Abstract

Fish oil is a rich source of n-3 polyunsaturated fatty acids, especially eicosapentaenoic acid and docosahexaenoic acid, which are crucial for the treatment of several chronic diseases. Fish and shellfish processing discards have been widely utilized as raw materials for oil extraction. Conventional methods including wet reduction, enzymatic-assisted, and solvent-assisted extraction processes result in lower oil recovery, reduced nutritive value, and high amounts of solvent used, respectively. To overcome these limitations, alternative novel extraction technologies have been employed, which increase the yield of oil with minimum loss of nutrients and less usage of solvent. Fish oil is highly susceptible to oxidation that led to the generation of undesirable odor and the formation of toxic compounds. Recent findings for the preservation and stabilization using various techniques are addressed. Some active compounds in fish oil such as astaxanthin and squalene are revisited. Also, the health benefits and viable application of n-3 fatty acids and the selected active components on human health are summarized.

This chapter submitted to “Fish Waste to Valuable Products: Recent Applications and Research Update”.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Antioxidants

- Astaxanthin

- Encapsulation

- Enzymatic hydrolysis

- Extraction techniques

- Health benefits

- n-3 Fatty acids

1 Introduction

Fish and shellfish caught from the sea or harvested from fish farming have been increased for consumption and commercial purposes (Kumar et al. 2018). Recently, demand for food with high nutraceutical properties and bioactive compounds has increased tremendously owing to their enormous beneficial effects (Rajasekaran et al. 2022). Increased consumption of fish and fishery products has created a huge challenge to seafood processing industries in handling and exploiting the wastes in a sustainable manner (Nirmal et al. 2020). In 2018, fish production was 179 million tonnes worldwide, of which 156 million tonnes were consumed by people, and 22 million tonnes were discarded as waste (FAO 2018). In finfish processing, leftovers including head, viscera, skin, scale, bone, etc. are produced, depending on the finished products and processes used. In the case of shrimp processing, inedible parts are removed from the whole shrimp including cephalothorax, hepatopancreas, carapace, and tail. Leftovers account for about 30–35% and 40–50% of the total weight of fish and shrimp, respectively (Kumar et al. 2018; Nirmal et al. 2020). Previously, those wastes were considered residues and dumped into the environment, creating severe pollution problems. Nowadays, byproducts from fish processing industries are better utilized by converting them into valuable products under the concept of ‘Zero Waste’ (Gulzar et al. 2020). The fish waste consists of around 40–60% oil, and abundance in polyunsaturated fatty acids (PUFA) (Adeoti and Hawboldt 2014). These fatty acids are beneficial for health and are utilized in the treatment and prevention of autoimmune diseases, heart ailments, high blood pressure, arthritis, high cholesterol levels, mental illness, etc. Also, vitamins including A, D, E, and K are abundant in fish oil (Yashodhara et al. 2009). The structure of bioactive compounds from fish and shrimp processing byproducts is documented (Fig. 1). Presently, fishing for their oil is not promoted due to the declining marine fishery resources. Therefore, utilizing leftovers from fish processing industries is a promising alternative approach to produce high-grade fish oil.

In general, fish oil contributes about 2% of the world’s consumption of fats. Globally, fish oil production is estimated to be 1.1 million tons, of which only 5% is utilized for human consumption. The remaining is used as an ingredient in animal and aquaculture feed (Ivanovs and Blumberga 2017). Traditionally, fish oil is a major byproduct of the fish meal industry (Benjakul et al. 2019). Oil recovery, fat content, and composition vary based on species, gender, season, and type of byproducts (Gulzar et al. 2020). Conventional processes are widely used for the extraction of fish oil on an industrial scale (Ivanovs and Blumberga 2017). These processes involve either high temperatures or toxic solvents. This results in the deterioration of oil via oxidation, thus reducing its nutritive value (Prameela et al. 2017). In addition, the solvent residue is not safe for human consumption. Moreover, fish oil extracted by conventional methods has a high level of impurities such as free fatty acids, peroxides, dienes, and cholesterol (Ramalhosa et al. 2012). Therefore, several refining processes have been adopted to reduce the impurities, and consequently augment the production cost. The common refining steps employed on an industrial scale include neutralization, degumming, bleaching, and deodorization processes (Rizliya and Mendis 2014). The quantity and quality of oil are mainly influenced by the extraction methods used. Therefore, the appropriate extraction method needs to be selected to produce oil with negligible impurities and minimize the need for further refining (Gulzar et al. 2020). Another major challenge related to the usage of fish oil is the rapid oxidative deterioration of PUFA which reduces consumer acceptance. This could be overcome by the addition of antioxidants and encapsulation, etc. (Rajasekaran et al. 2022). The application of an appropriate dose of antioxidants and potential encapsulation significantly maintains the stability, solubility, dispersibility, and bioavailability of active compounds in oil (Khoshnoudi-Nia et al. 2022). In this chapter, conventional and novel methods of oil extraction with recent developments were reviewed and challenges were also highlighted. Furthermore, recent techniques to preserve fish oil and its active component such as astaxanthin were addressed. Finally, the potential advantages of bioactive substances and their biological mechanisms were revisited.

2 Extraction of Oil from Fish and shellfish Processing Discards

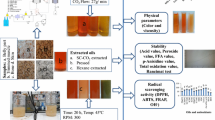

Oil has been extracted from fish processing discards by several conventional and novel methods. The oil recovery, composition, and quality are greatly influenced by selected methods for oil extraction (Gulzar et al. 2020). Moreover, each method has its own merits and demerits, thus affecting the quality and safety of the resulting oil. Different methods for oil extraction from fish and shellfish processing leftovers are demonstrated in Table 1.

2.1 Conventional Methods of Oil Extraction

2.1.1 Wet Reduction

A common technique to extract unrefined fish oil is wet reduction (Chantachum et al. 2000). It includes four stages involving cooking, pressing, and decanting, followed by centrifugation. Initially, the raw material is heated via steam cooking at a high temperature to rupture and coagulate the proteins. As a consequence, bound oil can be released easily followed by hydraulic pressing, mainly a twin-screw press, and centrifugation to remove liquid containing oil from solid residues (Bonilla-Méndez and Hoyos-Concha 2018). The wet reduction process is economically profitable when byproducts from fatty fish such as sardine, herring, salmon, and tuna are used for oil extraction. However, it is not feasible for lean fish, in which oil content is too low (Rubio-Rodríguez et al. 2012). Bako et al. (2014) postulated that the yield of oil from mackerel discards was 18.7% and oil quality was within the acceptable standards. Oil from Sardinella longiceps extracted by heating had lower primary and secondary oxidative products than solvent-assisted extraction (Chakraborty and Joseph 2015). The processing time and temperature directly influence the quality of the extracted oil. Longer exposure time in the heat exchanger accelerates oxidation, whereas a higher yield could be obtained at a high temperature (85 °C). Heating could minimize the microbial load and inactivate the endogenous enzymes (Ivanovs and Blumberga 2017). However, a lower yield was reported at 95 °C due to protein denaturation, in which a tightly packed structure is formed, thus preventing oil release. In contrast, crude oil was extracted effectively from herring byproducts at 95 °C for 8 min (Bonilla-Méndez and Hoyos-Concha 2018). Protein normally undergoes irreversible denaturation at a temperature range 90–100 °C. The coagulation temperature of fish protein is around 60–75 °C, but typical cooking is performed at 95–100 °C. Therefore, optimum temperature and process time should be standardized for raw materials from different sources to attain the highest extraction efficacy of the oil. Chantachum et al. (2000) found that precooking of tuna head (85 °C; 30 min) yielded oil with higher oxidation, while oil from a non-precooked sample showed lower lipid oxidation. In another study, the oil separation from herring by the wet reduction process at 70 °C had lower lipid oxidation with higher stability than enzymatic hydrolysis using Alcalase (Carvajal et al. 2015). Menegazzo et al. (2014) postulated that crude oil extraction from Nile tilapia processing discards was done at 40 °C for 3 h. The yield of fish oil was greater when heating the visceral depot fat of seabass under the vacuum than the solvent extraction method (Sae-leaw and Benjakul 2017). Heat applied can favor the liberation of oil and simultaneously inactivates the lipolytic enzyme which causes hydrolysis of the lipid (production of free fatty acids). However, a high temperature could partially alter the PUFA due to deteriorative reactions such as oxidation and hydrolysis (Bonilla-Méndez and Hoyos-Concha 2018). The alterations of oil quality depend upon various factors including temperature, heating time, degree of unsaturation of oil, etc. In general, the wet reduction process may harm the environment due to the release of a high amount of heat (Ivanovs and Blumberga 2017).

