Abstract

Four different commercial proteases (Protease-P-Amano6, Alcalase®, Protex 7L®, and Neutrase®) were evaluated for recovering lipids and protein simultaneously by hydrolysis. Fungal protease (Protease-P-Amano6) resulted in maximum lipid recovery (74.9%) followed by alcalase (61.7%). Peroxide value (PV; milli-equivalents of oxygen per kilogram) in the oil recovered after hydrolysis was 40.48 compared to 8.7 in lipids from fresh fish viscera. However, addition of tertiary butyl hydroxyl quinine at 200 ppm level maintained the PV of oil recovered by hydrolysis closer to oil from fresh waste. Degree of hydrolysis was the highest in case of fungal protease (49.1%) where neutrase resulted in higher total antioxidant activity (micrograms of ascorbic acid equivalents per milligram protein) of 34.4. Protein hydrolysate prepared using fungal protease had the higher diphenylpicrylhydrazyl radical scavenging activity as compared to those from other enzymes. The results indicate the utility of commercial proteases in providing an ecofriendly and feasible solution for reducing disposal problems associated with fish processing.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

India harvests more than 3 million metric tonnes of fresh water fishes from the inland fisheries sector [1]. Unlike marine fish processing, freshwater fish processing is not well organized. The by-products generated during fish processing includes scales, skin, visceral mass (viscera, air bladder, gonads, and other organs), head, and fins. Visceral mass constitutes approximately 20% of live weight of freshwater fishes and is a rich source of protein and lipids especially polyunsaturated fatty acids (PUFA) [2, 3]. Any method that utilizes solid wastes resulting from fish processing by recovering biomolecules like lipids and proteins not only results in additional revenue but would also help reduce the disposal problems associated therewith [4].

By-products/wastes from freshwater fish processing are well-known sources of nutritionally valuable components such as eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) [5]. Both EPA and DHA have been found to reduce the risk of cardiovascular disease, hypertension, autoimmune, and inflammatory diseases [6]. Further, in recent years, there is a growing interest to identify antioxidative properties in many natural sources including dietary proteins due to the potential health hazards of certain synthetic antioxidants [7]. The protein hydrolysates from aquatic sources have been reported to exhibit various biofunctionalities like antioxidative, antibacterial, antihypersensitive, anticancer properties, etc. [6].

Traditional methods for preparation of autolytic hydrolysate like fish silage exploit the endogenous enzymes, and it is rather difficult to control the autolysis by endogenous enzymes due to several factors including fish species and seasonality as well as the type and amount of enzymes [8]. Addition of exogenous enzymes could make the hydrolytic process more controlled, apart from hastening it, thereby making it reproducible. Hence, enzymatic hydrolysis is an ideal method to recover protein and lipids from fish by-products/wastes. Enzymes used to produce protein hydrolysates from fish or fish processing wastes have at least one common characteristic; they should be food grade and if they are of microbial origin, the producing organism has to be non-pathogenic. In most cases, involving hydrolysis of fish proteins alkaline/neutral proteases has been preferred as they are reported to result in less bitter principles compared to acidic proteases [9]. Further, utilization of natural (in situ) pH of the substrate—especially in case of fish processing wastes—is preferred as it avoids manipulation of pH conditions of hydrolysis. Alkaline proteases [10, 11] and neutral proteases [12] have been reported to be efficient especially considering the enzyme cost per activity. Proteolytic enzymes, especially alkaline proteases, have been applied for the recovery of protein [11, 13] and lipids [6]. Today where processing by-products of fish industry are seen as a potential resource instead of being discarded as wastes, enzymatic hydrolysis is believed to be a feasible method. Enzymatic hydrolysis is reported to be a better proposition for recovery of oil as compared to thermal treatment and competes with solvent extraction yielding a higher amount of DHA carried by polar lipids [14]. The recovered molecules have potential for several pharmaceuticals as well as feed formulations apart from providing value addition to fish processing waste. Against this background, the primary objective of this study was to evaluate four different commercial proteases (protease-P-amano, neutrase, alcalase, and protex-7L) for simultaneous recovery of lipids and proteins (in the form of protein hydrolysate) from freshwater fish processing wastes. The study also examined the antioxidative properties of hydrolysates obtained along with quality of oil recovered.

