000 ps.

References

Cooper M. Laser Cleaning in Conservation: An Introduction. ed. Oxford: Butterworth- Heinemann; 1998.

Fotakis C, Anglos D, Zafiropulos V, Georgiou S, Tornari V. Lasers in the Preservation of Cultural Heritage; Principles and applications. In: Brown RGW, Pike ER, editors. New York: Taylor and Francis; 2006.

Zafiropoulos V, Balas C, Manousaki A, Marakis Y, Maravelaki-Kalaitzaki P, Melesanaki K, Pouli P, Stratoudaki Th, Klein S, Hildenhagen J, Dickmann K, Luk’Yanchuk BS, Mujat C, Dogariu A. Yellowing effect and discoloration of pigments: Experimental and Theoretical studies. J. Cult. Heritage. 2003. https://doi.org/10.1016/S1296-2074(02)01205-0.

Pouli P, Oujja M, Castillejo M. Practical issues in laser cleaning of stone and painted artefacts: optimisation procedures and side effects. Appl. Phys. A-Materials Sci. Process. 2012. https://doi.org/10.1007/s00339-011-6696-2.

Weeks C. The ‘Portail de la Mere Dieu’ of Amiens cathedral: its polychromy and conservation. Stud. Conserv. 1998. https://doi.org/10.1179/sic.1998.43.2.101.

Shekede L, Post-Prints of the Analysis of Pigments and Plasters. London: United Kingdom Institute for Conservation of Historic and Artistic Works; 1998.

Pouli P, Emmony DC, The effect of Nd:YAG laser radiation on medieval pigments, J. Cult. Heritage, 2000. https://doi.org/10.1016/S1296-2074(00)00143-6.

Athanassiou A, Hill AE, Fourrier T, Burgio L, Clark RJH. The effects of UV laser light radiation on artists’ pigments. J. Cult. Heritage. 2000. https://doi.org/10.1016/S1296-2074(00)00180-1.

Zafiropulos V, Stratoudaki T, Manousaki A, Melesanaki K, Orial G. Discoloration of Pigments Induced by Laser Irradiation, Surface Engineering, 2001. https://doi.org/10.1179/026708401101517773.

Pouli P, Emmony DC, Madden CE, Sutherland I. Analysis of the laser-induced reduction mechanisms of medieval pigments. Appl. Surf. Sci. 2001. https://doi.org/10.1016/S0169-4332(00)00909-0.

Castillejo M, Martín M, Oujja M, Silva D, Torres R, Manousaki A, Zafiropulos V, van den Brink OF, Heeren RMA, Teule R, Silva A, Gouveia H. Analytical Study of the Chemical and Physical Changes Induced by KrF Laser Cleaning of Tempera Paints. Anal. Chem. 2002. https://doi.org/10.1021/ac025778c.

Cooper MI, Fowles PS, Tang CC, Analysis of the laser-induced discoloration of lead white pigment. Appl. Surf. Sci. 2002. https://doi.org/10.1016/S0169-4332(02)00499-3.

Chappé M, Hildenhagen J, Dickmann K, Bredol K, Laser irradiation of medieval pigments at IR, VIS and UV wavelengths. J. Cult. Heritage. 2003. https://doi.org/10.1016/S1296-2074(02)01206-2.

Keune K, Boon JJ. Analytical imaging studies clarifying the process of the darkening of vermilion in paintings. Anal. Chem. 2005. https://doi.org/10.1021/ac048158f.

Acquaviva S, Baraldi P, D’Anna E, De Giorgi ML, Della Patria A, Giotta L, Omarini S, Piccolo R, Yellow pigments in painting: characterisation and UV laser-induced modifications. J. Raman Spectrosc. 2009. https://doi.org/10.1002/jrs.2316.

Oujja M, Pouli P, Fotakis C, Domingo C, Castillejo M. Analytical Spectroscopic Investigation of Wavelength and Pulse Duration Effects on Laser-Induced Changes of Egg-Yolk-Based Tempera Paints. Applied Spectroscopy. 2010; 64:528–536.

Oujja M, Sanz M, Rebollar E, Marco JF, Castillejo M, Pouli P, Kogou S, Fotakis C. Wavelength and pulse duration effects on laser induced changes on raw pigments used in paintings. Spectrochim. Acta A Mol. Biomol. 2013. https://doi.org/10.1016/j.saa.2012.10.001.