2.1.2 Enzymatic Hydrolysis Process

In general, oil has been extracted from fish processing discards via enzymatic hydrolysis using proteases. The enzyme will hydrolyze the proteins, thereby facilitating the release of oil without using high temperatures or solvents. Liaset et al. (2003) postulated that around 80% of lipids were recovered from salmon frames via enzymatic hydrolysis using the commercial protease, Protamex. Linder et al. (2005) investigated different proteases such as Flavourzyme, Neutrase, and Alcalase for hydrolyzing the salmon head. The highest amount of oil released was achieved when Alcalase was used. Extraction of oil using enzymatic hydrolysis had a similar or higher yield as compared to the wet reduction process (Benjakul et al. 2019). Moreover, good quality oil can be obtained using enzymatic hydrolysis with the application of mild processing conditions. In addition, peptides in hydrolysate can also be utilized as beneficial functional components (Rustad et al. 2011). Oil extracted from the tuna head through enzymatic hydrolysis using Alcalase had the lowest acid value and oxidation products as well as the highest level of PUFA retained than the oils obtained from wet reduction and solvent-assisted extraction processes (de Oliveira et al. 2017). Indian major carp viscera were subjected to enzymatic hydrolysis using different proteases such as Alcalase, Protex 7L, Neutrase, and Protease-P-Amano. The highest recovery of oil was obtained when using Protease-P-Amano (74.9%), followed by Alcalase (61.7%) (Hathwar et al. 2011). Qi-Yuan et al. (2016) applied response surface methodology to optimize the factors influencing oil from mackerel viscera via enzymatic hydrolysis using Neutrase, pH, temperature, agitation, incubation time, availability of substrate, mode of action, and concentration of enzyme which markedly influenced the yield. The yield obtained with the optimized condition was 78.66%. This method is suitable for oil extraction from lean fish processing byproducts having low-fat content. Recently, extraction of astaxanthin via enzymatic hydrolysis from shrimp byproducts is gaining popularity (Ahmadkelayeh and Hawboldt 2020). Astaxanthin extracted via enzymatic hydrolysis had higher stability and bioavailability than solvent-assisted extraction due to the presence of protein in the form of carotenoproteins. De Holando and Netto (2006) reported a high yield of astaxanthin around 64.6% through enzymatic hydrolysis using Alcalase. The main drawback is the difficulty of recovering the oil phase after hydrolysis associated with the emulsion formed (Benjakul et al. 2019). Moreover, a suitable pH should be maintained for the maximal activity of the enzymes during hydrolysis. Therefore, adjusting the pH using acid or alkali could result in the generation of unwanted inorganic substances, especially sodium chloride in resulting hydrolysate (Benjakul et al. 2019).

2.1.3 Solvent-Assisted Extraction Process

Solvent-assisted extraction was frequently used for oil extraction from fish processing discards with the aid of solvents. Types of solvents used for the extraction directly influence the quantity and quality of the oil. The common criteria considered for the selection of solvent are toxicity, polarity, safe handling, easy removal of solvent, etc. (Gulzar et al. 2020). Presently, organic solvents such as ethyl acetate, acetone, ethanol, methyl ethyl ketone, hexane, and isopropanol are permitted to be used in food industries for oil extraction with the permitted residual level in the final products (Gulzar et al. 2020). Nevertheless, their solvents such as chloroform, dichloromethane, and dimethyl sulfoxide are restricted due to their toxicity (FDA 2010). Gulzar and Benjakul (2018) investigated the efficiency of different solvents to extract oil from cephalothorax, a shrimp processing byproduct, in which the highest yield was obtained using isopropanol as compared with acetone, chloroform, and n-hexane. However, oil extracted using n-hexane had greater carotenoid attributed to the high solubility of carotenoid in n-hexane or n-heptane (Sánchez-Camargo et al. 2011). In general, the oil consists of both polar (phospholipids) and non-polar (carotenoid) compounds. Thus, effective extraction can be obtained by the combination of polar and non-polar solvents at an appropriate ratio (Sachindra et al. 2006). The common procedure to extract oil for lab scale is the Bligh and Dyer method, in which solvent mixtures including chloroform, methanol, and water are used. Extraction yield is higher in the Bligh and Dryer method than Soxhlet extraction method (Macías-Sánchez et al. 2010). Gulzar and Benjakul (2018) reported that the mixture of hexane and isopropanol (1:1) had the highest lipid extraction yield and carotenoid content from shrimp cephalothorax. A significant amount of astaxanthin (53 µg/g) was obtained when extracted from byproducts of Paulo shrimp by the solvent mixture of n-hexane: isopropyl alcohol at a ratio of 60:40 (Sánchez-Camargo et al. 2011). Acetone was used for oil extraction from deep-sea shrimp, and the yield was 43.44 µg/g (Dalei and Shaoo 2015). Therefore, the yield and astaxanthin from crustacean oil vary based on the type of solvent, species, and source of raw materials used. Moreover, the selection of inappropriate solvents results in the consumption of excess solvents and a lower yield (Ivanovs and Blumberga 2017). The main drawback of the solvent extraction process is the disposal issue, though some solvents can be recycled for further uses. Moreover, the solvent can cause environmental pollution if not recycled or refined properly (Gulzar et al. 2020). The difficulties in the removal of residual solvents still require the development of potential novel extraction processes to ensure the safety of the resulting oil.

2.2 Novel Extraction Processes

2.2.1 Ultrasonic Assisted Extraction

To overcome the limitations of conventional extraction processes such as low extraction yield and excess solvent usage, ultrasonic-assisted extraction (UAE) is combined with the existing solvent extraction process to remarkably increase the quantity of lipids and reduce the solvent volumes (Mason et al. 1996). UAE is a physical process that utilizes high-energy sound waves with frequencies higher than the human hearing level (20 kHz), reaching up to 10 MHz (Gallo et al. 2018). During propagation through a medium, these high-energy waves disrupt the cell–matrix of the substrate to facilitate the deeper penetration of solvent for subsequent extraction of target compounds, particularly oil. The ultrasound waves produce a cavitation effect in the liquid solvent medium, in which microbubbles are created owing to the constant compression and rarefaction of the longitudinal waves (Povey and Mason 1998). These microbubbles are unstable and burst shortly after formation. However, the bursting of these microbubbles creates a strong localized effect, in which high pressure and temperature are generated which can reach up to 400 MPa (Flint and Suslick 1991). The high localized pressure disrupts the microstructure of substrates in the vicinity, thus destroying the tissue integrity and causing release of target compounds (Flint and Suslick 1991). The formation of thousands of microbubbles and their explosion literally tears down the substance, thus favoring the complete solvent penetration and extraction of lipids (Povey and Mason 1998). UAE also reduces the extraction time of lipids, but it can negatively impact bioactive compounds, mainly associated with enhanced oxidation.

UAE is commonly utilized in food industry, especially for the extraction and homogenization of bioactive substance (Gallo et al. 2018). In the seafood industry, UAE is employed for oil extraction from fish and shrimp processing discards (Al Khawli et al. 2019; Gulzar et al. 2020). Oil from Asian swamp eel fillet trimmings was extracted with enhanced yield using UAE (Abdullah et al. 2010). UAE pre-treatment resulted in the higher extraction yield of oil from the head of Labeo rohita by 8.74%, compared to the untreated counterpart (Bruno et al. 2019). Application of sonication for the squalene extraction from fish livers increased yield, reduced extraction time, and lowered solvents consumed (Ali et al. 2019). Oil from shrimp cephalothorax was obtained with enhanced yield by employing UAE (80% amplitude for 25 min) (Gulzar and Benjakul 2018). The quantity of shrimp oil extracted from the cephalothorax increased by almost 1.5 times by the combination of a heat pre-treatment followed by UAE (Gulzar and Benjakul 2019). Nevertheless, there are some disadvantages of the UAE process, since it can accelerate the oxidation and hydrolysis caused by the cavitation effect (Gulzar and Benjakul 2018). Therefore, some additional protective means have been implemented to maintain the quality of extracted oils. Those include the incorporation of natural antioxidants, extraction of oil under the inert atmosphere, and controlling the temperature rise during ultrasonication (Gulzar and Benjakul 2020a).

2.2.2 Supercritical Fluid Extraction

Supercritical fluid extraction (SFE) is an emerging technique widely used to overcome the limitations of conventional extraction methods. Supercritical fluids (SCF) are substances that exist at the temperature and pressure beyond their critical point, where it is difficult to differentiate gas and liquid phases (Carlès 2010). The physical properties of SCF lie between a liquid and a gas. For example, the viscosity of the SCF is very low and the diffusivity is high, whereas the SCF possesses solvating properties like a liquid (Morrell 2012). In SFE, SCF is used to extract low polarity lipids in an oxygen-free and moderate temperature environment, which results in high-quality lipids, which are free from oxidative deterioration (Rubio-Rodríguez et al. 2012). Moreover, SFE is fast and effective due to the high diffusivity of SCF into the substrate and rapid separation of solvent after extraction (Del Valle and Aguilera 1999). In SFE, CO2 is mostly used as SCF owing to its low-cost, non-flammable, and non-toxic nature, and it is considered as GRAS (Sahena et al. 2009). The ease of separation after extraction is another major advantage of using CO2 as SCF, since it is a gas at room temperature. Due to these advantages, SFE is a green technology to obtain bioactive compounds (Ivanovs and Blumberga 2017). In the seafood processing industry, SFE has been extensively used owing to the presence of highly unstable compounds such as PUFAs, carotenoids, vitamins, and some indigenous antioxidants which are prone to oxidation (Rubio-Rodríguez et al. 2012; Sánchez-Camargo et al. 2012).