Materials and Methods

General

Fish visceral waste (FVW) devoid of airbladder obtained by the processing of freshly harvested Indian major carps viz. catla (Catla catla) and rohu (Labeo rohita) collected from Mysore (Karnataka, India) fish market formed the material of the study. The FVW was brought to the laboratory under iced condition. Four food grade enzymes employed in the study included Alcalase® (Novo Industry, Denmark; alkaline enzyme; declared activity of 0.6 Anson-U/g), Neutrase® (Novo Industry, Denmark; microgranulated; declared activity of 1.5 Anson-U/g), Protex 7L® (Genencor Intl., USA; 580,000 DU/g), and Protease-P-amano® (P Amano6; 60,000 U/g). The former three were from bacterial sources while the latter is a fungal protease. Trichloroacetic acid (TCA) was purchased from Loba Chemei, India. All the chemicals used in different analysis were of analytical grade, unless otherwise mentioned. Proximate composition (protein, fat, and moisture) of the raw material and final product was estimated as per Association of Official Analytical Chemists (AOAC) [15] method. All protein measurements in the samples were carried out by Kjeldahl method using Kjeltec protein analyzer system (Foss-Tecator AB, Sweden).

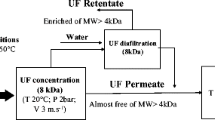

Enzymatic Hydrolysis of Fish Visceral Waste

The visceral mass was minced in a Waring blender (Stephen Mill, UM5 Universal, Hong Kong) followed by heating the visceral mass at 85 °C for 20 min to aid in inactivating the endogenous enzymes [16]. Enzymatic hydrolysis was carried out using different commercial proteases (Fig. 1). Briefly, 20 g of minced FVW was mixed with water (1:1 w/v), and the content was homogenized after addition of enzymes (0.5%, w/w of FVW). The content was incubated for 2 h at 40 °C with shaking after every 10 min. The resulting sample was centrifuged at 8,000 rpm for 20 min, and the upper oil layer was collected. The lower aqueous phase (protein hydrolysate) was extracted with demineralized water (1:1, w/v; 2×), and all the extractants were pooled. This pooled extract was analyzed for extractability, degree of hydrolysis, and antioxidant activities, and the residue was estimated for collagen recovery.

Yield and Quality of Recovered Lipid After Enzymatic Hydrolysis with or Without Antioxidant

Oil after enzymatic hydrolysis (20 g) was recovered by centrifugation, and volume of oil recovered was noted. Oil recovery was determined as percentage of total lipid content in fresh waste [17]. Total lipid content in the fresh waste was determined by the method of Bligh and Dyer [18]

Oil was transmethylated using 2 M methanolic sodium hydroxide followed by 2 M methanolic hydrochloric acid to obtain fatty acid methyl esters (FAME). FAME were analyzed by using a gas chromatography (GC) system (Shimadzu GC 2014; M/s Shimadzu, Kyoto, Japan) fitted with a flame ionization detector for identifying the individual fatty acids. FAME dissolved in hexane were analyzed on a fused silica capillary column (30 m × 0.32 mm × 0.25 μm; Omegawax™ 320; M/s Supelco, Bellefonte, PA, USA) with a split ratio of 1:30. The temperatures of injector, column, and detector were set at 250°C, 200°C, and 260°C, respectively. The fatty acids were identified by comparing with authentic standards. Fatty acid concentrations above 0.5% of total were only considered for calculation fatty acids composition. The data presented are a mean of two analyses. Acid value and peroxide value (PV) of the recovered oil were estimated as per AOAC [15]

Enzymatic hydrolysis of homogenized viscera was also carried out by adding tertiary butyl hydroxyl quinine (TBHQ) at 200 ppm (w/w) level to evaluate its effect on quality characteristics of lipids recovered from the fish visceral waste.

