Abstract

Sustainable textile design without harming the environment nowadays is one of the most important issues in the textile industry. Environmental concerns lead various researchers and artists to find and explore the applicability of more sustainable, renewable, and environment-friendly resources for fibers and colorants. In here, bacteria can help us. Microbial (bacterial) cellulose is an organic compound of the formula (C6H10O5)n produced by certain types of bacteria. On the one hand, the material produced by the advancements in the detection and synthesis methods of bacterial cellulose, the resultant bacterial cellulose can be used in a wide range of commercial applications comprising textile, medical, cosmetic, and food applications and products. From the textile point of view, apart from bacterial cellulose production for textile substrates, bacteria can also be utilized for textile coloration. Indeed, bacteria can also produce colored pigments. It is now possible to produce some bacterial pigments for food, pharmaceutical, cosmetic, and textile applications. For instance, specific bacterial pigments can be used successfully as textile colorants. Therefore, bacteria are now working for us to create sustainable textile materials and textile colorants leading to more sustainable textile design. In this chapter, information about sustainable bacterial cellulose for textile substrates and sustainable bacterial pigments as sustainable textile colorants is given in detail.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

Introduction

Sustainable textile design without harming the environment nowadays is one of the most important issues in the textile industry. Today, our clothes can be produced using many natural or synthetic fibers. However, it is well known that the use of water to produce plants such as cotton, where the water demand is increasing considerably, can be quite high. On the other hand, it is a known fact that petroleum-based fibers may not be produced due to the depletion of fossil fuels in the future. These reasons lead various researchers and artists to find and explore the applicability of more sustainable, renewable, and environment-friendly resources for fibers and dyes.

Microbial (bacterial) cellulose is an organic compound of the formula (C6H10O5)n produced by certain types of bacteria . Cellulose is the basic structural material of many plant substances but is also produced by bacteria from the genera Acetobacter, Sarcina ventriculi, and Agrobacterium. Bacterial or microbial cellulose exhibits different characteristics than vegetable-plant-based cellulose. These properties can be characterized as high purity, strength, moldability, and increased water retention. While bacterial cellulose can be produced in nature, a wide variety of methods are currently under investigation to increase cellulose growth from suitable cultures in laboratories for larger-scale commercial production. By effective control of the methods and conditions, it is stated that microbial celluloses with the desired specific properties can be developed. Therefore, nowadays, bacterial cellulose can be utilized in a wide variety of commercial applications such as textile, medical, cosmetic, and food applications and products with the material produced by the advancements in the detection and synthesis methods of bacterial cellulose.

The first discovery of bacterial cellulose was made in 1886 by A.J Brown (by Acetobacter xylinum bacteria). However, no intensive studies have been conducted on bacterial cellulose until the twentieth century. Later, other researchers have reported the formation of cellulose from other various organisms (such as Acetobacter pasteurianum, Acetobacter rancens, Sarcina ventriculi, and Bacterium xylinoides bacteria). In 1949, the microfibril structure of bacterial cellulose was characterized by Muhlethaler. Today, studies on bacterial cellulose continue in an increasing trend. Many researchers and artists began to look for alternative materials to cotton fiber. BioCouture is one of these alternatives. It is a radical project that expands the vision of the future, using nature, and is an idea from Suzan Lee’s Fashioning the Future: Tomorrows Wardrobe. The project team examined the usability of microbial cellulose growing in the laboratory to produce clothing. The aim of the team was to grow microbial cellulose to form a complete garment on a liquid boat and to create the targeted textile garment in this way.

Additionally, interest and search in natural dye alternatives increases in textile applications due to the fact that synthetic dyes can be toxic to humans and nature, and also too much water is used in the conventional dyeing processes. However, due to some disadvantages about extraction difficulty of natural dyes from plants and the need for large cultivation areas for mass commercial productions, the utilization of microorganisms as a source of dyes and pigments comes on the agenda, and researches have been conducted on microbial dyes. In the industry, it is now possible to produce some bacterial pigments for food, pharmaceutical, cosmetic, and textile applications. Frankly, from the textile point of view, apart from bacterial cellulose production for textile substrates, bacteria can also be used for textile coloration. Since bacteria can produce colored pigments. Pigment-producing bacteria can produce many different colors from all colors of the rainbow to unusual colors such as black, white, brown, gold, silver, fluorescent green, yolk, or blue. Red and purple pigments (known as prodigiosin and violacein, respectively) were applied to different fabrics such as acrylic, silk, cotton, polyester, and polyester microfibers. All pigments were found to have high staining and dyeing ability on fabrics. All these findings indicate that specific pigments can be utilized successfully as textile colorants. New type of safe and effective natural dyes and pigments can be used potentially instead of harmful conventional synthetic dyes.

Therefore, bacteria are now working for us to create sustainable textile materials and textile colorants leading to sustainable textile design. In this review chapter, information regarding sustainable bacterial cellulose for textile substrates and bacterial pigments as sustainable textile colorants is given in detail. In the first part of this chapter, bacterial cellulose, its history, and bacterial pigments are introduced. In the second part of the chapter, extended information about bacterial cellulose and its interesting application areas are given. Finally, in the third part, coloration with bacterial pigments is examined.