Oil from fish processing byproducts can be obtained by SFE with minimum damage to n-3 fatty acids. Moreover, due to selective extraction capabilities of SFE, it prevents the co-extraction of polar contaminants, such as certain inorganic derivates containing heavy metals (Rubio-Rodríguez et al. 2012). Several refining processes such as the de-acidification of fish oil can be easily achieved by modifying the density and solubility of SCF by adjusting its temperature and pressure (Kawashima et al. 2006). Extraction of lipids from shrimp processing discards using SFE led to an excellent astaxanthin recovery. Sánchez-Camargo et al. (2012) documented an upsurge in astaxanthin recovery from Brazilian redspotted shrimp (Farfantepenaeus paulensis) waste by 57.59% with the aid of SFE. The low temperature and oxygen-deficient environment of extraction by SFE has also proven to be favorable for enhanced recovery of n-3 PUFA (Amiguet et al. 2012). Krill oil extracted by SFE showed enhanced extraction yield, better astaxanthin retention, and augmented oxidative stability (Ali-Nehari et al. 2012). Nevertheless, the complex equipment, high cost of operation, and selective solubility of SCFs have made SFE unsustainable for commercial applications (Bin et al. 2020).

2.2.3 Pulsed Electric Field Extraction

Pulsed electric field (PEF) is a non-thermal processing technique, in which electroporation plays a profound role in extracting bioactive compounds with higher yield and good quality (López-Pedrouso et al. 2019). Electroporation is a phenomenon of creating minute pores in the tissues or intracellular matrix by placing the material between two electrodes and applying high-voltage electric pulses for a short time (Redondo et al. 2018). These pores facilitate solvent penetration and eventually enhance the extraction yield. Since the electric field is applied only for a short time, temperature increases barely in the product, which prevents the degradation of heat-labile compounds (Toepfl et al. 2006). The potency of PEF to facilitate extraction is dependent on physical and chemical properties of the material, the strength of the electric field, the electrical conductivity of the medium, and transmembrane potential (TMP) of the material (Gulzar et al. 2020). TMP typically acts as an ionic gradient across the cell membrane. By passing high-voltage pulses for a short duration, polarity is induced in the cell and produces a strong dipole moment, proportional to the applied electric field, causing irreversible pore formation in the cells (Zbinden et al. 2013). The cell organelles are therefore leaked into the solvent through these pores (Baiano and Del Nobile 2016).

PEF has a huge potential to replace the current conventional extraction process, either as a pre-treatment or in combination with other novel techniques (Donsì et al. 2010). In the seafood industry, PEF has been used modestly to valorize the processing discards, enhance the extraction yield, and preserve the quality of bioactive substances (Xi et al. 2021). Antioxidants from sea bass and sea bream waste (gills, bones, and heads) were extracted using PEF at a high yield (Franco et al. 2020). Pre-treatment of shrimp cephalothorax by PEF prior to UAE led to increased quantity of shrimp oil by 7.13% (Gulzar and Benjakul 2019). Moreover, the quality of extracted shrimp oil was superior to that of oil extracted by UAE alone, indicating that PEF could prevent lipid oxidation and hydrolysis to a large extent. Apart from oil extraction, PEF has been used for protein extraction from marine sources. A higher extraction yield of abalone viscera protein was obtained when PEF was used in combination with an enzymatic-assisted process (Li et al. 2016). Several advantages including high-quality extracts, low-operational temperature, and high disruption of biological cells in fish processing byproducts can be achieved using PEF without inducing detrimental effects (Puertolas et al. 2016). However, the utilization of PEF to extract oil from fish or shellfish processing leftover on a commercial scale is still not fully developed due to some challenges and obstacles involving the high cost, difficulty in handling equipment, and complex process involved (Gulzar et al. 2020).

2.2.4 Other Novel Extraction Processes

Among other novel extraction processes, high hydrostatic pressure (HHP) processing is noteworthy to separate bioactive compounds by applying high pressures (100–1000 MPa) at low temperatures (5–30 °C) (Gulzar et al. 2020). Application of high pressure disrupts the structure of material by breaking weak bonds including hydrogen, hydrophobic and electrostatic bonds in cell membranes, and destroying salt bridges, which ultimately improves solvent permeability (Bermúdez-Aguirre and Barbosa-Cánovas 2011). HHP has been substantially used in the seafood industry for the extraction of n-3 fatty acids (Ali et al. 2021), for obtaining bioactive peptides from fish byproducts (Yu et al. 2018) and for extracting astaxanthin from shrimp byproducts (Li et al. 2017). High pressure extraction of PUFA from liquid effluents generated by fish canning industry produced higher quantity of oil at the lowest cost (Monteiro et al. 2018). High pressure extraction contributed to increased yield of astaxanthin in a shorter time from dried shrimp waste with enhanced antioxidant activity (Li et al. 2017). The intrinsic factors including pH, composition as well as processing temperature and pressure levels influence the quantity and quality of the extracted products. To improve the extraction efficiency, further research is required for HHP process parameter optimization for the extraction of oil and other bioactive compounds on a commercial scale. Merits and demerits of conventional and novel approaches for the oil extraction and active components are summarized in Table 1.

3 Preservation and Stabilization of Oil Using Different Techniques

3.1 Encapsulation

Despite numerous beneficial effects of fatty acids present in fish or shrimp oils, the practical application is still limited mainly due to the rapid oxidation and hydrolysis of PUFA. Those reactions produce toxic and volatile compounds (off-odor). Furthermore, these changes negatively affect the nutritional value of oil (Rajasekaran et al. 2022). Encapsulation is one of the promising techniques for the preservation and stabilization of sensitive compounds like PUFA, astaxanthin, etc. (Gulzar et al. 2020). Encapsulation improves the dispersibility, stability, and bioavailability of active components without influencing the sensory attributes of the final product (Venugopalan et al. 2021). Encapsulation also masks fishy odor and delays oxidation and hydrolysis by preventing direct contact with oxygen and water during storage. Fortification of encapsulated fish oil in a food matrix shows high oxidative stability and better sensory attributes than those incorporated with unencapsulated fish oil (Venugopalan et al. 2021). There are several ways to encapsulate fish oil, and bioactive compounds as presented in Fig. 2. Micro- and nanoencapsulation are widely used for the protection of sensitive bioactive compounds and to ensure the target delivery of active compounds. Recently, novel techniques such as microfluidization and ultrasonication are widely applied to encapsulated EPA and DHA (Venugopalan et al. 2021). Ultrasound provided the microcapsules loaded with shrimp oil having high encapsulation efficiency (93.64%) than microfluidization (75.18%). Encapsulated oil had higher oxidative stability than unencapsulated oil over 8 weeks of storage (Gulzar and Benjakul 2020b). Oxidative stability of oil in the microcapsule is determined by wall materials used to prevent the oxidation of PUFA. Takeungwongtrakul et al. (2015) reported that microencapsulated shrimp oil using sodium caseinate, fish gelatin, and glucose syrup at a ratio of 1:1:4 as wall materials up to 3% improved the loaf volume and nutritive value of bread. Moreover, biscuits incorporated with encapsulated shrimp oil were stable toward lipid oxidation during storage over 12 days, while maintaining good sensory acceptability (Takeungwongtrakul and Benjakul 2017). Microencapsulated fish oil using chitosan and modified starch (1:9) was used to fortify bread up to 5% without adverse effects on sensory attributes (Hasani et al. 2020).

Nanoemulsion can be used to stabilize active compounds, depending upon the size of the droplet. Nanoemulsion with droplet diameter less than 100 nm possess higher bioavailability and physical stability (Venugopalan et al. 2021). The incorporation of nanoencapsulated fish oil using 25% gum Arabic and 4% tween 80 as emulsifiers did not show any adverse effects on consumer acceptability in fermented low-fat milk (Moghadam et al. 2019). Recently, Pickering emulsion is gaining more interest than conventional surface-active emulsifiers due to its low cost, environment-friendliness, controlled release of active components, and excellent physical and oxidative stability (Ding et al. 2020). In Pickering emulsion, food grade colloidal particles are generally used to form a thin film over oil droplets to stabilize the emulsion (Liu et al. 2021). Pickering emulsion of fish oil had a smaller droplet size than conventional emulsion (Ding et al. 2020). The smaller droplet size reveals greater stability against coalescence. Hosseini and Rajaei (2020) postulated that mayonnaise enriched with fish oil stabilized by chitosan-steric acid nanogel improved the stability of mayonnaise more effectively than non-emulsified fish oil added to mayonnaise. Multilayer emulsion is known as double emulsion, and has a complex structure as compared to the conventional micro and nanoemulsion (Jamshidi et al. 2018). There are two types of multilayer emulsion. They are water–oil–water (W/O/W) emulsion and oil–water–oil emulsion (O/W/O), in which W/O/W is more common and effective for the encapsulation of fish oil. For W/O/W emulsion formation, smaller water droplets disperse inside the larger droplets which themselves disperse in the water phase (Fig. 2) (Venugopalan et al. 2021). The multilayer emulsion has a broad application in different sectors including cholesterol reduction, control, and/or target release of the bioactive component such as vitamin D and PUFA (Venugopalan et al. 2021). Multilayer fish oil emulsion stabilized using fucoidan-whey protein concentrate delayed the formation of oxidative products, thereby increasing the stability of encapsulated fish oil (Jamshidi et al. 2018). Yu et al. (2017) postulated the encapsulation efficiency of fish oil by various techniques including spray-dried microcapsules, complex coacervation, and double-layer emulsion using gelatin-gum Arabic as emulsifiers. Among all the samples, the double emulsion method yielded higher encapsulation efficiency (93.7%) owing to the double layers over the surface oil, thus enhancing its protective activity toward the environment.