Vergès-Belmin V, Dignard C. Laser yellowing: myth or reality? J. Cult. Herit. 2003. https://doi.org/10.1016/S1296-2074(02)01203-7.

Klein S, Ferksanati F, Hildenhagen J, Dickmann K, Uphoff H, Marakis Y, Zafiropulos V. Discoloration of marble during laser cleaning by Nd:YAG laser wavelengths. Appl Surf Sci, 2001. https://doi.org/10.1016/S0169-4332(00)00706-6.

Potgieter-Vermaak SS, Godoi RHM, Grieken R, Potgieter JH, Oujja M, Castillejo M. Micro-structural characterization of black crust and laser cleaning of building stones by micro-Raman and SEM techniques. Spectrochim. Acta A Mol. Biomol. 2005. https://doi.org/10.1016/j.saa.2004.09.010.

Gaviño M, Hermosin B, Castillejo M, Oujja M, Rebollar E, Vergès-Belmin V, Nowik W, Saiz-Jimenez C. Black crusts removal: the effect of stone yellowing and cleaning strategies. Air Pollution and Cultural Heritage, CRC Press, 2004, pp. 239–245. https://doi.org/10.1201/b17004-37.

Vergès-Belmin V, Pichot C, Orial G. Elimination de croûtes noires sur marbre et craie : à quel niveau arrêter le nettoyage? In: Thiel M.-J. (Ed.), Conservation of Stone and Other Materials, London: E & FN Spon; 1993, pp. 534–541.

Maravelaki-Kalaitzaki P. Black crusts and patinas on Pentelic marble from the Parthenon and Erechtheum (Acropolis, Athens): Characterization and origin. Anal. Chim. Acta. 2005. https://doi.org/10.1016/j.aca.2004.10.065.

Gracia M, Gavino M, Vergès-Belmin V, Hermosin B, Nowik W, Saiz-Jimenez C. Mössbauer and XRD Study of the Effect of Nd:YAG-1064 nm Laser Irradiation on Hematite Present in Model Samples. In: Dickmann K, Fotakis C, Asmus JF, editors.Lasers in the Conservation of Artworks: LACONA V Proceedings. Berlin, Heidelberg: Springer Berlin Heidelberg; 2005. pp. 341–346. https://doi.org/10.1007/3-540-27176-7_42.

de Oliveira C, Vergès-Belmin V, Demaille D, Bromblet P. Lamp black and hematite contribution to laser yellowing: A study on technical gypsum samples. Stud. Conserv. 2016. https://doi.org/10.1179/2047058415Y.0000000003.

de Oliveira C, Vergès-Belmin V, Lafait J, Swider M, Andraud C, Tournié A, Galoisy L. Contribution of goethite to laser-induced stone yellowing. Appl. Phys. A. 2016. https://doi.org/10.1007/s00339-016-9818-z.

Godet M, Vergès-Belmin V, Bromblet P, Colombini A, Saheb M, Andraud C. Fly-ash contribution to Nd:YAG laser yellowing and its mitigation using UV-B light. J. Cult. Heritage. 2018. https://doi.org/10.1016/j.culher.2017.07.005.

Bartoli L, Pouli P, Fotakis C, Siano S, Salimbeni R. Characterization of Stone Cleaning by Nd:YAG Lasers with Different Pulse Duration. Laser Chemistry. 2006. https://doi.org/10.1155/2006/81750.

Marakis G, Pouli P, Zafiropulos V, Maravelaki-Kalaitzaki P. Comparative study on the application of the first and the third harmonic of a Nd:YAG laser system to clean black encrustation on marble. J. Cult. Heritage. 2003. https://doi.org/10.1016/S1296-2074(02)01208-6.

Pouli P, Fotakis C, Hermosin B, Saiz-Jimenez C, Domingo C, Oujja M, Castillejo M.The laser-induced discoloration of stonework; a comparative study on its origins and remedies. Spectrochim. Acta A Mol. Biomol. 2008. https://doi.org/10.1016/j.saa.2008.02.031.

Pouli P, Papakonstantinou E, Frantzikinaki K, Panou A, Frantzi G, Vasiliadis C, Fotakis C. The two-wavelength laser cleaning methodology; Theoretical background and examples from its application on CH objects and monuments with emphasis to the Athens Acropolis Sculptures. Herit.Sci. 2016. https://doi.org/10.1186/s40494-016-0077-2.