Degree of Hydrolysis and Extractability (%)

Degree of hydrolysis (DH) of the hydrolyzed protein resulting from enzymatic hydrolysis of fish waste was estimated as per the methodology described by Hoyle and Merritt [9] and was computed as

Extractability is calculated as

Preparation of Sample for In Vitro Antioxidant Activity Assays

The protein extract obtained after fermentation was filtered to obtain fish waste fermented hydrolysate (FWPH). FWPH was further centrifuged at 5,000×g for 20 min to obtain a sediment-free supernatant. This supernatant was used for all in vitro antioxidant activity.

Diphenylpicrylhydrazyl Radical Scavenging Activity

Diphenylpicrylhydrazyl (DPPH) radical scavenging capacity of FWPH was determined by the method previously described in Amit et al. [19]. Briefly, 2.0 mL of 0.16 mM DPPH solution (in methanol) was added to the test tube containing 100 μL of sample and made up to 2 mL with distilled water. The mixture was vortexed and kept at room temperature for 30 min in the dark. Sample blank was prepared by replacing DPPH with methanol. The absorbance of all the sample solutions was measured at 517 nm. Methanol along with DPPH served as the control. The scavenging activity (percent) was calculated by using the formula:

Total Antioxidant Activity

Total antioxidant activity (TAO) was carried out as per the method described by Amit et al. [19]. TAO of FWPH was determined by mixing sample and making up to 3 mL with reagent solution (3.0 mL; 0.6 M sulfuric acid/28 mM sodium phosphate/4 mM ammonium molybdate (1:1:1 v/v/v)). Reaction mixture was incubated in a water bath at 95 °C for 90 min. Absorbance of all sample mixtures was measured at 695 nm. Total antioxidant activity was expressed as of microgram of ascorbic acid equivalents (AAE) per milligrams of protein in FWPH.

Collagen Recovery

Collagen content in residue of hydrolyzed fish viscera using different proteases was estimated by spectroscopic determination of hydroxyproline content as per the method of AOAC [15].

Statistical Analysis

All the determinations except for fatty acid analysis were done in five batches. All the parameters were compared by ANOVA using the software STATISTICA Statsoft [20], and significant differences if any were separated by Duncan’s multiple range tests using the same software.

Results and Discussion

Characteristics of Mixed Visceral Waste

Mixed fish visceral waste had a fat and protein content of 52.97% and 12.82% (both on dry weight basis), respectively. The acid value in the oil was 15.34 mg KOH g−1 oil where as it had a PV of 8.7 meqv oxygen kg−1 oil (Table 1). The fatty acid composition of fresh visceral waste (Table 2) clearly reveals the dominance (47.7%) of unsaturated fatty acids (USFA) as compared to saturated fatty acid (44.1%) with rest being unidentified (8.2%). It corroborated well with our report on lipids from Indian major carps which were found to be a good source of unsaturated fatty acids [5]. However, individually palmitic acid (16:0) was the major fatty acid among all the fatty acids observed. Similar observation of higher amounts of palmitic acid and oleic acid has been reported in catfish viscera [21]. Among the USFA, oleic acid (C18:1n−9) was dominant one followed by linoleic acid (C18:2n−6). EPA (C20:5) and DHA (C22:6) was 1.5% and 0.8%.