Another novel encapsulation method, utilized in the pharmaceutical, cosmetics, and food industries, is liposomal technology. Liposomes are phospholipids that contain both polar and non-polar regions organized in a bilayer structure (Fig. 2) (Gulzar and Benjakul 2020b). Recently, liposomal technology is widely used to preserve and deliver bioactive compounds (Venugopalan et al. 2021). Liposomal technology ensures high encapsulation efficiency, bioavailability, and target release of bioactive substances as well as provides better oxidative stability of shrimp oil (Gulzar and Benjakul 2020b). Nanoliposomes ranging from 50 to 200 nm showed higher oxidative stability than encapsulated fish oil (>200 nm). Liposomal encapsulation can be done by various techniques including ethanol injection and thin film formation, etc. (Ajeeshkumar et al. 2021). In the injection process, phosphatidyl choline and targeted bioactive compound are dissolved in ethanol, followed by injection into water to form liposome (Ajeeshkumar et al. 2021). Ethanolic coconut husk extract-loaded liposome produced by the injection method using soybean phosphatidylcholine and cholesterol (4:1) had high encapsulation efficiency with the more uniform distribution of liposomes (Olatunde et al. 2020). In the thin film formation process, phosphatidyl choline, cholesterol and targeted bioactive compounds are dissolved in the appropriate solvent and hydration with suitable buffer, e.g., phosphate buffer and water to form liposomes. Hydrolyzed collagen-loaded liposomes were prepared using thin film formation by soybean phosphatidyl choline added with cholesterol or glycerol dissolved in ethanol, followed by hydration. The obtained hydrolyzed collagen liposomes had high encapsulation efficiency of 74.54 and 85.42%, respectively (Chotphruethipong et al. 2020). Gulzar and Benjakul (2020b) documented that the liposomal technique improved the oxidative stability of encapsulated shrimp oil during storage of 8 weeks and could mask the fishy odor. Shrimp oil nanoliposomes using an injection method and enriched up to 10% in skim milk showed acceptability and maintained stability under refrigerated condition (Gulzar and Benjakul 2020c). In an in vitro digestion study, controlled release of lipid phase was noticeable in liposome-loaded fish oil, thus ensuring the bioavailability of PUFA (Wang et al. 2015). Other encapsulation techniques include microgel encapsulation, nanofibers, and inclusion complexes (Venugopalan et al. 2021). Edible microgels are made from food-grade protein and polysaccharide that contains physical network and chemical crosslinking. Entrapment of the lipid phase inside the microgel can be done by various techniques such as injection, coacervation, and molding methods (Yan et al. 2020). For the injection method, microgel with oil trapped inside it was prepared by injecting oil droplets and gelling biopolymer into gelling solution (Fig. 2) (Venugopalan et al. 2021). In the case of the coacervation method, microgel encapsulation can be done by adding solutions of two oppositely charged biopolymers with oil (positively charged protein and negatively charged polysaccharide), also known as the phase separation method (Venugopalan et al. 2021). Fish oil encapsulated via a coacervation approach with a different combination of biopolymers (hydroxypropyl methylcellulose-maltodextrin and whey protein-gum Arabic) was prepared (Chang and Nickerson 2018). Nanofibers are long and thin fibrous substances made from protein or polysaccharides. These nanofibers can be used to encapsulate sensitive hydrophobic compounds like PUFA and vitamin D. Busolo et al. (2019) reported that DHA encapsulation using zein nanofibers via the electro-spraying method enhanced its oxidative stability. An inclusion complex method is an approach to trap lipid phase into a substance containing hydrophobic cavity, e.g., cyclodextrin (Fig. 2). Choi et al. (2010) postulated that the higher encapsulation efficiency of fish oil was obtained using cyclodextrin via inclusion complexes.

3.2 Addition of Antioxidants

Effective antioxidants must be added to prevent the generation of free radicals and to slow down oxidative processes (Rajasekaran et al. 2022). Synthetic antioxidants including butylated hydroxytoluene, propyl gallate, butylated hydroxyanisole (BHA), and tert-butylhydroquinone (TBHQ) may be harmful to human health (Hrebień-Filisińska 2021). Nowadays, clean labeled products (without synthetic additives) are gaining popularity among consumers. Therefore, antioxidants from natural sources have been paid more interest (Buamard and Benjakul 2017). Apart from antioxidant activity, natural antioxidants are known for various beneficial effects such as antimicrobial, antimutagenic, and antitumor properties (Buamard and Benjakul 2017). The antioxidant activity depends upon the polarity and solubility of the compounds. Hydrophilic antioxidants are generally effective in bulk oil, whereas hydrophobic compounds prevent oxidation in the emulsion system (Hrebień-Filisińska 2021). The α-tocopherol is used as a natural antioxidant to stabilize fish oil and/or oil-in-water emulsion. Addition of α-tocopherol at a low level (<100 ppm) is effective to scavenge free radicals, while a higher concentration leads to hydroperoxide accumulation (Zuta et al. 2007). Budilarto and Kamal-Eldin (2015) reported that tocopherol (1200–2000 ppm) and ascorbyl palmate (100–900 ppm) are not effective at higher concentrations, whereas phosphatidylcholine (1000–9000 ppm) and L-lysine (1000–9000 ppm) were found effective over a wide range of concentrations against oxidation of cod liver oil. Tocopherol donates hydrogen to peroxyl radicals, leading to the generation of tocopherol reactive radicals during storage (Rajasekaran et al. 2022). These radicals act as ‘pro-oxidants’ that abstract hydrogen from the lipid phase and accelerate oxidation. Pro-oxidant activity of tocopherol at later stages of storage was reported in several studies (Takeungwongtrakul and Benjakul 2013; Rajasekaran et al. 2022). Pro-oxidant activity of α-tocopherol is concentration-dependent. With excessive concentration, it may induce oxidation (Takeungwongtrakul and Benjakul 2013). This drawback can be overcome by the usage of multi-component antioxidants in the system, and it is a promising approach for the stabilization of shrimp oil against oxidation during storage (Rajasekaran et al. 2022). Incorporation of tocopherol in combination with ascorbic palmitate in the fish oil emulsion using lecithin inhibited the formation of primary oxidative products during 30 days of storage (Drusch et al. 2007). Moen et al. (2017) developed mixed antioxidants including tocopherol (19.1%), ascorbyl palmate (13.3%), rosemary extract (53.2%), and green tea catechin (0.54%) for the stabilization of EPA and DHA. Mixed antioxidants have a synergistic effect and show superior protection to tocopherol. A high antioxidant effect was found in shrimp oil-in-water emulsion with the inclusion of tocopherol and tannic acid (Takeungwongtrakul and Benjakul 2013). Chitoligosaccharides obtained from shrimp shells had a synergistic effect with α-tocopherol in shrimp oil-in-water emulsion using bovine serum albumin-chitosan complex (Rajasekaran et al. 2022). Free radicals generated during autoxidation of tocopherol can be scavenged by typical hydrogen donation from other antioxidants in the system. Thus, it prolonged the induction period of oxidation, thereby preventing the lipid phase from radical attack (Takeungwongtrakul and Benjakul 2013). Bakır et al. (2013) documented that ascorbic acid with tocopherol lengthened the inhibition period of linoleic acid peroxidation induced by either copper or copper-ascorbic acid system.

3.3 Addition of Phenolic Compounds

The secondary metabolism of plants produces phenolic compounds, which act as bioactive substances with one or more phenolic rings (Maqsood et al. 2014). Antioxidant activity of phenolic compounds varies based on their structure and the presence of the hydroxyl group (OH–). Phenolic compounds are efficient in both bulk oil and emulsion (Maqsood et al. 2014). Sánchez-Alonso et al. (2011) documented that caffeic acid effectively retarded oxidation in cod liver oil owing to its higher partitioning coefficient in the oil. The higher antioxidant effect of caffeic acid as compared to BHA was observed when incorporated into cod liver oil (Leonardis and Macciola 2003). Maqsood and Benjakul (2010) documented the preventive effect of various phenolic compounds (catechin, caffeic acid, ferulic acid, gallic acid, and tannic acid) in a menhaden oil-in-water emulsion, in which tannic acid showed the highest effectiveness in preventing oxidation. Among the tested concentrations of caffeic acid (0.02–0.1%), the concentration of 0.06% was found to be effective in stabilizing EPA and DHA (Navarro-García et al. 2016). Flavonoids are effective in stabilizing fish oil. Quercetin prevented oxidation in fish oil-in-water emulsion stabilized using whey protein isolate (Azizi et al. 2019) and was more effective than BHT at high temperatures (70 °C) (Huber et al. 2009). However, the application of flavonoids is restricted owing to their poor solubility in oil. Hydroxytyrosol, a byproduct obtained from the production of olive, is used to stabilize PUFA in cod liver oil (Pazos et al. 2008), and it was effective even at low concentrations (0.0025–0.04%) in pure triacylglycerols from fish oils (Mahdavianmehr et al. 2016). Plant extracts such as tea, rosemary, oregano, mustard seed, and clove oils were used for the stabilization of liver oil from cod and Alaska pollock, in which catechin-rich tea extract exhibited superior antioxidant activity to tocopherol and BHT (O’Sullivan et al. 2005). Grape seed extract prevented the oxidation of PUFA in fish oil (Luther et al. 2007). Topuz et al (2015) documented that the extract of pomegranate peel, a byproduct of pomegranate juice industries, showed higher antioxidant activity in anchovy oil at high concentrations (500 and 1000 ppm) than those with a low concentration (100 ppm) at 60 °C. Apple peel extract inhibited the oxidation of bulk fish oil induced by heat and UV radiation (Rupasinghe et al. 2010). Extract from dry apple peel followed by removal of sugar and organic acid had increased antioxidant properties in bulk fish oil (Rupasinghe et al. 2010). Microencapsulated fish oil added with ginger essential oil and oregano extract showed enhanced oxidative stability (Jeyakumari et al. 2018). Bay leaf extract enhanced the oxidative stability of microencapsulated fish oil at various temperatures (23, 40, and 60 °C) (Yesilsu 2019). Ethanolic extract from coconut husk exhibited good antioxidant properties by reducing the thiobarbituric acid reactive substances generated in a shrimp oil-in-water emulsion (Buamard and Benjakul 2017). Rosemary extract showed a synergistic effect in combination with tocopherol, ascorbyl palmate, and lecithin (Drusch et al. 2007). The greater antioxidant effect of rosemary extract is owing to the carnosic acid and its derivates, which act as cascade antioxidants (Tounekti and Munné-Bosch 2012). The addition of antioxidants at an appropriate dose therefore enhances the stability of fish oil during extended storage.