Bacterial Cellulose and Its Application Areas

In the production stages of many natural or synthetic fiber-based textile materials, massive amount of water is used. However, it is an important fact that oil-based fibers will be eventually depleted as a result of depletion of fossil fuels. These reasons lead various researchers and artists to search more sustainable, renewable, and environment-friendly resources for tomorrows’ textiles (Biocuture 2014). Suzan Lee, one of these researchers, established BioCouture when she began to look for alternative materials to cotton fiber (Biocuture 2014). BioCouture is a radical research project that uses nature and sheds light on the vision of the future fashion and is an idea from Suzan Lee’s book Fashioning the Future: Tomorrow’s Wardrobe (Biocuture 2014; Growing Your Own Fabric is Possible 2014). The project team examined the usability of microbial cellulose growing in the laboratory to produce garments (Biocuture 2014). As aforementioned, the material produced by the advancements in the detection and synthesis methods of bacterial cellulose, the resultant bacterial cellulose could be utilized in a wide range of commercial applications comprising textile, medical applications, cosmetics, and food products.

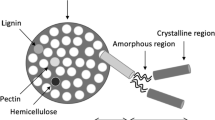

Cellulose is one of the most common polymers in the world (Güzel and Akpınar 2018). Although cellulose of formula (C6H10O5)n is the basic structural material of many plant materials, it can also be produced by Komagataeibacter, Gluconacetobacter, Acetobacter, Agrobacterium, Aerobacter, Achromobacter, Alcaligenes, Azotobacter, Pseudomonas, Rhizobium, and Sarcina (Güzel and Akpınar 2018; Wikipedia 2014; Dursun et al. 2006; Tozluoğlu et al. 2015; Costa et al. 2017). This type of cellulose is the first product of bacterial metabolism and serves as a cell protector (Güzel and Akpınar 2018). Bacterial or microbial cellulose is distinguished from vegetable cellulose by its properties such as high purity, strength, molding suitability, and increased water retention ability (Güzel and Akpınar 2018; Wikipedia 2014). Bacterial cellulose is about 100 times thinner and porous than vegetable cellulose (Fig. 1). During the synthesis of this cellulose, glucose chains are secreted from the bacterial cell wall and nanofibril cellulose strips are formed. The diameters of these strips were reported to be in the range of 10–100 nm (Güzel and Akpınar 2018; Tozluoğlu et al. 2015; Costa et al. 2017). Bacterial cellulose production is also 40 times faster than vegetable-plant cellulose production (Dursun et al. 2006).

Porous structure and width of bacterial cellulose fibers (Goh et al. 2012; https://commons.wikimedia.org/wiki/File:Sizes.png)

The comparison of the mechanical properties of bacterial cellulose (BC) with other fibers is given in Table 1 (Costa et al. 2017). Intermolecular and molecular hydrogen bonds hold the cellulose chains together, thus providing bacterial cellulose fibers with properties such as low solubility and high water retention, as well as high purity, mechanical resistance, elasticity, flexibility, and biocompatibility. BC membranes are elastic and flexible and can be sterilized. In the scientific world, bacterial cellulose is now being investigated and explored to find new potential usage possibilities in various fields (Costa et al. 2017).

Although the first discovery of bacterial cellulose with the utilization of Acetobacter xylinum bacteria by Adrean J. Brown was in 1886, the intensive works on bacterial cellulose have begun only after the twentieth century (Wikipedia 2014; Dursun et al. 2006; Costa et al. 2017; Tiboni et al. 2014). Brown vinegar fermentation studies observed a pellet-gelatinous heap on the surface of the liquid. Further analysis showed that this layer is actually cellulose (Dursun et al. 2006). Researchers reported that cellulose can actually be manufactured from various organisms such as Acetobacter pasteurianum, Acetobacter rancens, Sarcina ventriculi, and Bacterium xylinoides, and in 1949, the microfibril structure of bacterial cellulose was characterized by Muhlethaler (Fig. 2) (Wikipedia 2014; Costa et al. 2017). Today, bacterial cellulose studies are still continuing.

Chemical structure of bacterial cellulose (https://commons.wikimedia.org/wiki/File:Structure_of_a_bacterial_cellulose_synthase.png)

It is very interesting that bacterial cellulose is used as a local food (Nata) in Southeast Asia. What is more, it is also used in the production of some functional drinks (kombu and Manchurian tea) (Güzel and Akpınar 2018). It is possible to produce bacterial cellulose in nature, but studies are still continuing in the laboratories in order to realize large-scale production. Various methods are being investigated to enable the production of bacterial cellulose in larger sizes than appropriate cultures (Wikipedia 2014). Today, Acetobacter xylinum cellulose is used as a model microorganism in biosynthesis studies (Dursun et al. 2006). Another type of bacteria used today is Gluconacetobacter xylinus . This bacterium was taken as a model of microorganism in biosynthesis and crystallization and in obtaining structural characteristics of bacterial cellulose. More than 100 pores present in the membrane of this microorganism allow the extrusion of cellulose to form a fibril element with a diameter of 3.5 nm. Approximately 46 contiguous fibrils join along hydrogen bonds to form a band having a width of 40–60 nm. The bands are wound to form the other entangled fibers dispersed in the culture medium. Its thickness depends on the culture time and can usually reach to 1 or 2 cm (Costa et al. 2017; Pecoraro et al. 2008; Wood 2007). Using a bacterium G. xylinus and Gluconacetobacter hansenii, 2% glucose (as a carbon source), pH 5–7, and a temperature range of 25–37 °C begin to form a viscous gel after 2 h (Costa et al. 2017).

