Abstract

Electrostatic precipitators, which are frequently used in industry, use corona discharge to remove particles from dust air. This article uses COMSOL simulation software to conduct numerical simulation on wire plate electrostatic precipitators, exploring the multiple physical characteristics of electrostatic precipitators with different numbers of wire electrodes, and delving into the collection mechanism and phenomenon of particles in electrostatic precipitators. The simulation results show that the space charge produced by the discharge of the wire plate electrode has the highest density near the discharge electrode and gets weaker in all directions. As the quantity of wire electrodes grows, the lateral flow velocity of the airflow in the entire channel decreases, and the removal efficiency of each particle size also gradually increases. By studying the removal efficiency of particles with different radii, it is found that particles at the submicron level have the lowest removal efficiency. Based on the simulation, experiments are conducted on the wire plate electrostatic precipitator to study the voltage and current characteristics and dust removal effect of the electrostatic precipitator under different numbers of wire electrodes. The experimental results demonstrate that as the number of wire electrodes increases, the peak current increases and the dust removal effect improves, achieving good consistency with the numerical simulation results.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

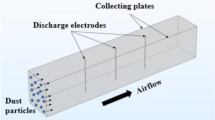

With the economy and technology developing so quickly in recent years, the total global energy consumption and pollutant emissions have sharply increased. Air pollution, especially particulate pollution, has caused serious harm to human health and the living environment, so it is of great significance to develop effective dust removal technology. Therefore, it is crucial to create efficient dust removal technology. Among various gas filtration and separation technologies [1], electrostatic precipitators have the characteristics of high dust collection efficiency, low energy consumption, low maintenance cost, and small pressure loss. They are widely used for smoke and dust control, especially in industrial waste gas emissions. The principle of an electrostatic precipitator is to ionize the surrounding air molecules by applying a high voltage between the dust collector and the discharge electrode to form a corona discharge, which generates a huge quantity of electrons and ions. When the dust particles in the air enter the electrostatic precipitator and are charged near the discharge electrode, the charged dust particles change their trajectory under the action of the electric field force and start to move in the direction of the dust collector, which is captured by the plate used to gather dust. The overall removal rate of electrostatic precipitators can reach over 99%. For submicron particles, due to the small particle size carrying less charge, the efficiency is as low as 70–80% [2, 3], and the dust removal effect is not ideal.

To increase the effectiveness of dust removal of electrostatic precipitators, many scholars have conducted research. Kılıç et al. [4] concluded by a combination of experimental and numerical modeling that the effectiveness of particle collecting of all diameters increases with increasing wire diameter. Choi et al. [5] examined the impact of wire electrode arrangement on the characteristics of electrostatic precipitators. For low voltage conditions, the wire electrodes' stacked arrangement caused a turbulence effect and therefore the collection efficiency increased more than the series arrangement. However, under high voltage conditions, the collection efficiency decreased. Chen et al. [6] developed a model in mathematics of an electrostatic precipitator and simulated the occurrence of electrostatic shielding in a wire-plate electrostatic precipitator, and the results showed that increasing the number of discharge electrodes within a particular range can improve the effectiveness of dust removal of an electrostatic precipitator. Khaled and Eldein [7] proposed that a laboratory model of an electrostatic precipitator’s corona voltage and current parameters are impacted by the discharge. According to the experimental findings, when the number of discharge wires grows, the corona current also increases noticeably. From the study, it is clear that the number of wire electrodes is one of the crucial parameters impacting the ability of electrostatic precipitators to remove dust.

This paper takes the wire plate electrostatic precipitator as the research object and uses COMSOL simulation software to carry out two-dimensional numerical simulation for electrostatic precipitators with a different number of wire electrodes. It contrasts and evaluates the electrostatic precipitator's flow field velocity distribution as well as the path taken by particles as they pass between the plates. Then, based on the simulation, experiments are conducted on the wire plate electrostatic precipitator to study its voltage and current characteristics and dust removal effect with a different number of wire electrodes, verifying the accuracy of the simulation model.