4 Active Components in Fish and Shrimp Oil

4.1 Astaxanthin

Discards from crustacean processing industries are rich sources of carotenoids. Lipid-soluble pigments are present in different forms (Gulzar et al. 2020). The most valuable and prevalent (65–98%) carotenoid from the marine source is astaxanthin, by considering its anti-cardiovascular, anti-inflammatory, and anti-aging properties (Ahmadkelayeh and Hawboldt. 2020). Astaxanthin is a reddish-orange colored pigment, also known as a marine carotenoid (Fig. 1) (Ambati et al. 2014). The enzymes β-carotene hydroxylase and β-carotene ketolase produce astaxanthin from β-carotene or zeaxanthin, respectively. It is mostly produced from byproducts of crustacean, particularly shrimp and krill (Šimat et al. 2022). It is commonly used in the food, feed, pharmaceutical, and nutraceutical industries. The global astaxanthin market was 1371.24 million USD in 2020, and it is expected to upsurge in the upcoming years (Šimat et al. 2022). The human body cannot produce astaxanthin; it must be acquired through food sources and dietary supplements. By considering its potential benefits, USFDA approved and recommended the addition of astaxanthin in foodstuff as a natural coloring agent (E161) (Dalei and Sahoo 2015). Astaxanthin from the natural source occurs in two forms, namely esterified (stable) and unesterified (unstable). Ambati et al. (2014) reported that Antarctic krill has a more esterified form of astaxanthin than Atlantic salmon. Astaxanthin has antioxidant properties and is reported to have stronger antioxidant activity as compared to other compounds such as vitamin C and β-carotene (Šimat et al. 2022). Astaxanthin is an amphiphilic molecule that exerts 500 times greater antioxidant activity than α-tocopherol and 10 times than other commercial antioxidants (Gulzar et al. 2020). It is grouped in ketocarotenoid under the xanthophylls group, which has OH– (hydroxyl) and CO– (keto) groups at the terminals that function as strong electron donors, and scavenge the free radicals. This typical structure of astaxanthin is highly responsible for its antioxidant activity (Ahmadkelayeh and Hawboldt. 2020). Also, astaxanthin increased the activity of some antioxidant enzymes including manganese superoxide dismutase, glutathione transferase, etc. (Takahashi et al. 2002). Astaxanthin contents from the shrimp oil extracted from cephalothorax and hepatopancreas were 1.2 mg/g oil and 1.9 mg/g oil, respectively (Raju et al. 2021). Astaxanthin recovery from various shrimp processing leftovers using different extraction methods is given in Table 2. The astaxanthin in shrimp oil extracted from cephalothorax by UAE and vacuum-microwave heat pre-treatment under an inert atmosphere was found to be higher (1.36 mg/g oil) than that of the oil extracted using the solvent extraction process (0.98 mg/g oil) (Gulzar and Benjakul 2020a).

4.2 Squalene

Squalene (C30H50) is a natural polyunsaturated hydrocarbon (Fig. 1) present in shark liver oil. The deep-sea shark family squalidae is the most abundant source of squalene (Kim and Karadeniz 2012). It has been documented that shark (Centrophorus artomarginatus) liver oil has more quantity of squalene (80–85%) with 97.5% purity. Squalene from shark liver oil is referred to as cure-all, miracle oil or gift from the sea (Gopakumar 2012). It possesses potential benefits such as a cytoprotective agent. It also has antioxidant activity, cholesterol-lowering ability, and lowers high blood pressure (Gopakumar 2012). Squalene is a key intermediate for the synthesis of cholesterol, vitamin D, and steroid hormones in humans (Suresh et al. 2018). Considering its rapid transdermal absorption, non-greasiness, and antibacterial properties, it draws more attention from the anti-aging and skincare cosmetics manufacturing industries. Dietary intake of squalene enhanced high-density lipoprotein and lowered low-density lipoprotein, and triglycerides (Kim and Karadeniz 2012). Squalene showed a promising action against lung and colon cancer. Moreover, it enhances the immune system and improves the function of liver and kidney (Gopakumar 2012). Bindu et al. (2015) reported that squalene exhibits antimicrobial activity against foodborne pathogens. Squalene from spot-tail shark liver (Carcharhinus sorrah) was extracted and concentrated via fractional crystallization, followed by column purification. The yield of squalene is 6.8 g/100 g liver with a purity of ≥94% (Ali et al. 2019). Squalene extracted from the liver of two deep-sea sharks (Carcharhinus plunketi and Somniosus pacificus) was up to 50% (Bakes and Nichols 1995). The amount of squalene in shark liver is greatly influenced by habit and species (Achouri et al. 2018). Moreover, extraction using the green extraction process via ultrasound-assisted direct in situ saponification efficiently extracted squalene with a high yield (0.13–6.86 g/100 g) than conventional solvent extraction (0.10–5.52 g/100 g) using methanol (Ali et al. 2019).

4.3 Vitamins

Fish oil contains fat-soluble vitamins such as vitamin A (retinal), D (cholecalciferol), and E (α-tocopherol), which play key roles in maintaining human health (Suresh et al. 2018). Vitamin E (Fig. 1) has been known as a potent natural antioxidant preventing oxidative stress (Merdzhanova et al. 2014). Vitamin content in fishery byproducts varies, based upon the type, species, age, sex, season, type of byproduct, and extraction method (Gulzar et al. 2020). Vitamin A is known to improve vision and develop the immune system. Vitamin E acts as an antioxidant and develops the muscular and reproductive systems (Afonso et al. 2016). Vitamin D is crucial for calcium regulation. It acts on target organs such as bone, kidney, and intestinal mucosa for the regulation calcium and phosphate metabolisms (Chatterjea and Shinde 2011). The level of vitamins was higher in lipid storage organs such as the liver (fish) and hepatopancreas (shrimp) than that found in meat. Vitamin A and D are higher in halibut, cod, and tuna liver oil (Venugopal 2005). Suresh and Prabhu (2013) reported that sardine oil contained an average of 125 µg/g of vitamin A and D. Also, vitamin E levels in various fishes such as 30 μg/g in menhaden oil, over 60 μg/g in anchovy oil, and 25 μg/g in capelin oil were documented. López-Cervantes et al. (2006) reported that oil from shrimp processing wastes contained vitamin A (0.9–1.6 mg/100 g) and vitamin E (26.2–49.0 mg/100 g), respectively. Mathur et al. (2015) documented the antioxidant effect of tocopherol in the inhibition of lipid peroxidation, cardiovascular disease, and atherosclerosis. Vitamin E was reported to be 7.73 and 50.5 mg/100 g of meat from brown shrimp and fermented shrimp waste (Merdzhanova et al. 2014).

5 Health Benefits of n-3 Fatty Acid-Enriched Oil and Active Components

Increased usage of vegetable oils increased the consumption of n-6 fatty acids, which are pro-inflammatory and prothrombotic (Lange 2020). Fish oil and shrimp oil have been known as the excellent source of n-3 fatty acids (Fig. 1). Various health benefits of n-3 fatty acids are shown in Fig. 3. The dietary ratio of n-6 to n-3 fatty acids has drastically shifted from 1:1 to approximately 10:1 in the modern diet (Covington 2004). The n-3 fatty acids are essential fatty acids that are not synthesized in the body and are obtained only from the diet (Gulzar et al. 2020). In humans, α-linolenic acid is converted into EPA and DHA, which are the precursors of eicosanoids such as prostaglandins, thromboxane, and leukotrienes. These compounds exert several beneficial effects such as anti-inflammatory, antithrombotic, and antiarrhythmic (Simopoulos 2001). However, conversion rate is approximately less than 1 percent. This insufficient enzymatic conversion also increases the dietary ratio of n-6 to n-3 fatty acids (Lange 2020). Therefore, dietary intake of fish oil is required and can be directly absorbed in the body and acts as a precursor of eicosanoids without enzymatic conversion (Bunn and Keith 2002). Also, astaxanthin confers health benefits in preventing several diseases.