Nowadays, bacterial cellulose could be used in a wide variety of commercial applications such as textile, medical, cosmetic, and food applications and products with the advancements in the synthesis of the material production and the detailed determination of the bacterial cellulose properties (Güzel and Akpınar 2018; Wikipedia 2014; Dursun et al. 2006). For instance, London fashion designer Suzan Lee (senior lecturer at Central Saint Martins Textile Fashion School in London) has been able to grow a kind of vegetable skin using green tea, sugar, bacteria, and yeast (Biocuture 2014; Growing Your Own Fabric is Possible 2014; Wood 2007; Lee 2014; 10 Eco-Fashion Garments Inspired by Nature and Biomimicry 2012; Alter Nature: The Future That Never Was 2011; Arcadia Boutique 2011). In kombucha tea, a kind of fermented tea, it is possible to produce BioCouture extract and dry cellulose with the help of bacteria, tea, and sugar which are used for fermentation (Fig. 3) (Biocuture 2014). Kombucha tea is a fermented beverage/drink prepared from tea, sugar, bacteria, and yeast (Wood 2007; Bauer 2014).

Kombucha tea, microorganisms, and mother of kombucha tea (https://upload.wikimedia.org/wikipedia/commons/b/b8/Kombucha_fermenting_black_tea.jpg; https://upload.wikimedia.org/wikipedia/commons/4/4a/Kombucha_mushroom.jpg; https://upload.wikimedia.org/wikipedia/commons/f/f6/Kombuchacultsm.jpg)

Yeast is added to the tub containing sweetened tea and bacteria to produce bacterial cellulosic fibers, which then turn into a skin-like state (thin bacterial cellulose leaves) (Biocuture 2014; Costa et al. 2017; Lee 2014). This material is a by-product of the fermentation process and can remain in the tub for about 2 weeks (under the controlled temperature conditions) to reach a sufficient thickness to produce garments. This layer is then taken and dried to form a final layer or dried to mold in order to produce jackets, clothing, or other types of end-use-product garments (Biocuture 2014; Costa et al. 2017). As the layers dry, the overlapping edges fuse and form seams. When all fibers dry, the garment can be colored with natural plant dyes or bleached if used as white (Biocuture 2014; Costa et al. 2017; Lee 2014; 10 Eco-Fashion Garments Inspired by Nature and Biomimicry 2012). Using this material, Lee has been able to produce many different types of garments such as jackets, dresses, shoes, kimono, shirts, etc. Shoes also were made as part of the BioCouture project (Fig. 4). In this study, nine green tea bags in plastic containers, 540 g sugar, 632 mL vinegar, and 100 g commercial combo yeast bacterial cellulose were created and used for Scarlett and Rhett designs (Nam and Lee 2016).

Having studied at Central Saint Martins Textile Fashion School, Erdem Kızıltoprak has combined fashion, textile, and science and technology in his collection. In his study, he aimed to design modern body jewelry for men. In Kiziltoprak’s work, kombucha tea, kombucha yeast (mixture of yeast and bacteria), sugar content, and black/green tea mixture were used to grow its own fabric (Coleman 2011).

Another designer, Sammy Jobbins Wells, stretched the bacteria-made material to make wearable objects and placed them on previously prepared frames. Wells says her first inspiration was Suzanne Lee’s BioCouture project. He used kombucha-cultured bacterial cellulose in his project. Wells stated that cellulose was very flexible and durable when wet and that it was very difficult to remove bacterial cellulose having a thickness of more than 2 mm. It was also stated that when the material dries, it retains much of its strength and exhibits a structure and attitude similar to old human skin. Wells kept a mixture of glucose, tea, and water at room temperature to produce the material. Tea is added as a nutrient for bacteria and gives color to the final material. Wells stated that the material has some defects. For instance, unfortunately, the material is not waterproof in its present form, and if it comes into contact with constant moisture, it will eventually return to its original wet state (Dezeen 2014; http://www.2014interiorideas.com/beauty-and-fashion/wearable-structure-of-bacteria-references-antique-animal-bone-corsets.html).

Rachel Trattles conducted a bio-jewelry study using bacterial cellulose. In Rachel’s study, Rachel used green tea, yeast, bacteria, and vinegar to obtain bacterial cellulose (Trattles 2014). Some graduate students at the University of Iowa also obtained bacterial cellulose from the fermented green tea bacteria and yeasts, along with sustainable biopolymers from corn and soybean oil, which are agricultural plant products. This project team is one of the 7 teams to win awards among 40 teams at the National Sustainable Design Expo in Washington (National Sustainable Design Expo 2014).

According to Bunch, bacterial cellulose membranes are durable and can be dyed naturally. Therefore, clothes can be produced (Costa et al. 2017). In 2012, microbial cellulose produced from kombucha tea was characterized in a study. In order to characterize the produced microbial cellulose, SEM, FTIR, and X-ray diffractometry analyses were carried out, and also swelling properties were examined. The SEM results showed that the microbial cellulose layer exhibits an ultrafine mesh structure of compact cellulose. FTIR results also displayed that microbial cellulose does not contain contaminants such as lignin or hemicellulose (Goh et al. 2012).

In a study conducted in 2018, the current state of bacterial cellulose in the development of textile was examined, and innovative cultivation techniques were tried to adapt to different usage forms and forms of bacterial cellulose in various garments. Novel bacterial cellulose cultivation techniques shaped as cut in tailor not only improve the environmental values of this material but also improve the production method as a sustainable application. This organic material can be grown in any desired garment panel, providing less textile waste without the need to cut. Two different sowing techniques have been developed, called contact surface blocking sowing and panel-shaped sowing. The naturally degradable bacterial cellulose with its self-synthesized property can shed light on the development of sustainable new textile materials and production applications in the future (Chan et al. 2018).