2 Numerical Simulation and Result Analysis

The foundation of numerical simulation is modeling. We analyze the physical characteristics and dust removal effect of the dust collector with different numbers of wire electrodes through the model and simulation results, understand the actual experimental situation, and optimize the structural parameters.

2.1 Simulation Module

Electric Field Model

The electric field of the wire plate electrostatic precipitator is non-uniform. The generated electrostatic field can be described by Poisson and current continuity equations. The ionic charge density and electric field intensity distribution can be estimated using the following formulae [8,9,10,11]:

where, \(\vec{J}\) denotes current density; \(\rho\) denotes space charge density; S denotes current source; \(Z_{q}\) denotes charge number; \(\vec{E}\) table denotes electric field strength; V denotes electric potential; \(\mu_{i}\) denotes ionic mobility; \(\vec{u}\) denotes fluid velocity vector; \(\varepsilon_{0}\) denotes vacuum dielectric constant.

The strength of the corona electric field is given by Pick's law [12]:

Flow Field Model

Inside the electrostatic precipitator, the gas flow is seen as incompressible and stable turbulence. The k-ε turbulence model has good convergence. The following are the equations for the conservation of mass and momentum:

where, \(\mu\) denotes the dynamic viscosity; \(\rho\) denotes the fluid density; P denotes the pressure; \(F_{EHD}\) denotes the electrohydrodynamic force, \(F_{EHD} = \rho \vec{q}E\).

Particle Charging Model

The charge accumulation model of particles is as follows:

where, \(\tau_{c}\) denotes the characteristic charging constant; \(R_{f}\) and \(R_{d}\) denote the charge rate parameters of field charge and diffusion charge, respectively; \(f_{a}\) denote the function connecting diffusion charge and field charge.

Particle Tracking Model

In electrostatic precipitators, the movement of particles is mainly affected by drag and electric field forces. Newton's second law is applied to describe the momentum equation of the particle phase.

The momentum equation is as follows:

where, \(\vec{F}t = \vec{F}d + \vec{F}_{e}\); \(\vec{F}_{d} = \frac{1}{8}\pi C_{d} \rho {}_{g}d_{p}^{2} \left| {\vec{u} - \overrightarrow {{u_{p} }} } \right|(\vec{u} - u_{p} )\); \(\vec{F}_{e} = e\vec{Z}E\).

where, Z denotes the amount of charge accumulated by each particle; \(C_{d}\) denotes the drag coefficient; \(m_{p}\) denotes the mass of particles; \(u_{p}\) denotes particle velocity; \({\text{Re}}_{p}\) denotes the particle Reynolds number.

2.2 Simulation Results

The geometric model is built using 2D modeling. The double plate electrodes inside the dust collector are equally spaced on both sides of the wire electrode array and are used not only as grounding electrodes but also as dust collection electrodes. The wire electrodes are connected to 20 kV DC high voltage. The inlet flow rate is fixed at 1 m/s.

Space Charge Density Distribution

The distribution of space charge density at different numbers of wire electrodes is shown in Fig. 1. The charge generated by the discharge of the wire plate electrode is mainly concentrated on both sides of the wire electrode, and the density of space charge is highest near the wire electrode, and gets weaker and weaker away from the wire electrode. When the particles flow through the wire electrodes, the charge accumulates rapidly near the electrodes and moves toward the dust collection plate when the electrostatic force is at work. As the number of wire electrodes increases, the charge density increases accordingly, and most of the particles are more likely to accumulate charge during the flow and spread towards the dust collector plate on both sides and are successfully captured.

