Abstract

Hydrophobicity and hydrophobicity migration, as important indicators for evaluating the aging degree of composite insulators and the operating condition of transmission lines, have significant research value. This article takes AC composite insulators with different years of grid operation in Shandong region as the research object. The static contact angle method is used to conduct artificial pollution experiments on the high, medium, and low voltage end skirts of composite insulators under different years of operation. Molecular dynamics software is used to simulate the adsorption effect of different substances in the pollution layer on siloxane molecules, and the microscopic mechanism of electric field on hydrophobic migration is studied. The results indicate that in the artificial pollution experiment, the hydrophobicity migration of the high and medium voltage ends is superior to that of the low voltage end. The adsorption of siloxane molecules on the surface of kaolin is the strongest. The greater the electric field intensity, the stronger the adsorption capacity.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

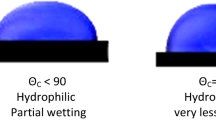

Composite insulators are widely used in power systems due to their advantages of light weight and good pollution flashover resistance that glass and porcelain insulators do not possess [1]. The excellent pollution flashover resistance of composite insulators is related to the good hydrophobicity and hydrophobicity migration of the silicone rubber material used [2]. However, after years of operation, the aging of silicone rubber materials and the accumulation of dirt on the surface of insulators have reduced or lost their hydrophobicity, leading to a significant decrease in their pollution resistance [3]. The hydrophobicity of the composite insulator after contamination still has a high flashover voltage, effectively suppressing the occurrence of pollution flashover accidents. At present, research suggests that the hydrophobicity and migration of silicone rubber are due to the presence of non crosslinked hydrophobic small molecule polysiloxanes in the silicone rubber material, which can migrate to the surface fouling layer and obtain hydrophobicity from the surface fouling layer [4]. Therefore, the hydrophobicity migration and hydrophobicity of composite insulators that have been in operation for many years are of great research significance as indicators for insulator status detection and aging degree evaluation.

At present, there are many studies on the mechanism of hydrophobic migration. Scholars at home and abroad generally believe that hydrophobic migration is the process by which the fouling layer obtains small molecules of siloxane in silicone rubber [3]. Reference [4] conducted hydrophobic material transfer experiments by setting different temperatures in a constant temperature chamber to study the effect of temperature on hydrophobic migration. It was concluded that the higher the temperature, the better the hydrophobic migration. Reference [5] studied the hydrophobic migration process of insulator strings coated with RTV anti pollution flashover coating running near different pollution sources. It was found that the hydrophobic migration on the surface of coated insulators became worse and slower with increasing service life. Reference [6] studied the hydrophobicity changes of silicone rubber material for composite insulator umbrella skirts under strong AC corona action. The conclusion is drawn that an appropriate amount of pollution layer is beneficial for the silicone rubber umbrella skirt of composite insulators to resist corona aging. Moreover, after corona action, due to the migration of hydrophobic small molecule siloxanes within the silicone rubber material, the surface hydrophobicity can be restored to a near initial state in a short period of time, whether in a clean or dirty state. Reference [7] conducted hydrophobicity tests under natural pollution and after removal of pollution, as well as hydrophobicity migration tests after artificial coating. The research results indicate that the hydrophobicity of the high-voltage and low-voltage ends of DC composite insulators is generally worse than that of the middle, and the hydrophobicity distribution along the string shows an inverted U-shaped shape. Umbrella skirts with poor hydrophobicity and migration are more commonly found near the high and low voltage ends. Reference [8] conducted a systematic hydrophobicity migration test using the static contact angle method. The research results showed that the edge of the insulator umbrella skirt had the worst hydrophobicity migration, while the root had the best hydrophobicity migration. The hydrophobicity migration of insulators in different directions also varied. In the case of natural pollution, there is a lot of research on the hydrophobicity of composite insulators, but there is relatively little research on hydrophobicity migration [9,10,11]. There is limited research on the adsorption effect of the dirty layer on hydrophobicity and hydrophobicity migration. There is limited research on the micro mechanisms of hydrophobicity and hydrophobicity migration through molecular dynamicsubsequent paragraphs, however, are indented.