5.1 Cardiovascular Disease Treatment

Cardiovascular disease is one of the serious concerns worldwide causing sudden death due to heart-related ailments (Tørris et al. 2018). EPA and DHA are the main components in fish oil and show promising effects on the prevention and treatment of coronary heart disease via different mechanisms (Chen et al. 2022). Consumption of n-3 fatty acids lowered the production of atherosclerotic plaques, thus decreasing the risk of thrombus formation in blood vessels (Von Schacky et al. 1999). Also, the n-3 fatty acids impart a protective effect against cardiovascular disease by reducing platelet aggregation, increasing high-density lipoprotein, decreasing low-density lipoprotein, lowering blood pressure, and improving vasodilation (Yashodhara et al. 2009). Dietary intake of fish oil prevents arrhythmias, related to the abnormal rhythm of the heartbeat that causes sudden cardiac arrests (Dallongeville et al. 2003). The risk of ventricular arrhythmias and cardiac death was lowered to 38 and 28% in myocardial infarction patients (Leaf et al. 2005). Myocardial infarction was effectively lowered with the intake of n-3 fatty acids at a dosage of 2 g per day (Gulzar et al. 2020). The n-3 fatty acids prevent atrial fibrillation during bypass surgery. The reduction of heart rate is due to the ability to alter electrophysiology by extending PR interval and reducing QT interval in electrocardiogram (Leaf et al. 2005). Coronary heart disease patients showed preventive effects against coronary atherosclerosis, stenosis, and restenosis after coronary angioplasty when consuming a fish oil-incorporated diet (Yashodhara et al. 2009). Furthermore, consumption of n-3 fatty acids lowers the risk of ischemic stroke. The study conducted with 4775 adults showed the incidence of stroke was lowered to 27 to 30% by the intake of n-3 fatty acid-enriched diets (Mozaffarian et al. 2005). Moreover, the incidence of congestive heart failure was reduced significantly in a cohort study using 2735 adult patients when supplemented with EPA and DHA (Mozaffarian et al. 2005). A study with apoE-mice showed that fish oil treatment resulted in reduced atherosclerotic lesions, thus preventing the thickening of arteries wall (Wang et al. 2004). Regular dietary intake of n-3 fatty acid at a dose of 1 g per day belated the incidence of heart-related aliments (Lee et al. 2008). Bonaccio et al. (2017) documented that intake of fish oil capsules showed benefits in terms of cardioprotection and stroke prevention. The myocardial infarction and secondary cardiovascular complications were lowered by 59% due to the intake of fish and shellfish in a regular diet (Gulzar et al. 2020). Furthermore, administration of synthetic astaxanthin (CDX-085) to C57BL/6 mice over 6–8 weeks augmented blood flow in basal arteries and attenuated the formation of occlusive thrombosis (Khan et al. 2010). Sprague–Dawley rats fed with the astaxanthin-incorporated diet showed a depleted level of cardiovascular disease markers (Xu et al. 2014).

5.2 Antioxidant and Anti-inflammatory Effects

Free radicals and reactive oxygen species (ROS) generated by the cell-regulating process cause oxidative stress, resulting in cell injuries/death (Oppedisano et al. 2020). These compounds are majorly responsible for several diseases such as Alzheimer’s, steatohepatitis, aging, cardiovascular, and diabetes (Chen et al. 2022). Free radicals (peroxynitrite) also increase the synthesis of pro-inflammatory cytokines by regulating the cyclooxygenase pathway (COX) (Rodrigo et al. 2013). Mollace et al. (2013) reported that n-3 fatty acids showed a protective effect on endothelial cells and cardiomyocytes against oxidative stress and cell death. Moreover, it exhibited substantial antioxidant activity by restoring imbalanced endogenous antioxidant moieties and regulating the antioxidant signaling pathway (Oppedisano et al. 2020). In general, DHA in the mitochondria is crucial for the synthesis of adenosine triphosphate (ATP) by oxidative phosphorylation. Fish oil rich in DHA is involved in various pathways to decrease oxidative stress by increasing cytochrome c oxidase activity and manganese-dependent superoxide dismutase (Mn-SOD) activity in the mitochondrial membrane (Oppedisano et al. 2020). Supplementation of fish oil inhibited membrane peroxidation and improved the antioxidant superoxide dismutase (SOD) activity in the rat model (Li et al. 2019). Another possible mechanism related to antioxidant activity is the preventive effect against ROS-induced ischemia–reperfusion injury and increased glutathione peroxidase (GSH-Px) levels (Rodrigo et al. 2013). Herrera et al. (2015) documented a lowered oxidative stress marker such as F2-isoprostane in human urine due to supplementation of EPA and DHA in the diet. The n-3 fatty acid can regulate inflammatory pathways by inhibiting IkB phosphorylation process and reducing signaling pathways such as TLR- and TNF-α signaling pathways (Alzoubi and Al-Domi 2017). The administration of fish oil as a supplement increased the activity of antioxidant enzymes in apoE-mice (Wang et al. 2004). An in vivo rat study revealed a higher antioxidant effect in the plasma after the administration of n-3 fatty acids (Erdogan et al. 2004). Fish oil is used for the treatment of rheumatoid arthritis, an autoimmune disease, causing severe pain and inflammation in joints. PUFA has the ability to convert into natural anti-inflammatory compounds in the human body, e.g., prostaglandins and leukotrienes (Chen et al. 2022). Also, n-3 fatty acids showed promising effects in the prevention of inflammatory bowel disease and kidney disease (Chen et al. 2022). Bhattacharya et al. (2007) documented a higher anti-inflammatory effect in C57BL/6 mice by retarding pro-inflammatory cytokines such as TNF-α, IL-6, and IL-1β. Also, antioxidant enzymes (catalase and glutathione transferase) were higher in the kidneys of mice with the intake of fish oil. In addition, astaxanthin was reported to prevent oxidative stress and inflammation in several studies. Astaxanthin can directly inhibit ROS generation and hydrogen peroxide-induced NF-kB activation (Lee and Bai 2003). Furthermore, the addition of astaxanthin reduced the expression of inflammatory markers due to its high anti-inflammatory activity (Fassett and Coombes 2011).

5.3 Mental Health and Brain Development

The role of PUFA has been well recognized in brain development and neuroprotection. DHA is the major component contributing to the formation of brain membrane phospholipids (Swanson et al. 2012). Brain development and its function are directly proportional to the intake of n-3 fatty acids (Bazinet and Layé 2014). In humans, EPA and DHA are obtained from α-linolenic acid in several steps such as desaturation, elongation, and β-oxidation (Lange 2020). However, biological conversion is inadequate and a slow process. Thus, n-3 fatty acid dietary supplements improve the function of the brain by changing the biophysical characteristics of cell membranes which includes activating receptors, cell signaling pathways, and controlling the endocannabinoid system (Bazinet and Layé 2014). The n-3 fatty acids modulate several brain functions including gene transcription, neurotransmission, and neuroinflammation (Bazinet and Layé 2014). The intake of fish oil capsule prevents depression, dementia, schizophrenia, bipolar disorder, and attention-deficit hyperactivity disorder (Lange 2020). Also, EPA and DHA showed preventive effects against Alzheimer’s and Parkinson’s diseases (Chen et al. 2022). Intake of n-3 fatty acids has a beneficial impact on dopamine level and lipid profile by improving the gene expression of hydroxytryptamine 1A (HT1A) in the Wistar rat in vivo study (Chen et al. 2022). Rotenone rats fed with a fish oil-added diet showed enhanced neuroprotection and could be used for the treatment of Parkinson’s disease (Denny-Joseph 2015). Recently, a detailed report on the role of n-3 fatty acids in brain development, mental health, and psychiatric disorders was reviewed by Lange (2020).

5.4 Other Medical Conditions

Intake of fish oils normalizes glucose metabolism and imparts protective effects against diabetes mellitus (Covington 2004). Also, it showed protection against various carcinomas in humans. The antitumor effects of n-3 fatty acids are owing to the suppression of cell proliferation and controlled synthesis of prostaglandins (Wang et al. 2014). The intake of n-3 fatty acids reduces the risk of hyperlipemia by decreasing serum triglycerides levels to 25–30% and increasing the high-density lipoprotein to 1–3%, respectively. Salama et al. (2013) documented that hepatoprotective effect of cod oil in rat against sodium nitrite induced hepatotoxicity. In another report, consumption of fish oil reduced the acetaminophen-induced hepatic injury in rats (Kalra et al. 2012). Basheer et al. (2017) reported that administration of EPA and DHA exhibited protective action in the liver by lowering isoniazid-rifampin-induced hepatotoxicity in rats. Apart from the above-mentioned bioactivities, n-3 fatty acid consumption provides numerous health benefits, such as wound healing, gut microbiota modulation, and skincare (Gulzar et al. 2020). The wound-healing property of astaxanthin was also investigated in mice. Mice fed with astaxanthin showed a high level of healing markers, fibroblast growth factor, and collagen type I α 1 (Col1A1) production (Meephansan et al. 2017). In the acetone-induced dry skin rat model, oral administration of EPA and DHA reduced dryness, pruritus, trans-epidermal water loss, and improved skin hydration (Barcelos et al. 2015). Davinelli et al. (2018) documented the preventive effect of astaxanthin against skin cancer and aging.