Effect of Enzyme Type on Lipid Recovery and Protein Hydrolysis

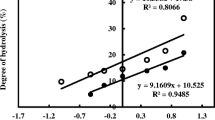

Homogenized FVW was cooked to inactivate the endogenous enzymes (proteases, lipases, etc.) and microflora present in the fish waste, as reported earlier by our group [11]. Although enzymatic hydrolysis of fish waste has been reported for preparation of protein hydrolysate [11, 13], lipids were discarded in that process. On enzymatic hydrolysis of homogenized FVW using different commercial proteases, recovery of lipids ranged from 42% to 74% (Fig. 2) considering the lipids extracted using solvents as 100%, depending on the type of enzyme. FVW hydrolyzed with fungal protease resulted in highest recovery of lipids (74.9%) as well as higher DH (49.1%) when compared to recovery of lipids and DH in case of other enzymes. Similar DH has also been reported in case of hydrolysis of visceral wastes of catla [12]. DH correlated well with that of oil recovery (Fig. 2). The least recovery of lipids (42.2%) was in control, where no enzyme was added. Control also had the lowest DH (18.9%). Extractability of the FWPH also followed the similar pattern wherein FWPH of fungal protease (55.41%) was found to be the highest. Extractability was in the range of 21.3–55.41% (Fig. 3), least being in control. The DH, extractability, and oil recovery observed in case of control could possibly be due to the heat treatment step and partly due to the activity of endogenous enzymes before or after and to some extent during heat treatment, as fish are known to contain some heat-activated proteases [22]. Hydrolysis of protein involves major structural changes where the protein molecule is gradually cleaved into smaller peptide units and thereby increasing the solubility of hydrolyzed protein with increased hydrolysis [10]. The collagen content (percentage of total collagen) recovered in the residue on enzymatic hydrolysis is shown in Fig. 3. Among different commercial proteases used, Protex 7L showed the highest recovery (49.5%), least being in alcalase (35.9%). However, maximum collagen recovery was found in case of control (76.5%). This again clearly shows that there was least hydrolysis in case of control and also that part of the collagen could be hydrolyzed by the proteases used.

Effect of Antioxidant During Hydrolysis on Lipid Quality and Fatty Acid Composition

The quality of oil was assessed (Table 1). In case of acid value, oil recovered using neutrase showed the highest acid value (milligrams of KOH per gram oil) of 22. No significant changes were observed in acid value with or without antioxidant. PV in the oil recovered after hydrolysis was 40.48 in case of control compared to 8.7 in oil extracted from fresh fish viscera. However, addition of TBHQ maintained the PV values of oil recovered by hydrolysis closer to levels of PV in oil from fresh waste. Hence, addition of TBHQ can be an effective step in the process to maintain the quality of oil. Further, enzymatic hydrolysis of FVW may also result in formation of peptides possessing antioxidant activity (as discussed in the next section) which can further add to prevention of lipid oxidation. Addition of antioxidants to prevent rancidity-related changes has been suggested in case of preparation of fermented fish waste silage [23]. Changes in PV, an indicator of lipid oxidation, during fermentation of fish viscera has been reported [23], where slight increase was observed in peroxide value which later reduced due to breakdown of oxidized products.

With regards to fatty acid composition of oil recovered by hydrolysis using different enzymes, no change was observed irrespective of the type of enzyme as compared to the oil recovered by solvent extraction. Similarly, recovery of fish waste lipids by enzymatic hydrolysis with or without antioxidant did not also affect the fatty acid composition (Table 2). In enzymatic hydrolysis, there was no significant change in the fatty acid profile in the oil recovered by enzymatic hydrolysis using different proteases to that of fresh oil. Thus, enzymatic hydrolysis can be an effective approach for the recovery of oil without affecting the quality of oil.

In Vitro Antioxidant Activities of Protein Hydrolysates Prepared Using Different Enzymes

The in vitro antioxidant properties analyzed in this study included TAO and DPPH radical scavenging activity. DPPH radical scavenging activities and TAO of hydrolysates obtained using different commercial proteases are presented in Fig. 4a, b, respectively. Control had lower TAO as well as DPPH scavenging activity when compared to hydrolysate samples prepared using commercial enzymes. TAO (expressed as of milligrams of ascorbic acid equivalents per micrograms of protein in hydrolysate; AAE/mg) was found to be the highest in hydrolysate obtained using neutrase (34.4) and least was in case of hydrolysate obtained with alcalase (22.1). The TAO exhibited by the hydrolysate could possibly be due to the peptides and amino acids resulting from the hydrolysis of FVW.

a EC50 (milligrams of protein required for scavenging 50% of radicals generated) values for DPPH radical scavenging and b total antioxidant activity (TAO; micrograms of ascorbic acid equivalents per milligram protein) of fish waste protein hydrolysate on enzymatic hydrolysis using different commercial proteases (n = 5)