This article takes AC composite insulators with different years of grid operation in Shandong region as the research object. In order to study the hydrophobicity migration performance of composite insulators with different positions of umbrella skirts under different operating years, manual contamination and hydrophobicity migration tests were conducted. In order to further study the hydrophobicity and hydrophobicity migration mechanism of insulator contamination layer, the adsorption capacity of contamination types in the contamination layer was first simulated through the molecular dynamics software Materials Studio, and then the substances with the strongest adsorption capacity among the pollutants were selected through the radial distribution function and binding energy indicators, and the effects of electric field strength and temperature on the adsorption capacity were studied. The adsorption capacity of kaolin to siloxane molecules was analyzed according to binding energy, and the mechanism of temperature and electric field on hydrophobicity and hydrophobicity migration was explored. The hydrophobicity and hydrophobicity migration tests, as reasonable reference indicators, can provide guidance for the operation status detection and aging degree judgment of AC composite insulators in Shandong region of China.

2 Test Method and Result Analysis

2.1 Test Sample

The test samples used in the experiment were all taken from AC 220 kV transmission line insulators from different manufacturers operating on site in Shandong region. The selected samples were composite insulators with different years of operation in different regions. Although the surface of the umbrella skirt had some degree of fouling and powdering, it still maintained good hydrophobicity. The sample type is FXBW-220/100. For the operational composite insulators sampled for inspection, the umbrella skirts at the high voltage end, medium voltage end, and low voltage end are taken for analysis, and detailed information is shown in Table 1.

In order to test the hydrophobicity and migration of composite insulators, a large umbrella skirt was cut along the interface between the umbrella skirt and the sheath to form a test piece. Take a large umbrella skirt at the high, medium, and low voltage ends, and evenly take 5 test points from the root to the edge on each 1/4 round small test piece, taking the average value.

2.2 Test Method

Clean and pre-treat the surface sample with anhydrous ethanol and deionized water. After drying, place it in a dust-proof container and store it under laboratory conditions for at least 24 h. Conduct coating pre-treatment on the sample and test the surface hydrophobicity migration according to the standard DL/T 376-2019. Add 21 g of sodium chloride powder and 242 g of kaolin solution per liter of water, and then place it in a soaking tank. Soak the pretreated sample in the soaking tank. Maintain the laboratory environment temperature at around 22 ℃ and relative humidity between 50 and 60% [12]. Measure and record the surface hydrophobicity of the test sample at regular intervals, and observe the hydrophobicity migration of each composite insulator at the high, medium, and low voltage ends. The hydrophobicity migration time is 96 h. Use a static contact angle measuring instrument to collect static contact angle data for the test samples before and after the experiment (Fig. 1).

2.3 Analysis of Test Results

In order to study the effect of different positions of umbrella skirts on the hydrophobicity migration performance of composite insulators, manual contamination and hydrophobicity migration tests were conducted. The hydrophobicity migration results of 10 strings of composite insulators with different operating years at the high, medium, and low voltage ends of each string of umbrella skirt are shown in Fig. 2.

Overall, the A and C string insulators with shorter operating years are less affected by the position of the umbrella skirt, while the F and J string insulators with longer operating years are more affected by the position of the umbrella skirt. This shows that the degree of hydrophobic migration at the high and medium voltage ends is generally higher than that at the low voltage end.

The mechanism of the influence of umbrella skirt position on hydrophobicity migration is as follows. Insulators with short service life have a low probability and proportion of corona and arc discharge, and the surface of silicone rubber produces fewer small molecules. The influence of electric field strength on hydrophobicity migration is small. However, insulators with long service life are more likely to have corona and arc discharge, and the high discharge probability at the high-voltage end is more likely to damage the chemical bond inside the umbrella skirt, resulting in more small siloxane molecules. The concentration of siloxane molecules at the high-pressure end is at a high level, which is influenced by the concentration difference inside and outside the umbrella skirt. The degree and speed of hydrophobic migration at the high-pressure end are at a high level. Secondly, the ability of the dirt layer to adsorb siloxanes increases with the increase of electric field strength. The adsorption capacity of the pollution layer generally leads to a higher degree of hydrophobic migration at the high and medium pressure ends than at the low pressure ends. Furthermore, the temperature at the high voltage end continuously increases due to corona and arc discharge, leading to an increase in molecular migration speed, resulting in a generally higher degree of hydrophobic migration at the high and medium voltage ends than at the low voltage ends. In order to further verify the impact of the above reasons on hydrophobic migration, simulation analysis will be conducted in the following text.