In a recent study conducted in 2019, strength and thinness values of bacterial cellulose obtained from kombu tea were examined. Thus, the usability of bacterial cellulose in the fashion industry was also investigated. Owing to the presence of fermentation residues, the bacterial cellulose is sensitive to drying temperature. The best deformation characteristics are maintained when the bacterial cellulose material is dried at low temperature (about 25 °C). Bacterial cellulose material hardens at high drying temperatures due to rapid water vapor effect and tears when lower deformations are applied. Over time, it has been confirmed that the properties of bacterial cellulose have changed significantly and that the final products may have problems with the durability of this material (Domskiene et al. 2019). In 2019, a wallet was developed using leather-like textiles, namely, bacterial cellulose. As an outcome of this study, it was that the products that are tried to be developed by using bacterial cellulose may be more suitable for disposable plastics rather than textile applications (https://plantchicago.org/2019/05/29/scoby-textiles-part-2/). Apart from clothing, German designer Jannis Hülsen covered a stool with bacterial cellulose (Jannis Hülsen 2012). In addition to these applications, bacterial cellulose was also used in the medical field in a study conducted in Germany. In this study, bacterially synthesized nano-cellulose was tested for use in wound therapy by combining with various active ingredients (Views 2010).

Although the presence of bacterial cellulose produced by bacteria and yeasts was discovered in the late 1800s, it was expected to come to life in various innovative applications. Bacterial cellulose applications in the textile field have not yet reached an industrial scale. However, the potential future for bacterial cellulose is far beyond existing practices, especially if explorations can develop large-scale production processes using low-cost raw materials or agro-industrial waste. In addition to the economic potential of this biotechnology polymer, investment in research and industrial interest in the production of this high value-added polymer will not only reduce the disposal of by-products by reusing industrial wastes but also reduce global forest destruction (Costa et al. 2017).

In our world, where natural resources are about to be exhausted, the availability of renewable, environmentally friendly, and sustainable resources is becoming increasingly important. Therefore, with the interesting and improvable properties of bacterial cellulose, it makes it a promising potential biomaterial that plays an active role in the textile and medical applications of the future. From the textile point of view, apart from bacterial cellulose production for textile substrates, bacteria can also be used for textile coloration. Textile coloration with bacterial pigments is covered in the next section.

Coloration with Bacterial Pigments

Recently, since the problem of depletion of clean water resources is becoming more and more important, there is increasing interest and attention in the utilization of sustainable, renewable, and natural colorant resources instead of possible toxic and polluting synthetic dyes. However, significant water consumption in the extraction or cultivation of natural plant dyes and the need for large planting areas also necessitate the new searches for alternative colorant solutions. The use of microorganisms as a source of colorants comes to the fore and researches are carried out on microbial pigments. In the industry, it is now possible to produce some bacterial pigments for food, pharmaceutical, cosmetic, and textile applications (http://enneblog.com/; Venil et al. 2013; http://www.amm-mcrc.org/programmes/biotech/Pigments.html; Ökmen and Dilek 2014; Perumal et al. 2009). There is growing interest in the utilization of microorganisms as a color source because less labor and less soil is needed and bacterial colorants are more cost-effective than plant-based colorants (Perumal et al. 2009).

In the industry, it is now possible to produce some bacterial pigments for food, pharmaceutical, cosmetic, and textile applications. Indeed, bacteria can produce colored pigments (http://www.biotecharticles.com/Applications-Article/Colorful-Bacteria-612.html). Microorganisms produce a wide variety of stable pigments such as carotenoids, flavonoids, quinones, and verubramins and have higher yields than fermentation products of plants and animals (Gurcum and Ones 2018). Pigment-producing bacteria have many colors ranging from all colors of the rainbow to unusual colors such as black, white, brown, gold, silver, fluorescent green, yellow, or blue (http://www.biotecharticles.com/Applications-Article/Colorful-Bacteria-612.html). In the 2000s, yellow-orange, red, and purple pigments were obtained from bacteria such as Chryseobacterium sp., Serratia marcescens, and Chromobacterium violaceum, respectively (http://microbewiki.kenyon.edu/index.php/Industrial_Applications_of_Bacterial_Pigments). It has also been reported that textile materials are colored using these pigments. Red and purple pigments (known as prodigiosin and violacein, respectively) were applied as colorants to different fabrics such as acrylic, silk, cotton, polyester, and polyester microfiber. These pigments are told to have high staining ability on fabrics. This shows that bacterial pigments can be successfully used as textile colorants. New safe and effective natural dyes and pigments can substitute or take the place of potentially harmful synthetic dyes (http://microbewiki.kenyon.edu/index.php/Industrial_Applications_of_Bacterial_Pigments). For example, one of the most researched pigments of microbial origin is prodigiosin. Prodigiosins belong to the natural red pigment family. Prodigiosin was commercially produced for a short time before the synthetic chemical dyes were developed and utilized for dyeing silk and wool. Over the past years, interest in prodigiosins, as textile dyes, has been revived, and a small number of publications have been produced. It was suggested that biosynthetic prodigiosins can be utilized as a functional colorant for different textile materials (Kramar et al. 2014).

In addition to bacteria, fungal pigments are also alternative sources of synthetic pigments/dyes. Among the pigment-producing fungi identified, Aspergillus rubber, Aspergillus glaucus, and Trichoderma viride were reported to produce red, yellow, and yellow-green pigments, respectively. Fungi were obtained from barley in orange pigments from Ganoderma lucidum, Coriolus versicolor, and Amanita muscaria and applied to silk and cotton fabrics. Many fungi produce pigments from mycelium under natural growth conditions and when grown in a nutrient medium or body (Perumal et al. 2009).

