Abstract

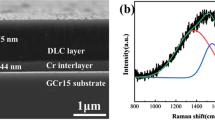

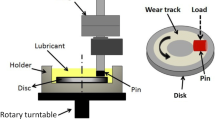

Diamond-like Carbon (DLC) film and Carbon Nitride (CNx) film are expected to be applied to automotive engine bearings because they show low friction and high wear resistance. Whereas many fundamental tribological re-searches of DLC and CNx have been conducted, practical researches of these coatings on engine bearings are still not enough. Therefore, clarifying friction and wear properties of the coatings on real engine bearings are strongly required. Especially, since lubrication conditions of engine bearings vary in automotive drive, clarifying the effect of lubrication conditions on tribological properties is important. For the reasons, we focus on the clarification of the effect of lubrication condition on friction and wear properties of the bearings coated with several DLC coatings. In this research, tribological properties of three different types of bearings, aluminium-alloy bearings without any coatings, a-C:H coated bearings and CNx coated bearings, are compared. The CNx coating was deposited by Ion Beam Assisted Deposition (IBAD) method on a-C:H coated bearings. As results, it is clarified that CNx coated bearings show the lowest friction coefficient, μ = 0.10, between three bearings under low sliding speed conditions. Under high sliding speed conditions, CNx after running-in also shows the lowest friction co-efficient. In the view point of wear, CNx coating reduces specific wear rate to 4.5 × 10−9 mm3/Nm from the value of a-C:H coating, 7.9 × 10−8 mm3/Nm. From these results, it is clarified that CNx coating on a-C:H coated bearing achieves low friction and high wear resistance coating on engine bearings.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Holmberg, K., Andersson, P. and Erdemir, A.: Global energy consumption due to friction in passenger cars, Tribology International 47, 221-234 (2012).

Podgornik, B., Jacobson, S. and Hogmark, S.: DLC coating of boundary lubricated components—advantages of coating one of the contact surfaces rather than both or none, Tribology International, 36 (11), 843-849 (2003).

Tasdemir, H. A., Wakayama, M., Tokoroyama, T., Kousaka, H., Umehara, N., Mabuchi, Y. and Higuchi, T.: Ultra-low friction of tetrahedral amorphous diamond-like carbon (ta-C DLC) under boundary lubrication in poly alpha-olefin (PAO) with additives, Tribology International, 65, 286-294 (2013).

Ogawa, Y., Tokoroyama, T., Umehara, N., Fuwa, Y. : Super low Friction with CNx Coating under Oil Lubrication, Transactions of the JSME series C, 75(752), 1088-1093 (2009).

Liu, X., Yamaguchi, R., Umehara, N., Deng, X., Kousaka, H. and Murashima, M.,:Clarification of high wear resistance mechanism of ta-CNx coating under poly alpha-olefin (PAO) lubrication, Tribology International, 105, 193-200 (2017).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Umehara, N. et al. (2019). Effect of Carbonaceous Hard Coatings Overcoat on Friction and Wear Properties for Al Alloy Sliding Bearing in Oil Lubrication. In: Uhl, T. (eds) Advances in Mechanism and Machine Science. IFToMM WC 2019. Mechanisms and Machine Science, vol 73. Springer, Cham. https://doi.org/10.1007/978-3-030-20131-9_376

Download citation

DOI: https://doi.org/10.1007/978-3-030-20131-9_376

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-20130-2

Online ISBN: 978-3-030-20131-9

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)