Effect of the Number of Wire Electrodes on the Velocity of the Flow Field

The velocity distribution of the flow field at varying amounts of wire electrodes is shown in Fig. 2. It can be found that there is a very obvious low wind speed area behind each electrode, while high-speed locations appear on each of the electrodes’ sides. When the number of electrodes increases, the high-speed zone also increases accordingly, the transverse flow velocity of airflow in the whole channel decreases, and the residence time of particles in the reaction zone is prolonged, which is more easily captured by the dust-collecting pole under the action of ionic wind.

The Influence of the Number of Wire Electrodes on the Dust Removal Effect

As shown in Fig. 3, the diffusion of particles to the two plate electrodes and the quantity of particles caught by the dust collecting plate both increase as the number of wire electrodes rises. From the particle motion trajectory, it can be concluded that the amplitude of each particle diffusion gradually decreases, which is due to the fact that the distance between the particle stream and the wire electrodes increases after each diffusion, and the ability of the particles to be charged and the electric field force on the particles after being charged will be weakened accordingly, and the amplitude of each particle diffusion decreases. By comparison, it can be seen that the dust removal effect of one and two-wire electrodes is significantly weaker than that of three and four-wire electrodes, and most of the particles are not captured by the dust collection poles, but escape in the original direction of motion after several diffusions, so the more the number of wire electrodes, the better the dust removal effect.

As shown in Fig. 4, when there are four wire electrodes, particles of various sizes can be collected with more efficiency than when there are fewer wire electrodes. When there are more electrodes, the probability of particles being fully charged gradually increases, and it is furthermore simpler to migrate toward the plate electrode under the influence of the electric field force. The collection efficiency of particles of different particle sizes decreases and then increases for different numbers of wire electrodes. The particle collecting efficiency is at its lowest when the particle radius is around 0.2 μm. The accumulated charge number of particles is positively correlated with the particle radius. When the particle radius is too small, the accumulated charge number of particles is less, but it is easier to adhere to the dust collection plate because the traction force is also smaller, thus the collection efficiency of small radius particles is higher. Large-radius particles accumulate more charges during the flow process and are more likely to move towards the dust collection plate under the electrostatic force, resulting in the same high particle collection efficiency.

3 Experiments and Results Analysis

3.1 Experimental Setup and Test Methods

The wire electrodes of the same radius in the wire plate electrostatic precipitator are fixed at equal intervals, and the multi-wire electrodes are placed parallel to the plate electrodes. The specification of the plate electrode is 100 mm × 100 mm stainless steel plate as a ground electrode and dust collection pole, and the wire electrode at the high voltage end is tungsten wire with 10 mm spacing between wire and plate placed to get high dust removal efficiency. The whole reactor is placed inside the closed acrylic box.

In this experiment, high-voltage probes, current coils, and oscilloscopes are used to measure the discharge characteristic images and corresponding voltage and current values. The method of lighting a fixed time moxibustion smoke stick is used to ensure that the initial particle number is at the same level, and the particle level in the reaction box after 220s of stable operation of the dust collector is detected by a particle counter to compare the dust removal effect of different numbers of wire electrodes. After each experiment, the particles inside the reaction box are blown out by a fan to bring the particle number inside the box back to the normal level.

3.2 Experimental Results

Electrical Characteristics and Dust Removal Effect

The peak current variation with voltage for different numbers of wire electrodes is shown in Fig. 5a. The experimental environment will have an impact on the data acquisition, resulting in some errors in the experimental results, but the overall trend is within a reasonable range. The overall current peak increases with the rising voltage, and the larger the current peak, the more intense the discharge. For the same voltage applied, the current peak increases as the number of wire electrodes increases, which is mainly due to the increased electric field between adjacent wire electrodes and between the dust collection pole and the wire electrodes.

This experiment mainly compares the particles with particle size greater than or equal to 1.0 μm at different numbers of wire electrodes, so that the dust removal results can be observed more intuitively. According to the comparison of the removal effect of particles with particle size greater than 1.0 μm at different numbers of wire electrodes in Fig. 5b, the more wire electrodes there are, the better the electrodes' ability to remove dust, which is consistent with the earlier simulation results. And the dust removal rate increases slightly with time.