Pouli P, Zafiropulos V, Fotakis C. The Combination of Ultraviolet and Infrared Laser Radiation for the Removal of Unwanted Encrustation from Stonework; a Novel Laser Cleaning Methodology. In: Kwiatkowski D, Lofvendahl R, editors. Proceedings of the 10th International Congress on Deterioration and Conservation of Stone: Stockholm, June 27-July 2, 2004. Stockholm: ICOMOS Sweeden; 2004. pp. 315–322. ISBN: 9163114585.

Pouli P, Frantzikinaki K, Papakonstantinou E, Zafiropulos V, Fotakis C. Pollution encrustation removal by means of combined ultraviolet and infrared laser radiation: The application of this innovative methodology on the surface of the Parthenon West Frieze. In: Dickmann K, Fotakis C, Asmus JF, editors. Springer Proceedings in Physics 100; 2005, pp. 333–340. https://doi.org/10.1007/3-540-27176-7_41.

Papanikolaou A, Siozos P, Philippidis A, Melessanaki K, Pouli P. Towards the understanding of the two wavelength laser cleaning in avoiding yellowing on stonework: a micro-Raman and LIBS study. In Targowski P, Walczak M, Pouli P editors. Lasers in the Conservation of Artworks XI, Proceedings of LACONA XI. Torun: NCU Press; 2017, pp. 95–104. https://doi.org/10.12775/3875-4.0.

Asmus JF, Guattari J, Lazzarini L. Holography in the conservation of statuary, Stud. Conserv. 1973. https://doi.org/10.1179/sic.1973.005.

Asmus JF, Murphy CG, Munk WH. Studies on the interaction of lasers with art artifacts, In Developments in laser Technology II. International Society for Optics and Photonics. 1974. pp. 19–30. https://doi.org/10.1117/12.953831.

Asmus JF, Seracini M, Zetler MJ. Surface morphology of laser-cleaned stone. Lithoclastia. 1976;1;23–46.

Asmus JF. Light cleaning: laser technology for surface preparation in the arts. Technology and Conservation. 1978;3;14–18.

Cooper MI, Emmony DC, Larson J. Characterization of laser cleaning of limestone. Opt. Laser Technol. 1995. https://doi.org/10.1016/0030-3992(95)93962-Q.

Cooper MI, Larson JH. The use of laser cleaning to preserve patina on marble sculpture, Conservator. 1996. https://doi.org/10.1080/01410096.1996.9995100.

Watkins KG. A review of materials interaction during laser cleaning in art restoration. In Kautek W, Konig E editors. LACONA I Proceedings –Restauratorenblätter. Vienna: Mayer & Corp; 1997. pp. 7.

Beadman K, Scarrow J. Laser cleaning Lincoln Cathedral’s Romanesque frieze, J. Architectural Conserv. 1998. https://doi.org/10.1080/13556207.1998.10785215.

Calcano G, Koller M, Nimmrichter H. Laser based cleaning on stonework at St. Stephen’s Cathedral Vienna. In Kautek W, Konig E editors. LACONA I Proceedings -Restauratorenblätter. Vienna: Mayer & Corp; 1997. pp. 39

Calcagno G, Pummer E, Koller M. St. Stephen’s Church in Vienna: criteria for Nd:YAG laser cleaning on an architectural scale. J. Cult. Heritage. 2000. https://doi.org/10.1016/S1296-2074(00)00138-2.

Armani E, Calcagno G, Menichelli C, Rossetti M. The church of the Maddalena in Venice: the use of laser in the cleaning of the façade. J. Cult. Heritage. 2000. https://doi.org/10.1016/S1296-2074(00)00134-5.

Siano S, Margheri F, Pini R, Mazzinghi P, Salimbeni R. Cleaning processes of encrusted marbles by Nd:YAG lasers operating in free-running and Q-switching regimes. Appl. Opt.1997. https://doi.org/10.1364/AO.36.007073.

Salimbeni R, Pini R, Siano S. A variable pulse width Nd:YAG laser for conservation, J. Cult. Heritage. 2003. https://doi.org/10.1016/S1296-2074(02)01149-4.