DPPH has been used extensively as a free radical to evaluate reducing substance and is a useful reagent for investigating the free radical scavenging activities of protein hydrolysate. The method is based on the reduction of methanolic DPPH solution in the presence of a hydrogen donating antioxidant due to formation of a non-radical form of DPPH-H by the reaction, and this modification is visually noticeable as a discoloration from purple to yellow [24]. DPPH radical scavenging activity (percent) in the protein hydrolysate samples was used for determining EC50, which is the concentration of hydrolysate protein (milligrams) that effectively scavenges 50% of DPPH radicals generated. EC50 in case of protein hydrolysate prepared using fungal protease was the lowest (3.47 mg protein) and highest in case of neutrase (3.99 mg protein) indicating the effectiveness of fungal protease. Previous work done by Song et al. [7] has shown strong antioxidant activities exhibited by hydrolysates of Arca subcrenata obtained by enzymatic hydrolysis. Antioxidants can effectively prevent lipid oxidation which is a major cause of chemical spoilage in foods as well as the reason for oxidative stress in terrestrial or aquatic animals. Much attention has recently been focused on natural antioxidants because of their positive health effects against oxidative stress. Protein hydrolysates prepared from fish processing wastes has the potential to be an ingredient in livestock or aquaculture feed formulations and can effectively reduce the oxidative stress apart from providing balanced amino acid composition [4, 13, 25].

Conclusion

Enzymatic hydrolysis process can be effectively used to recover biomolecules like lipids, protein hydrolysate, and collagen from fish processing wastes, thus reducing the organic load caused by the processing industry and resolving the pollution problem adding to the economy of the processing plant. Lipids recovered are rich sources of PUFA which have several health benefits that can be a better alternative for fish oil. The protein hydrolysates obtained which are rich in low molecular weight peptides exhibit various biofunctionalities like antioxidant activity which can reduce the oxidative stress in animal system. Collagen recovered also finds its way in diverse fields like cosmetic and biomedical industries. In all, the recovered biomolecules have potential application as a feed ingredient and/or as a nutraceutical in animal/livestock feeds. Enzymatic hydrolysis thus allows simultaneous recovery of all the bioactive molecules (lipids, peptides, and collagen) in the fish processing waste and hence could be a better proposition in effectively managing wastes from fish processing.

References

FAO (2010). Year book of fishery statistics—latest summary of tables. Available at http://www.fao.org/fishery/statistics/en; last accessed on May 18, 2010.

Bhaskar, N., Sachindra, N. M., Suresh, P. V., Mahendrakar, N. S. (2010). Microbial reclamation of fish industry bi-products. In: D. Montet & RC. Ray (Eds.), Aquaculture microbiology (pp. 248–275). Science, Enfield.

Sachindra, N. M., Bhaskar, N., Hosokawa, M., & Miyashita, K. (2010). Value addition to fish processing by-products. In C. Alasalvar, K. Miyashita, U. Wanasundara, & F. Shahidi (Eds.), Seafood quality, safety and health applications (pp. 390–401). UK: Blackwell.

Vidotti, R. M., Viegas, E. M. M., & Careiro, D. J. (2003). Amino acid composition of processed fish silage using different raw materials. Animal Feed Science and Technology, 105, 199–204.

Swapna, H. C., Amit, K. R., Bhaskar, N., & Sachindra, N. M. (2010). Lipid classes and fatty acid profile of selected Indian fresh water fishes. Journal of Food Science and Technology, 47, 394–400.

Kim, S. K., & Mendis, E. (2006). Bioactive compounds from marine processing by-products—a review. Food Research International, 39, 383–393.

Song, L., Li, T., Yu, R., Yan, C., Ren, S., & Zhao, Y. (2008). Antioxidant activities of hydrolysates of Arca subcrenata prepared with three proteases. Marine Drugs, 6, 607–619.

Sikoroski, Z. E., & Naczk, M. (1981). Modification of technological properties of fish protein concentrate. CRC Critical Review Food Science and Nutrition, 14, 201–230.

Hoyle, N. T., & Merritt, J. H. (1994). Quality of fish protein hydrolysate from herring (Clupea harengus). Journal of Food Science, 59, 76–79.