5.5 Dietary Recommendations of Fish Oil

The American Heart Association recommends a person with no heart ailments can consume fish twice a week, and once a week for a person with coronary heart disease (Covington 2004). The commercially available fish oil capsule normally contains 1 g, comprising 180 mg of EPA and 120 mg of DHA. Thus, the recommended dose of n-3 fatty acids is 0.9 g per day which can be achieved by taking three 1 g capsules of fish oil per day (USFDA 2004). The daily recommendation of n-3 fatty acids is 1 g per day for cardioprotection. A higher dosage of approximately 2–4 g per day is recommended to reduce triglycerides and joint pain caused by rheumatoid arthritis (Covington 2004). The Environmental Protection Agency (EPA) and Food and Drug Administration (FDA) recommended children and pregnant women to avoid the consumption of oil or meat from shark, king mackerel, and tilefish that may contain a high level of mercury (Covington 2004). FDA provided generally regarded as safe (GRAS) status for dietary intake of marine n-3 fatty acids up to 3 g per day (USFDA 2004). The recommended intakes of EPA and DHA by various organizations are presented in Table 3. Astaxanthin extracted from shrimp processing discards are considered as safe for consumption in its free or ester form (Šimat et al. 2022). Its bioavailability depends on dosage, form (mono or diester), and food intake (before or after food). In food supplements, the recommended level of astaxanthin is 8 mg/day and the acceptable daily intake for adults is 0.034–0.2 mg/kg of body weight (Šimat et al. 2022).

6 Future Prospects

Fish oil or shrimp oil is an excellent source of PUFA, carotenoid, and other active components. Mostly, conventional methods are adopted to extract oil on an industrial scale using solvents or at high temperatures. Recent studies using UAE, SFE, and PEF show a promising result with higher yields and reduced consumption of solvents. Despite its benefits, a few methods affect the quality of the extracted oil. Therefore, some novel pre-treatment techniques are needed to overcome the drawbacks. The economic viability and scalability of the novel extraction methods need to be elucidated for commercialization. To improve the stability of oil, encapsulation techniques must be optimized or standardized for the specific food product without affecting its sensory attributes. Development of fish oil or shrimp oil as functional foods and beverages is still required, in which marketable products can be available. As a consequence, the consumption of fish oil or shrimp oil will increase among the consumers, especially after the removal of cholesterol. Furthermore, clinical studies are required to ensure the health benefit of fish oil or shrimp oil for reducing the risk of heart-related diseases or other diseases.

7 Conclusion

The demand for oil extracted from fish or shrimp processing wastes has been increasing globally for their wide range of health benefits. This chapter summarizes the oil extraction methods and stabilization techniques to preserve active compounds. Discards from fish/crustacean processing can be used to extract oil thus improving waste management and ensuring sustainability of marine resources. Also, shrimp oil containing carotenoid pigments (astaxanthin) can be used as natural colorants in oil-based foods such as mayonnaise, soups, butter, and confectionery products, while providing health benefits. The consumption of functional food fortified with fish oil exerts potential benefits on human health.

References

Abdullah S, Mudalip SA, Shaarani SM, Pi NC (2010) Ultrasonic extraction of oil from Monopterus albus: effects of different ultrasonic power, solvent volume and sonication time. J Appl Sci (Faisalabad) 10(21):2713–2716

Achouri N, Smichi N, Kharrat N, Rmili F, Gargouri Y, Miled N, Fendri A (2018) Characterization of liver oils from three species of sharks collected in Tunisian coasts: in vitro digestibility by pancreatic lipase. J Food Biochem 42(1):e12453

Adeoti IA, Hawboldt K (2014) A review of lipid extraction from fish processing by-product for use as a biofuel. Biomass Bioenerg 63:330–340

Afonso C, Bandarra NM, Nunes L, Cardoso C (2016) Tocopherols in seafood and aquaculture products. Crit Rev Food Sci Nutr 56(1):128–140

Ahmadkelayeh S, Hawboldt K (2020) Extraction of lipids and astaxanthin from crustacean by-products: a review on supercritical CO2 extraction. Trends Food Sci Technol 103:94–108

Ajeeshkumar KK, Aneesh PA, Raju N, Suseela M, Ravishankar CN, Benjakul S (2021) Advancements in liposome technology: preparation techniques and applications in food, functional foods, and bioactive delivery: a review. Compr Rev Food Sci Food Saf 20(2):1280–1306

Al Khawli F, Pateiro M, Domínguez R, Lorenzo JM, Gullón P, Kousoulaki K, Ferrer E, Berrada H, Barba FJ (2019) Innovative green technologies of intensification for valorization of seafood and their by-products. Mar Drugs 17(12):689

Ali AMM, Bavisetty SCB, Prodpran T, Benjakul S (2019) Squalene from fish livers extracted by ultrasound-assisted direct in situ saponification: purification and molecular characteristics. J Am Oil Chem Soc 96(9):1059–1071

Ali A, Wei S, Liu Z, Fan X, Sun Q, Xia Q, Liu S, Hao J, Deng C (2021) Non-thermal processing technologies for the recovery of bioactive compounds from marine by-products. LWT 147:111549

Ali-Nehari A, Kim SB, Lee YB, Lee HY, Chun BS (2012) Characterization of oil including astaxanthin extracted from krill (Euphausia superba) using supercritical carbon dioxide and organic solvent as comparative method. Korean J Chem Eng 29(3):329–336

Alzoubi MR, Al-Domi HA (2017) Could omega-3 fatty acids a therapeutic treatment of the immune-metabolic consequence of intermittent hypoxia in obstructive sleep apnea? Diabetes Metab Syndr 11(4):297–304

Ambati RR, Phang SM, Ravi S, Aswathanarayana RG (2014) Astaxanthin: sources, extraction, stability, biological activities and its commercial applications—a review. Mar Drugs 12(1):128–152

Amiguet VT, Kramp KL, Mao J, McRae C, Goulah A, Kimpe LE, Blais JM, Arnason JT (2012) Supercritical carbon dioxide extraction of polyunsaturated fatty acids from Northern shrimp (Pandalus borealis Kreyer) processing by-products. Food Chem 130(4):853–858

Azizi M, Li Y, Kaul N, Abbaspourrad A (2019) Study of the physicochemical properties of fish oil solid lipid nanoparticle in the presence of palmitic acid and quercetin. J Agric Food Chem 67(2):671–679

Baiano A, Del Nobile MA (2016) Antioxidant compounds from vegetable matrices: biosynthesis, occurrence, and extraction systems. Crit Rev Food Sci Nutr 56(12):2053–2068

Bakes MJ, Nichols PD (1995) Lipid, fatty acid and squalene composition of liver oil from six species of deep-sea sharks collected in southern Australian waters. Comp Biochem Physiol B Biochem Mol Biol 110(1):267–275

Bakır T, Yıldoğan Beker B, Sönmezoğlu İ, İmer F, Apak R (2013) Antioxidant and prooxidant effects of α-tocopherol in a linoleic acid-copper (II)-ascorbate system. Eur J Lipid Sci Technol 115(3):372–376

Bako T, Umogbai VI, Obetta SE (2014) Extraction and characterization of Mackery (Scomber scombrus) oil for industrial use. Researcher 6(8):80–85

Barcelos RC, de Mello-Sampayo C, Antoniazzi CT, Segat HJ, Silva H, Veit JC, Piccolo J, Emanuelli T, Bürger ME, Silva-Lima B, Rodrigues LM (2015) Oral supplementation with fish oil reduces dryness and pruritus in the acetone-induced dry skin rat model. J Dermatol Sci 79(3):298–304

Basheer AS, Siddiqui A, Paudel YN, Hassan MQ, Imran M, Najmi AK, Akhtar M (2017) Hepatoprotective and antioxidant effects of fish oil on isoniazid-rifampin induced hepatotoxicity in rats. PharmaNutrition 5(1):29–33

Bazinet RP, Layé S (2014) Polyunsaturated fatty acids and their metabolites in brain function and disease. Nat Rev Neurosci 15(12):771–785

Benjakul S, Sae‐leaw T, Simpson BK (2019) Byproducts from fish harvesting and processing. In: Byproducts from agriculture and fisheries: adding value for food, feed, pharma, and fuels, pp 179–217

Bermúdez-Aguirre D, Barbosa-Cánovas GV (2011) An update on high hydrostatic pressure, from the laboratory to industrial applications. Food Eng Rev 3(1):44–61

Bhattacharya A, Sun D, Rahman M, Fernandes G (2007) Different ratios of eicosapentaenoic and docosahexaenoic omega-3 fatty acids in commercial fish oils differentially alter pro-inflammatory cytokines in peritoneal macrophages from C57BL/6 female mice. J Nutr Biochem 18(1):23–30

Bin LK, Janakiraman AK, Abd Razak FS, Uddin AH, Sarker MZI, Ming LC, Goh BH (2020) Supercritical fluid technology and its pharmaceutical applications: a revisit with two decades of progress. Indian J Pharm Educ Res 54(2):1–11

Bindu BSC, Mishra DP, Narayan B (2015) Inhibition of virulence of Staphylococcus aureus—a food borne pathogen—by squalene, a functional lipid. J Funct Foods 18:224–234

Bonaccio M, Ruggiero E, Di Castelnuovo A, Costanzo S, Persichillo M, De Curtis A, Cerletti C, Donati MB, De Gaetano G, Iacoviello L, Vermylen J (2017) Fish intake is associated with lower cardiovascular risk in a Mediterranean population: prospective results from the Moli-sani study. Nutr Metab Cardiovasc Dis 27(10):865–873

Bonilla-Méndez JR, Hoyos-Concha JL (2018) Methods of extraction refining and concentration of fish oil as a source of omega-3 fatty acids. Ciencia y Tecnología Agropecuaria 19(3):645–668