Innocenti C, Pieri G, Yanagishita M, Pini R, Siano S, Zanini A. Application of laser welding to the restoration of the ostensory of the martyr St. Ignatius from Palermo. J. Cult. Heritage. 2003. https://doi.org/10.1016/S1296-2074(02)01146-9.

Siano S, Salimbeni R. Τhe Gate of Paradise: physical optimization of the laser cleaning approach. Studies in Conservation. 2001. https://doi.org/10.2307/1506776.

Siano S, Casciani A, Giusti A, Matteini M, Pini R, Porcinai S, Salmbeni R. The Santi Quattro Coronati by Nanni di Banco: cleaning of the gilded decorations. J. Cult. Heritage. 2003. https://doi.org/10.1016/S1296-2074(02)01139-1.

Siano S, Giusti A, Pinna D, Porcinai S, Giamello M, Sabatini G, Salimbeni R. The Conservation Intervention on the Porta della Mandorla. In Dickmann K, Fotakis C, Asmus JF editors. Lasers in the Conservation of Artworks- LACONA V. Springer Proceedings in Physics 100. Berlin, Heidelberg: Springer; 2005. pp. 171–178. https://doi.org/10.1007/3-540-27176-7_22.

Siano S, Giamello M, Bartoli L, Mencaglia A, Parfenov V, Salimbeni R. Laser cleaning of stone by different laser pulse duration and wavelength. Laser Phys. 2008. https://doi.org/10.1134/S1054660X08010064.

Siano S, Agresti J, Cacciari I, Ciofini D, Mascalchi M, Osticioli I, Mencaglia AA. Laser cleaning in conservation of stone, metal, and painted artifacts: state of the art and new insights on the use of the Nd:YAG lasers. Appl. Phys. A. 2012. https://doi.org/10.1007/s00339-011-6690-8.

Osticioli I, Mascalchi M, Pinna D, Siano S. Removal of Verrucaria nigrescens from Carrara marble artefacts using Nd:YAG lasers: comparison among different pulse durations and wavelengths. Appl. Phys. A. 2015. https://doi.org/10.1007/s00339-014-8933-y.

Hontzopoulos E, Fotakis C, Doulgeridis M. Excimer Laser in Art Restoration. Proc. SPIE 1810, 9th International Symposium on Gas Flow and Chemical Lasers, (4 May 1993); pp. 748–751. https://doi.org/10.1117/12.144595.

Maravelaki PV, Zafiropulos V, Kylikoglou V, Kalaitzaki MP, Fotakis C. Laser Induced Breakdown Spectroscopy as a Diagnostic Technique for the Laser Cleaning of Marble. Spectrochim Acta Part B At Spectrosc. 1997. https://doi.org/10.1016/S0584-8547(96)01573-X.

Maravelaki PV, Zafiropulos V, Kylikoglou V, Kalaitzaki MP, Fotakis C. Diagnostic Techniques for Laser Cleaning of Marble. In Kautek W, Konig E editors. LACONA I Proceedings -Restauratorenblätter. Vienna: Mayer & Corp; 1997. pp. 31–35.

Gobernado-Mitre I, Prieto AC, Zafiropulos V, Spetsidou Y, Fotakis C. On-line monitoring of laser cleaning of limestone by laser induced breakdown spectroscopy. Applied Spectroscopy. 1997. https://doi.org/10.1366/0003702971941944.

Georgiou S, Zafiropulos V, Anglos D, Balas C, Tornari V, Fotakis C. Excimer laser restoration of painted artworks: procedures, mechanisms and effects, Appl. Surf. Sci. 1998. https://doi.org/10.1016/S0169-4332(97)00734-4.

Maravelaki-Kalaitzaki P, Zafiropulos V, Pouli P, Anglos D, Balas C, Salimbeni R, Siano S, Pini R. Short Free Running Nd:YAG laser to clean different encrustation on Pentelic marble: procedure and evaluation of the effects. J. Cult. Heritage. 2003. https://doi.org/10.1016/S1296-2074(02)01151-2.

Pouli P, Selimis A, Georgiou S, Fotakis C. Recent studies of laser science in paintings conservation and research. Accounts of Chemical Research, 2010. https://doi.org/10.1021/ar900224n.