3 Simulation Analysis of Adsorption Capacity

Some scholars have conducted extensive research on the effects of corona and arc discharge on the hydrophobicity characteristics of insulators. However, there is limited research on the influence of electric field and temperature on the adsorption effect of the pollution layer, which leads to differences in hydrophobicity characteristics. This article focuses on simulating the influence of electric field and temperature on the hydrophobicity characteristics of insulators. Regardless of the influence of siloxane concentration, fix the number of siloxanes in the simulation. Soluble substances are greatly affected by relative humidity, while insoluble substances are less affected by relative humidity. Simulation focuses on studying the adsorption effect of insoluble substances on siloxanes.

3.1 Interface Model Simulation

The molecular dynamics simulation method is used to study the adsorption of siloxane on the surface of insoluble substances. The simulation software uses Materials Studio, and the force field uses COMPASS force field. The simulation time is 50 ps, totaling 50,000 steps. The GUIP/Dreiding module is selected for simulation, with a simulation temperature of 20 ℃. The interface model simulation diagram of four molecular structures at 293 K is shown in Fig. 3.

In order to further investigate the adsorption of small molecule siloxanes on the surfaces of various insoluble substances, this article analyzed the results and parameters of molecular dynamics simulations. The adsorption energy Eads can be used to study the adsorption capacity of various insoluble surfaces for small molecule siloxanes. The surface areas of each simulation system are different. In order to unify the quantitative standard, the adsorption of the system is measured by the binding energy E'ads per unit surface area.

Eads is the adsorption energy between siloxane molecules and the surface in the system; When Eads is negative, siloxane molecules can adsorb on the solid surface, and the greater the absolute value, the stronger the adsorption effect; When Eads is positive, it indicates that they are mutually exclusive, meaning that siloxane molecules cannot adsorb on the surface. From Table 2, it can be seen that for the adsorption energy of siloxane molecules on the unit surface, kaolin has the highest, followed by Al2O3 surface, SiO2 surface has the smallest, and siloxane molecules have the strongest adsorption effect on the surface of kaolin.

3.2 The Effect of Electric Field on Adsorption Capacity

The migration of hydrophobicity in artificial pollution experiments exhibits a certain pattern due to different positions of umbrella skirts. In order to study the reasons for the occurrence of the above laws, it is of great significance to simulate the influence of electric fields on the adsorption capacity of insoluble pollutants in the pollution layer.

Based on the electric field distribution of 220 kV composite insulators in the literature, the electric field strengths at the high, medium, and low voltage ends were selected to be 5.3kV/cm, 0.66kV/cm, and 0.14kV/cm, respectively. When studying the influence of electric field on the adsorption capacity of insoluble pollutants in the pollution layer, molecular simulation was set to a temperature of 20 °C (293K) at room temperature; The air pressure is standard atmospheric pressure (0.1 MPa); The integration step size is 0.1 fs; The number of iterations is 100000; The total simulation duration is 100 ps; The simulation module is GULP/Dreiding. The simulation selects the Si–O surface of kaolin, and the calculation results of binding energy under different electric fields are shown in Table 3.

From Table 3, it can be seen that the adsorption energy of siloxane molecules on a unit surface at different umbrella skirt positions is as follows: high voltage end > medium voltage end > low voltage end > no electric field.

The adsorption of siloxane by the fouling layer increases with the increase of electric field strength, and the content of siloxane in the fouling layer also increases. The hydrophobicity of the fouling layer is enhanced, and the migration degree of siloxane is increased. The degree and speed of hydrophobic migration at the high and medium voltage ends are superior to those at the low voltage end.