Bruno SF, Kudre TG, Bhaskar N (2019) Impact of pretreatment-assisted enzymatic extraction on recovery, physicochemical and rheological properties of oil from Labeo rohita head. J Food Process Eng 42(3):e12990

Buamard N, Benjakul S (2017) Ethanolic coconut husk extract: in vitro antioxidative activity and effect on oxidative stability of shrimp oil emulsion. Eur J Lipid Sci Technol 119(11):1700131

Budilarto ES, Kamal-Eldin A (2015) Stabilization of cod liver oil with a quaternary combination of α-tocopherol and synergists: method of assessment. Eur J Lipid Sci Technol 117(10):1598–1606

Bunn PA Jr, Keith RL (2002) The future of cyclooxygenase-2 inhibitors and other inhibitors of the eicosanoid signal pathway in the prevention and therapy of lung cancer. Clin Lung Cancer 3(4):271–277

Busolo MA, Torres-Giner S, Prieto C, Lagaron JM (2019) Electrospraying assisted by pressurized gas as an innovative high-throughput process for the microencapsulation and stabilization of docosahexaenoic acid-enriched fish oil in zein prolamine. Innov Food Sci Emerg Technol 51:12–19

Carlès P (2010) A brief review of the thermophysical properties of supercritical fluids. J Supercritical Fluids 53(1–3):2–11

Carvajal A, Slizyte R, Storrø I, Aursand M (2015) Production of high quality fish oil by thermal treatment and enzymatic protein hydrolysis from fresh Norwegian spring spawning herring by-products. J Aquat Food Prod Technol 24(8):807–823

Chakraborty K, Joseph D (2015) Cooking and pressing is an effective and eco-friendly technique for obtaining high quality oil from Sardinella longiceps. Eur J Lipid Sci Technol 117(6):837–850

Chang C, Nickerson MT (2018) Encapsulation of omega 3-6-9 fatty acids-rich oils using protein-based emulsions with spray drying. J Food Sci Technol 55(8):2850–2861

Chantachum S, Benjakul S, Sriwirat N (2000) Separation and quality of fish oil from precooked and non-precooked tuna heads. Food Chem 69(3):289–294

Chatterjea MN, Shinde R (2011) Textbook of medical biochemistry. Wife Goes On

Chen J, Jayachandran M, Bai W, Xu B (2022) A critical review on the health benefits of fish consumption and its bioactive constituents. Food Chem 369:130874

Choi MJ, Ruktanonchai U, Min SG, Chun JY, Soottitantawat A (2010) Physical characteristics of fish oil encapsulated by β-cyclodextrin using an aggregation method or polycaprolactone using an emulsion–diffusion method. Food Chem 119(4):1694–1703

Chotphruethipong L, Battino M, Benjakul S (2020) Effect of stabilizing agents on characteristics, antioxidant activities and stability of liposome loaded with hydrolyzed collagen from defatted Asian sea bass skin. Food Chem 328:127127

Covington M (2004) Omega-3 fatty acids. Am Fam Physician 70(1):133–140

Dalei J, Sahoo D (2015) Extraction and characterization of astaxanthin from crustacean shell waste from shrimp processing industries. Int J Pharm Sci Res 6(6):2532–2537

Dallongeville J, Yarnell J, Ducimetière P, Arveiler D, Ferrières J, Montaye M, Luc G, Evans A, Bingham A, Hass B, Ruidavets JB (2003) Fish consumption is associated with lower heart rates. Circulation 108(7):820–825

De Holanda HD, Netto FM (2006) Recovery of components from shrimp (Xiphopenaeus kroyeri) processing waste by enzymatic hydrolysis. J Food Sci 71(5):C298–C303

de Oliveira DA, Licodiedoff S, Furigo A Jr, Ninow JL, Bork JA, Podestá R, Block JM, Waszczynskyj N (2017) Enzymatic extraction of oil from yellowfin tuna (Thunnus albacares) by-products: a comparison with other extraction methods. Int J Food Sci Technol 52(3):699–705

Del Valle JM, Aguilera JM (1999) Revision: Extracción con CO2 a alta presión. Fundamentos y aplicaciones en la industria de alimentos/Review: high pressure CO2 extraction. Fundamentals and applications in the food industry. Food Sci Technol Int 5(1):1–24

Denny Joseph KM (2015) Combined oral supplementation of fish oil and quercetin enhances neuroprotection in a chronic rotenone rat model: relevance to Parkinson’s disease. Neurochem Res 40(5):894–905

Ding M, Zhang T, Zhang H, Tao N, Wang X, Zhong J (2020) Gelatin molecular structures affect behaviors of fish oil-loaded traditional and Pickering emulsions. Food Chem 309:125642

Donsì F, Ferrari G, Pataro G (2010) Applications of pulsed electric field treatments for the enhancement of mass transfer from vegetable tissue. Food Eng Rev 2(2):109–130

Drusch S, Serfert Y, Scampicchio M, Schmidt-Hansberg B, Schwarz K (2007) Impact of physicochemical characteristics on the oxidative stability of fish oil microencapsulated by spray-drying. J Agric Food Chem 55(26):11044–11051

Erdogan H, Fadillioglu E, Ozgocmen S, Sogut S, Ozyurt B, Akyol O, Ardicoglu O (2004) Effect of fish oil supplementation on plasma oxidant/antioxidant status in rats. Prostaglandins Leukot Essent Fatty Acids 71(3):149–152

FAO (2018) The state of world fisheries and aquaculture 2018—Meeting the sustainable development goals. FAO, Rome, Italy. ISBN 978-92-5-130562-1

Fassett RG, Coombes JS (2011) Astaxanthin: a potential therapeutic agent in cardiovascular disease. Mar Drugs 9(3):447–465

FDA (2010) Food and drug administration. In: FDA (ed) Status (L.O.F.A., ed) Food and drug administration, MD, USA

Flint EB, Suslick KS (1991) The temperature of cavitation. Science 253(5026):1397–1399

Food US (2004) Drug administration centre for food safety and applied nutrition. Agency response letter. GRAS notice no. GRN 000105, October 15, 2002

Franco D, Munekata PE, Agregán R, Bermúdez R, López-Pedrouso M, Pateiro M, Lorenzo JM (2020) Application of pulsed electric fields for obtaining antioxidant extracts from fish residues. Antioxidants 9(2):90

Gallo M, Ferrara L, Naviglio D (2018) Application of ultrasound in food science and technology: a perspective. Foods 7(10):164

Gopakumar K (2012) Therapeutic applications of Squalene-A review

Gulzar S, Benjakul S (2018) Ultrasound waves increase the yield and carotenoid content of lipid extracted from cephalothorax of Pacific white shrimp (Litopenaeus vannamei). Eur J Lipid Sci Technol 120(5):1700495

Gulzar S, Benjakul S (2019) Effect of pre-treatments on yield and properties of lipid extracted from cephalothorax of Pacific white shrimp (Litopenaeus vannamei) by ultrasonic assisted process. LWT 100:106–113

Gulzar S, Benjakul S (2020a) Impact of pretreatment and atmosphere on quality of lipids extracted from cephalothorax of Pacific white shrimp by ultrasonic assisted process. Food Chem 309:125732

Gulzar S, Benjakul S (2020b) Characteristics and storage stability of nanoliposomes loaded with shrimp oil as affected by ultrasonication and microfluidization. Food Chem 310:125916

Gulzar S, Benjakul S (2020c) Fortification of skim milk with nanoliposomes loaded with shrimp oil: properties and storage stability. J Am Oil Chem Soc 97(8):929–940

Gulzar S, Raju N, Nagarajarao RC, Benjakul S (2020) Oil and pigments from shrimp processing by-products: extraction, composition, bioactivities and its application—a review. Trends Food Sci Technol 100:307–319

Hasani S, Ojagh SM, Ghorbani M, Hasani M (2020) Nano-encapsulation of lemon essential oil approach to reducing the oxidation process in fish burger during refrigerated storage. J Food Biosci Technol 10(1):35–46

Hathwar SC, Bijinu B, Rai AK, Narayan B (2011) Simultaneous recovery of lipids and proteins by enzymatic hydrolysis of fish industry waste using different commercial proteases. Appl Biochem Biotechnol 164(1):115–124

Herrera EA, Farías JG, González-Candia A, Short SE, Carrasco-Pozo C, Castillo RL (2015) Ω3 Supplementation and intermittent hypobaric hypoxia induce cardioprotection enhancing antioxidant mechanisms in adult rats. Mar Drugs 13(2):838–860

Hosseini RS, Rajaei A (2020) Potential Pickering emulsion stabilized with chitosan-stearic acid nanogels incorporating clove essential oil to produce fish-oil-enriched mayonnaise. Carbohyd Polym 241:116340

Hrebień-Filisińska A (2021) Application of natural antioxidants in the oxidative stabilization of fish oils: a mini-review. J Food Process Preserv 45(4):e15342

Huber GM, Rupasinghe HV, Shahidi F (2009) Inhibition of oxidation of omega-3 polyunsaturated fatty acids and fish oil by quercetin glycosides. Food Chem 117(2):290–295

Ivanovs K, Blumberga D (2017) Extraction of fish oil using green extraction methods: a short review. Energy Procedia 128:477–483

Jamshidi A, Shabanpour B, Pourashouri P, Raeisi M (2018) Using WPC-inulin-fucoidan complexes for encapsulation of fish protein hydrolysate and fish oil in W1/O/W2 emulsion: characterization and nutritional quality. Food Res Int 114:240–250