Anglos D, Detalle V. Cultural heritage applications of LIBS. In Mussazi A, Perini U. Laser-Induced Breakdown Spectroscopy – Theory and Applications, Springer Series in Optical Sciences 182. Berlin Heidelberg: Springer-Verlag; 2014. pp. 531–553. https://doi.org/10.1007/978-3-642-45085-3_20.

deCruz A, Wolbarsht ML, Hauger SA. Laser removal of contaminants from painted surfaces. J. Cult. Heritage. 2000. https://doi.org/10.1016/S1296-2074(00)00182-5.S173.

Bracco P, Lanterna G, Matteini M, Nakahara K, Sartiani O, deCruz A, Wolbarsht ML, Adamkiewicz E, Colombini MP. Er:YAG laser: an innovative tool for controlled cleaning of old paintings: testing and evaluation. J. Cult. Heritage. 2003. https://doi.org/10.1016/S1296-2074(02)01232-3.

deCruz A, Wolbarsht M, Palmer R, Pierce S, Adamkiewicz, E. Er:YAG Laser Applications on Marble and Limestone Sculptures with Polychrome and Patina Surfaces. In Dickmann K, Fotakis C, Asmus JF editors. Lasers in the Conservation of Artworks- LACONA V. Springer Proceedings in Physics 100. Berlin, Heidelberg: Springer; 2005. pp. 113–124. https://doi.org/10.1007/3-540-27176-7_14.

deCruz A, Wolbarsht M, Andreotti A., Colombini M, Pinna D, Culberson C. Investigation of the Er:YAG Laser at 2.94 μm to Remove Lichens Growing on Stone. Studies in Conservation. 2009. https://doi.org/10.1179/sic.2009.54.4.268.

Pereira-Pardo L, Korenberg C. The use of erbium lasers for the conservation of cultural heritage. A review. J. Cult. Heritage. 2018. https://doi.org/10.1016/j.culher.2017.10.007.

Andreotti A, Colombini M, DeCruz A. Er:YAG laser cleaning of a marble Roman urn. Journal of the Institute of Conservation. 2020. https://doi.org/10.1080/19455224.2019.1706593.

Pozo-Antonio JS, Papanikolaou A, Melessanaki K, Rivas T, Pouli P. Laser assisted removal of graffiti from granite: advantages of the simultaneous combination of two wavelengths. Coatings. 2018. https://doi.org/10.3390/coatings8040124.

Grammatikakis G, Demadis KD, Melessanaki K, Pouli P. Laser assisted removal of dark cement crusts from the mineral gypsum (selenite) architectural elements from the peripheral monuments of the archaeological site of Knossos. Studies in Conservation. 2015. https://doi.org/10.1179/0039363015Z.000000000201.

Andreotti A, Colombini MP, Nevin A, Melessanaki K, Pouli P, Fotakis C. Multianalytical Study of Laser Pulse Duration Effects in the IR Laser Cleaning of Wall Paintings from the Monumental Cemetery of Pisa. Laser Chemistry. 2006. https://doi.org/10.1155/2006/39046.

Papadakis V, Loukaiti A, Pouli P, A spectral imaging methodology for determining on-line the optimum cleaning level of stonework. J. Cult. Heritage. 2020. https://doi.org/10.1016/j.culher.2009.10.007.

Kapsalas P, Maravelaki-Kalaitzaki P, Zervakis M, Delegou ET, Moropoulou A. Optical inspection for quantification of decay on stone surfaces. NDT & E International. 2007. https://doi.org/10.1016/j.ndteint.2006.07.012.

Fortes FJ, Cabalín LM, Laserna JJ. The potential of laser-induced breakdown spectrometry for real time monitoring the laser cleaning of archaeometallurgical objects. Spectrochim Acta Part B At Spectrosc. 2008. https://doi.org/10.1016/j.sab.2008.06.009.

Colao F, Fantoni R, Lazic V, Caneve L, Giardini A, Spizzichino V. LIBS as a diagnostic tool during the laser cleaning of copper based alloys: experimental results. J. of Analytical Atomic Spectrometry. 2004. https://doi.org/10.1039/B315488B.

Targowski P, Iwanicka M. Optical Coherence Tomography: its role in the non-invasive structural examination and conservation of cultural heritage objects—a review. Appl. Phys. A. 2012. https://doi.org/10.1007/s00339-011-6687-3.

Striova J, Fontana R, Barucci M, Felici A, Marconi E, Pampaloni E, Raffaelli M, Riminesi C. Optical devices provide unprecedented insights into the laser cleaning of calcium oxalate layers. Microchemical Journal. 2016. https://doi.org/10.1016/j.microc.2015.09.005.