As a result of the studies, the majority of bacteria are perceived (voting on a subject affecting the colony and reporting their presence to other bacteria), chemotactic signaling (movement of the organism in response to a chemical stimulus; detection of positive and harmful objects in the environment), and plasmid exchange (for transfer of antibiotic-resistant genes) (https://isea2011.sabanciuniv.edu/paper/communicating-bacteria; http://www.wellcome.ac.uk/News/2011/News/WTVM052287.htm). For instance, Chromobacterium violaceum is a common soil bacterium which produces striking purple colonies (https://isea2011.sabanciuniv.edu/paper/communicating-bacteria; http://exploringtheinvisible.com/page/4/). The color produced by these bacteria depends on the communication between the bacteria. If there is a small amount of bacteria, the color turns white, and if another bacterium receives notification, the color turns purple. If grown in the colony, individuals of these species constantly send and receive notifications to other bacteria, and as a result the colony turns purple (https://isea2011.sabanciuniv.edu/paper/communicating-bacteria; http://exploringtheinvisible.com/page/4/).

The advantages of using bacterial pigments as dyestuff (Gurcum and Ones 2018):

-

Versatile and easy to produce compared to other sources.

-

The ability to obtain different colors and shades by interfering with genes.

-

Easy propagation and low cost for industrial production.

However, in addition to these mentioned advantages, it has been shown in the recent studies that industrial applications are needed for large-scale production of bacterial pigments produced by designers in small petri dishes (Gurcum and Ones 2018). The latest advances in molecular biology are utilized to make the production of bacterial pigment economically feasible. The production of these pigments can be increased by cloning genes responsible for the biosynthesis of a large number of pigments. Some scientists have succeeded in producing indigo on an industrial scale using the Escherichia coli bacteria in fermentation tanks. Furthermore, the process can be modified by biosynthetic means to form the molecular structure and hence the color of a bacterial pigment. Streptomyces coel producing blue pigment actinorhodine has been genetically modified to produce a polyketite which exhibits bright yellow color. Alternatively, studies have been conducted to produce orange or yellow-red colors. In order to use bacterial pigments in a wide range, they should avoid environmental factors, especially UV light. UV light initiates the reaction of free radicals leading to the deterioration of the pigments (Gurcum and Ones 2018). Studies on coloration textile materials by using pigments obtained from these bacteria and fungi have been going on since the beginning of the 2000s, and many artistic and scientific coloration processes were carried out.

For the last 30 years, Anna Dumitriu has been working with medical microbiologists (http://www.ecouterre.com/anna-dumitriu-embroiders-deadly-bacteria-antibiotics-into-textiles/anna-dumitriu-super-bug-quilt-11/). Dumitriu and Sue Craig investigated whether natural and sustainable bacterial pigments can be used in textile coloration. The starting points were Serratia marcescens red-pigmented bacteria and Chromobacterium violaceum purple-pigmented bacteria (Fig. 5) (http://exploringtheinvisible.com/2013/07/18/biodyes-2/).

Serratia marcescens and Chromobacterium violaceum bacteria in petri dish (https://commons.wikimedia.org/wiki/File:Serratia_marcescens.jpg)

Dumitriu also grew the MRSA bacteria (Methicillin-resistant Staphylococcus aureus) (Fig. 6) on fabric to produce colored fabrics (http://www.smithsonianmag.com/arts-culture/artist-dyes-clothes-quilts-tuberculosis-and-staph-bacteria-180949511/?no-ist).

Staphylococcus aureus and its color (https://commons.wikimedia.org/wiki/File:Staphylococcus_aureus_VISA_2.jpg; https://commons.wikimedia.org/wiki/File:MRSA_on_Brilliance_MRSA_Chromogenic_Agar.jpg)

After all these studies, Dumitriu produced a dress stained with vancomycin (an antibiotic species)-resistant Staphylococcus variant (VRSA), a bacterium more dangerous than MRSA (Fig. 7) (http://www.smithsonianmag.com/arts-culture/artist-dyes-clothes-quilts-tuberculosis-and-staph-bacteria-180949511/?no-ist). In another work, microbiologists Dr. Simon Park and Dr. John Paul, working with video artist Alex May, obtained and presented a dress as a result of their communicating bacteria project (https://isea2011.sabanciuniv.edu/paper/communicating-bacteria; http://www.wellcome.ac.uk/News/2011/News/WTVM052287.htm).

An autogenic textile design was carried out by inoculating bacteria growing on polyester/cotton fiber blended fabrics. In this study, the fabric was colored with completely natural bacterial pigments. The final design of the colored fabric is determined by the interaction of bacteria with each other. Red and purple bacteria are aggressive and want to cover a larger area on the fabric. Invaded regions also contain other bacterial species. Blue and orange-brown bacteria produce antibiotics and establish defense zones. Here, other bacteria die and invasion was prevented (http://exploringtheinvisible.com/page/4/). A similar method was used in the study of communicating bacteria.

Anna Dumitriu also exhibited a silk dress she designed using bacterial pigments, natural and synthetic antibiotics in an exhibition at the modern art museum (MOCA) in Taipei (http://annadumitriu.tumblr.com/post/68010439679/anna-dumitriu-has-created-a-new-work-the). Designer and researcher Natsai Audrey Chieza has also developed a new method to color fabrics with pigments produced from bacteria (Biocuture 2014).