Kristinssons, H. G., & Rasco, B. A. (2000). Fish protein hydrolysates: Production, biochemical and functional properties. Critical Reviews in Food Science and Nutrition, 40, 43–81.

Bhaskar, N., Benila, T., Radha, C., & Lalitha, R. G. (2008). Optimization of enzymatic hydrolysis of visceral waste proteins of catla (Catla catla) for preparing protein hydrolysate using a commercial protease. Bioresource Technology, 99, 335–343.

Bhaskar, N., & Mahendrakar, N. S. (2008). Protein hydrolysate from visceral waste proteins of catla (Catla catla): Optimization of hydrolysis conditions for a commercial neutral protease. Bioresource Technology, 99, 4105–4111.

Slizyte, R., Dauksas, E., Falch, E., Storro, I., & Rustad, T. (2005). Characteristics of protein fractions generated from hydrolysed cod (Gadus morhua) by-products. Process Biochemistry, 40, 2021–2033.

Grodji, A. G., Michel, L., Jacques, F., & Michel, P. (2006). Analysis of lipids extracted from salmon (Salmo salar) heads by commercial proteolytic enzymes. European Journal of Lipid Science and Technology, 108, 766–775.

AOAC. (2000). Official methods of analysis (17th ed.). Washington, DC: Association of Official Analytical Chemists.

Guerard, F., Dufosse, L., De, L., Broise, D., & Binet, A. (2001). Enzymatic hydrolysis of proteins from yellowfish tuna (Thunnus albacares) wastes using Alcalase. Journal of Molecular Catalysis. B, Enzymatic, 11, 1051–1059.

Amit, K. R., Swapna, H. C., Bhaskar, N., Halami, P. M., & Sachindra, N. M. (2010). Effect of fermentation ensilaging on recovery of oil from fresh water fish viscera. Enzyme and Microbial Technology, 46, 9–13.

Bligh, E. G., & Dyer, W. J. (1959). A rapid method of total lipid extraction and purification. Canadian Journal of Biochemistry and Physiology, 37, 911–917.

Amit, K. R., Bhaskar, N., Halami, P. M., Indirani, K., Suresh, P. V., & Mahendrakar, N. S. (2009). Characterisation and application of a native lactic acid bacterium isolated from tannery fleshings for the fermentative bioconversion of tannery fleshing. Applied Microbiology and Biotechnology, 83, 757–766.

Statsoft. (1999). Statistica for Windows. Tulsa: Statsoft.

Sathivel, S., Prinyawiwatkul, W., Grimm, C. C., King, J. M., & Lloyd, S. (2002). FA composition of crude oil recovered from catfish viscera. Journal of the American Oil Chemist’s Society, 78, 989–992.

Klomklao, S., Benjakul, S., & Visessanguan, W. (2004). Comparative studies on proteolytic activity of splenic extract from three tuna species commonly used in Thailand. Journal of Food Biochemistry, 28, 355–372.

Ahmed, J., & Mahendrakar, N. S. (1996). Autolysis and rancidity development in fish viscera during fermentation. Bioresource Technology, 58, 247–251.

Shon, M. Y., Kim, T. H., & Sung, N. J. (2003). Antioxidants and free radical scavenging activity of Phellinus baumii (Phellinus of Hymenochaetaceae) extracts. Food Chemistry, 82, 593–597.

Sachindra, N. M., & Bhaskar, N. (2008). In vitro antioxidant activity of liquor from fermented shrimp biowaste. Bioresource Technology, 99, 9013–9016.

Acknowledgments

Authors thank Department of Biotechnology, Govt. of India for partial funding of this work through Grant ##BT/PR 9474/AAQ/03/345/2007. Authors place on record their thanks to Dr. V Prakash, Director, CFTRI for encouragement and permission to publish the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hathwar, S.C., Bijinu, B., Rai, A.K. et al. Simultaneous Recovery of Lipids and Proteins by Enzymatic Hydrolysis of Fish Industry Waste Using Different Commercial Proteases. Appl Biochem Biotechnol 164, 115–124 (2011). https://doi.org/10.1007/s12010-010-9119-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-010-9119-5