Márton Zs, Kisapáti I, Török Á, Tornari V, Bernikola E, Melessanaki K, Pouli P. Holographic testing of possible mechanical effects of laser cleaning on the structure of model fresco samples NDT&E INTERNATIONAL. 2014. https://doi.org/10.1016/j.ndteint.2014.01.007.

Tornari V, Bernikola E, Hatzigiannakis K, Melessanaki K, Pouli P. Synchronized deformation monitoring in laser cleaning: an application for Cultural Heritage conservation. Universal Journal of Physics and Application. 2013. https://doi.org/10.13189/ujpa.2013.010215.

Tserevelakis GJ, Pozo-Antonio JS, Siozos P, Rivas T, Pouli P, Zacharakis G. On-line photoacoustic monitoring of laser cleaning on stone: Evaluation of cleaning effectiveness and detection of potential damage to the substrate. J Cul Her. 2018. https://doi.org/10.1016/j.culher.2018.05.014.

Papanikolaou A, Tserevelakis GJ, Melessanaki K, Fotakis C, Zacharakis G, Pouli P. Development of a hybrid photoacoustic and optical monitoring system for the study of laser ablation processes upon the removal of encrustation from stonework. Opto-Electronic Advances. 2020. https://doi.org/10.29026/oea.2020.190037.

Tserevelakis GJ, Pouli P, Zacharakis G. Listening to laser light interactions with objects of art: a novel photoacoustic approach for diagnosis and monitoring of laser cleaning interventions. Herit Sci. 2020. https://doi.org/10.1186/s40494-020-00440-w.

Frantzikinaki K, Panou A, Vasiliadis C, Papakonstantinou E, Pouli P, Ditsa Th, Zafiropulos V, Fotakis C. The cleaning of the Parthenon west frieze: an innovative laser methodology. In: Kwiatkowski D, Lofvendahl R, editors. The proceedings of the 10th International Congress on Deterioration and Conservation of Stone, ICOMOS; 2004, Stockholm Sweden, pp. 801–808.

Frantzikinaki K, Marakis G, Panou A, Vasiliadis C, Papakonstantinou E, Pouli P, Ditsa Th, Zafiropulos V, Fotakis C. The Cleaning of the Parthenon West Frieze by Means of Combined Infrared and Ultraviolet Radiation. In: Nimmrichter J, Kautek W, Schreiner M, editors. Springer Proceedings in Physics 116, 2007. pp. 97–104. https://doi.org/10.1007/978-3-540-72130-7_12.

Pouli P, Zafiropulos V, Balas C, Doganis Y, Galanos A. Laser cleaning of inorganic encrustation on excavated objects: evaluation of the cleaning result by means of multi-spectral imaging. J. Cult. Heritage. 2003. https://doi.org/10.1016/S1296-2074(02)01217-7.

Sarantopoulou E, Kollia Z, Gomoi I. Preventing biological activity of Ulocladium sp spores in artifacts using 157 nm laser. Appl. Phys. A. 2006. https://doi.org/10.1007/s00339-006-3554-8.

López AJ, Lamas J, Ramil A, Yáñez A, Rivas T, Taboada J. Optimization of laser cleaning parameters for the removal of biological black crusts in granites. In: Radvan R, Asmus JF, Castillejo M, Pouli P, Nevin, editors. Lasers in the Conservation of Artworks VIII. London: Taylor & Francis Books; 2010. pp. 105. https://doi.org/10.1201/b10567-18.

Speranza M, Sanz M, Oujja M, de los Rios A, Wierzchos J, Pérez-Ortega S, Castillejo M, Ascaso C. Nd-YAG laser irradiation damages to Verrucaria nigrescens. International Biodeterioration & Biodegradation. 2013. https://doi.org/10.1016/j.ibiod.2012.02.010.

Mascalchi M, Osticioli I, Cuzman OA, Mugnaini S, Giamello M, Siano S. Laser removal of biofilm from Carrara marble using 532 nm: The first validation study. Measurement. 2018. https://doi.org/10.1016/j.measurement.2018.08.012.

Costela A, García-Moreno I, Gomez C, Caballero O, Sastre R. Cleaning graffitis on urban buildings by use of second and third harmonic wavelength of a Nd:YAG laser: A comparative study. Appl. Surf. Sci. 2003. https://doi.org/10.1016/S0169-4332(02)01241-2.