4 Conclusion

-

(1)

The simulation results show that the high-density area of charge grows in proportion to the number of wire electrodes, and most particles are more likely to accumulate charges during the flow process. The high-speed zone in the flow field also increases accordingly, and the maximum wind speed gradually decreases. The transverse flow velocity of the entire channel decreases, and the dwelling time of particles in the reaction zone is extended, making it easier for them to be captured by the dust collector under the action of ion wind.

-

(2)

The efficacy of dust removal increases with the number of wire electrodes. The particle collecting efficiency of different particle sizes first declined and subsequently increased under the number of various wire electrodes. The particle collecting efficiency is at its lowest when the particle radius is around 0.2 μm.

-

(3)

The outcomes of the trial indicate that as the number of wire electrodes increases, the peak current also increases, the discharge intensity becomes stronger, and the dust removal effect becomes better, which is consistent with the simulation results.

References

Zhou W, Jiang R, Sun Y et al (2021) Study on multi-physical field characteristics of electrostatic precipitator with different collecting electrodes. Powder Technol 381:412–420

Dong M, Zhou F, Zhang Y et al (2018) Numerical study on fine-particle charging and transport behaviour in electrostatic precipitators. Powder Technol 330:210–218

Zhuang Y, Kim YJ, Lee TG et al (2000) Experimental and theoretical studies of ultra-fine particle behavior in electrostatic precipitators. J Electrostat 48(3–4):245–260

Kılıç M, Mutlu M, Altun AF (2022) Numerical simulation and analytical evaluation of the collection efficiency of the particles in a gas by the wire-plate electrostatic precipitators. Appl Sci 12(13):6401(2022)

Choi HY, Park YG, Ha MY (2020) Numerical study on the effect of staggered wire electrodes in an electrostatic precipitator. J Mech Sci Technol 34:3303–3310

Chen B, Li S, Guo Y et al (2022) Research on electrostatic shielding characteristics of electrostatic precipitator. J Air Waste Manag Assoc 72(4):331–345

Khaled U, Eldein AZ (2013) Experimental study of V-I characteristics of wire–plate electrostatic precipitators under clean air conditions. J Electrostat 71(3):228–234

Arif S, Branken DJ, Everson RC et al (2016) CFD modeling of particle charging and collection in electrostatic precipitators. J Electrostat 84:10–22

Cagnoni D, Agostini F, Christen T et al (2013) Multiphysics simulation of corona discharge induced ionic wind. J Appl Phys 114(23):233301

Adamiak K, Atten P (2004) Simulation of corona discharge in point–plane configuration. J Electrostat 61(2):85–98

Wang Y, Gao W, Zhang H et al (2019) Insights into the role of ionic wind in honeycomb electrostatic precipitators. J Aerosol Sci 133:83–95

Zhu Y, Gao M, Chen M et al (2019) Numerical simulation of capture process of fine particles in electrostatic precipitators under consideration of electrohydrodynamics flow. Powder Technol 354:653–675

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 Beijing Paike Culture Commu. Co., Ltd.

About this paper

Cite this paper

Yang, X., Zhang, D., Han, C., Liu, F., Fang, Z. (2024). The Effect of the Number of Wire Electrodes on the Performance of Wire Plate Electrostatic Precipitators. In: Dong, X., Cai, L. (eds) The Proceedings of 2023 4th International Symposium on Insulation and Discharge Computation for Power Equipment (IDCOMPU2023). IDCOMPU 2023. Lecture Notes in Electrical Engineering, vol 1102. Springer, Singapore. https://doi.org/10.1007/978-981-99-7405-4_8

Download citation

DOI: https://doi.org/10.1007/978-981-99-7405-4_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-7404-7

Online ISBN: 978-981-99-7405-4

eBook Packages: EnergyEnergy (R0)