Natsai Chieza also colorized a silk scarf with soil bacteria that produce beautiful colors such as dark blue, indigo, orange, and blood red (Fig. 8) (http://www.wired.co.uk/magazine/archive/2014/04/play/to-live-and-dye). According to Natsai Chieza, microbes have their own cellular color and can produce pigments of different colors. Chieza observed that these colors stain and color various types of silk fiber fabrics. As a result, Chieza wanted to modify the genetics of bacteria in order to produce the different colors demanded by fashion houses (http://www.wired.co.uk/magazine/archive/2014/04/play/to-live-and-dye). The basis of the research is that the Streptomyces bacteria commonly found in soil can be programmed to produce pigments when they grow under laboratory conditions. In this study, live bacterial isolates were inoculated into solids and directly into silk fibers. During a 7–14-day period in the laboratory environment, silk fabrics appear in terms of design according to environmental temperature, air circulation, and the effect of other factors affecting the speed and quality of pigmentation. Although the obstacles to the reproducibility of Chieza’s results in a petri dish remain on a larger scale, bacteria-colored textiles may be a different alternative to sustainable fashion in the near future (Gurcum and Ones 2018).

Scarf dyed with bacteria (https://lovin.ie/entertainment/celebs/the-future-of-fashion-these-silk-scarves-are-dyed-with-bacteria)

Nidiya Vomiting, an Indonesian textile designer, began to work on the coloring of textile surfaces with bacteria and microfungus pigments, inspired by the Aspergillus niger microfungus, which caused black spots on moist clothing (Gurcum and Ones 2018). In the studies of Nidiya, she performed various experiments using the black Aspergillus niger , the orange Monascus sp., the white Trichoderma bacteria, and the red-pink bacteria Serratia Marcescens which can grow in the moist environment of the bathrooms. The fabrics were sterilized in an autoclave at high temperature and pressure to prevent infection while working with bacteria. Therefore, in the studies of Nidiya, coloration has utilized natural fabrics such as silk and cotton that are resistant to high temperatures (Gurcum and Ones 2018).

Amsterdam designers Laura Luchtman and Ilfa Siebenhaar examined the effect of sound frequencies on the growth of bacterial pigments and the controllability of this process with the “Living Color” project. With this project, it was tried to give antibacterial properties to the fabrics without using chemicals and consuming less water (Gurcum and Ones 2018). In a project led by Dutch designer Jelte van Abbema, alternative printing inks made from soy or natural plant pigments were used, and a series of bacteria were planted on fabrics to “enlarge” prints. As a result, it was a living bask pressure that developed over time, changed color, and died. This may not currently have a place in clothing, but is widely used as an art form (Wood 2007; https://lovin.ie/entertainment/celebs/the-future-of-fashion-these-silk-scarves-are-dyed-with-bacteria).

In 2013, designers Johanna Glomb and Rasa Weber developed a printing technique using microalgae, which they called an “Algaemy” to give an aesthetic approach to algae. In this technique, a wooden textile printing machine was developed, and rubber pattern molds were turned into printing rolls on the cylindrical surface. In order to obtain pigment, algae were planted in water and grown on sunlight and carbon dioxide, and then the resulting liquid solution was heated by filtration. Then a paste-like paint was created and printed with a printing roller (Gurcum and Ones 2018).

In addition to artistic studies, scientific studies have also been carried out on coloring textile materials using microbial pigments. A study conducted in 2014 focused on the identification of milk fungi from a compost pit containing cow manure and biodynamic herbal preparations. Pigments were obtained from these fungi and applied on cotton yarn. In this study, the colors obtained by pigments at different pH values were also examined. In Table 2, the colors of the extract at different pH values are given (Perumal et al. 2009).

After the pigments were extracted, pigment coloration was done on cotton fabrics using different chemical and natural mordants (Table 3) (Perumal et al. 2009).

Pigments obtainable from microbial sources have many important advantages. For example, they can be produced in the desired quantity, and production is not dependent on climate, geographic conditions, and the whims of nature. It is therefore advantageous to obtain pigments from microorganisms, and there are many species of bacteria and fungi that can provide high color yield (Perumal et al. 2009).

In another study conducted in 2014, Streptomycetes used as pigment sources were utilized, and pigments obtained from these microorganisms displayed different colors. Cultures developed in-house were stored in the refrigerator until the studies were performed (Ökmen and Dilek 2014). In addition, the effects of pH and temperature on Streptomycetes were also investigated. Different pH, medium, and temperature values provided different colors. The results of the study showed that Streptomycetes can produce pigments in various shades. Further studies have indicated that these pigments can be used in textile coloration (Ökmen and Dilek 2014).

Two new strains of Streptomyces (NP2 and NP4) were isolated to obtain deep blue and red pigments. Crude mycelium extracts of both strains were utilized as bio-colorants in conventional textile coloration. The thus obtained bio-stimulant yield was 62 and 84 mg/g per micelle for NP2 and NP4, respectively. With these pigments, polyamide and acrylic fibers were colored in the deepest shades, polyester and triacetate fibers are marked, but at a much lower color depth, while cotton and cellulosic fibers are colored in weak shades (Kramar et al. 2014).