Gomez C, Costela A, García-Moreno I, Sastre R. Comparative study between IR and UV laser radiation applied to the removal of graffitis on urban buildings. Appl. Surf. Sci. 2006. https://doi.org/10.1016/j.apsusc.2005.04.051.

Sanjeevan P, Klemm AJ, Klemm P. Removal of graffiti from the mortar by using Q-switched Nd:YAG laser. Appl. Surf. Sci. 2007. https://doi.org/10.1016/j.apsusc.2007.04.030.

Samolik S, Walczak M, Plotek M, Sarzynski A, Pluska I, Marczak J. Investigation into the removal of graffiti on mineral supports: Comparison of nanosecond Nd:YAG laser cleaning with traditional mechanical and chemical methods. Stud. Conserv. 2015. https://doi.org/10.1179/0039363015Z.000000000208.

Pozo-Antonio JS, Rivas T, Fiorucci M.P, López AJ, Ramil A. Effectiveness and harmfulness evaluation of graffiti cleaning by mechanical, chemical and laser procedures on granite. Microchem. J. 2016. https://doi.org/10.1016/j.microc.2015.10.040.

Doganis Y, Galanos A, Legakis A, Pouli P, Melessanaki K. The conservation of fifteen islamic plaster stained glass windows, the Benaki Museum Islamic Art Collection. In: Kwiatkowski D, Lofvendahl R, editors. Proceedings of the 10th International Congress on Deterioration and Conservation of Stone: Stockholm, June 27-July 2, 2004. Stockholm: ICOMOS Sweeden; 2004. pp. 1025–1032. ISBN: 9163114585

Rozniakowski K, Klemm P, Klemm AJ. Some experimental results of laser beam interaction with surface layer of brick. Building and Environment. 2001. https://doi.org/10.1016/S0360-1323(00)00012-3.

Pozo-Antonio JS, Rivas T, López AJ, Fiorucci MP, Ramil A. Effectiveness of granite cleaning procedures in cultural heritage: A review. Science of the Total Environment. 2016. https://doi.org/10.1016/j.scitotenv.2016.07.090.

Pozo-Antonio JS, Papanikolaou A, Philippidis A, Melessanaki K, Rivas T, Pouli P. Cleaning of gypsum-rich black crusts on granite using a dual wavelength Q-Switched Nd:YAG laser. Constr. Build. Mater. 2019. https://doi.org/10.1016/j.conbuildmat.2019.07.298.

Platia N, Chatzidakis M, Doerr C, Charami L, Bekiari Ch, Melessanaki K, Hatzigiannakis K, Pouli P. ‘POLYGNOSIS’: the development of a thesaurus in an Educational Web Platform on optical and laser-based investigation methods for cultural heritage analysis and diagnosis. Herit. Sci. 2017. https://doi.org/10.1186/s40494-017-0163-0.

Acknowledgments

This manuscript reflects knowledge gained within the past 20 years through multidisciplinary research carried out at IESL-FORTH. Fruitful teamwork with all the colleagues who contributed to the experiments and applications, as presented in the original publications, is acknowledged, while the guidance and collaboration from the personnel of the Acropolis Restoration Service, the Acropolis Museum, “Lithou Sintirissis” Conservation Associates, and the Ephorate of Antiquities of Heraklion in Crete is considered particularly important. Financial support by several National, European, and other funds was decisive for this research. The EU Research Infrastructures operating at FORTH (a) ULF-FORTH offering transnational access since 1990 as an active partner and among the founders of LASERLAB Europe, (b) IPERION-CH, H2020-GA-654028, (c) IPERION-HS, H2020-GA-871034 and (d) E-RIHS.eu) ensured the ideal research environment to strengthen the laser research landscape and foster networking between the laboratories and CH end-users.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Pouli, P. (2022). Laser Cleaning on Stonework: Principles, Case Studies, and Future Prospects. In: Gherardi, F., Maravelaki, P.N. (eds) Conserving Stone Heritage. Cultural Heritage Science. Springer, Cham. https://doi.org/10.1007/978-3-030-82942-1_3

Download citation

DOI: https://doi.org/10.1007/978-3-030-82942-1_3

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-82941-4

Online ISBN: 978-3-030-82942-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)