4 Conclusion

The degree and speed of hydrophobic migration at the high and medium voltage ends of composite insulators are superior to those at the low voltage end. Due to the influence of electric field intensity on the adsorption capacity of siloxane molecules, the concentration of siloxane molecules on the surface of kaolin is as follows: high voltage end > medium voltage end > low voltage end. The simulation verified the law of hydrophobic migration at different positions of the umbrella skirt from a microscopic perspective.

References

Peng J, Liu Y, Peng W, Liu Z, Zhang C (2021) Study on hydrophobicity of umbrella sleeve material for hard composite insulator. Trans China Electrotechnical Soc 36(S1):14–21 (in Chinese)

Huang Z, Peng X, Wang Z, Chen L, Fang P (2018) Study on small molecular siloxane in operating composite insulator. High Voltage Eng 44(09):2822–2827 (in Chinese)

Chen G (2020) Study on hydrophobic material transfer and its characteristics of superhydrophobic antifouling flashover material. Huazhong University of Science and Technology (in Chinese)

Lei L, Lin M, Wang Y, Wang W, Fu Z, Huang S, Huang D (2021) Experimental study on the influence of iron oxide on hydrophobic migration characteristics of room temperature vulcanized silicone rubber. Power Grid Technol 45(02):833–839 (in Chinese)

Jia Z, Li T, Chen C, Yang C, Chen R, Lin C (2014) Operation characteristics of room temperature vulcanized silicone rubber anti pollution flashover coating in Guangdong. High Voltage Technol 40(07) 1963–1969 (in Chinese)

Zhu Y, Yu J, Liu J, Liu C, Zhang D, Fang J (2019) Effect of AC Corona on hydrophobicity of silicone rubber umbrella skirt of composite insulator. Electric Power Sci Eng 35(02):33–37 (in Chinese)

Yang C, Wu M, He J, Wang Y, Dong Y, Zhang C, Jia Z, Chen C (2014) Hydrophobicity distribution law of operating DC composite insulators. Power Grid Technol 38(06):1650–1656 (in Chinese)

Jia Z, Yang C, Wang X, Wang Z, Zhicheng G, Yu X (2015) Aging characteristics of composite insulators based on hydrophobic migration test. High Voltage Technol 41(06):1907–1914 (in Chinese)

Shi J, Dong H, Quan Y, Chen C, Yan S (2020) Evaluation of thermoplastic polyolefin materials for the hard shed of composite insulators. J Appl Polym Sci 137(36)

Tian Y, Yuan Z, Huang X, Liu C, Li S, Lu D (2020)High-efficiency enhancement of the surface weatherability and electrical and mechanical properties of a cycloaliphatic epoxy-based hybrid nanocomposite via reaction-induced organic functional groups. Prog Org Coat 148

Meng X, Peng G, Niu K, Wang X, Mei H, Wang L (2022) Characteristics of Small-molecule migration of silicone rubber insulator in electrical power systems. Polymers 14(13)

Li M, Cao B, Liu Y, Wang L (2022) Novel micro-capsule-doped insulating material with hydrophobicity transfer capability triggered by creepage discharge. High Voltage 7(5)

Acknowledgements

This work was supported by the Science and Technology Project of State Grid Shandong Electric Power Company Entitled “Research and application of lean evaluation technology for aging performance of synthetic insulators” (Grant: 520618220001).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 Beijing Paike Culture Commu. Co., Ltd.

About this paper

Cite this paper

Fu, Y., Song, X., Wang, W., Han, F., Li, T. (2024). Study on Hydrophobic Mobility of Composite Insulators at Different Umbrella Skirt Positions. In: Dong, X., Cai, L. (eds) The Proceedings of 2023 4th International Symposium on Insulation and Discharge Computation for Power Equipment (IDCOMPU2023). IDCOMPU 2023. Lecture Notes in Electrical Engineering, vol 1102. Springer, Singapore. https://doi.org/10.1007/978-981-99-7405-4_68

Download citation

DOI: https://doi.org/10.1007/978-981-99-7405-4_68

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-7404-7

Online ISBN: 978-981-99-7405-4

eBook Packages: EnergyEnergy (R0)