Conclusion

Nowadays, one of the most important issues in the textile industry is sustainable textile design without harming the environment. Environmental concerns lead various researchers and artists to find and explore the applicability of more sustainable, renewable, and environment-friendly resources for fibers and colorants. In here, bacteria can aid us. Bacterial cellulose is an organic compound of the formula (C6H10O5)n produced by certain types of bacteria. Cellulose is the basic structural material of many plant substances but can also be produced by bacteria such as Acetobacter, Sarcina ventriculi, and Agrobacterium. Although the presence of bacterial cellulose produced by bacteria and yeasts was discovered in the late 1800s, it was expected to come to life in various innovative applications. The material produced by the advancements in the detection and synthesis methods of bacterial cellulose, the resultant bacterial cellulose can be used in a wide range of commercial applications including textile, medical, cosmetic, and food applications and products. Bacterial cellulose applications in the textile field have not yet reached an industrial scale. However, the potential future for bacterial cellulose is far beyond existing practices, especially if explorations can develop large-scale production processes using low-cost raw materials or agro-industrial waste. In addition to the economic potential of this biotechnology polymer, investment in research and industrial interest in the production of this high value-added polymer will not only reduce the disposal of by-products by reusing industrial wastes but also reduce global forest destruction.

In our world, where natural resources are about to be exhausted, the availability of renewable, environmentally friendly, and sustainable resources is becoming increasingly important. Therefore, with the interesting and improvable properties of bacterial cellulose, it makes it a promising potential biomaterial that plays an active role in the textile and medical applications of the future. From the textile point of view, apart from bacterial cellulose production for textile substrates, bacteria can also be used for textile coloration.

The interest and search in natural dye alternatives increases in textile applications due to the fact that synthetic dyes can be toxic to humans and nature, and also too much water is used in the conventional dyeing processes. However, due to some disadvantages about the extraction difficulty of natural dyes from plants and the need for large cultivation areas for mass commercial productions, the utilization of microorganisms as a source of dyes and pigments comes on the agenda, and researches have been conducted on microbial pigments. As a result of these developments, bacterial pigments can be used in textile as alternative colorants. Indeed, bacteria can also produce colored pigments. It is now possible to produce some bacterial pigments for food, pharmaceutical, cosmetic, and textile applications. For instance, specific bacterial pigments can be used successfully as textile colorants. Pigments obtainable from microbial sources have many important advantages. For example, they can be produced in the desired quantity, and production is not dependent on climate, geographic conditions, and the whims of nature. It is therefore advantageous to obtain pigments from microorganisms, and there are many species of bacteria and fungi that can provide high color yield.

Indeed, bacteria are now working for us to create sustainable textile materials and textile colorants leading to more sustainable textile design. Although the usage of bacterial cellulose and pigments for textile materials may seem to come out of science fiction films, it has now been proven that this is happening with many different examples, and such samples are expected to increase day by day. In conclusion, it is an undeniable fact that this can open great horizons for people as a result of its development leading to more sustainable textile production, therefore more sustainable world.

References

10 Eco-Fashion Garments Inspired by Nature and Biomimicry. 2012 [cited 2014 30.09]. Available from http://www.ecouterre.com/10-eco-fashion-garments-inspired-by-nature-and-biomimicry/3/

Alter Nature: The Future That Never Was. 2011 [cited 2014 30.09]. Available from http://inspir3d.net/2011/02/06/alter-nature-the-future-that-never-was/

Arcadia Boutique; Inspiring Individuals of the Ecofashion World! 2011 [cited 2014 30.09]. Available from http://arcadiaboutiquephilly.blogspot.com.tr/2011/07/inspiring-individuals-of-ecofashion.html

Bauer BA. What is Kombucha tea? Does it have any health benefits. [cited 2014 24.10]. Available from http://www.mayoclinic.org/healthy-living/consumer-health/expert-answers/kombucha-tea/faq-20058126

Biocuture. [cited 2014 30.09]. Available from https://www.tumblr.com/search/biocouture

Biocouture by Suzan Lee. [cited 2014 30.09]. Available from http://www.ecouterre.com/u-k-designer-grows-an-entire-wardrobe-from-tea-fermenting-bacteria/bio-couture-2/

Chan CK, Shin J, Jiang SXK (2018) Development of tailor-shaped bacterial cellulose textile cultivation techniques for zero-waste design. Cloth Text Res J 36(1):33–44

Coleman M. Bacterial motility: a second skin that grows and moves. 2011 [cited 2014 30.09]. Available from http://fashioningtech.com/profiles/blogs/bacterial-motility

Costa AFS, Rocha MAV, Sarubbo LA (2017) Bacterial cellulose: an ecofriendly biotextile. Int J Text Fashion Technol 7:11–26

Dezeen: bacteria produces textiles for skin body adornments. 2014 [cited 2014 30.09]. Available from: http://www.dezeen.com/2014/08/12/skin-sammy-jobbins-wells-wearable-objects-bacteria-cellulose/

Domskiene, J., Sederaviciute, F. and Simonaityte, J. (2019), “Kombucha bacterial cellulose for sustainable fashion”, International Journal of Clothing Science and Technology, Vol. 31 No. 5, pp. 644-652. https://doi.org/10.1108/IJCST-02-2019-0010

Dursun D, Yakar N, Çakır İ, Çakmakçı ML (2006) Mikrobiyel Selüloz Üretimi ve Gıda Sanayinde Kullanımı, Türkiye Gıda Kongresi, Bolu, 24–26 Mayıs 2006

Goh WN, Rosma A, Kaur B, Fazilah A, Karim AA, Bhat R (2012) Microstructure and physical properties of microbial cellulose produced during fermentation of black tea broth (Kombucha). II. Int Food Res J 19(1):153–158

Growing Your Own Fabric is Possible. 2014 [cited 2014 30.09]. Available from http://www.tdsblog.com/2014/02/13/growing-fabric-possible-see-suzanne-lee-discovered-ted-talk/

Gurcum BH, Ones A (2018) Bakteri ve mikroalglerin tekstil boyacılığında ve baskıcılığında kullanım olanakları. İdil Dergisi 7(46):701–709

Güzel M, Akpınar Ö (2018) Bakteriyel Selülozların Üretimi ve Özellikleri ile Gıda ve Gıda Dışı Uygulamalarda Kullanımı. Akademik Gıda 16(2):241–251

How to grow a Stool Cover Cellulose-Fibre Xylinum stool by Jannis Hülsen - Chair Blog. 2012. Available from http://www.chairblog.eu/2012/03/21/how-to-grow-a-stool-cover-cellulose-fibre-xylinum-stool-by-jannis-hulsen/

http://annadumitriu.tumblr.com/post/68010439679/anna-dumitriu-has-created-a-new-work-the

http://microbewiki.kenyon.edu/index.php/Industrial_Applications_of_Bacterial_Pigments

http://www.biotecharticles.com/Applications-Article/Colorful-Bacteria-612.html

http://www.wired.co.uk/magazine/archive/2014/04/play/to-live-and-dye

https://commons.wikimedia.org/wiki/File:MRSA_on_Brilliance_MRSA_Chromogenic_Agar.jpg

https://commons.wikimedia.org/wiki/File:Serratia_marcescens.jpg

https://commons.wikimedia.org/wiki/File:Staphylococcus_aureus_VISA_2.jpg

https://commons.wikimedia.org/wiki/File:Structure_of_a_bacterial_cellulose_synthase.png; https://upload.wikimedia.org/wikipedia/commons/2/2f/Microbial_cellulose_pellicle.JPG

https://isea2011.sabanciuniv.edu/paper/communicating-bacteria

https://upload.wikimedia.org/wikipedia/commons/4/4a/Kombucha_mushroom.jpg ;

https://upload.wikimedia.org/wikipedia/commons/b/b8/Kombucha_fermenting_black_tea.jpg;

https://upload.wikimedia.org/wikipedia/commons/f/f6/Kombuchacultsm.jpg

Iowa State wins with leather-like vest at National Sustainable Design Expo _ College of Human Sciences _ Iowa State University. 2014 [cited 2014 30.09]. Available from http://www.hs.iastate.edu/news/2014/04/25/renewable-cellulose/

Kramar A, Ilic-Tomic T, Petkovic M, Radulović N, Kostic M, Jocic D, Nikodinovic-Runic J (2014) Crude bacterial extracts of two new Streptomyces sp. isolates as bio-colorants for textile dyeing. World J Microbiol Biotechnol 30(8):2231–2240

Nam, Changhyun and Lee, Young-A, “RETHINK II: Kombucha Shoes for Scarlett and Rhett” (2016). International Textile and Apparel Association (ITAA) Annual Conference Proceedings. 68. https://lib.dr.iastate.edu/itaa_proceedings/2016/design/68

Ökmen G, Dilek IŞIK (2014) Doğal Pigment Adayı Streptomisetlerin Gelişimlerine Çevresel Faktörlerin Etkisi. Biyoloji Bilimleri Araştırma Dergisi 7(1):37–41

Pecoraro, É., Manzani, D., Messaddeq, Y., & Ribeiro, S. J. L. (2008). Monomers, polymers and composites from renewable resources, Bacterial Cellulose from Glucanacetobacter xylinus: Preparation, Properties and Applications, pp 369–383. https://doi.org/10.1016/B978-0-08-045316-3.00017-X

Perumal K, Stalin V, Chandrasekarenthiran S, Sumathi E, Saravanakumar A (2009) Extraction and characterization of pigment from Sclerotinia sp. and its use in dyeing cotton. Text Res J 79(13):1178–1187

Tiboni, M., Grzybowski, A., & Fontana, J. D. (2014). Bacterial cellulose: a peculiar polymer for biotechnological applications. Cellulose and other naturally occurring polymers Research Signpost: Kerala, 1–10

Tozluoğlu A, Çöpür Y, Özyürek Ö, Çıtlak S (2015) Nanoselüloz üretim teknolojisi. Türkiye Ormancılık Dergisi 16(2):203–219

Trattles. [cited 2014 30.09]. Available from http://racheltrattles.tumblr.com/

Venil KC, Zakaria AZ, Ahmad WA (2013) Bacterial pigments and their applications. Process Biochem 48:1065–1079

Views C (2010) Bacteria help healing. [cited 2014 30.09]. Available from http://www.chemistryviews.org/details/news/886233/Bacteria_Help_Healing.html

Wearable structure of bacteria references antique animal bone corsets _ 2014 interior ideas. 2014 [cited 2014 30.09]. Available from: http://www.2014interiorideas.com/beauty-and-fashion/wearable-structure-of-bacteria-references-antique-animal-bone-corsets.html

Wikipedia. Bacterial cellulose. [cited 2014 30.09]. Available from http://en.wikipedia.org/wiki/Bacterial_cellulose

Wood JE (2007) Are microbes the future of fashion? The Microbiologist 18(2–4). https://e-space.mmu.ac.uk/618497/3/Microbiologist_June_Jane%20Wood%20%286%29.pdf

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Yıldırım, F.F., Yavas, A., Avinc, O. (2020). Bacteria Working to Create Sustainable Textile Materials and Textile Colorants Leading to Sustainable Textile Design. In: Muthu, S., Gardetti, M. (eds) Sustainability in the Textile and Apparel Industries. Sustainable Textiles: Production, Processing, Manufacturing & Chemistry. Springer, Cham. https://doi.org/10.1007/978-3-030-37929-2_6

Download citation

DOI: https://doi.org/10.1007/978-3-030-37929-2_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-37928-5

Online ISBN: 978-3-030-37929-2

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)